THE DESIGN AND FABRICATION OF

IMPLANTED INTRACRANIAL PRESSURE SENSOR

Tian Bian, Zhao Yulong and Jiang Zhuangde

State Key Laboratory for Manufacturing Systems, Xi’an Jiaotong University, Xi’an 710049, China

Keywords: Piezoresistive, Pressure sensor, Implantable intracranial pressure, Biocompatible.

Abstract: For the purpose of intracranial pressure measurement, implantable intracranial pressure monitoring sensor

applying to the long-term and real-time monitoring to the intracranial pressure of the brain patients, a

pressure sensor was designed based on the piezoresistive principle. The fabrication of pressure sensor

adopted the technology of bulk micromachining to form the structure, and used the ion implanted technique

to form resistances. The packaging was successfully fabricated by using biocompatible material, such as

titanium alloy and polyurethane. The output characteristic of the sensor is measured. It was demonstrated

that this pressure sensor has good performance, include linearity, accuracy and sensitivity for medical

applications.

1 INTRODUCTION

The intracranial pressure (ICP) is extremely valuable

in many cases in order to monitor and control the

clinical condition of a patient. Presently there are

essentially three types of intracranial-pressure

sensors: (a) the sensors requiring handling of the

cephalorachitic intraventricular liquid or cisternal

liquid, (b) the so called sub dural sensors to be

implanted in the subdural space between the dura

mater and the arachnoid, (c) the extra-dural sensors

to be implanted on the dura mater between this dura

mater and the skull.

The sensors of the first type (a) measure directly

the pressure of the cephalorachitic liquid which is

transmitted by a catheter to a transducer. The sensors

of the second type (b) measure the intracranial

pressure by using the arachnoid as an interface, the

arachnoid being a very fine and very flexible

membrane capable of integrally transmitting the

pressures. In both cases the pressure to be measured

is directly accessible, without there being

distortions, whereby the measurement provides

significant information without need for special

precautions and while making use of conventional

pressure sensors which are merely selected to have

the required sensitivity.

However implanting the sensors (a) or (b) entails

effraction of the dura mater necessitating a far more

complex surgical intervention than that required by

an extradural implant (c) and carries risks well

known to the practitioners; in particular, only the

extradural implant is suitable for danger-free, long-

term surveillance.

In this study, compared with conventional

monitoring, adopted the type of extradural implant, a

pressure sensor based on MEMS was designed for

ICP motoring. Considering minimized size and low

range of sensor, the corresponding finite element

analysis modules of the pressure sensor was set up.

The material and structure design of packaging were

also involved for compliant and stable implantation

purpose.

2 STRUCTURE DESIGN

AND FABRICATION

The ICP monitoring was evaluated at the standard of

2.00KPa, normally, the ICP under 2.00KPa, but the

lightly increased value of ICP is between 2.00KPa to

2.70KPa. Compared with other kind of pressure

sensors, piezoresistive pressure sensors have more

advantages which could satisfy the demand of ICP

monitoring, such as micro size, simplicity

fabrication process and high sensitivity. To fulfill

the requirement of pressure measurement for high

sensitivity and low range applications, this paper

presents a piezoresistive pressure sensor developed

on Si wafers.

296

Bian T., Yulong Z. and Zhuangde J. (2009).

THE DESIGN AND FABRICATION OF IMPLANTED INTRACRANIAL PRESSURE SENSOR.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 296-299

DOI: 10.5220/0001777202960299

Copyright

c

SciTePress

In this research, it was utilized the anisotropy

characteristic along different orientation of single

crystal silicon. The piezoresisitance characteristic is

used to produce the pressure sensor. There is the

largest piezoresistance coefficient along the crystal

direction [110] or [1

1

0]. However there is almost no

piezoresistance coefficient along the crystal

direction [100] and [010] in (100) silicon. The

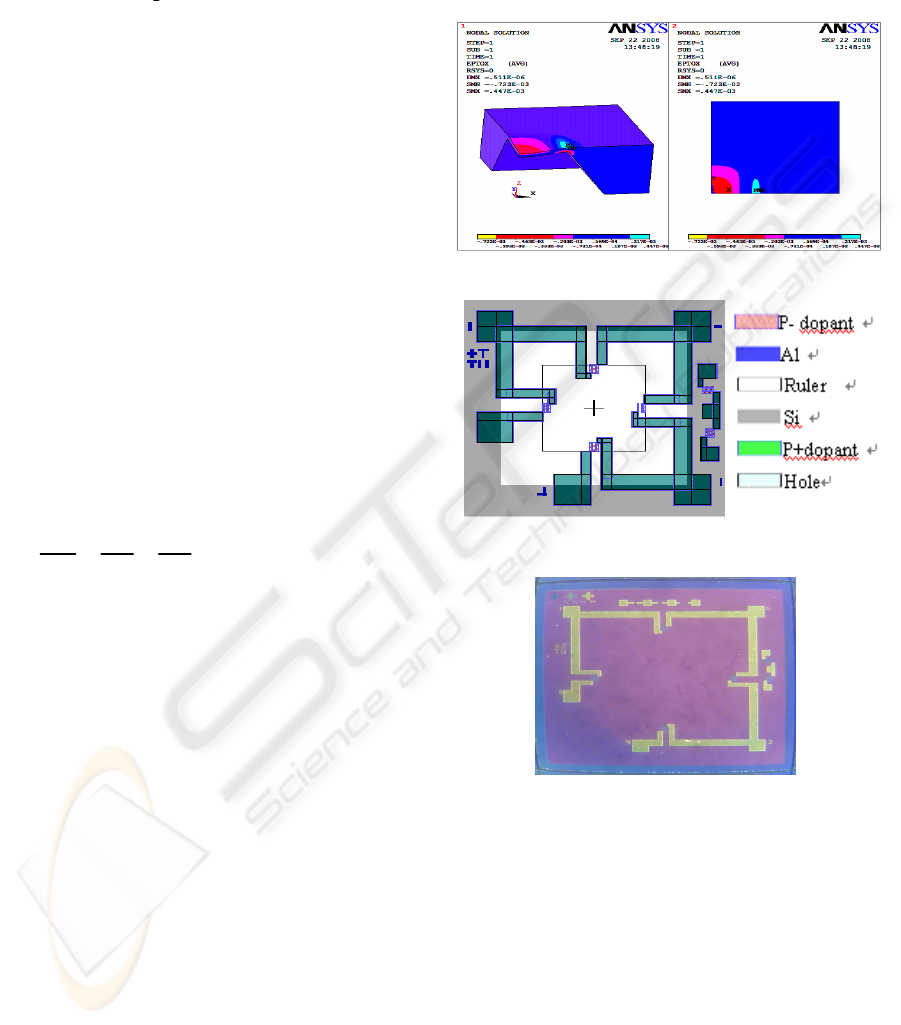

simulation was done for the pressure range 0~10kPa

by finite element method (FEM) software ANSYS.

Since the pressure sensor device is a quartered

symmetry, the quarter FEM of pressure sensor was

established, and the stress distribution of structure is

showed in Fig 1. The stress concentration zone is

located at the edge of the membrane, where the

resistors are implanted. The mechanical stresses

obtained by FEM should be transformed into output

voltage in such a way that the simulation stress value

can be applied to predict the equivalent output

electrical signal. All the four piezoresistances of the

pressure sensor are formed the Wheatstone bridge

circuit. Eq. (1) indicates the output voltage,

resistance and stress variation relation,

l

π

is the

longitudinal piezoresistance coefficient and

t

π

is the

transverse piezoresistance coefficient.

l

σ

is the

uniaxial stress, and a transverse stress

t

σ

:

11 tt

in

VR

VR

ρ

σ

πσπ

ρ

ΔΔΔ

=== +

(1)

The pressure sensor chip is processed from a 4

inch (100) orientation silicon wafer using

conventional lithographic technology. The thickness

of silicon wafer is 400

m

μ

. The single crystal

silicon is n-type. The fabrication and the packaging

processes comprise several steps, a schematic view

of the device layout is showed in Fig 2.

First, a silicon oxide layer with the thickness of

120 nm is deposited on the substrate silicon by high

thermal way, and patterned by the mask for the

piezoresistance of pressure sensor. Then the boron

ion is implanted to the substrate through the pattern

of the mask to a depth of 2 ~ 2.5µm at the dose of

2.0×

15

10 cm-2 with the energy of 80keV. This forms

resistors patterns of pressure sensor. The purpose of

resistance is about 25 Ω /

□. A Si3N4 layer with

depth of 120 ± 20nm is formed using Low Pressure

Chemical Vapor Deposit (LPCVD) to protect the

circuit of the sensors. And then etch the backside of

the substrate to form a 25µm silicon diaphragm. An

aluminum film which thickness is 1.5 microns is

splashed to form the interdigitated electrode and

connecting wire in the chip. The fabricated sensor

was showed in Fig 3. The size of pressure sensor

is

5500 5500 400mmm

μ

μμ

×

×

, and the membrane

is

4500 4500mm

μ

μ

×

.

Figure 1: Stress distribution of structure.

Figure 2: Schematic view of the device.

Figure 3: Photo of the fabricated sensor.

3 PACKAGING OF SENSOR

3.1

Titanium Alloy Packaging

Light, strong and totally biocompatible, titanium is

one of few materials that naturally match the

requirements for implantation in the human body.

The high strength, low weight, outstanding corrosion

resistance possessed by titanium and titanium alloys

have led to a wide and diversified range of

successful applications which demand high levels of

reliable performance in surgery and medicine. The

THE DESIGN AND FABRICATION OF IMPLANTED INTRACRANIAL PRESSURE SENSOR

297

natural selection of titanium for implantation is

determined by a combination of most favourable

characteristics including immunity to corrosion, bio-

compatibility, strength, low modulus and density

and the capacity for joining with bone and other

tissue - osseointegration. For the advantages above,

the titanium alloy TC4 type was used for the

material of packaging. As showed in Fig 4, the shell

of titanium alloy packaging has two parts, the cover

and foundation. The extended wire was connected

with outer through the hatch of the cover. The liquid

was introduced to the pressure senor through the

hole of foundation for sensing.

3.2 Extended Wire

The extended wire introduced the signal of pressure

sensor to peripheral part for monitoring. For the

requirement of biocompatible and possibility of

long-term implants, the wire is covered with

polyurethane for medical application. Polyurethane

film's performance and characteristics make it a

perfect fit for use in the medical industry. Polyether's

unique combination of strength, biocompatibility,

and innate anti-microbial qualities make it an ideal

material for extensive use in the medical field. The

diameter of extended wire is 1.45mm, and the photo

of wire is showed in Fig 5.

3.3 Process of Packaging

Considering minimized size of hatch which was

punctured on skull, the diameter of packaged sensor

was set to 11mm and 3mm high. The diameter of

transfer circuit is 10mm and the height is 0.2mm.

The structure of packaged sensor was showed in Fig

6, and the transfer circuit is showed in Fig 7. The

process of packaging has several steps as follows:

First, the pressure sensor chip was covered by an

insulated macromolecule material parylene film

which transmited the pressure. The insulated film

could conduct intracranial pressure indirectly and

biocompatible with body. Through the technology of

ultrasonic cleaning make the titanium alloy shell

pure to achieve the standard for medical implanted.

The inside packaging cover was spread with

insulated material. The insulated material could

descend the possibility of creepage which is due to

the contact between wire and titanium alloy shell

accidently. Second, pressure sensor chip and signal

transfer circuit were glued on the foundation of shell

by cyanoacrylate, and connected by spun gold

welding. The extended wire was also weld to circuit.

Finally, the cover of shell was glued on foundation

part.

Figure 6: Structure of packaged sensor.

Figure 7: Transfer circuit.

4 RESULT AND ANALYSIS

The output of the pressure sensor is showed in Fig 8

and the performances of pressure sensor are showed

in Table 1, respectively. The inc represents the

Figure 5: Photo of extended wire.

a. Cover b. Foundation

Figure 4: Shell of titanium alloy packaging.

Titanium alloy shell

Insulated layer

Extended wire

Pressure senor chip

Parylene film

Circuit board

Cyanoacrylate

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

298

pressure inputs from lower to higher, contrarily, the

dec shows the outputs when pressure lower. The

sensitivity is 5.66mv/KPa. The non-linearity and

hysteresis of the sensor are less than 0.1%FS and

0.05%FS, respectively.

Figure 8: The output characteristic of the sensor.

Table 1: The performances of pressure sensor.

5 CONCLUSIONS

It has been shown that the design and fabrication of

pressure sensor including packaging. The pressure

sensor was fabricated for intracranial pressure

monitoring based on MEMS. The sensor chip

possesses the better characteristics including size,

linearity, and accuracy. The packaging of the sensor

was designed for well biocompatible implanted in

skull. The pressure sensor chip is able to measure

the parameter for the demands of less volume and

less pressure range conditions for medical

applications.

ACKNOWLEDGEMENTS

This work was supported by the National Natural

Science Fund (Item NO.: 50535053) and

international cooperation item (Item

No.:2006DFA73620). The authors appreciate Dr

Jingbo Xu’s help from institute of Precision

Engineering, China, for providing pressure sensors

and relative testing, and thank Mr Gaofeng Zhou

from our lab for their help with fabrication.

REFERENCES

N. Bruder, P. N'Zoghe, N. Graziani, D. Pelissier, F. Grisoli

and G. François. A comparison of extradural and

intraparenchymatous intracranial pressures in head

injured patients [J]. Intensive Care Medicine, 1995,

21(10):850-852.

U. Kawoos, G.K.Mugalodi, M.R.Tofighi, S.Neff, A.Rosen.

A Permanently Implantable Intracranial Pressure

Monitor[C]// Proceedings of the 2005 IEEE 31st

Annual Northeast Bioengineering Conference,

Hoboken, NJ, United States, 2005:17-19.

Procaccio F, Stocchetti N, Citerio G, et al. Guidelines for

the Treatment of Adults with Severe Head

Trauma(partⅠ ) [J].J Neurosurg Sci, 2000, 44(1):1~10.

Gregory T A 2003 Micromachined Transducers

Soucebook(Beijing: Science Press) pp 47–50

Kroetz G H, Eickhoff M H and Moeller H 1999 Silicon

compatible materials for harsh environment

sensors,Sensors Actuators 74 182-9

Paramete

r

Value

Pressure ran

g

e

(

KPa

)

10

Re

p

ea

t

abilit

y

(

%FS

)

0.03

Non-linearit

y

(

%FS

)

0.01

Accurac

y(

%FS

)

0.04

H

y

steresis

(

%FS

)

0.02

S

y

stem erro

r

(

%FS

)

0.01

Diameter of senso

r

(

mm

)

11

THE DESIGN AND FABRICATION OF IMPLANTED INTRACRANIAL PRESSURE SENSOR

299