MODELLING COLLABORATIVE FORECASTING IN

DECENTRALIZED SUPPLY CHAIN NETWORKS WITH A

MULTIAGENT SYSTEM

Jorge E. Hernández, Raúl Poler and Josefa Mula

Centro de Investigación de Gestión e Ingeniería de Producción (CIGIP). Universidad Politécnica de Valencia

Escuela Politécnica Superior de Alcoy, Plaza Ferrándiz y Carbonell, 2, 03801, Alcoy, Alicante, Spain

Keywords: Collaborative forecasting, Multiagent system, Supply chain management, Decentralized decision-making

process.

Abstract: Information technology has become a strong modelling approach to support the complexities involved in a

process. One example of this technology is the multiagent system which, from a decentralized supply chain

configuration perspective, supports the information sharing processes that any of its node will be able to

carry out to support its process in a collaborative manner, for example, the forecasting process. Therefore,

this paper presents a novel collaborative forecasting model in supply chain networks by considering a

multiagent system modelling approach. The hypothesis presented herein is that by collaborating in the

information exchange process, less errors are made in the forecasting process.

1 INTRODUCTION

The development of supply chains increasingly

addresses the establishment of relationships among

the participating firms, companies or nodes,

generally in the manufacturing and logistic process.

Therefore, in order to carry on a collaborative

forecasting process in the supply chain, Aviv (2001)

considers that each member is not only able to

jointly maintain a single forecasting process in the

system, but is also capable of integrating this joint

forecasting process into its individual replenishment

process. In fact, the collaborative forecasting process

applies supply chain management concepts to the

forecasting process and uses available information

and technology to force a shift from independent,

forecasted demand to dependent, known demand

(Rodriguez et al., 2008). Moreover, Poler et al.

(2008) based the collaborative forecasting process

on the fact that each interrelated company had

relevant information available to forecast what the

rest did not have. This scenario facilitates the

implementation of the collaboration model and the

progressive spreading across non-collaborative

firms.

Moreover, information fields can be used as the

basis for coordinating an organization, which can be

seen as a collective agent composed of other

individual collective agents that may encompass

multiple embedded information fields (Filipe, 2003).

In this same supply chain forecasting context,

Liang and Huang (2006) establish that two types of

agents may be employed to respond to the various

types of services to support a forecasting process, for

example, control and demand forecast agents. Thus,

the multiagent-based modelling approach was the

tool selected to support decentralized collaborative

forecasting in the supply chain networks proposal.

Therefore, this paper has been set out as follows:

firstly, the decentralized supply chain agent-based

model under a collaborative context is presented by

considering Hernández et al. (2008) modelling

methodology. Then, the simulation results of a

particular model are briefly presented. Finally, the

main conclusion and a brief description of our future

work are presented.

372

E. Hernández J., Poler R. and Mula J. (2009).

MODELLING COLLABORATIVE FORECASTING IN DECENTRALIZED SUPPLY CHAIN NETWORKS WITH A MULTIAGENT SYSTEM.

In Proceedings of the 11th International Conference on Enterprise Information Systems - Artificial Intelligence and Decision Support Systems, pages

372-375

DOI: 10.5220/0002008503720375

Copyright

c

SciTePress

2 SUPPLY CHAIN

AGENT-BASED MODEL

2.1 The Collaborative Forecasting

Process in a Decentralized Supply

Chain. Generic Model Formulation

Collaborative forecasting firstly considers a demand

pattern (real demand) within a period length of

1>

T

. Then according to a decentralized

perspective, each node in this forecasting process is

able to identify two kinds of partners or nodes with

which it will become involved in the forecasting

process (Figure 2 shows an example of a generic and

complex supply chain network configuration which

will be used to support the following decentralized

collaborative forecasting agent model and the

experiments.).

Therefore, a generic supply chain network is

defined by interconnected

Y

supply chains (

SC

).

Thus, the total number of supply chains is defined

by

Y

SC

given the fact that

1≥

Y

. Then,

Y

SC

∀

and for all the nodes in which the forecasting

process is going to take place, the collaborative

nodes are firstly identified. This characteristic means

that this type of nodes will send the demand plan

related to certain products and periods. Finally, it is

necessary to identify non-collaborative nodes to

obtain firm orders which will be classically

forecasted.

Thus by considering the distributed supply chain

network made up of

K

nodes, where

1/ >∈ KSCK

Y

, a total of NC nodes is

considered to be collaborative, and a total of

NNC

is considered non-collaborative. Therefore, we allow

t

CN

β

to be defined as the demand from the

collaborative node

β

in period t where Tt > , and

t

NCN

δ

is the firm order for the non-collaborative

node

δ

in period t where

NNCTt ≤≤∧≤≤

δ

11 . In addition, the total

sum of the demand plans considers a number of

periods which is the equivalent to the minimal

common interval among the demand plans.

Therefore, by considering

β

P to be the number of

periods of each

β

node, it is possible to define

MINF as these minimal forecasted periods, where

(

)

β

PMINF min= , given the fact that

NC

≤

≤

β

1 . With this in mind, and also from a

generic viewpoint of the proposed model, the first

term, the collaborative forecasting component

(

)

CFC

, is composed of the information exchanged

among the

NC nodes which, from a matrix

perspective, can be defined as follows (Eq. 1):

Y

NC

j

MINF

NC

T

SCY

CN

CN

CFC ∈∀

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎣

⎡

⇒

∑

∑

=

=

+

ββ

β

β

β

/,,

1

1

1

#

(1)

Along these lines, each component of Eq. 1,

represents the total sum of the common period in

relation to each collaborative node until term MINF

is defined. With the second term however (Eq. 2),

which represents the non-collaborative information

exchange process, a classical forecasting process is

considered (to make the explanation of the process

easier), as is the exponential smoothing of the real

demand

t

RD involved in the t periods (where

Tt

≤

≤

1 ); in this case, a

τ

factor is considered to

take over the forecasting fix factor regarded in the

real forecast. This factor is between

0

and

1

and is

also called the smoothing constant. Thus, by

defining

S

NCN

δ

as the forecasted demand in

relation to the real demand for each period and node,

where

TS

≤

≤

1 , the forecasted demand value for

the next

1

+

T

period for each t and

δ

is defined

as follows (Eq. 2):

()

⎪

⎪

⎩

⎪

⎪

⎨

⎧

+>∈∀

+≤≤∈∀−×+

=∈∀

=

−

−

−

−

1//,,

12//,,

1//,

1

1

1

1

,

TSSCYNCN

TSSCYNCNRDNCN

SSCYRD

NCN

Y

S

Y

S

S

S

YS

S

δδ

δδτ

δδ

δ

δδδ

(2)

Therefore, given the collaborative forecasting in

the already defined descentralized supply chain, the

final matrix expression, which defines collaborative

forecasting (by considering the collaborative and

non-collaborative aspects) for the next

1

+

T

periods, is defined as follows (Eq. 3):

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎣

⎡

+

+

∑∑

∑∑

=

+

=

+

=

+

=

+

NC

MINFT

NCN

MINFT

NC

T

NCN

T

CNNCN

CNNCN

11

1

1

1

1

β

β

δ

δ

β

β

δ

δ

#

(3)

MODELLING COLLABORATIVE FORECASTING IN DECENTRALIZED SUPPLY CHAIN NETWORKS WITH A

MULTIAGENT SYSTEM

373

2.2 The Collaborative Forecasting

Agent-based Model

The agent-based model that supports collaborative

forecasting in decentralized supply chain networks

mainly considers two aspects. First, the related

agents involved in the process and, second, the

behaviour that each of them are able to recognize in

order to carry out their activities. As it is also

assumed that agents are self-interested, they will

participate for the purpose of obtaining the most

precise forecasting process by sharing their demand

plans (collaborative nodes) and by providing firm

orders (non-collaborative nodes)

Therefore from a generic point of view, the

agents to be considered in the collaborative

forecasting process are described as follows:

Forecasting Agent: this agent carries out the

forecasting process. In terms of the

decentralized environment where the agents

are involved, and depending on the particular

case, this agent is able to obtain its forecast

and may also behave as a (collaborative or

non-collaborative) customer in order to send

information to the other agents. Thus, the

forecasting agent is able to detect whether

information comes from a collaborative node,

or not. With these facts in mind, it will sum

the demand plans or will apply a classical

forecasting process.

Collaborative Agent: this agent exchanges its

demand plans, and is collaborative. In that

sense, this agent generates its demand plans or

sends them to the corresponding forecasting

agents. Thus, the information generated for

this agent is assumed to support a mid- or

long-term decision-making process.

Non-Collaborative Agent: this agent

contemplates the facts by considering its

needs, and only sends a short-term

information horizon with certain frequency

which may be known or not. Therefore, it is

feasible to say that this agent represents the

uncertainty of the environment

In addition, the communication process (see

Figure 1) among the agents is supported by

behaviours that are oriented to generate demand and

firm orders, to develop the forecasting calculus, to

identify the collaborative or non-collaborative

agents, and to send and receive the corresponding

messages. All this is done by considering the FIPA

standard communication protocols.

Collaborative

Agent

Non‐Collaborative

Agent

Forecasting

Agent

FIPA‐REQUEST‐PROTOCOL

FIPA‐REQUEST‐PROTOCOL

Generate

demand

plan

Generate

firm

orders

Send (demand Plan)

Send

(firm orders)

Sumarize

demand

plan

Classical

order

forecasting

Collaborative

forecasting

Demand

summatory

Classical

forecast

Deviaton

calculus

Send (firm orders)

Error

factor

Figure 1: A collaborative agent-based forecasting process.

2.3 Impact Analysis of the Proposed

Model

Regarding collaboration at upper levels, information

is considered to support the decisional process to

better match the nodes’ requirements. Then the next

lower levels will make their decision by considering

the information and constraints from the next upper

level.

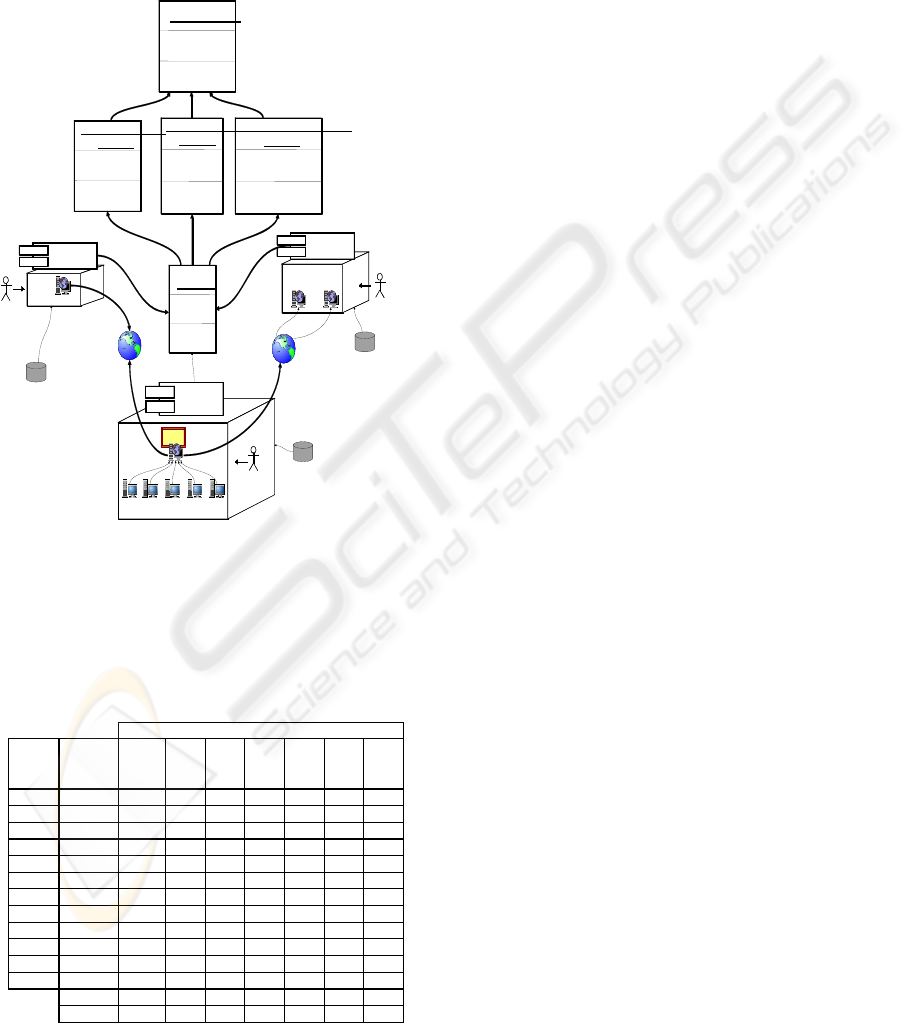

3 EXPERIMENTS

The experiments carried out in this paper consider

the specific case shown in Figure 2. Thus eight

nodes have been considered (N1, N12, N13, N14,

N15, N17, N31and N32), and have been assumed to

be geographically distributed and belong to different

supply chains.

Nine main scenarios (Table 1) have been defined

to show the impact of collaborative forecasting on

the deviation of the forecasted data compared with

the real demand pattern (Figure 1). These nine

scenarios (S1, S2, S3, S4, S5, S6, S7, S8 and S9)

compare the results by increasing the collaboration

level (by increasing the number of

β

nodes and by

decreasing the number of

δ

nodes).

In addition, and in order to support decentralized

collaborative forecasting, each supply chain that

makes up the supply chain network is related to its

own container which is managed by the main JADE

container.

ICEIS 2009 - International Conference on Enterprise Information Systems

374

3.1 Main Results and Discussions

Therefore with the simulated agent-based model, the

results (Table 1) aim to highlight the forecasting

deviaton in terms of the collaborative configuration

which has been assigned to differents nodes. In

Figure 2, these are the instantiated classes that carry

out the ACLMESSAGES.

N1

N11

N17

N12

N14

N13

N15

N31N32

JADE

Container 1

JADE

Container 2

JADE

Container 3

1

1

1

N

N

N

Network1

1

1

1

N

N

N

ACLMESSAGE()

Forecasting

agen

t

Collaborative

agent

Non-Collaborative

agent

User 2

User 3

User 1

Supply chain

network 1

Supply chain

network 2

Supply chain

network 3

Information

repository

FIPA-PROTOCOLS

(AchieveRE)

Network2

Setup() Setup() Setup()

Behaviour

s

Main

Setup()

FIPA-PROTOCOLS

(AchieveRE)

FIPA-PROTOCOLS

(AchieveRE)

Information

repository

Information

repository

Demand plan

/

firm orders

Demand plan/

firm orders

Figure 2: Particular decentralized supply chain network

agent-based model (a UML-based model approach).

According to Table 1, a clear impact caused by

increasing the collaborative level has been observed

in the forecasting deviation.

Table 1: Deviation of the forecasted demand.

Periods

TOTAL

real

orders

S9

(100%)

S8

(88%)

S7

(75%)

S6

(63%)

S5

(50%)

S2

(13%)

S1

(0%)

61 112 ‐1 ‐14,2 ‐28 ‐44,4 ‐44 ‐55,4 ‐41,8

62 85 ‐3 ‐12,2 ‐19 ‐12,4 ‐8 ‐22,4 ‐14,8

63 88 4 ‐11,2 ‐11 ‐19,4 ‐23 ‐22,4 ‐17,8

64 82 3 ‐2,2 ‐8 ‐14,4 ‐19 ‐20,4 ‐11,8

65 80 ‐2 ‐2,2 ‐6 ‐12,4 ‐22 ‐23,4 ‐9,8

66 102 2 ‐4,2

‐8 ‐16,4 ‐25 ‐44,4 ‐32,8

67 66 ‐1 4,8 7 17,6 11 4,6 4,2

68 74 12,8‐2 ‐14,4 ‐7 ‐7,4 ‐3,8

69 123 2 ‐2,2 ‐19 ‐30,4 ‐40 ‐50,4 ‐53,8

70 68 2 ‐11,2 ‐4 ‐12,4 ‐18 ‐8,4 2,2

71 113 ‐3 ‐16,2 ‐30 ‐31,4 ‐44 ‐56,4 ‐43,8

72 83 ‐2 ‐5,2 ‐30,6‐9 ‐13,4 ‐13,8

Average 0,2 ‐6,1 ‐10,9 ‐15,8 ‐20,7 ‐26,7 ‐19,8

Std.Dev. 2,4 6,8 11,0 15,7 16,5 20,3 18,9

Collaborativelevel

4 CONCLUSIONS

A collaborative forecasting agent-based model to

support the decentralized supply chain has been

proposed. Thus, under the supply chain network

supported by multiagent systems, the deviation was

lower compared with the real demand than the

traditional forecasting process when considering a

collaborative forecasting demand. In addition, full

collaboration among the nodes was not seen to be

necessary, but at list of more than a half of them to

collaborate is needed to generate real contribution

from this collaborative forecasting process. In future

research, the proposed model will be applied to a

real supply chain network in the automobile supply

chain sector, and will consider real demand data.

ACKNOWLEDGEMENTS

This research has been carried out in the framework

of a project funded by the Spanish Ministry of

Science and Education, entitled ‘Simulation and

evolutionary computation and fuzzy optimization

models of transportation and production planning

processes in a supply chain. Proposal of

collaborative planning supported by multi-agent

systems. Integration in a decision system.

Applications” (EVOLUTION project, DPI2007-

65501, http://www.cigip.upv.es/evolution).

REFERENCES

Aviv, Y. (2001). The Effect of Collaborative Forecasting on

Supply Chain Performance. Management Science,

47(10): 1326–1343.

Filipe, J. (2003). Information Fields in Organization Modeling

Using an EDA Multi-agent Architecture. Agent-Mediated

Knowledge Management, 2926: 130-142.

Hernández, J.E, Mula, J., and Ferriols, F.J. (2008). A

reference model for conceptual modelling of production

planning processes. Production Planning & Control,

19(8): 725–734.

Liang, W. Y., and Huang, C. C. (2006). Agent-based demand

forecast in multi-echelon supply chain. Decision Support

Systems, 42: 390–407.

Poler, R, Hernandez, J. E, Mula, J., and Lario, F.C. (2008).

Collaborative forecasting in networked manufacturing

enterprises. Journal of Manufacturing Technology

Management, 19(4): 514-528.

Rodriguez, R., Poler, R., Mula, J., and Ortiz, A. (2008).

Collaborative forecasting management: fostering

creativity within the meta value chain context. Supply

Chain Management: An International Journal, 13(5):

366–374.

MODELLING COLLABORATIVE FORECASTING IN DECENTRALIZED SUPPLY CHAIN NETWORKS WITH A

MULTIAGENT SYSTEM

375