AN ANALYTICAL AND NUMERICAL STUDY

OF PRESSURE TRANSIENTS IN PNEUMATIC

DUCTS WITH FINITE VOLUME ENDS

N. I. Giannoccaro, A. Messina and G. Rollo

Dipartimento di Ingegneria dell’Innovazione, Università del Salento, Via per Monteroni, Lecce, Italia

Keywords: Industrial automation, Pneumatic transmission line, Finite volumes, Ducts, Fluid mechanics.

Abstract: In this paper, the response of a pneumatic transmission line is analysed through two different approaches.

Both the approaches, based on the same physical model, are able to simulate the dynamics of a pneumatic

line, with finite volume ends. The first approach analytically provides the transients through an equation in a

quasi-closed form; the second approach is based on a numerical procedure yielding the inversion of the

Laplace transform by the application of a trapezoidal rule. The analysis of the mutual performances of the

two approaches, in the frame of pneumatic systems normally operating in industrial automation, can be

useful in terms of control of the response and could assist in the design of pneumatic systems.

1 INTRODUCTION

Pneumatic actuators are often employed in industrial

automation for reasons related to their good power/

weight ratio, easy maintenance and assembly

operations, clean operating conditions and low cost.

This set of advantages, however, is negatively

balanced by the difficulties met during the design.

Indeed, the presence of air, along with its natural

compressibility, introduces further complexities to

those already existing: friction forces, losses and

time delays in cylinder and transmission lines

(Messina, 2005), (Carducci, 2006). For these

reasons, fast transients involved in wave

propagations in pneumatic transmission lines

deserve to be taken into account in the design of the

system (Rollo, 2007).

The pneumatic transmission line, analysed in this

work, consists of a tube, of a certain length,

connecting two finite capacities. As far as the gas-

dynamic inside the duct is concerned, in literature

there are several papers dealing with such systems

but only describing lines with one of the two

capacities being finite. In this work, the

mathematical description of a pneumatic line, with

finite volume terminations, is presented. This setting

complicates the mathematics of the phenomena but

it is interesting because of the industrial practice

(Messina, 2005), (Rollo, 2007) where finite

capacities are very common. The transient in the line

is described through two partial differential

equations, whose solution is obtained in

correspondence to suitable initial and boundary

conditions. The mathematical model (Rollo, 2007)

gives the pressure response for a double volume

terminated pneumatic line and includes as a

particular case a previous model presented by

Schuder and Binder (Schuder, 1959).

The model is obtained assuming small pressure

and temperature changes, such that the following

assumptions are valuable (Schuder, 1959): (i)

incompressible flow and (ii) laminar flow; the

accuracy of the response, in correspondence of

different operative conditions, has been discussed

elsewhere (Rollo et al., 2007).

The assumptions of the model mainly concern

the flow conditions which allow an approach based

on the Laplace transform (Rollo, 2007), (Schuder,

1959). This type of model could be considered

attractive in the frame of industrial automation, but a

possible difficulty arises in the inverse

transformation especially when an analytical

description of the transient is attempted (Rollo,

2007). In this respect, a numerical method (Crump,

1976), (Duffy, 1993), that readily determines the

Laplace transform inversion, could be considered

attractive in order to achieve the pressure transient.

These two approaches, the analytical one (Rollo,

2007) and the numerical one (Duffy, 1993), that

60

I. Giannoccaro N., Messina A. and Rollo G.

AN ANALYTICAL AND NUMERICAL STUDY OF PRESSURE TRANSIENTS IN PNEUMATIC DUCTS WITH FINITE VOLUME ENDS.

DOI: 10.5220/0002169000600066

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2009), page

ISBN: 978-989-674-001-6

Copyright

c

2009 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

have different complexities, are taken into account

herein. The first analytically provides the description

of the pressure transients through an equation in a

quasi-closed form. The second is numerically able to

yield the inversion of the Laplace transform in a

direct way, through a trapezoidal rule (Crump,

1976), (Duffy, 1993). This latter, under certain

conditions, requires no manipulation on Laplace

transform.

The two approaches, with the analysis of the

mutual performances, can suggest, in the frame of

pneumatic systems normally operating in industrial

automation, the strategies in terms of design and

control of the response. In this respect, interesting

conclusions can be extracted.

2 SYSTEM ANALYSED

For a self comprehension of the present work, a brief

description of the real system analysed is also

presented. The relevant physical model which is

referred to in the present work is illustrated in Fig. 1.

The system under investigation consists of two

chambers having volumes Q

1

, Q

2

. The chambers are

connected through a cylindrical tube (also termed as

pneumatic transmission line) whose transversal

section is constant in the range of commercial

tolerances. The x-longitudinal coordinate is settled

from the upstream (chamber 1: Q

1

) to the

downstream chamber (chamber 2: Q

2

).

The upstream chamber consists of a five litre

tank arranged with four holes in order to allow the

external connections. In particular, chamber 1 is

filled up through a tap air supply until an established

static pressure, measured by the absolute pressure

gage, is reached. An airtight adapter is screwed onto

chamber 1. The adapter is made airtight through an

internal membrane made of commercial sticky tape.

The test and simulated condition consists of

suddenly breaking the membrane in order to allow a

wave pressure travel from chamber 1 to chamber 2

and vice versa; the sudden rupture of the membrane

is caused by a puncturing actuator placed at the

symmetrical end with respect to the membrane; the

puncturing actuator is quasi-statically activated by

manually pushing its rod through orifice A.

When a step pressure signal propagates through

the duct an on/off valve can be considered simulated

(Rollo, 2007). Based on these motivations the

approaches (analytical and numerical) have been

tested with respect to the mentioned step-type signal.

The downstream volume consists of the ram

chamber of a commercial double acting pneumatic

actuator. The established volume Q

2

can be in

practice settled by grounding the rod of the actuator

at a fixed position.

Figure 1: Scheme and nomenclature of the system.

3 SCHUDER AND BINDER

EXTENDED (SBE) MODEL:

ANALYTICAL APPROACH

In the SBE model (Rollo, 2007), (Schuder, 1959),

the equation describing the pressure transient in the

duct, obtained from an analytical solution of two

partial differential equations (one-dimensional mass

and momentum conservation law (Schuder, 1959)),

is obtained using the Laplace transform.

This kind of procedure yields, in the Laplace

domain and in correspondence of an established

section of the line (x=L), the following response:

()

()

()

()

s

p

βLsinhQkQ

a

β

β

a

βLcoshQkQ

1

kQ

s

pp

sL;P

0

21

21

1

0m

+

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+

++

⋅⋅

⎟

⎠

⎞

⎜

⎝

⎛

−

=

(1)

where a is the cross sectional area of the duct, k the

ratio of specific heats at pressure and volume

constant (c

p

/c

v

), L the length of the duct, p

m

and p

0

the initial pressure in the sending volume and

connecting duct respectively, Q

1

and Q

2

the sending

and receiving volume respectively and β is the

following parameter:

(

)

2

ρc

ρsRs

β

+

=

(2)

depending on R (frictional resistance in duct in the

presence of laminar flow), s the Laplace variable, ρ

the density (constant) and c the sound speed

(constant).

AN ANALYTICAL AND NUMERICAL STUDY OF PRESSURE TRANSIENTS IN PNEUMATIC DUCTS WITH

FINITE VOLUME ENDS

61

The inverse transform of (1) is not a

straightforward task; in this respect, following

Schuder and Binder, Jaeger’s result is taken into

account (Schuder, 1959): evaluating the coefficients

of an exponential series, it is possible to obtain the

following analytical solution showing the pressure in

the time domain in the position close to chamber 2

(x=L):

()

()

()

∑

∞

=

−

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎣

⎡

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−

+

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+++

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎠

⎞

⎜

⎝

⎛

+

⎟

⎠

⎞

⎜

⎝

⎛

⋅

⋅−−

++

++

=

1n

n

1n

n2

n

1

2

n

2

1

2

n

n

n

n

2ρ

Rt

0m

21

201m

A

cosα

kQα

aL

aL

αQ

sinα

kQα

aL

aL

Q

kQ

Q

1

α

2

t

sin

ρ

R

2

t

cos

epp2

aLQkQ

aLQpkQp

tL;P

ϑ

ϑ

ϑ

(3)

where t is the time; α

n

and θ

n

are functions of the

geometry of the line and initial flow conditions; in

particular, the poles in Equation (1) are function of

α

n

too (Rollo, 2007), (Schuder, 1959). In fact, by

substituing in Equation (1)

()

iα

ρc

ρsRs

LβL

2

1

2

=

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+

=

(4)

and equating to zero the common denominator of

Equation (1), an implicit equation in α is obtained;

once it is solved (numerically, with the Newton-

Raphson method), after some simple mathematical

manipulations, it is possible to obtain, along with

s

0

=0 (Rollo, 2007), (Schuder, 1959):

2

2

n

n

ρ

R

L

c2α

2

i

2ρ

R

s

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−

⎟

⎠

⎞

⎜

⎝

⎛

±−=

(5)

in which the real part of the poles is negative or

zero.

The quasi-closed form solution (3) depends on

the number of the terms in the series; the only non-

serious drawback is the necessity of resorting to a

numerical method in order to assess α

n

. Equation (3)

yields p(L;t) for a double volume terminated

pneumatic line and it is an extension of a previous

model presented by Schuder and Binder (Schuder,

1959). The analytical approach to the SBE model is

one of the most complete treatments among those

presented about transients in pneumatic lines within

relevant literature, in which the influence of pressure

waves propagating in ducts is, sometimes, neglected

or poorly described. Furthermore, even if it is

obtained using the following assumptions: (i)

incompressible flow and (ii) laminar flow, it can be

adopted, without significantly reducing the accuracy

of the response, in correspondence to certain

operative conditions (Rollo et al., 2007), where the

relevant investigations showed its ability to describe

pressure transients including reflecting waves.

4 NUMERICAL APPROACH

The Jaeger’s results, in the SBE model, are related to

the fact that the solution (3) depends i) on the

numerical evaluation of α

n

and ii) on a certain

amount of labor for the mathematical procedure

leading to Equation (3) in the inverse Laplace

transform (Rollo, 2007), (Schuder, 1959). A kind of

resolution allowing to obtain the inverse transform

of Equation (1) in a direct way, could be considered

attractive in the frame of systems normally operating

in industrial automation. In this respect the authors

suggest, in this work, to solve the problem of readily

determining the inverse Laplace transform using a

numerical approach. Within relevant literature, a

large number of different methods for numerically

inverting the Laplace transform have been

introduced and tested: one of these uses a Fourier

series approximation (Crump, 1976), (Duffy, 1993).

In fact, in (Duffy, 1993) the following

straightforward application of a trapezoidal rule in

order to provide the numerical inversion of Laplace

transform (here referred to Eq. (1)) is proposed:

()

()

[]

()

()

⎪

⎪

⎪

⎪

⎭

⎪

⎪

⎪

⎪

⎬

⎫

⎪

⎪

⎪

⎪

⎩

⎪

⎪

⎪

⎪

⎨

⎧

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎠

⎞

⎜

⎝

⎛

−

+

+

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎠

⎞

⎜

⎝

⎛

+

−

+

=

∑

∞

=1z

z

μt

2t

πi12z

μL;PIm

t

i πz

μL;PRe

1

μL;PRe

2

1

2t

e

tL;P

(6)

where t is the time, i the imaginary unit, Im and Re

indicate the imaginary and real part of the quantity

in the brackets respectively and μ must be greater

than the real part of any singularity (poles) in P(L;s)

(Duffy, 1993).

The accuracy and efficiency of such a numerical

approach depend on a suitable choice of some

parameters. In particular, μ can be evaluated

through certain considerations about the

discretization error (related to the step size π/t for

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

62

the trapezoidal rule) deriving from the application of

Eq. (6). Following the approach proposed in

(Crump, 1976), introducing the hypothesis that the

function of interest is bounded by:

()

λt

MetL;P ≤

(7)

(with M and λ real numbers) it is possible to choose

μ through the following relation:

(

)

2

t

Errln

λμ −=

(8)

where Err is the error parameter within the

numerical accuracy desired and the parameter λ can

be chosen slightly larger than the maximum of the

real part of all the poles (Crump, 1976). Once μ is

known, the series (6) can be summed until it

converges to the desired number of significant

figures (Crump, 1976). Usually the series in (6) can

converge slowly (this has been observed in some

tests not reported here); furthermore, (Crump, 1976)

the use of a sequence accelerator in conjunction with

the numerical inversion is recommended, also in

order to obtain a reduction of the truncation error

(indeed the series in Eq. (6) is not summed to

infinity). In this case, following the considerations in

(Crump, 1976), (Duffy, 1993), here Wynn’s epsilon-

algorithm is adopted. More specifically, to

accelerate the convergence of the sequence of partial

sums in (6) using the epsilon-algorithm, it is possible

to calculate them as in (9):

()

[]

()

()

1.1,...,2Nz

,

2t

πi12z

μL;PIm

t

i πz

μL;PRe

1SS

,μL;PRe

2

1

S

z

1zz

0

+=

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎠

⎞

⎜

⎝

⎛

−

+

+

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎠

⎞

⎜

⎝

⎛

+

−+=

=

−

(9)

It is possible, then, to define ε

-1

(m)

=0, ε

0

(m)

=S

m

,

m=0, 1,..,2N and then put:

() () () ()

[]

0,...,2Np

,εεεε

1

m

p

1m

p

1m

1p

m

1p

=

−+=

−

++

−+

(10)

In this way, the sequence ε

0

(0)

, ε

2

(0)

, ε

4

(0)

,.., ε

2N

(0)

gives better successive approximation to the sum of

the series (Crump, 1976). So, Equation (6),

including the sequence accelerator, becomes

Equation (11):

()

()

0

2N

μt

NUM

ε

2t

e

tL;P ⋅=

(11)

5 ANALYTICAL VS NUMERICAL

APPROACH: CONDITIONS,

RESULTS AND DISCUSSIONS

The analytical approach presented in Section 3

(Rollo, 2007) was used for an interesting

comparison, with respect to a more refined model

NLC (for Non Laminar Compressible flow) (Rollo,

2007), (Rollo et al., 2007). This latter model, whose

behaviour was validated through experimental

investigations (Rollo, 2007) on the physical model

of Fig. 1, takes into account i) flow not necessarily

laminar and ii) compressible flow. Through a

suitable error parameter, the discrepancy on the

response of a pneumatic line with established

geometrical characteristics (L=2.53m, D=3 or 6 mm,

Q

1

= 5dm

3

), for polyurethane ducts with an assumed

internal roughness of 3μm (Rollo, 2007) was

estimated for various flow conditions. In both

models, the relevant solution can be obtained and

displayed, in space (at a fixed time) and in time (at a

fixed position); however, the major relevance of the

performance in industrial applications (Messina,

2005), (Rollo, 2007) is related to the behaviour of

the pressure in the ram chamber of the actuator

(x=L). Therefore, only p(L;t) was discussed, in

correspondence of the various receiving volumes Q

2

(obtained fixing the stroke of the pneumatic actuator

employed as downstream volume, in correspondence

of different positions).

This comparison highlighted that, for a fixed

geometrical configuration, the error between the

SBE and NLC models is as small as the pressure

ratio p

m

/p

o

is close to 1 (Rollo, 2007); in this case

the match of SBE response with the NLC curve is

very satisfactory. This comparison was made after

appropriate convergence tests, that suggested to use

n=0,…..,30 in the Equation (3) for the SBE model.

In this work, the comparison between the

analytical (3) and numerical (11) approach is

discussed, in correspondence of some settings

yielding a satisfactory agreement of the SBE with

the NLC model. In particular, a line with L=2.53m,

D=3 mm and Q

1

= 5dm

3

will be considered. The case

of interest concerns the transient caused by an

AN ANALYTICAL AND NUMERICAL STUDY OF PRESSURE TRANSIENTS IN PNEUMATIC DUCTS WITH

FINITE VOLUME ENDS

63

upstream initial pressure in Q

1

of 1.1 times higher

than initial atmospheric pressure. This setting is

completed arranging the actuator employed as

downstream volume to establish, in a first case, a

volume Q

2

= 1.5 cm

3

(capacity corresponding to the

dead space of the ram chamber) and, in a second

case, Q

2

= 26.5 cm

3

(Rollo, 2007).

A suitable error parameter is introduced (12) for

the detection of discrepancy of the two approaches

(3) and (11):

() ()

()

A

NUMA

tL;p

tL;ptL;p

ERROR

−

=

(12)

in correspondence to various values of the time (10

ms≤t≤150 ms). In applying (11), it is assumed

Err=10

-6

and, for the considerations about Eqs. (5)

and (8), it can be assumed λ=0. In this way, the μ

value is known in all the time instants considered.

The comparison will be made firstly assuming, as far

as the numerical approach (11) is concerned, N=25.

In this respect, for the first case (Q

2

=1.5 cm

3

) the

following Table 1 was produced:

Table 1: Simulated Pressure with L=2.53 m, D=3 mm,

p

m

/p

0

=1.1, Q

2

=1.5 cm

3

(n=30, N=25).

Time Instants

(ms)

Analytical

Pressure

(bar)

Numerical

Pressure

(bar) ERROR

10 1.092289 1.092282 6.8E-06

20 1.116303 1.116265 3.4E-05

30 1.101538 1.101535 2.1E-06

40 1.097992 1.097992 3.5E-08

50 1.099557 1.099561 3.7E-06

60 1.099927 1.099927 1.5E-07

70 1.099681 1.099659 1.9E-05

80 1.099693 1.099693 1.7E-07

90 1.099725 1.099726 2.8E-07

100 1.099725 1.099726 1.1E-07

110 1.099723 1.099723 1.1E-07

120 1.099724 1.099724 2.9E-09

130 1.099724 1.099724 1.5E-08

140 1.099724 1.099724 4.5E-09

150 1.099724 1.099724 4.4E-10

Pressure

computational

time (ms) ~ 5 ~ 290

In Table 1 the first column shows the time

instants taken into account, the second and third

columns show the pressure values obtained with the

two approaches, the analytical one and the numerical

one respectively, the fourth column shows the

ERROR values. Table 1 shows an agreement of the

analytical and numerical results (second and third

column) that can be considered very satisfactory;

furthermore, it is possible to notice that the

computational times (evaluated on a 2.8 GHz

Pentium IV using a Matlab routine) show that the

analytical approach needs about 5 ms to provide the

pressure values in the second column, whilst the

numerical computational time is about 290 ms.

As far as the second case (Q

2

=26.5 cm

3

) is

concerned, the following Table 2 was produced:

Table 2: Simulated Pressure with L=2.53 m, D=3 mm,

p

m

/p

0

=1.1, Q

2

=26.5 cm

3

(n=30, N=25).

Time Instants

(ms)

Analytical

Pressure

(bar)

Numerical

Pressure

(bar) ERROR

10 1.018830 1.018831 3.6E-07

20 1.053451 1.053449 2.1E-06

30 1.076250 1.076250 1.6E-08

40 1.087726 1.087726 1.9E-08

50 1.093537 1.093539 1.6E-06

60 1.096557 1.096557 9.1E-09

70 1.098006 1.098006 3.3E-08

80 1.098703 1.098703 2.0E-07

90 1.099047 1.099047 5.3E-09

100 1.099214 1.099214 1.6E-07

110 1.099294 1.099293 1.1E-06

120 1.099333 1.099333 5.3E-12

130 1.099352 1.099352 5.9E-09

140 1.099361 1.099361 1.4E-09

150 1.099366 1.099366 1.9E-10

Pressure

computational

time (ms) ~ 5 ~ 290

Table 2 is also able to show a satisfactory

agreement of the results of the two approaches (3)

and (11) and, as in Table 1, it is possible to notice

that the numerical computational time is about 290

ms, whilst the analytical approach needs about 5 ms

to provide the pressure values in all the time instants

considered.

Table 1 and Table 2 can suggest that the

numerical approach (11) is not always advisable in

engineering applications in which the performance is

required in terms of design and fast control of the

response. A possible way to highlight this drawback

can be based on the study of the discrepancies with

the analytical approach, decreasing N in such a way

as to reduce the computational time of the numerical

approach (like in Table 3). In Table 3, the first

column shows the operative conditions taken into

account, the second column the mean of ERROR

values and the third the numerical computational

times. As can be seen, the computational times

decrease if N decreases, but this behaviour still

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

64

seems far from the more attractive computational

times of the analytical approach. Furthermore

decreasing the value of N, the mean ERROR value

slightly increases.

Table 3: ERROR for a pneumatic line with L=2.53 m,

D=3 mm, p

m

/p

0

=1.1, Q

2

=1.5 cm

3

and Q

2

=26.5 cm

3

, n=30.

Mean of

ERROR

values

Numerical

computational

times (ms)

N=25

Q

2

=1.5 cm

3

4.4E-6 290

N=25

Q

2

=26.5 cm

3

3.8E-7 290

N=20

Q

2

=1.5 cm

3

2.4E-5 204

N=20

Q

2

=26.5 cm

3

7.2E-7 204

N=10

Q

2

=1.5 cm

3

6.4E-5 77

N=10

Q

2

=26.5 cm

3

7.6E-6 77

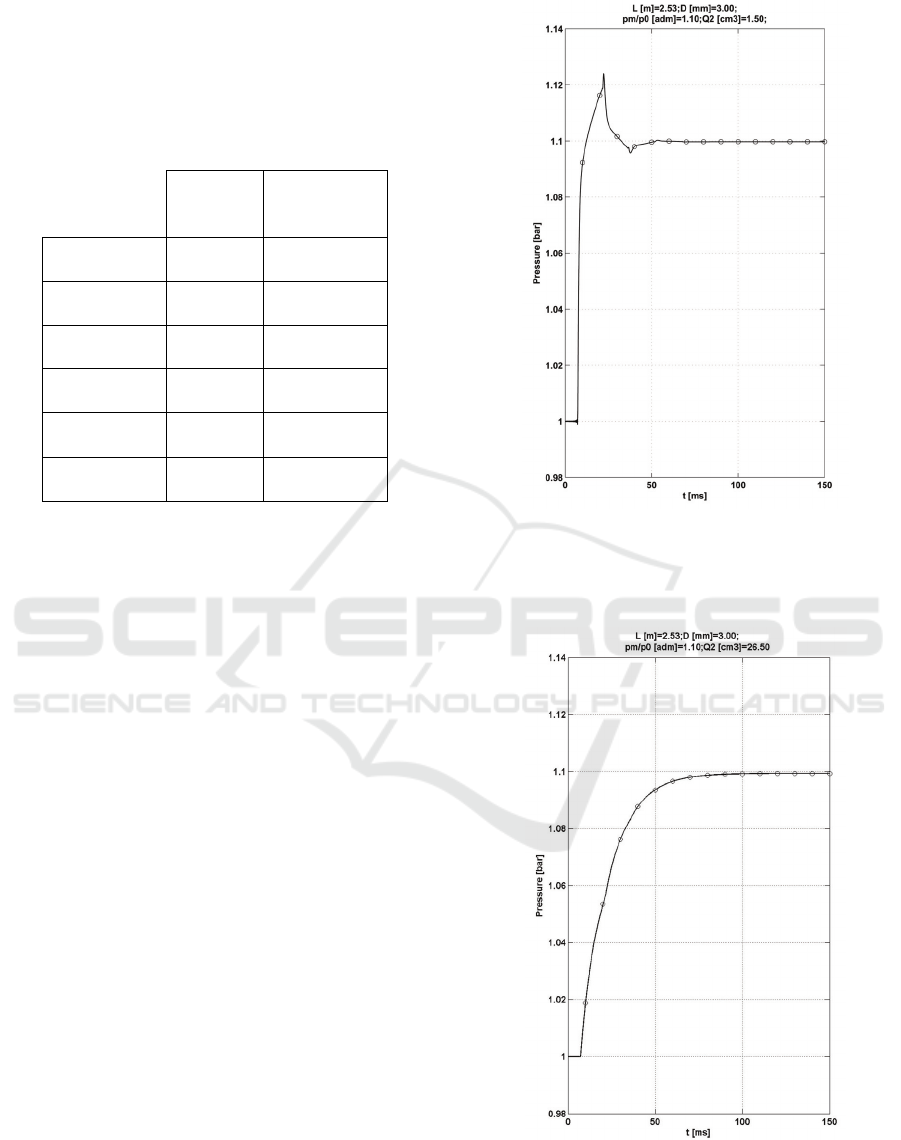

An estimation of the behaviour of both

approaches concerning the transient in the

aforementioned pneumatic lines, can be obtained

through the following Fig. 2 and Fig. 3, useful also

in order to estimate the pressure transients of Eq. (3)

and Eq. (11) in terms of design of the line.

Finally, also Figure 4 has been produced. This

latter figure has been introduced with the motivation

of showing the satisfactory agreement of both the

proposed approaches, also in correspondence of an

intermediate receiving volume (Q

2

=16.5 cm

3

).

6 CONCLUSIONS

In this paper, two approaches of different

complexities, concerning the dynamics of a

pneumatic transmission line with finite volume ends,

have been analysed: one analytical and another one

numerical. The first one provides the description of

the pressure transients through an equation in a

quasi-closed form and gives the pressure response

for a double volume terminated pneumatic line.

Figure 2: Simulated pressure at the receiving volume

through analytical (__) and numerical (°) approach with

D=3mm, L=2.53m, p

m

/p

0

=1.1 and Q

2

=1.5cm

3

(n=30,

N=25).

Figure 3: Simulated pressure at the receiving volume

through analytical (__) and numerical (°) approach with

D=3mm, L=2.53m, p

m

/p

0

=1.1 and Q

2

=26.5cm

3

(n=30,

N=25).

AN ANALYTICAL AND NUMERICAL STUDY OF PRESSURE TRANSIENTS IN PNEUMATIC DUCTS WITH

FINITE VOLUME ENDS

65

Figure 4: Simulated pressure at the receiving volume

through analytical (__) and numerical (°) approach with

D=3mm, L=2.53m, p

m

/p

0

=1.1 and Q

2

=16.5cm

3

(n=30,

N=25).

The second, numerically, is able to yield the

inversion of the Laplace transform through a

trapezoidal rule (in conjunction with a sequence

accelerator). Using certain geometrical

configurations and flow conditions, for which it was

shown that the SBE model can be used without

significantly reducing the accuracy of the response,

the two kinds of resolution can be compared and

analysed. The introduction of a suitable error

parameter, able to provide the discrepancies of the

two approaches, allows interesting discussions.

The trapezoidal rule, in its numerical simplicity,

could avoid the long mathematical procedures

yielding the inversion of the Laplace transform. The

advantage related to the application of this direct

rule seems, however, negatively balanced by the

extra computational efforts required to achieve a

satisfactory convergence (the series approximation

can converge slowly and, usually the use of a

sequence accelerator in conjunction with the

numerical inversion is highly recommended). For

these reasons, the numerical approach could not

always be advisable in engineering applications in

which performances are required in terms of design

and control of the response. This, indeed, has been

showed by the comparison with an analytical

solution in a quasi-closed form, in terms of

computational times. The possible drawback of this

latter approach is a verbose procedure giving the

final relation and the need to resort to a numerical

method in order to assess all the poles involved in

the Laplace transform. However, the relevant

simulations carried out highlight an excellent

behaviour of the analytical approach: these

properties can be considered attractive also

considering the satisfactory overlap of the curves

provided by the analytical approach with a more

performing numerical model (NLC), whose

excellence has been confirmed with experimental

validations.

The study presented in this paper gives the

possibility of investigating relevant dynamic

behaviours, suggesting an efficient estimation of

control and design parameters, in the frame of

systems normally operating in industrial automation.

REFERENCES

Messina, A., Giannoccaro, N. I., Gentile, A., 2005.

Experimenting and modelling the dynamics of

pneumatic actuators controlled by the pulse width

modulation (PWM) technique. Mechatronics, 15, 859-

881.

Carducci, G., Giannoccaro, N. I., Messina, A., Rollo, G.,

2006. Identification of viscous friction coefficients for

a pneumatic system model using optimization

methods. Mathematics and Computers in Simulation,

71, 385-394.

Rollo, G., 2007. Analisi dinamiche di tipici sistemi

meccanici ad attuazione pneumatica. Ph. D. Thesis,

Università del Salento, Dipartimento di Ingegneria

dell’Innovazione, Lecce.

Schuder, C.B., Binder, R.C., 1959. The response of

pneumatic transmission lines to step inputs. Trans.

ASME, 81, 578-584.

Rollo, G., Messina, A., Gentile, A., 2007. Influence of

geometrical parameters and operative conditions on

pressure transients in pneumatic ducts. XVIII

Congresso AIMETA di Meccanica Teorica e

Applicata, MA 15, 453.

Crump, K. S., 1976. Numerical inversion of Laplace

transforms using a Fourier series approximation.

Journal of the Association for Computing Machinery,

23, 89-96.

Duffy, D. G., 1993. On the numerical inversion of Laplace

transforms: comparison of three new methods on

characteristic problems from application. ACM

Transaction on Mathematical Software, 19, 333-359.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

66