MANAGING ENGINEERING CHANGES ALONG WITH

NEW PRODUCT DEVELOPMENT

Weilin Li

L. C. Smith College of Engineering & Computer Science

Syracuse University, 223 Link Hall, Syracuse, NY 13244, U.S.A.

Keywords: Engineering Change Management, New Product Development, Process Modeling, Discrete-Event

Simulation.

Abstract: This proposed research is to develop a process model for managing Engineering Changes (ECs) while other

New Product Development (NPD) activities are being carried out in a company. The discrete-event

simulation model incorporates Engineering Change Management (ECM) into an NPD environment by

allowing ECs to compete for limited resources with regular NPD activities. The goal is to examine how the

size and frequency of NPD as well as ECM, NPD process structure (in terms of overlapping and department

interaction), and the policies one organization employs (such as resource using priority and project

cancellation policy) affect lead time and productivity of both NPD and ECM. Decision-making suggestions

for minimum EC impact are drawn from an overall enterprise system level perspective based on the

simulation results.

1 PROBLEM DEFINITION

New product development is defined as the complete

process from idea generation, product design, to

detail manufacturing until bringing a product to

market. It is the whole process beginning with the

perception of a market opportunity and ending in

production. There are several important

characteristics of NPD. First, a product design and

development company usually launches certain

number of new products according to a relatively

strict schedule. Second, although scarce engineering

capacity has always been a huge problem faced by

most organizations, the resources provided for NPD

projects are relatively placed and fixed firmly. That

is to say, there are always certain amounts of

resources to be dedicated to each NPD project. Third,

though the NPD process tends to become more and

more complex attributable to the increasing volume

of information involved, it has some repeatable

structure due to fact that design is something of an

art but with many consistent patterns (Browning,

2007).

Engineering change management, on the other hand,

is defined as a collection of procedures, tools, and

guidelines for handling modifications and changes to

a product that has been released to the market

(Terwiesch and Loch, 1999; Bhuiyan 2006). Unlike

the iterations within NPD process, engineering

change is the rework after production. It occurs in

far more random pattern compared with regular

NPD projects. The amount of time and effort

required for each ECM also varies from case to case.

As an industry norm, ECM usually doesn’t have its

own specified resources. It shares the same pool of

engineering capacity with NPD projects. That is to

say, NPD and ECM activities normally compete for

limited resources available.

ECM is a major competitive component in product

design and development process that should not be

neglected. It plays a critical role in finally realizing

actual profits from new product development efforts.

Companies benefit from ECM by correcting design

faults; solving safety or functionality problems;

providing better customers’ satisfaction; reflecting

technology improvements. However, on the other

hand, ECM consumes considerable amount of

resource, which in turns affects the lead time and

productivity of regular NPD projects significantly. It

also accounts for high EC costs with regards to

manufacturing tool costs, engineering rework,

inventory obsolescence, and possible downstream

EC propagation. (Loch, 1999; Balakrishnan, 1996).

193

Li W. (2009).

MANAGING ENGINEERING CHANGES ALONG WITH NEW PRODUCT DEVELOPMENT.

In Proceedings of the 11th International Conference on Enterprise Information Systems, pages 193-200

DOI: 10.5220/0002193901930200

Copyright

c

SciTePress

2 RESEARCH QUESTIONS

The objective of this research is to fully model the

ECM process within a multi-project environment to

provide insightful decision-making suggestions for

companies regarding how engineering changes

should be implemented with minimal adverse effects

on normal NPD activities. To be more specific, this

research intends to answer the following questions.

1) How important is ECM for a firm that is

engaged in developing new products?

2) What are the key contributors to long lead

times in NPD in relation with ECM? And

vice versa.

3) How will the occurrence of an ECM

influence regular NPD activities? Within

which activity during which phase in the

NPD process will the impact be the most

tremendous?

4) What are the key contributors to low

production rates in ECM in relation with

NPD? And vice versa.

5) What is an optimal way of allocating

limited resources between NPD and ECM?

6) Is there a generic guideline for incomplete

NPD/ ECM cancellation when engineering

capacity is overloaded?

3 METHODOLOGY

This research focuses on the “flow of information”

standpoint of an NPD process (Krishinan, Eqqinger,

and Whitney 1997). From this information

processing point of view, an NPD project can be

treated as evolving product information that travels

through time (total development cycle time) and

space (all the departments involved), seizing and

releasing engineering capacity. However, we are not

interested in the way how the input information of

an NPD activity from its previous one evolves

gradually into the eventual output information, but

the separated points in time when entities arriving

and leaving an NPD activity and change of the state

of system. By doing this, we can check the duration

of each NPD/ECM activity and resource utilization.

Also, the repeatable nature of an NPD process

structure provides validation for decomposing an

NPD process into successive design and

development phases, each enclosing several

sequentially repeated activities. Nevertheless, NPD

is also an iterative process rather than a purely linear

one with unforeseen uncertainty and ambiguity

(Terwiesch and Loch 1999). This feature can be

represented by both NPD iteration and variation of

activity duration.

Among various kinds of mathematical and computer

models, a stochastic discrete-event simulation are

adopted as the modeling approach for the following

reasons: 1) it is more suitable to represent such a

complex and dynamic system; 2) allows for more

detailed analysis; 3) matches the nature of problem

well as discussed above; 4) several sophisticated

software packages available.

4 STATE OF THE ART

While NPD is an area that attracts lots of

investigations by huge amounts of researchers over

the past decades, ECM, particularly, how ECM

affects general NPD activities and vice versa, is

overlooked in the past.

The review of papers until 1995 was done by Wright.

(Wright, 1997) The author categorized the EC

related papers into two main topics, computer-based

“tools” for the analysis of EC problems and

“methods” to reduce the impact of ECs on

manufacturing and inventory control. We can find

that most of the publications in that time period

predominantly focused on the EC control

mechanisms and systems. An important observation

by Wright is that understanding of the positive effect

EC can provide for product improvement and

enhanced market performance is long omitted by EC

research.

Terwiesch and Loch presented a process-based view

of ECM. (Terwiesch and Loch, 1999) They showed

by an industrial case study that a complicated and

congested administrative support process is one of

the root causes of long lead time and high cost.

Based on the field study, they identified five key

contributors to lengthy ECO lead time: complex

ECO approval process, scarce capacity and

congestions, setups and batching, snowballing

changes, and organizational issues.

In another paper they wrote, an analytical

framework that explains the extreme ratio between

theoretical processing time and actual lead time was

developed. (Loch and Terwiesch, 1999) They

showed how congestion and batching influence

engineering processes at a more detailed level.

Special Session DR 2009 - Special Session on Doctoral Research

194

Based on the processing network framework, they

suggested improvement strategies such as flexible

work times, the grouping of several tasks, workload

batching, the pooling of resources, and the reduction

of setup times.

Krishnan presented a model-based framework to

manage the overlapping of coupled product

development activities. (Krishnan, 1997) The author

studied the overlapping problem based on two

properties, upstream information evolution and

downstream iteration sensitivity, of the information

exchanged between product design phases. The

mathematical model and conceptual framework of

the overlapped process were illustrated with

industrial examples to provide managerial insights.

The most related work to this research is done by

Bhuiyan and her co-workers. They built a stochastic

computer model to examine how overlapping and

functional interaction affect the performance

measures of development time and effort under

varying conditions of uncertainty. (Bhuiyan, 2004) It

is the first comprehensive model using a discrete

event simulation for the entire NPD process by

taking into account functional interaction at different

values of overlapping under different uncertainty

conditions. Development effort was also introduced,

in the form of total person-days for a project, as a

measure of NPD performance that was neglected by

earlier researchers. A number of conclusions were

drawn from the model, however, their model

assumed an unlimited amount of resources, which is

unrealistic in practice.

Bhuiyan’s research group has also expanded this

framework to compare two methods for managing

Engineering Change Requests (ECRs): immediate

individual processing as issued and batch processing

after accumulation. (Bhuiyan, 2006) They evaluated

the effects of the methods in terms of development

time and effort. The model they developed, though,

has a couple of limitations: (i) the research scope

only on immediate or batch processing is too

simplified compared with a large amount of ECM

problems; (ii) treating all ECRs similarly is

acceptable only for comparative analysis. Despite of

these limitations, Bhuiyan’s model is the only study

on ECM using the discrete-event simulation. Thus it

inspired our model.

Another important work is the comprehensive

heuristic for a stochastic, resource-constrained

project scheduling problem in an iterative project

network. (Cho and Eppinger 2005) Their model

uses a parallel discrete event simulation

methodology to compute the distribution of lead

time of engineering design processes for project

scheduling analysis. Many important characteristics

of complex design process, such as overlapping,

iteration of tasks, rework concurrency, task priority,

are incorporated in this model. Design Structure

Matrix (DSM) is employed to capture the

information flows between tasks.

Browning presented a thorough literature survey on

the topic of activity network-based models for NPD

project management. (Browning, 2007) The paper is

based upon four major categories: visualization,

planning, execution and control, and project

development. And he highlighted five research

directions for future study: activity interactions,

global process improvements, process models as an

organizing structure for knowledge management,

modeling in cases of uncertainty and ambiguity, and

determining the optimum amount of process

prescription and structure for an innovative project.

Insufficient resource allocation always remains as

one of the important questions faced by NPD

organizations. At the same time, discovery of major

problems is so often identified in final stages of the

development cycle, which will require significant

additional resources from other projects, especially

those ones still in early phases, thus further

detriment the problem of dysfunctional resource

allocation. Black and Repenning propose a

simulation framework to analyze different policies

organizations may adopt for earlier problem

resolution, better quality and performance in a multi-

projects environment. This paper concludes with the

following two main insights: 1) the importance of

realistic schedules and appropriate amounts of

resources at the early phases of NPD projects; 2) a

strict and inflexible version of cancellation policy

offers the highest potential to produce effective

improvement in NPD projects.

5 STATE OF THE RESEARCH

In this part, the first model version is introduced by

the illustration of both model screenshots and word

explanation. Arena simulation package is used for

the project.

MANAGING ENGINEERING CHANGES ALONG WITH NEW PRODUCT DEVELOPMENT

195

5.1 Model Configuration

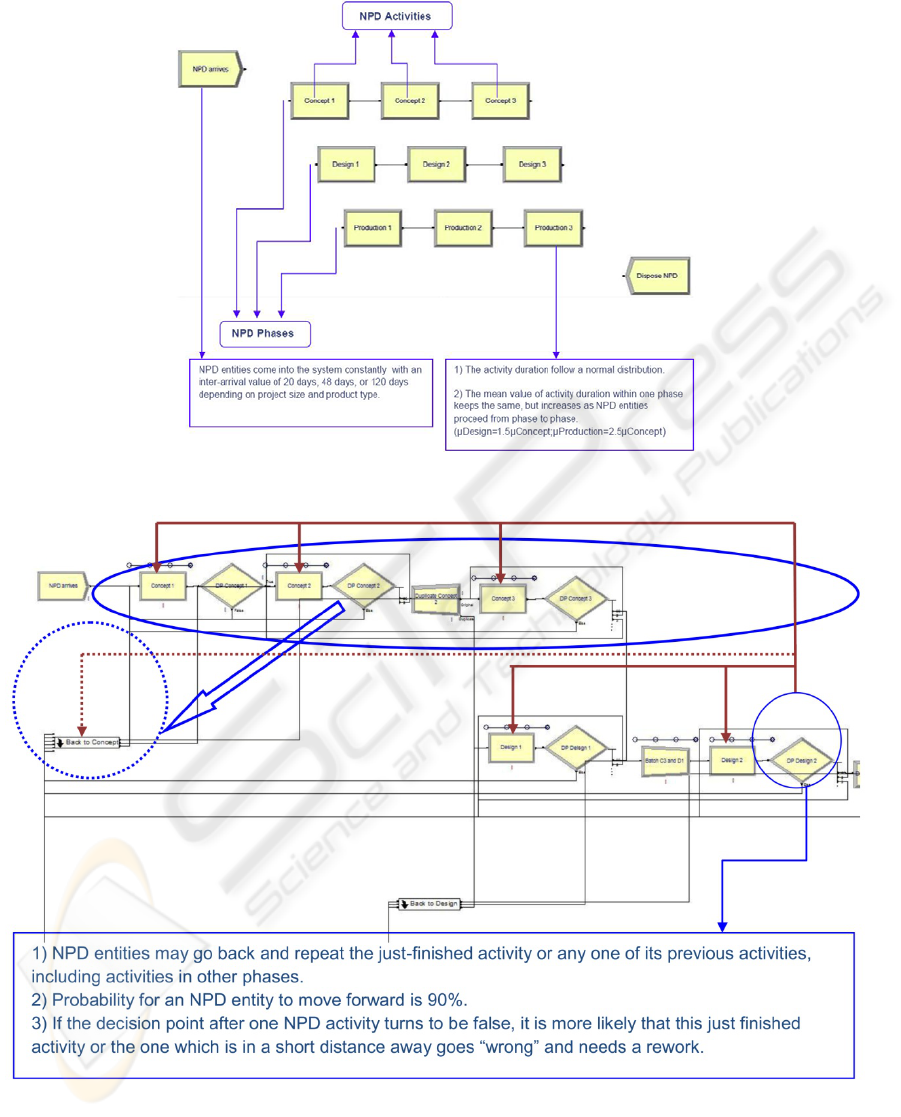

Figure 1: 3 phase and 3 activity framework for NP.

Figure 2 : Model overview of the NPD part.

Special Session DR 2009 - Special Session on Doctoral Research

196

Figure 3: Model overview of the ECM part.

5.2 Preliminary Results

For the model described above, we analyzed the

influence of resource constraint, resource using

priority, overlapping, NPD departmental interaction,

ECM effort, on both NPD and ECM lead time and

productivity under different NPD and ECM arrival

rates. Three levels of NPD and ECM arrival rates are

combined in pairs according to their value. That is,

high NPD arrival rate is studied with high ECM

arrival rate, and low NPD arrival rate with low ECM

arrival rate.

Partial results are presented in this poster due to

space limitation. The following two charts show the

impacts of overlapping, NPD departmental

interaction, and ECM effort on NPD Total Time and

Productivity under resource constraint of 60 units

from each department.

The NPD and ECM model framework introduced

above address several issues that earlier models

didn't. In this model, we capture important new

product design and development characteristics such

as iteration and overlapping of NPD process,

interaction among different functional areas,

resource constraints and its using priority. We also

take into account the size of NPD projects and ECRs

in terms of their arrival rates and processing effort.

From the simulation results, a number of

conclusions can be drawn:

Figure 4: Simulation Results.

1) ECM is an important aspect to the success of an

NPD project. On one hand, it solves safety or critical

functionality problems of a product. And it reflects

customer requirements or technology developments.

On the other hand, it also consumes a considerable

amount of product development resources which in

turns affects the lead time and productivity of

regular NPD activities significantly.

MANAGING ENGINEERING CHANGES ALONG WITH NEW PRODUCT DEVELOPMENT

197

2) While each of the six model variables,

overlapping, NPD departmental interaction, ECM

effort, resource constraints, arrival rate, and resource

using priority, affects the overall lead time and

productivity of both NPD and ECM by some extent,

the effect of resource constraints is most significant.

3) This model addresses decision-making

suggestions for firms under different organization

environment and resource constraint condition.

Specifically, when the resource capacity is limited, a

medium level of overlapping and high departmental

interaction is suggested to optimize system resource

utilization.

6 FUTURE WORK

6.1 Model Extention

There are several aspects of this model that need

further investigation.

1) The assumption that one EC is confined in one

NPD activity is not always true. An EC that requires

rework in a design activity may propagate to other

activities in design or production phase. Future study

should include engineering change propagation as

one feature of the ECM process.

2) In the current model, probabilities for feedback

iterations are assigned to an NPD project. However,

when a new product project needs to go back to

earlier NPD activities for a rework, subsequent

activities need to be followed again no matter how

many times these activities are repeated. In other

words, an NPD entity has to go through again all the

downstream activities after being sent back to the

iteration starting point. Feed-forward flexibility and

learning effects for iteration need to be considered in

future work.

3) In this model, it is assumed that NPD and ECM

share the same pool of resources with using priority.

I could let NPD and ECM have their own dedicated

resources. Or, NPD and ECM still use the same pool

of resources. But ECM requests for outsourcing

when resources are not available. In this case,

different utility costs can be set for using resources

within a department, cross departments, and for

outsourcing.

4) Besides lead time and productivity, other critical

criteria such as resource utilization, total cost, and

customer satisfaction, can be adopted to review and

evaluate the impact of ECM throughout NPD

process.

5) As we can see from the preliminary running

results of the first model version, production of NPD

and ECM keeps to be less than 1 and is far less when

the resource level is low (with a number of 60 per

department). Black found out from her policy

analysis model that the policy cancellation of the

work that falls behind schedule well in advance of

its launch date can ensure consistently high

performance and recovering productive capability.

(Black and Repenning 2001) Effective cancellation

of incomplete NPD/ECM is also one direction of

this research.

6.2 Model Validation and Verification

1) Use output analysis as the first step of model

validation, and check to see if the simulation output

is reasonable.

2) Comparison of this model and related studies

provides another way of validation.

3) Apply the correlated inspection approach. That

is, compare real-world observation and simulation

output with historical system input data. For

example, given input parameter from industry

(actual observed inter-arrival time of NPD projects

and EC Requests; actual observed activity duration

in different NPD phases; etc.), we can determine the

accuracy of the model by comparing the model

output data and the inspection from company).

6.3 Model Validation and Verification

1) Use animation to enhance the credibility of this

model.

2) Run the model under simplifying assumptions

for which its true characteristics are known, and then

gradually add details into the simulation project.

3) Run the model under a variety of settings of the

input parameters, especially in those extreme

conditions, and check to see if the output is

reasonable.

6.4 Experimental Design

From the preliminary running of the first model

version, we have already got some ideas about

which model variables, such as inter-arrival rates of

NPD and ECM, NPD departmental interaction,

ECM effort, are likely to be important. However,

Special Session DR 2009 - Special Session on Doctoral Research

198

carefully designed experiments should be carried out

for efficient experimentation in determining which

factors are most important and joint effect of the

factors on a response as well. Table 1 shows

possible model factors and responses.

6.5 Data Collection from Industry

Some of the parameter setting and input data for the

first model version are hypotheses based on relevant

results from similar studies or the modeler’s

experience. These may be obsolete due to time

concerns but still realistic when this simulation study

is initiated. We can replace them by real inspection

from industry in later stages of this research.

REFERENCES

Balakrishnan, N., A. K. Chakravarty, 1996. Managing

Engineering Change: Market Opportunities and

Manufacturing Costs. Production and Operations

Management. 5 (4):335-356.

Balcerak, K. J., B. G. Dale, 1992. Engineering Change

Administration: The Key Issues. Computer-Integrated

Manufacturing Systems. 5 (2):125-132.

Bhuiyan, N., D. Gerwin, V. Thomson, 2004. Simulation of

the New Product Development Process for

Performance Improvement. Management Science.

50(12):1690-1703.

Bhuiyan, N., G. Gr, V. Thomson, 2006. Engineering

Change Request Management in a New Product

Development Process. European Journal of Innovation

Management. 9(1):5-19.

Black, L. J., N. P. Repenning, 2001. Why Firefighting Is

Never Enough: Preserving High-Quality Product

Development. System Dynamic Review. 17(1):33-62.

Bouikni, N., A. Desrochers, 2006. A Product Feature

Evolution Validation Model for Engineering Change

Management. Journal of Computing and Information

Science in Engineering. 6(2):188-195.

Browning, T. R., E. Fricke, H. Negele, 2006. Key

Concepts in Modeling Product Development

Processes. System Engineering. 9(2):104-128.

Browning, T. R., R. V. Ramasesh, 2007. A Survey of

Activity Network-Based Process Models for

Managing Product Development Projects. J. Product

Innovation Management. 16(2):160-172.

Causey, J. W.,1989. On the Art/Science of Expediting.

Production and Inventory Management Journal.

30(1):73-88.

Cho, S. H., S. D. Eppinger, 2005. A Simulation-Based

Process Model for Managing Complex Design

Projects. IEEE Transactions on Engineering

Management. 52(3):316-328.

Eckert, C., P. J. Clarkson, W. Zanker, 2004. Change and

Customisation in Complex Engineering Domains.

Research in Engineering Design. 15(1):1-21.

Huang, G. Q., K. L. Mak, 1999. Current Practices of

Engineering Change Management in Hong Kong

Manufacturing Industries. Journal of Materials

Processing Technology. 19(1):21-37.

Huang, G. Q., W. Y. Yee, K. L. Mak, 2003. Current

Practices of Engineering Change Management in UK

Manufacturing Industries. International Journal of

Operations & Production Management. 139(1-3):481-

487.

Krishnan, V., S. D. Eppinger, D. E. Whitney, 1997. A

Model-Based Framework to Overlap Product

Development Activities. Management Science.

43(4):437-451.

Loch, C. H., C. Terwiesch, 1999. Accelerating the Process

of Engineering Change Orders: Capacity and

Congestion Effects. J. Product Innovation

Management. 16(2):145-159.

Moon, Y.B. 2007, Enterprise Resource Planning (ERP): a

review of the literature. International Journal of

Management and Enterprise Development, 4(3): 235-

264.

Tavcar, J., J. Duhovnik, 2005. Engineering Change

Management in Individual and Mass Production.

Robotics and Computer-Integrated Manufacturing.

21(3):205-215.

Terwiesch, C., C. H. Loch, 1999. Managing the Process of

Engineering Change Orders: The Case of the Climate

Control System in Automobile Development. J.

Product Innovation Management. 16(2):160-172.

Wright, I.C., 1997. A Review of Research into

Engineering Change Management: Implications for

Product Design. Design Studies. 18:33-42.

Kelton, W. David, R. P. Sadowski, D. T. Sturrock, 2006.

Simulation with Arena, The McGraw-Hill Companies.

London, 4

th

edition.

Law, Averill M., 2007. Simulation Modeling & Analysis,

The McGraw-Hill Companies. 4

th

edition.

MANAGING ENGINEERING CHANGES ALONG WITH NEW PRODUCT DEVELOPMENT

199