MODELING OF CONTINUOUS FERTILIZER

GRANULATION-DRYING CIRCUIT FOR COMPUTER

SIMULATION AND CONTROL PURPOSES

Gediminas Valiulis and Rimvydas Simutis

Department of Process Control, Kaunas University of Technology, Studentų St. 48, Kaunas, Lithuania

Keywords: Granulation, Modeling, Simulation, Control.

Abstract: The paper presents the model-based approach to process simulation and advanced control in the industrial

granulation circuit of fertilizer production. Different knowledge sources, such as physical phenomena,

statistical analysis of process parameters, expert information cover different cognition domains of the

process. The mechanistic growth model developed is based on particle coating phenomena, mass and energy

transfer. The model partially takes into account the main process parameters, features and the equipment

used. Simulation has been executed to test the model performance. The model built can be used for the

evaluation of plant control methods and staff training.

1 INTRODUCTION

Drum granulation is a commonly used process in a

commercial fertilizer production. Many continuous

granulation plants operate well below design

capacity, suffering from high recycle rates and even

periodic instabilities (Wang and Cameron, 2002).

The main reasons are related to raw material

properties, process equipment and control problems.

The process control still depends on the

experience and skills of process operators, namely

experts. Diagnostic systems show potential to apply

systems engineering approaches to complex

operational problems such that operators are well

informed, are able to quickly diagnose abnormal

conditions, test quickly possible solutions via detailed

simulations and then proceed to apply corrective

actions (Salmon et al., 2007). However, a number of

interacting process variables (some of them are

stochastic in nature) lead to a complex dynamic

system that might be hard to predict and optimize

just by intuition, especially for unskilled operators.

Fortunately, it is possible to use granulation process

simulations provided by PC for the investigation of

such complex problems.

The aim of this paper is to propose the process

simulator based on an extended modeling approach

for continuous drum granulation-drying processes,

focused on simulation and control. This approach

involves the dynamic process model built from

heterogeneous knowledge sources such as physical

principles, empirical (measured) data and expert

information.

The mechanistic part incorporates the

understanding of physics and underlying

mechanisms (e.g. mass and energy balances, growth

kinetics).

The empirical part uses raw and/or filtered

process sensors’ data, their storage, retrieval and

parameter identification techniques in addition to the

mechanistic (white box) model.

The expert component involves the process

experts’ recommendations, which are of great value

due to the lack of other knowledge mentioned above.

2 MAIN PROCESS DETAILS

Drum granulation is a particle size enlargement

process often obtained by spraying a liquid binder or

slurry onto fine particles as they are agitated in a

rotary drum (Wang and Cameron, 2002). The

particle circulation is achieved mechanically (by the

action of the rotating drum and lifters). Granules are

cycled many times through the spray zone and the

liquid layer attached is pre-dried before the particle

returns to the spray zone again (Figure 1).

98

Valiulis G. and Simutis R. (2009).

MODELING OF CONTINUOUS FERTILIZER GRANULATION-DRYING CIRCUIT FOR COMPUTER SIMULATION AND CONTROL PURPOSES.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Signal Processing, Systems Modeling and

Control, pages 98-103

DOI: 10.5220/0002206300980103

Copyright

c

SciTePress

Figure 1: View of the coating phenomenon.

The desired mode of granule growth is layering

(coating), resulting in very tight granule size

distributions.

A commercial continuous granulation circuit for

granulated diammonium phosphate fertilizer

(formed by the reaction of phosphoric acid and

ammonia) production consists of the following

major parts: a pipe reactor, spray nozzle system,

drum granulator-dryer, granule classifier (screens),

crusher and nuclei feed system (Figure 2).

Drum Granulator - Drier

Pipe reactor

Natural gas

Air

Furnace

External

Nuclei feed

Screens

Crusher

motor

Slurry

Product Size

Recycle feed

Undersize

Oversize

Exhaust gas

Internal

Nuclei feed

Neutralizer (H

3

PO

4

)

Gaseous NH

3

Liquid NH

3

Figure 2: Typical drum granulation-drying circuit utilized

in the diammonium phosphate (DAP) production industry.

A granulation drum is made of an inclined

cylinder with simultaneous drying (there is no

separate drying device). Drying is performed by the

heat of burned natural gas and/or reaction heat of

phosphoric acid and ammonia. Liquid DAP feed

(slurry) is sprayed onto the tumbling bed of seeds

via spraying nozzles. The drum is tilted lengthwise a

few degrees to provide the flow of granules through

the drum length. The backward screw sends a part of

granules (internal nuclei) back to the spraying zone.

Granules from the granulator-drier are transmitted to

the classifier and split into three fractions: undersize,

oversize, and marketable product size. The oversize

fraction is crushed and sent back to the granulator

together with undersize granules.

Fortunately, nowadays some important granule

size distribution variables can be measured on-line

using advanced particle size analysis systems.

Detailed and more accurate information provides the

producers of granulated materials with more data to

improve product quality and to control production

processes. Size Guide Number (SGN), related to the

median of granule population, and Uniformity Index

(UI), which shows the dispersion of population, can

be evaluated. A part of important granule size

distribution intervals can be also provided.

However, some process variables connected with

material and equipment properties can not be

evaluated and controlled directly. In such a situation

the process model can provide information about

important process states, such as recycle size flow

rate and distribution, drum system jamming factor,

granule moisture content, size evolution of single

granule inside the granulator-dryer. This information

can help to predict future process states and prevent

abnormal situations, which can initiate process

stoppage and loss of productivity.

3 MODELING

The model presented here is essentially based on

fundamental conservation principles, with partial

consideration of equipment properties and the

stochastic nature of the process. For modeling

purposes, it is necessary to divide the granulation

circuit into several balance areas with the central

component of the model – the drum granulator-drier.

There are two main processes inside the granulator-

drier: the growth of particles and moisture

evaporation (drying).

Basic modeling assumptions are:

• granule shape is spherical;

• each granule in the granulation circuit is

analyzed;

• stochastic nature of the process is estimated;

• preferred growth is by layering;

• granule agglomeration is an unacceptable mode

of operation;

• growth rate is a function of initial granule size,

slurry flow rate, temperature inside the

granulator, granule position in the drum, number

of particles in the granule bed;

• mechanical attrition of granules inside the

granulator-drier is defined by attrition function;

• presumable nucleation (formation of new seeds)

occurs during slurry spraying;

• external classification of granules into three

fractions (undersize, marketable and oversize) is

defined by classification function;

MODELING OF CONTINUOUS FERTILIZER GRANULATION-DRYING CIRCUIT FOR COMPUTER

SIMULATION AND CONTROL PURPOSES

99

• external crushing of oversize granules is

characterized by grinding function;

• residence and transportation delays in the plant

are considered;

• internal and external seeds serve as nuclei for new

granules.

3.1 White Box Modeling

There are two basic granule growth mechanisms that

act independently or in combination (Findlay et al.,

2005). A successive layering of binding material on

an initial nucleus is termed layering, coating or

‘‘onion-skin’’ growth mechanism. Another

mechanism is an agglomeration or coalescence

process that occurs upon particle collision. Whereas

growth by agglomeration mostly occurs when a

binder is added, layered growth is the result of

particle coating by the feed material, followed by

solidification of the material on the particle surface

(

Degreve et al., 2006).

The granulation regime depends on some factors

such as slurry viscosity and purity, N:P mole ratio,

granule curtain density, temperature of slurry and

seed to be coated, granule density, air temperature

inside the granulator-dryer, etc. Some of these

parameters can be observed and controlled, some of

them are not.

The design and control scheme of the drum

granulator-dryer normally force layered growth or

coating and block coalescence or agglomeration.

Sometimes the formation of undesirable

agglomerates indicates a shift of granulation regime

from layering to coalescence, which is not a normal

case of operation and must be avoided.

Granule growth by spraying the slurry onto the

previously formed seed is shown in Figure 3.

Initial seed dispersed slurry granule with added layer

Figure 3: Granule growth by layering.

To model the layering phenomenon, the

thickness of a new layer applied is determined by the

diameter of the initial particle and the volume of the

slurry applied. Assuming a spherical primary

particle and a uniform distribution of all sprayed

slurry applied onto the particle, the volume of the

added layer V

l

is calculated from the difference in

the volumes of the layered particle and the initial

one:

The thickness of the applied layer:

23

3

00

11

(6)

22

l

adVd

ππ

π

=+−

(1)

here d

0

– initial width of granule (seed), a – thickness of

the applied layer.

The explicit mass and energy balance model with

its wide and quite complex mathematical and

physical features is beyond the scope of this paper.

Hence, the following is the simplified version of the

model developed.

The overall mass balance inside the granulator in

liquid phase:

,,

L

L

in L out e c

dM

F

FFm

dt

=

−−−

(2)

here M

L

– accumulated mass of liquid solution, F

L,in

– flow

of liquid solution into the granulator, F

L,out

– flow of liquid

solution out of the granulator, F

e

– flow of evaporated

liquid solution, m

c

– mass of crystallized solution (solid

material).

The overall mass balance inside the granulator in

solid phase:

,,

S

S in S out c g att

dM

F

Fmmm

dt

=− ++−

(3)

here M

S

– accumulated mass of solid material, F

S,in

– flow

of solids into the granulator, F

S,out

– flow of solids out of

the granulator, m

g

– mass due to growth, m

att

– mass due to

attrition.

The overall energy balance inside the granulator:

in f r e l out

dE

EEEEEE

dt

=++−−−

(4)

here E – overall energy, E

in

– energy provided into the

granulator, E

out

– energy removed from the granulator, E

f

–

energy due to gas furnace action, E

r

– energy of reaction

heat, E

e

– energy for moisture evaporation, E

l

– loss of

energy from the granulator to environment.

The model presented is placed in stochastic

background, which can better suit the growth

kinetics, heat and mass transfer phenomena that

actually happen in the real plant, with addition of

uncertainty and plant equipment properties.

This section has presented only a part of the

general model, which is in nature a grey box.

Complementary models from measured process data

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

100

have been also built and expert information used to

enrich the model presented.

3.2 Statistical Analysis for Modeling

Nowadays it is possible to measure, store and retrieve

process sensors’ data and afterwards perform

statistical analysis to “mine” some knowledge. For

this purpose, descriptive and inferential statistics need

to be used.

Taking different combinations of data sets of the

essential process variables, the following results have

been obtained:

(1) Scatter plots of the parameters.

(2) Reduced linear correlation matrix with

entries of defined correlation degree (used for fast

determination of parameter combinations which have

a strong linear correlation).

(3) Linear models of the first order polynomial

(application of stepwise regression, which is a

technique for choosing variables, i.e. terms, to include

in a multiple regression model).

(4) Residuals, confidence intervals of

parameters, t-statistic, p-value, R

2

calculated for the

generated linear models.

(5) Plots of cross-correlation function for

probable lead/lag determination.

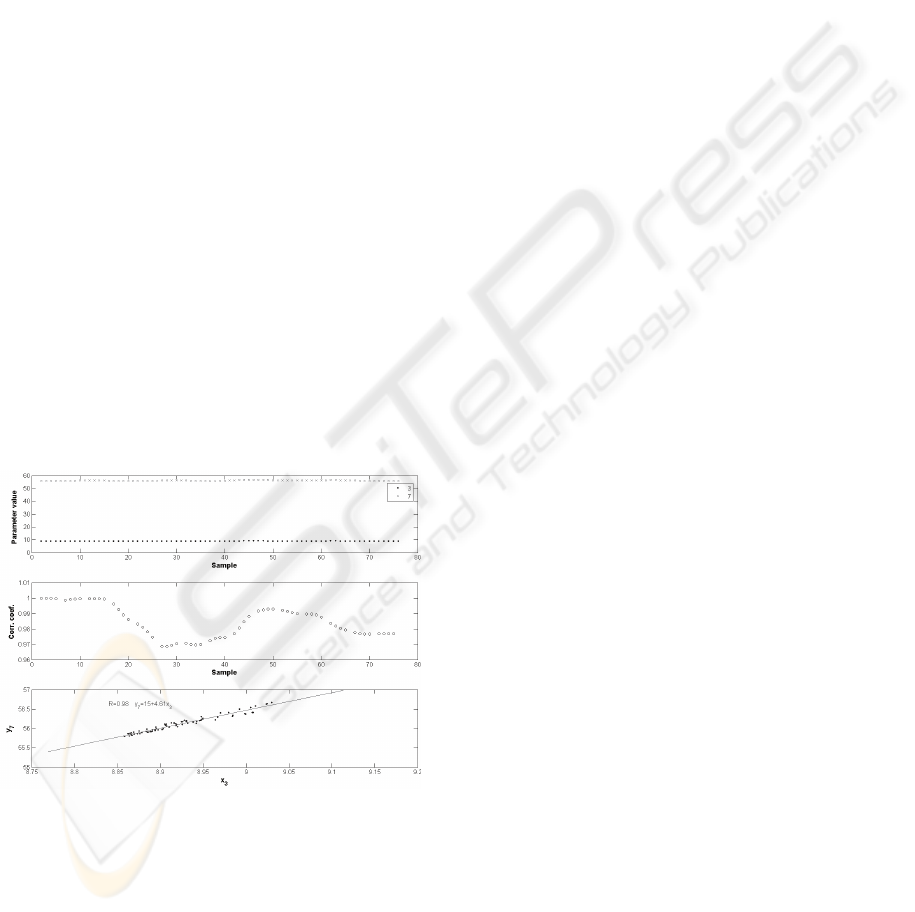

Figure 4 presents the fragment correlation and

regression analysis of two process parameters (

3 and

7).

Figure 4: Results of the regression analysis of process

parameters.

These findings are significant for determination

of process parameters and their relationship. They

can also provide additional knowledge for the plant

diagnostics. A more detailed statistical analysis of

granulation process can be found in (Valiulis and

Simutis, 2007).

Mere statistical analysis is rarely helpful. Some

heuristic knowledge should be also applied to make it

work.

3.3 Knowledge-based Modeling

Complex multiscale process systems which are

difficult to model properly (such as granulation)

require a combination of various analytical and

heuristic techniques. Effective solutions are often

based on information from heterogeneous

knowledge sources. One of them is knowledge-

based systems built on the methods and techniques

of Artificial Intelligence.

The expert knowledge of the process is an

invaluable source of knowledge, especially, when

there is a lack of reliable physical description and

suitable measurement equipment. Rule-based expert

systems use “if…then…” rules to represent human

expert knowledge, which is often a mix of

theoretical knowledge, heuristics derived from

experience, and special-purpose rules for dealing

with abnormal situations (Shang, 2004).

An example of the “if…then…” rule of new seed

formation inside the drum granulator-dryer is

presented as follows:

If

granule curtain in the spray zone is poor and

gas temperature in the spray zone is high, then new

small nuclei formation rate is high.

In the proposed modeling approach, the expert

knowledge is represented by the rule set. The rules

involve variables such as “poor”, “high”, dealing

with fuzziness, which is very common in real world

problems. Unlike conventional expert systems,

which are mainly symbolic reasoning engines, fuzzy

expert systems are oriented toward numerical

processing (Hemmer, 2008). These principles can be

applied for the future development of the granulation

process model and simulator for automated guidance

and diagnostic purposes.

4 SIMULATOR

Increasing capabilities of computer hardware and

software ensure the incorporation of complex

knowledge (models) represented by differential and

algebraic equations, measured process data, process

experts’ information, etc. But to be of use for the

day-to-day work of the engineer these models have

to become more user friendly, than the one that the

scientist is dealing with (Ihlow et al., 2004). A new

“GrowSim” simulation package for granulation

process modeling and simulation is under

MODELING OF CONTINUOUS FERTILIZER GRANULATION-DRYING CIRCUIT FOR COMPUTER

SIMULATION AND CONTROL PURPOSES

101

Figure 5: Graphical user interface of “GrowSim” simulator.

development to realize this concept. The simulator is

intended to be used by novice process operators to

improve their skills in process control and to acquire

knowledge of underlying mechanisms. The

graphical user interface (Figure 5) has been built to

mimic the process control environment available to

the process operator in the real plant, with important

additional information provided.

The simulation environment is composed of

sections where the operator can change the

manipulative process parameters, observe the

current or past output parameters, get some advice

on how the process in the current state should be

controlled by the skilled operator. The manual or

automatic process control modes are available. The

operator can take a challenge to manage the process

by hand or leave all or part of the job to PID or

Fuzzy controller. The simulation time is much

shorter compared to the real process and can be

easily adjusted if the computing resources are

sufficient. It is important to note that simulation can

be paused at any moment, to make it possible to

weigh one’s decisions. The main process parameters

are stored and can be observed during the simulation

or even later. The simulator is provided with routine

to compare the simulated and real measured process

data.

5 VALIDATION EXAMPLES

Some experiments have been carried out to validate

model performance against measured plant data in

prediction of the granule size distribution.

Experimental data have been obtained using particle

image analysis system.

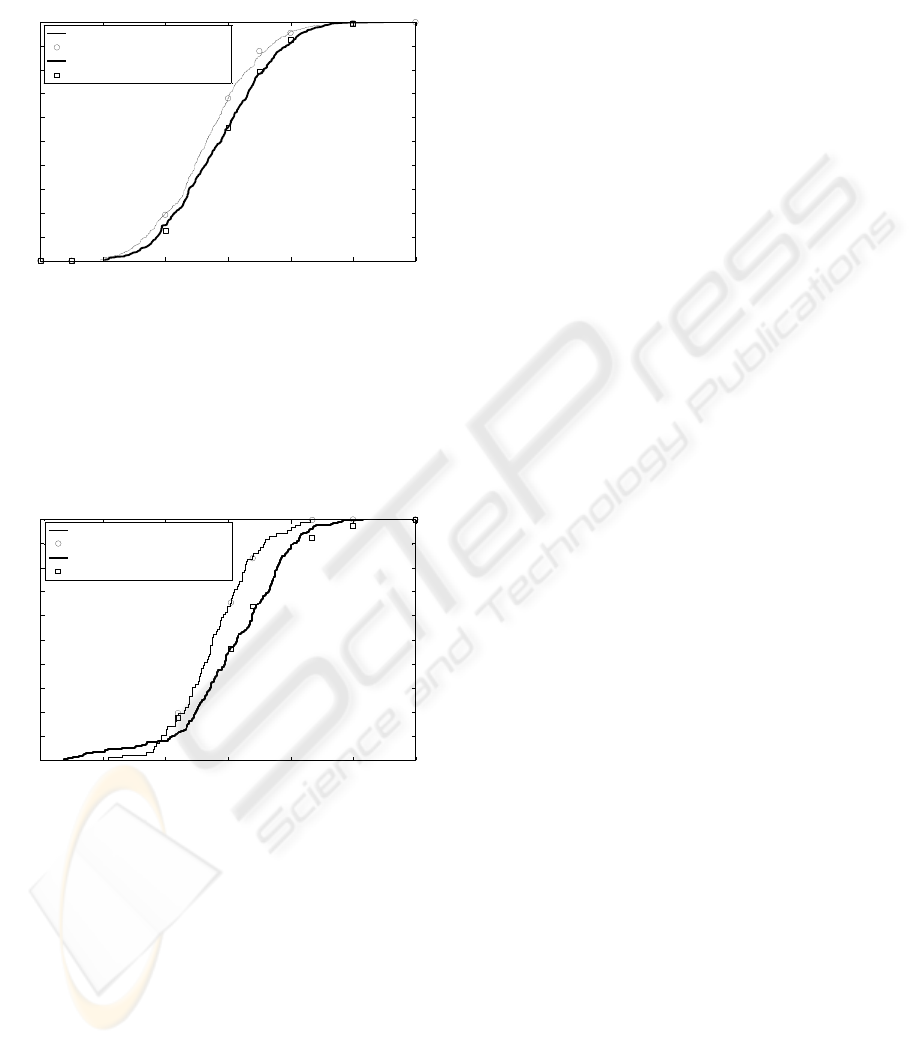

Figure 6 presents the impact of slurry feed rate

on the cumulative granule size distribution.

In

phase A the process is kept in some steady

state, with the median granule size nearly 2.65 mm.

In

case B the slurry feed rate is increased

approximately by 35 %. In this situation the granule

median size is nearly 2.9 mm. Change in the slurry

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

102

flow rate alters the granule growth rate. Increase in

the slurry flow rate raises the granule growth rate

and a shift of cumulative granule size distribution to

the right is observed.

0 1 2 3 4 5 6

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Cumulative Size Distributions

Granule Diameter, mm

F(x)

Model Prediction (Slurry flow A)

Measured (Slurry flow A)

Model Prediction (Slurry flow B)

Measured (Slurry flow B)

Figure 6: Impact of the change of the slurry flow rate on

the cumulative granule size distribution.

Figure 7 presents the measured and simulated

cumulative granule size distributions of initial seeds

fed to the granulator (mean size is about 2.75 mm)

and granules flowing out of the granulator (mean

size is about 3.15 mm) in steady state.

0 1 2 3 4 5 6

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Cumulative Size Distributions

Granule Diameter, mm

F(x)

Model Prediction (initial seeds)

Measured (initial seeds)

Model Prediction (granules out)

Measured (granules out)

Figure 7: Cumulative size distributions of initial seed flow

and granule flow out of the granulator.

6 CONCLUSIONS

An industrial DAP fertilizer granulation circuit,

including drum, sieves, crusher, transportation

system, has been modeled using basic physical

principles such as growth kinetics, mass and heat

transfer. Statistical analysis and system

identification procedures have been performed for

the estimation of unknown model parameters. As an

extension to the model, additional information has

been extracted from the process experts to define

unmeasured parameters and assess some equipment

properties. The whole model has been implemented

and simulation executed using “GrowSim” simulator

in the MATLAB environment.

Some model validation procedures have been

performed and the results appear to be in fair

accordance with the plant measured data. The

findings, presented in Figures 6 and 7, show some

kind of mismatch, but still can be treated

satisfactory.

The current and future research is focused on

further model development, implementation and

testing of different plant control modes such as PID,

Fuzzy and model predictive control. The primary

results demonstrate the need of combination of the

aforementioned control methods for a robust process

control.

REFERENCES

Degreve J., Baeyens J., Van de Velden M., De Laet S.

(2006). Spray-agglomeration of NPK-fertilizer in a

rotating drum granulator. Powder Technology, vol.

163, p. 176-183.

Findlay W.P., Peck G.R., Morris K.R. (2005).

Determination of Fluidized Bed Granulation End Point

Using Near-Infrared Spectroscopy and

Phenomenological Analysis. Journal of

Pharmaceutical Sciences, vol. 94, p. 604-612.

Hemmer M.C (2008). Expert Systems in Chemistry

Research. CRC Press.

Ihlow M., Drechsler J., Peglow M., Henneberg M.,

Mörl L. (2004). A New Comprehensive Model and

Simulation Package for Fluidized Bed Spray

Granulation Processes. Chemical Engineering and

Technology, vol. 27, p. 1139-1143.

Salmon A.D., Hounslow M.J., Seville J.P.K. (2007).

Handbook of Powder Technology, vol. 11.

Granulation. Elsevier.

Shang Yi (2004). Expert Systems. The Electrical

Engineering Handbook (Section 5). Elsevier Academic

Press, p. 367-377.

Valiulis G., Simutis R. (2007). Application of Regression

Analysis for Modelling of Granule Size Distribution.

Proceedings of International Conference “Electrical

and Control Technologies – 2007”, p. 62-67.

Wang F.Y, Cameron I.T., (2002). Review and future

directions in the modelling and control of continuous

drum granulation. Powder Technology, vol. 124, p.

238-253.

MODELING OF CONTINUOUS FERTILIZER GRANULATION-DRYING CIRCUIT FOR COMPUTER

SIMULATION AND CONTROL PURPOSES

103