MODEL-DRIVEN DEVELOPMENT IN INDUSTRIAL

AUTOMATION

Automating the Development of Industrial Automation Systems using

Model Transformations

Mathias Maurmaier and Peter Göhner

Institute of Industrial Automation and Software Engineering, Universität Stuttgart

Pfaffenwaldring 47, 70550 Stuttgart, Germany

Keywords: Model-driven Development, MDE, Model Transformation, Domain-specific Modeling Language, Industrial

Automation Systems.

Abstract: The complexity of modern automation systems is growing steadily. In software engineering, model-driven

development proved that it contributes significantly to cope with this complexity in development, while

increasing efficiency and the quality of the development results. However, hardware-software dependencies,

different types of requirements that must be considered in development and the large number of modeling

languages are specific challenges for a model-driven approach in automation technology. In this paper a

concept of model-driven system development is presented that takes into account these challenges, and thus

provides the possibility to leverage model-driven development in industrial automation technology.

1 INTRODUCTION

Because of the integration of new functions and

technologies necessary to fulfill customer require-

ments, environmental regulations or safety stan-

dards, the complexity of automation systems

increases steadily (Ramebäck, 2003). Therefore,

adequate development methods are needed pro-

viding the means to increase efficiency in develop-

ment and to increase the quality of the development

results. In software engineering, model-driven deve-

lopment has proven that it offers mechanisms to

cope with the increasing complexity and to boost

efficiency in development (Schmidt, 2006).

In this paper we analyze, why model-driven

development is rarely used for the development of

industrial automation systems and present a concept

based on extended model transformations that

allows to benefit from the advantages of model-

driven development in industrial automation

technology. Therefore we discuss specific challen-

ges in development of industrial automation systems

in chapter 2. Starting with a theoretical consideration

of system development and the theory of model-

driven development in chapter 3, the limiting factors

regarding the application for automation systems

development are presented in chapter 4. Based on

the limitations a concept of model-driven develop-

ment for industrial automation systems is deducted.

2 CHALLENGES IN

INDUSTRIAL AUTOMATION

Industrial automation systems are complex hard-

ware-software systems, whose objective is the con-

trol and supervision of a technical process. Many

different disciplines as software engineering,

hardware development, or electrical engineering are

involved in the development of such systems.

Modeling is seen as an important lever for coping

with the complexity in, since any model allows to

focus on specific aspects. Therefore, for system

development, many different models are used. Since

dependencies between the various models are not

automatically managed, there is a high manual effort

for multiple entries of the same information and for

ensuring consistency of the models (Schenk and

Schlereth, 2008). Therefore, we need concepts to

manage the dependencies between the various

models used during development.

244

Maurmaier M. and Göhner P. (2009).

MODEL-DRIVEN DEVELOPMENT IN INDUSTRIAL AUTOMATION - Automating the Development of Industrial Automation Systems using Model

Transformations.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 244-249

DOI: 10.5220/0002209502440249

Copyright

c

SciTePress

In contrast to software engineering, there is no

established, universal modeling language such as the

UML in industrial automation technology. This is

due to the various disciplines involved in develop-

ment, using specific modeling languages tailored to

their needs. Thus, the development method must be

open to the use of different modeling languages.

The hardware of an industrial automation system

consisting of sensors, actuators and processing units,

and the software are highly integrated, leading to a

large number of dependencies in development. In

order to increase efficiency and the quality of the

developed industrial automation systems, reusable

partial solutions should be used whenever possible.

These partial solutions consist both of hardware

parts and a specification or implementation of the

related software parts. Hence, the development

method for industrial automation systems must pro-

vide reusable partial solutions and has to offer con-

cepts to manage hardware-software dependencies.

In the development of an industrial automation

system different types of requirements must be

fulfilled. First of all, the technical process needs to

be controlled and monitored. Further specific re-

quirements for the automation system arise from the

realization of the technical system, from existing

legacy systems as well as from legal and economic

constraints. These requirements can demand a

specific property of the overall automation system as

for example reduced energy consumption or a

property of an individual subsystem, e.g. the manu-

facturer of a specific subsystem or a specific bus-

system to be used. These requirements vary between

different automation systems that realize the same

technical process. Any development method in

industrial automation technology must support these

different kinds of requirements.

3 SYSTEMS DEVELOPMENT

3.1 Basic Definitions

According to Smith and Browne (1993) develop-

ment is the creation of a system or artifact to solve a

given problem. Therefore representations of the real

world are used. In the representation of the problem

R(P) the problem is described using the vocabulary,

concepts and metrics of the problem space. Starting

from this representation the representation of the

solution R(L) is developed in several development

steps. Based on the representation of the solution

R(L), the system can be produced. There may be

representations of different formalization degrees. A

textual requirements specification, for example, is an

informal representation of the problem to be solved;

the source code of the automation software is a

formal representation of the solution.

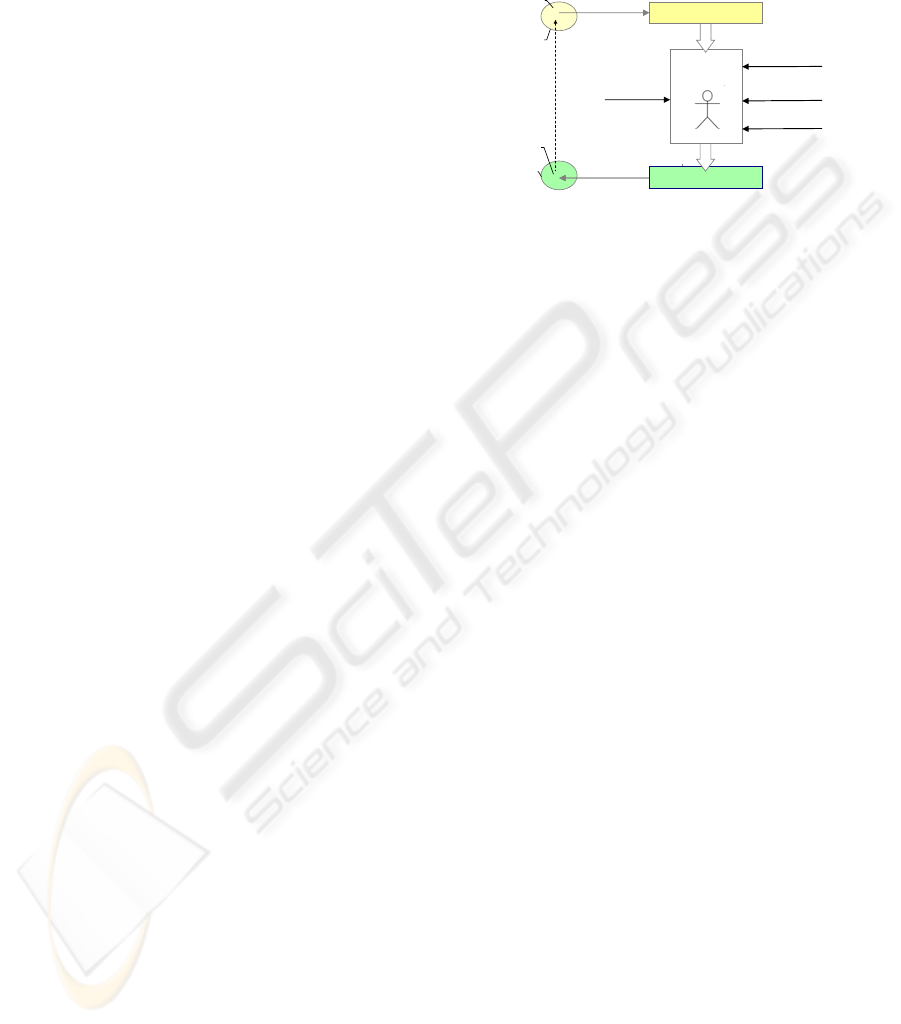

implementation

representation R(L)

x

solution L

solution

space

x

problem P

problem

space

production

developers‘

know-how

technology

required

system properties

design

decisions

partial

solutions

representation R(P)

documentation

Figure 1: Systems development.

The system to be developed consists of a set of

individual elements, which are related to each other

and interact in a way, that they fulfill a common goal

(Sommerville, 2007). The elements can be atomic or

subsystems, i.e. in this case they are systems as well.

The system properties comprise both the properties

of the individual elements, e.g. the manufacturer of

the element or subsystem, and the properties that

arise from the interplay of the elements as for

example energy consumption or reliability. The

latter are known as global system properties.

Considering the requirements to be fulfilled by a

system, they can focus on different aspects: First of

all, there are requirements describing the problem to

be solved by the system. Other requirements focus

on the global properties, the system must prove.

Examples for this class are requirements concerning

energy consumption. A third class of requirements

prescribes properties of individual elements. These

latter two classes of requirements restrict the number

of possible solutions of the problem.

During development, a multitude of design

decisions have to be made, which affect the solution.

These decisions are made by the engineer combining

his own knowledge and expertise with the required

system properties, available technologies and

reusable partial solutions. In decision-making the

engineer has to consider all interdependencies

between the technologies and partial solutions. If

there is a modification in the problem to be solved,

in required system properties or in the partial

solutions, all decisions must be checked manually

for correctness under the new circumstances.

The aim of model-driven development is to auto-

matically generate the representation of the solution

R(L) from the representation of the problem R(P).

Therefore the basics of model-driven development

are described in the following section.

MODEL-DRIVEN DEVELOPMENT IN INDUSTRIAL AUTOMATION - Automating the Development of Industrial

Automation Systems using Model Transformations

245

3.2 Model-driven Development

In model-driven development, the course of the

development from problem analyses to design and

implementation is defined by models (OMG, 2003),

whereas a model is a formalized representation of

some aspects of the problem to be solved or the

system to be developed. The formalized represen-

tation of the problem is called conceptual model

M(P). This model has a high level of abstraction. As

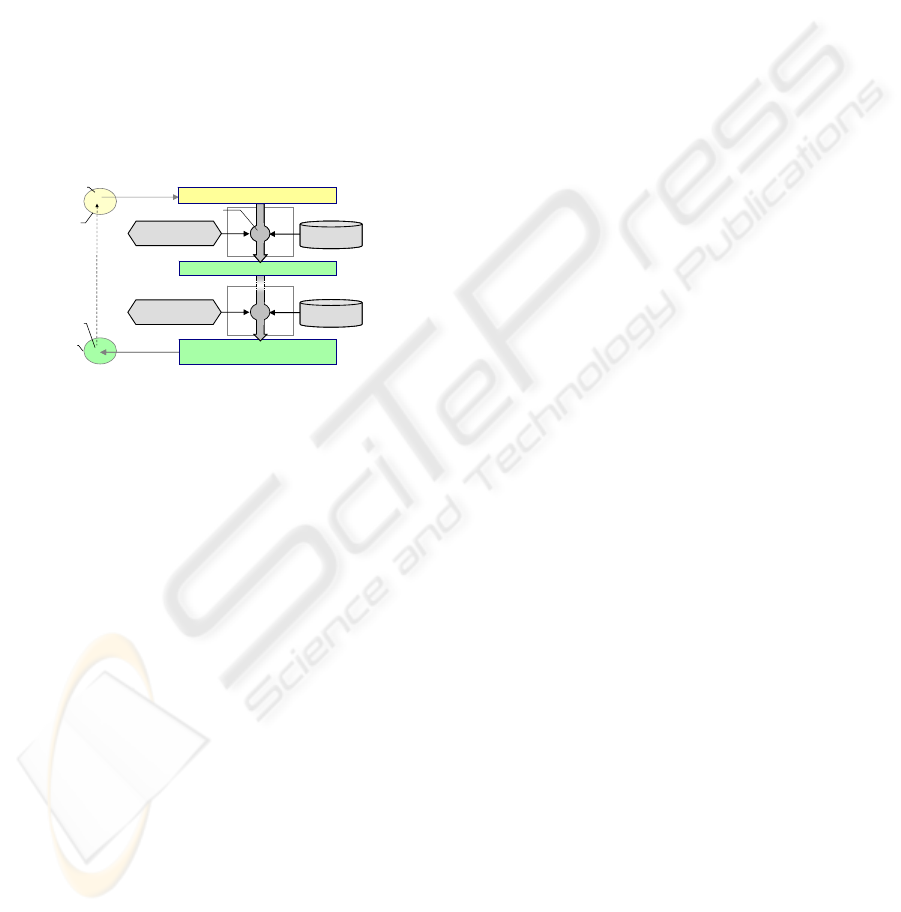

shown in figure 2, transformations are used for the

automated generation of the model of the solution

M(L) out of the conceptual model M(P). A trans-

formation is the conversion of a source model into a

target model based on a formalized specification. As

prerequisite for an automated transformation, all

factors affecting the solution must be formalized.

production

x

x

problem P

problem

space

transformation

rules 1

platform 1platform 1

platform nplatform n

model of solution M(L) =

target model of transformation n

target model of transformation 1

transformation

transformation

rules n

conceptual model M(P)

solution L

solution

space

modeling

implementation

Figure 2: Model-driven systems development.

To implement a transformation, a platform and

transformation rules are needed. The platform con-

tains all available reusable partial solutions of one

dedicated level of abstraction, whose interfaces and

properties are described in a formalized way.

The platforms used in the various transforma-

tions determine much of the system properties. In

reverse requirements concerning system properties

such as high reliability or the operating system to be

used determine the platforms to be chosen for the

development of the system.

Transformation rules formalize the part of the

developer’s knowledge needed for the selection,

linkage and configuration of the partial solutions of

the platform, which are needed to implement the

problems that can be modeled in the source model.

When executing a transformation, the transformation

rules link the problem modeled in the source model

with the partial solutions of the platform.

Since the transformation rules link the model

elements of the source model with the partial solu-

tions of the platform, they depend on the modeling

language of the source model and the description of

the partial solutions. This is why standards for the

specification of transformation rules such as QVT

(OMG, 2008) define the structure of the rules using

metamodels. These standards are very generic and

require high efforts to define the necessary trans-

formation rules when introducing model-driven

development in a specific domain. Hence, currently

transformations are usually realized for specific

modeling languages and platforms within integrated

development environments. Since in software engi-

neering there are standard modeling languages as for

example the UML or signal flow diagrams, model-

driven development techniques are applied especial-

ly in application domains in software engineering

that traditionally use these modeling languages.

The identification of the necessary transforma-

tions and the modeling languages used within a

domain as well as the development of platforms and

transformation rules takes place in a preceding,

project-independent development phase, called

infrastructure development. In this phase, domain

engineering activities are executed in order to

develop the artifacts, which will be reused within

various projects later in the system development

phase. In the system development phase, the

platforms and transformation rules are reused.

In model-driven development dependencies

between different views and partial solutions are

used to define transformations allowing an

automated generation of more detailed models, or

source code from other usually more abstract

models. In the following chapter, we discuss the

limitations of the current transformation concepts

regarding the application for the development of

industrial automation systems and propose concepts

allowing to leverage the advantages of model-driven

development in industrial automation technology.

4 MODEL-DRIVEN

DEVELOPMENT OF

AUTOMATION SYSTEMS

4.1 Model-driven Development and

Challenges of Industrial

Automation Technology

In model-driven development platforms are used to

manage reusable partial solutions, which are

described in a formalized way and stored in a clear

structure within the platforms. Partial solutions

consisting of hardware-software parts, as needed in

automation technology, are not supported by

existing model-driven approaches. Therefore, an

extension of the classical model-driven development

approach is needed to support partial solutions with

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

246

hardware and software parts and to be able to

manage hardware-software dependencies.

In classical model-driven development, the

solution is built based on the conceptual model M(P)

and the selected platforms. Platforms and trans-

formation rules are not adaptable in system develop-

ment. Hence, besides the conceptual model M(P)

and the selection of the platforms, there are no

further possibilities to influence the solution in the

system development phase. Requirements con-

cerning system properties can only be fulfilled, if

there is a platform, which has exactly the required

properties. As in automation technology there are a

lot of requirements focusing on system properties,

we would need an enormous number of platforms

for any combination of required system properties.

As this is not feasible in practice, we propose an

extension of the classical model-driven development

approach allowing to specify required system

properties and thus to influence the solution.

Existing implementations of transformations

cannot be used in automation technology due to the

variety of modeling languages and the close hard-

ware-software dependencies. To reduce the efforts in

infrastructure development and to make the concept

applicable to engineers, the generic concepts for the

definition of transformation rules must be

concretized. Standards as AutomationML (Drath et

al., 2008) define metamodels for the description of

automation technical solutions. As engineers are

getting familiar with these standards, the description

of the platform elements is based on these standards.

The integration of these approaches into a

concept for hardware-software integration is

described in the following paragraph in more detail.

4.2 Platforms for Hardware-Software

Integration

In industrial automation technology, reusable partial

solutions are composed of hardware and software

parts. On the level of models, this means that the use

of a partial solution has an impact both on hardware

models (e. g. circuit diagram) and on software

models such as source code. One partial solution has

representations in several models. In order to

integrate the representations belonging to one partial

solution the concept of platforms is extended by

views. The platform for model-driven development

in automation technology consists not only of

software components but integrates partial

automation technical solutions of one abstraction

level. An automation technical partial solution is

created by the encapsulation of the representations

of the partial solution for the hardware and the soft-

ware models and a general description. For example,

the partial solution representing a speed sensor is

composed of a representation for the circuit diagram,

for the simulation model and a software driver.

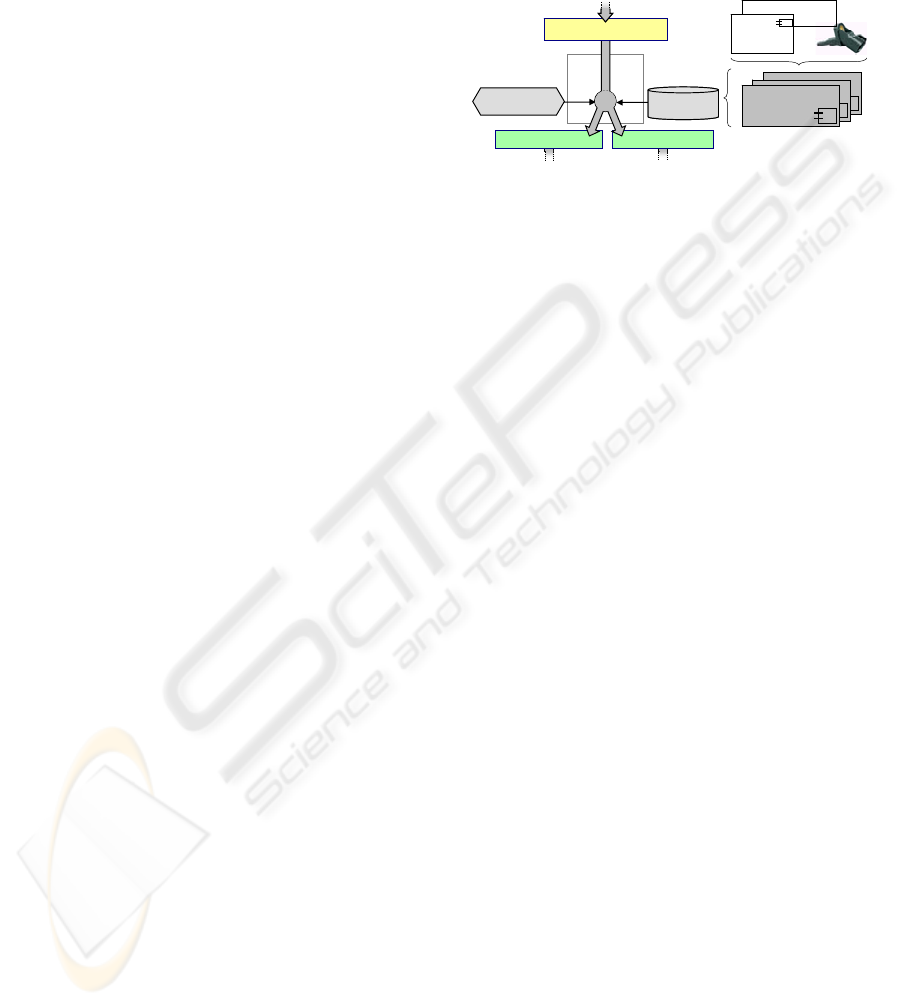

software model hardware model

source model

sensor simulation

model

sensor-

software

component

sensor-

software

component

automation-tech-

nical partial

solution

platformplatform

transformation

rules

Figure 3: Transformation generating the hardware and

software model.

All automation technical partial solutions of one

abstraction level are merged into one platform. If,

during the execution of a transformation, a partial

solution is selected by a transformation rule, the

corresponding representation of the partial solution

is instantiated in any model generated by the

transformation. Figure 3 illustrates the course of a

transformation, which generates several target

models from one source model.

4.2.1 Unified Metamodel of Automation

Technical Partial Solutions

The knowledge, which partial solution should be

selected during the execution of a transformation,

how it must be connected and configured, is

encapsulated in the transformation rules. The

selection, linkage and configuration dependent on

many parameters. The required properties of a

partial solution are extracted from the source model.

Then, the suitable partial solution is selected from

the platform. To avoid that for any combination of

required properties a new transformation rule must

be created, the properties of any partial solution are

subsumed within its formalized description. Thus

transformation rules can select partial solutions by a

set of required properties. This leads to a greatest

possible decoupling between the transformation

rules and the partial solutions allowing to add new

partial solutions to the platform without having to

modify the transformation rules. The description of

each partial solution follows the metamodel

presented in figure 4. Any partial solution disposes

of features that are either fixed (property), optional

(option) or can be configured (parameters).

The representations of a partial solution in

different types of target models are encapsulated in

the partial solution (target model representation).

MODEL-DRIVEN DEVELOPMENT IN INDUSTRIAL AUTOMATION - Automating the Development of Industrial

Automation Systems using Model Transformations

247

Each representation is assigned to a specific view

(View). A partial solution is linked with other partial

solutions using ports (Port).

Partial Solution

Name: String

Target model

representation

<<Enum>>

ViewType

General

Signal Flow

Circuit Diagram

Class Diagram

View

ViewType: ViewType

View

ViewType: ViewType

1..*

Property Option Parameter Outgoing Incoming

1..*

*

*

Feature Port

Configuration Rule

Consistency

Rule

Figure 4: Metamodel of an automation technical partial

solution within a platform.

Since dependencies between the hardware and

software parts of a partial solution are known best by

the developer of the partial solution, these can be

integrated as consistency rules. Configuration rules

adapt the representations within the different types

of target models to the actual configuration of the

partial solution. For example, if there is a parameter

allowing to adjust the value range of a sensor, the

configuration rules set the configuration values in

the source code of the driver and adjust the values of

the series resistor in the circuit diagram. When a

partial solution is selected, linked or configured

during the execution of a transformation, these rules

are evaluated. This allows automatic internal

adjustments of the partial solution to ensure

consistency between the different views.

4.2.2 Transformation Rules

One benefit of the unified metamodel of the partial

solutions within the platforms is the possibility to

define a general structure of the transformation rules

in automation technology. There are three major

types of transformation rules:

Transformation rules that encapsulate the know-

ledge to define the structure of the target model,

which allows solving the problem modeled in the

source model, are called structure-defining (SD)

rules. They extract the information from the source

model, which is relevant for the structure of the

target model, and create a possible structure of the

target model. In further steps, this structure has to be

detailed using partial solutions from the platform.

Selective (SL) transformation rules are used for

the selection of the correct partial solutions from the

platform. They encapsulate the knowledge about the

relevant properties, a partial solution needs to have

in order to be deployed in a certain position within

the structure of the target model. Selective

transformation rules define in a first step a complete

requirements specification for any position in the

structure of the target model that has to be detailed

by a partial solution. In the second step, the

requirements aggregated in the first step are used to

select the correct partial solution from the platform.

Transformation rules of the third type, called

configurational (CF) rules, ensure a consistent

configuration of the selected partial solutions within

all target models.

When a transformation is executed, the structure-

defining rules are applied first, followed by the

selective rules and in the end the configurational

rules. If a set of transformation rules produces

several possible solutions for a given source model,

there is the possibility to optimize the solution con-

cerning specific system properties.

Platforms and transformation rules are developed

in infrastructure development preceding the systems

development, where they are reused within many

systems. This allows increasing efficiency in de-

velopment and shortening the development time

within individual projects. Crucial disadvantages are

the high initial costs for the project-independent de-

velopment of transformation rules and platforms,

and the inflexibility regarding the consideration of

requirements concerning individual system pro-

perties in the transformations. A solution to this

problem is presented in the following section.

4.3 Adaptability of Transformations

In order to be able to specify the different kinds of

requirements and thus to fulfill them, the concept of

transformations of the classical model-driven

development is extended by two additional variation

points. These variation points can be used to modify

the solution. In analogy to framework theory, these

variation points are called hot spots of the

transformation. The first hot spot allows to adapt the

transformation rules to the requirements of a specific

project. This adaptation allows to model and thus to

respect required global system properties within the

transformation, i.e. properties that arise from the

interaction of the system elements. During the tool-

supported execution of the transformation different

architectural variants of the solution can be analyzed

in terms of meeting the required global system

properties. Finally, the one that meets best the

requirements is selected. For example, a reliable

temperature measurement can be realized using one

highly reliable sensor or a redundant measurement

with two or even more standard sensors. The

knowledge of the possible architectural variants and

the calculation of the reliability is formalized in the

transformation rules. Using the hot spot, these

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

248

transformation rules are configured or even

completed by new rules formalizing the know-how

on the reliability that should be reached in the

current project, on possible architectural alternatives

and on their properties. The decision, which

alternative is best suited within the specific project,

is made during the execution of the transformation.

If the properties concerning reliability of the

available sensors are known, this decision for one

architectural variant can be made automatically

depending on the required reliability.

Required properties of individual system

elements such as the supplier of a specific partial

solution can be specified using the second hot spot.

This hot spot allows to access all properties of the

partial solutions of the platform and thus to select or

exclude specific partial solutions by any property.

The project-specific adaptation of the platform at

this hot spot prepares the set of partial solutions

from the platform, which may be used in the specific

development project.

Furthermore, the concept of hot spots allows

upgrading the transformation rules or the platform

within a development project. Thus, model-driven

development can be introduced iteratively, since the

missing transformation rules and partial solutions

can be added at the corresponding hot spot.

5 CONCLUSIONS

In model-driven development the course of

development is defined by models using the

principle of abstraction to focus only on the relevant

aspects in any development steps. Transformations

are used to transform the abstract models of the

problem to more detailed models of the solution.

The mature concepts of model-driven software

development can not be applied directly for the

development of automation systems, since they miss

concepts for the high variability concerning the

requirements on specific system properties and hard-

ware-software dependencies. Furthermore, a concept

for model-driven development in industrial auto-

mation technology must be adaptable to different

modeling languages as there are no standard

languages as for example the UML.

In this paper we presented a concept for model-

driven development of industrial automation

systems. Central aspects of this concept are

platforms built on automation technical partial

solutions, hot spots in the transformations and a

metamodel based definition of automation technical

partial solutions. The platforms allow reusing partial

solutions consisting of hardware and software parts.

Hardware-software dependencies are modeled by the

developer of the partial solution and are taken into

account when using a partial solution within a

transformation. Hot spots enable the developer to

adapt the transformation in order to fulfill

requirements concerning specific system properties.

The metamodel-based definition of the partial

solutions allows to reuse transformation rules and to

adapt them to different modeling languages.

The presented concept allows applying model-

driven development to the development of industrial

automation systems and leads to a better controlla-

bility of the complexity, increases efficiency and

shortens the development time within individual

industrial automation projects.

REFERENCES

Drath, R., Peschke, J., Lips, S. (2008). AutomationML

Top-level Architecture Document. AutomationML

consortium, Stuttgart.

International Organization for Standardization (1997).

Flow diagrams for process plants -- General rules.

ISO 10628:1997, Geneva: ISO.

Maurmaier, M. (2007). Model-driven system development

in product automation. In VDI-Bericht Nr. 1980 mit

CD 'GMA-Kongress 2007 Automation im gesamten

Lebenszyklus' ISBN 978-3-18-091980-5. VDI-Verlag,

Düsseldorf.

Maurmaier, M. (2008). Leveraging Model-driven

Development for Automation Systems Development.

In Proceedings of IEEE Conference on emerging

technologies and factory automation. Hamburg.

Object Management Group (2003). MDA Guide Version

1.0.1.

Object Management Group (2008). Meta Object Facility

(MOF) 2.0 Query/View/Transformation, Version 1.0.

Ramebäck, C. (2003). Process automation systems-history

and future. In Proceedings of IEEE Conference on

emerging technologies and factory automation.

Lisbon.

Schenk, B., Schlereth, M. (2008). Model Driven

Development applied to Automation Engineering. In

VDI-Bericht Nr. 2032 mit CD 'AUTOMATION 2008 -

Lösungen für die Zukunft' ISBN 978-3-18-092032-0.

VDI-Verlag, Düsseldorf.

Schmidt, D. (2006). Model-Driven Engineering. In: IEEE

Computer 39 (2), 25–31.

Smith, G., Brown, G. (1993). Conceptual Foundations of

Design Problem Solving. In IEEE Transactions on

Systems, Man, and Cybernetics; 23 (5), 1209-1219.

Sommerville, I (2007). Software Engineering. 8

th

ed.,

Pearson Education Limited, Harlow.

MODEL-DRIVEN DEVELOPMENT IN INDUSTRIAL AUTOMATION - Automating the Development of Industrial

Automation Systems using Model Transformations

249