APPLYING A SOFTWARE FRAMEWORK FOR SUPERVISORY

CONTROL OF A PLC-BASED DISCRETE EVENT SYSTEM

B. Curto, V. Moreno

Department of Informática y Automática, Salamanca University, Plaza de los Caídos, Salamanca, Spain

C. Fernández-Caramés, R. Alves, A. Chehayeb

Department of Informática y Automática, Salamanca University, Plaza de los Caídos, Salamanca, Spain

Keywords: Supervisory Control, Automated Manufacturing Systems, Software Framework, Discrete Event System.

Abstract: In this paper we propose a software framework where the main aim is to make easier the implementation of

supervisory control. The main idea is that functionalities must be offered with no effects on the robustness

of the system. We prove that our methodology has a solid base, so the approach can be applied to any kind

of industrial process unit. In this way, a real application of a developed framework is presented. The

implementation is done over well-known devices (such as PLC with a conveyor belt) so the technical

feasibility of the procedure is guaranteed.

1 INTRODUCTION

Due to the market evolution, manufacturing industry

suffers some pressures in order to reduce product

prices, to increase the model complexity and to

support a model proliferation (Beck, 2000). To

achieve these goals, it is necessary to accomplish

shorter production cycles and lower manufacturing

costs. More flexible and intelligent workcells are

needed in order to find a competitive manufacturing

process. Thus, as a part of a Computer Integrated

Manufacturing (CIM) goal, Flexible Manufacturing

Systems (FMS) offer the best promise of reducing

costs and increasing flexibility.

Current robotic workcell systems can generally

be classified as large, monolithic and centralized

systems. The main reason comes from the fact that,

in a typical industrial workcell, a Programmable

Logic Controller (PLC) acts as an operation

sequence controller of the cell. Several problems

arise with these systems: limited functionality and

flexibility, low levels of intelligence, and so on. As a

solution we will propose the use of a distributed

architecture design.

In (Curto, 2001), a proposal of a software

architecture is realized where the development of

distributed systems is taken into account. In a natural

way, the development of a framework is the next

step where some wrong situations appear when the

provided services at the system becomes blocked

due to an erroneous sequence of service invocations.

Thus, it is necessary to achieve that these blocked

situations will be avoided.

We propose the use of the Supervisory Control

Theory (SCT) (Ramadge, 1987) that is proposed

initially by P. J. Ramadge and W. M. Wonham in

the late 80s. This theory has received a special

attention from the academic environment in such a

way it has reached a great evolution. Nevertheless,

actually just a few applications at industrial

environment can be found that applies the SCT due

to mainly a complete model of the system (with a

sound mathematical load) and a corresponding

implementation is needed.

Although some works exist where the real

implementation of controller is obtained using the

SCT, they are not too much. Some of the most

representative are (Chandra, 2000) and (Mušić,

2002). The first one describes the way to design a

control system for assembling line whereas the

second one is focused on the implementation of a

concrete task on a PLC. In both cases, the controller

formally obtained using the SCT is restricted to

reach a particular goal at a concrete task.

This approach presents two main disadvantages.

First, if a modification of the task is made, it is

263

Curto B., Moreno V., Fernández-Caramés C., Alves R. and Chehayeb A. (2009).

APPLYING A SOFTWARE FRAMEWORK FOR SUPERVISORY CONTROL OF A PLC-BASED DISCRETE EVENT SYSTEM.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 262-267

DOI: 10.5220/0002211502620267

Copyright

c

SciTePress

necessary to perform the complete redesign and

implementation of the controller. Second, a unique

controller is not feasible when the task implies a

large set of sensors and actuators. In this situation,

the physical restrictions imposed by the

communications and a possible overload of the

controller are two questions that have to be taken

into account. Consequently, we propose to make a

separation between the particular device control and

the task to be performed at the plant.

In (Chandra, 2000), when the restriction of the

plant behaviour has to be done, two kinds of

specifications can be distinguished: security

specifications and progress specifications. The first

ones are considered to prevent that no plant section

takes undesirable actions and the second ones are

concerned to reach the finalization of the task.

Security specifications can affect to a unique plant

element or several elements.

In this work we propose to perform the controller

design for each device taking into account the

service that the component provides with no

consideration on the task that has to be done. The

key element will be the development and use of a

software framework where it will be necessary to

model and implement a set of specifications.

The rest of the paper is organized as follows: In

section 2 we review the Supervisory Control Theory.

Next, the main relevant topics of the proposed

architecture and the resulting framework will be

presented. In section 4, in order to prove the validity

of our proposal we will present a case of study

where a real industrial element will be considered.

Finally the main conclusions are presented.

2 MODELING DISCRETE EVENT

SYSTEMS

The SCT of Discrete Event Systems is based on the

use of automata and formal language models. Under

these models the main interest is on the order in

which the different events occur. In this way, a plant

(Phoha, 2004) is assumed to be the generator of

these events. The behaviour of the plant model is

described by event trajectories over the finite event

alphabet . These event trajectories can be thought

of as strings over , so represents the set of

those event strings that describe the behaviour of the

plant.

Σ

Σ

*

Σ⊆L

The SCT restricts the behaviour of a plant G by

disabling temporarily certain events that can be

created by

Σ , so the goal is that the plant cannot

create undesired or illegal event chains in L(G). In

the following, a few basic definitions will be posed.

The plant G will modelled by the deterministic

finite state automaton (DFSA)

),,,,,(

0 mGGG

XxfXG Γ

Σ

=

where,

X is the set of states;

G

Σ

is the finite set of events over

G

;

XXf

GG

→

Σ

×

:

is the state transition

function;

G

X

is the active event function;

G

Σ

→Γ 2:

Xx

∈

0

is the initial state;

XX

m

⊆

is the set of marked states, which

represent the completion of a certain task or a

set of tasks.

*

G

Σ

is used to denote the set of all finite length

strings over

G

Σ

including the empty string

ε

.

can be extended from to the

domain by means of recursion:

G

f

*

G

Σ

x

G

X Σ×

X ×

xf

G

=

),(

ε

,

)),,( esxff

G

( f

GG

),( sex

=

for , and

.

Xx∈

G

Σe∈

*

G

Σs ∈

The SCT distinguish between the controllable set

(

c

Σ

), which can be disabled, and the non-

controllable set (

nc

Σ

) which cannot be disabled. The

following relations are fulfilled: and

ncc

Σ∪Σ=Σ

∅

=

Σ

∩

Σ

ncc

.

In order to restrict the behaviour of the plant G,

one or more specifications can be defined, that are

usually modelled by a DFSA

),,,,,(

0 mHHH

YyfYH Γ

Σ

=

A restriction limits the behaviour of the plant by

means of one of the two composition operations

defined by the SCT. Informally, it can be said that a

composition operation allows two DFSA to run

synchronously, which means that certain events will

only be created if both DFSA are capable of doing

so. In this work we will consider (synchronous)

parallel composition of G and H, defined as:

)),,(,,,,(||

00|||| mmHGHGHG

YXyxfYXAcHG

×

Γ

Σ

∪

Σ

×

=

where

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

264

⎪

⎪

⎩

⎪

⎪

⎨

⎧

Γ∈Σ∉

Σ∉Γ∈

Γ∩Γ∈

=

caseother definednot

)( and if)),(,(

and )( if)),,((

)()( if)),(),,((

)),,((

||

yeeeyfx

exeyexf

yxeeyfexf

eyxf

HGH

HGG

HGHG

HG

Γ

G

||

H

(

x

,y) =[Γ

G

(

x

)∩Γ

H

(y)]∪[Γ

G

(

x

) −Σ

H

]∪[Γ

H

(y)

−

Σ

G

]

Ac() denotes the accessible automaton part,

excluding thus the states which cannot be accessed

from x

0

state.

3 OVERVIEW OF DEVELOPED

FRAMEWORK

Traditionally, when changes in the production

process occur, the PLC that control the process need

to be reprogrammed as well. In order to get highly

flexible manufacturing systems, we propose a

framework with a core element: a service repository.

In this proposal, the services can be invoked

dynamically based on the production needs.

Therefore, if the production process is altered, then

the sequence of invocation of the services will be

modified. In this way, the main advantage is that the

software running on the PLC does not need any

modification at all, if all the required services have

been taken into account.

In our framework, if an input event e

i

is triggered

by an external entity for a certain service,

then ; if an internal event e

i

is created by the

plant, then . When certain services are

invoked, the system can stop working properly. In

order to avoid this, our proposal considers

supervising the behaviour of the system using SCT.

As stated in the previous section, once the plant G is

modelled, its behaviour is restricted by means of one

or more specifications H

k

that can temporarily

disable certain input events. Consequently, no

undesired actions will ever take place.

ci

e Σ∈

e

nci

Σ∈

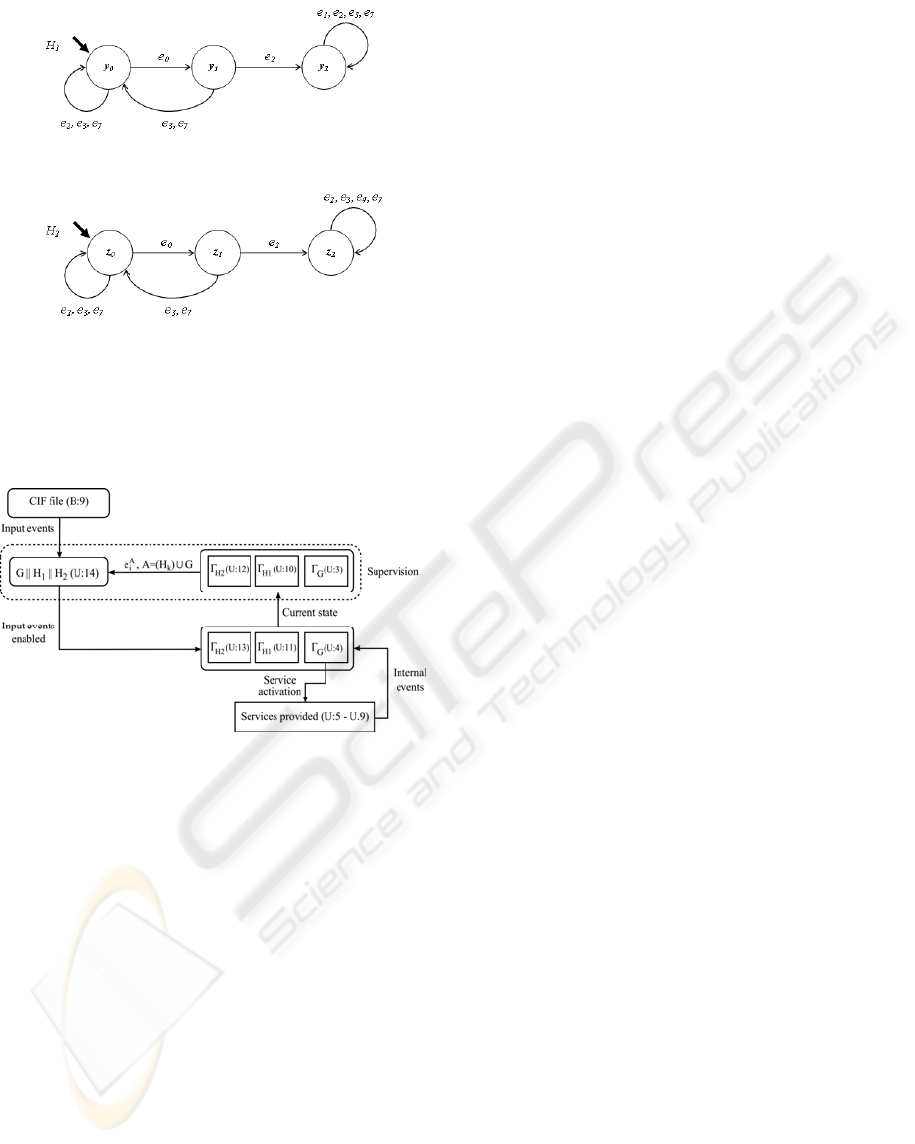

Our framework (Figure 1) consists of the

following components:

Interface with external entities. Clients

invoke the services provided by the system

through this interface, and the

corresponding input event will be triggered.

Supervision: it is made up of a) the active

event function

Γ

of A, being

}

k

H

and b) the

synchronous composition

k

H

,

where the input events can be disabled if

needed.

{

HGA ∪∪∪= K

1

HG ||||||

1

K

State transition functions, which evolve in

accordance with 1) the input events that

have not been disabled previously in the

supervision and 2) the internal events of G.

In the plant, if an input event causes a

transition

G

f , it will activate the execution

of the corresponding service.

Services provided that gather a specified

functionality. Due to design criteria they are

isolated from the supervision role so it is

possible to perform modifications on the

functionality regarding supervision

consideration. This characteristic can be

seen as the main advantage.

In the following, the main behaviour will be

described. When an input event is triggered,

it is processed by the supervisor. The composition

operation, taking into account for each DFSA,

decides if e

i

must be disabled or not. If e

i

is enabled,

it is then processed by the f

A

of each DFSA,

including G. Therefore, if a transition is defined in

for e

i

and the current state of G, the

corresponding service will be run. Otherwise, if e

i

is

disabled, the transition does not happen, and the

requested service will never take place. As a result,

we make sure that the system behaves according to

its specifications at all times.

ci

e Σ∈

A

Γ

G

f

Figure 1: Global overview of the framework.

4 A CASE OF STUDY

In what follows we discuss how to use our proposed

framework in a typical element of a FSM cell: a

conveyor belt. We have chosen it because it is a

component found in every cell instance and because

the working specifications are changed frequently,

given that the conveyed elements must be moved to

APPLYING A SOFTWARE FRAMEWORK FOR SUPERVISORY CONTROL OF A PLC-BASED DISCRETE EVENT

SYSTEM

265

different target positions using different velocities as

well.

The plant is made up of a BOSCH conveyor belt

with encoder, dynamo and position sensors. The

control is carried out by the Allen Bradley SLC 500

series with the IMC 110 motion control module.

Depending on the operation mode of the IMC,

the conveyor belt can be moved manually or

automatically. Movements in manual mode are used

for initialization and maintenance by an operator and

are always executed at constant velocity.

Movements in automatic mode are performed when

some of the MML programs loaded in the IMC 110

memory is running, and it is possible to modify both

the velocity and the acceleration of the motion. In

order to work in automatic mode and know where

the tray is located it is needed to perform a home

operation. For security reasons, emergency stops

must be considered when in automatic mode.

Figure 2: Plant operation modelled by a DFSA G.

The DFSA G (Figure 2) models both the manual

and automatic mode of the conveyor belt. This plant

model DFSA is given as the 5-tuple with x

0

as initial

state. In the definition of the state set

(

{

70

,, xxX K=

}

Table 1) three factors have been

considered:

IMC operation mode (automatic or manual)

belt state (moving or not)

the presence of an emergency stop.

So, in this case, .

m

XX =

Respect to

Σ

(Table 2), the set

{

}

872

,, eee

NC

=Σ

{

654310

,,,,, eeeee

is generated from the information provided by the

IMC from sensors,

corresponds with the events provided by the system.

}

e

C

=Σ

The behaviour of the plant is controlled by two

restrictions:

R1) the movement to a target position (e

1

event) is not allowed prior to completing a

successful homing operation

R2) the change to automatic mode (e

4

event)

is not allowed prior to completing a

successful homing operation.

Table 1: G plant states.

State Mode Conveyor belt state e-stop

x

0

Manual Stopped Yes

x

1

Manual Stopped No

x

2

Manual Moving No

x

3

Automatic Stopped No

x

4

Automatic Moving Yes

x

5

Automatic Moving No

x

7

Automatic Moving Yes

Let H

1

and H

2

be the two DFSA that model the

restrictions R1 and R2, respectively.

According to the H

1

state transition diagram

(Figure 3), the state y

1

represents the action

“performing home operation”. If it is completed

successfully (e

2

event), the state changes to y

2

. Given

that

)(

211

ye

H

Γ

∈

, then it is not possible to perform

any type of movement to any position.

Table 2: Defined events in G (C - controllable, NC - non

controllable).

Event Description Type

e

0

Request for performing a home

operation

C

e

1

Request for moving until the target

position is reached

C

e

2

Movement completed successfully NC

e

3

Request for stopping the current

movement

C

e

4

Request for changing the IMC 110

operation mode

C

e

5

Request for setting the velocity of

automatic movements

C

e

6

Request for setting the acceleration of

automatic movements

C

e

7

Emergency stop occurs NC

e

8

Emergency stop situation is finished NC

Taking into account the state transition diagram

(Figure 4) for H

2

, it is only possible to change to

automatic mode (e

4

event) if a home operation has

been completed successfully.

Diagrams H

1

and H

2

are structurally identical,

and both restrictions over G could have been

modelled by only one specification H. However,

modelling several modular specifications H

i

,

structurally simpler than H, is easier to verify and

understand (Cassandrass, 2007).

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

266

In order to avoid these possible incidents, we use

the Supervised Control Theory. The framework we

propose allows modelling one or more specifications

which guarantee that the system behaves properly at

all times. This is achieved by temporarily disabling

the input events which could put the system at risk.

Our framework also differentiates between the

specifications and the functionality provided. Thus,

it is possible to modify both parts independently.

Figure 3: State transition diagram for H

1

.

To prove the main features of our framework,

some implementation issues must be solved, due to

the synchronous nature of PLC.

ACKNOWLEDGEMENTS

Figure 4: State transition diagram for H

2

.

In order to implement the supervisor system

(Figure 5), we have followed the proposed

framework, taking into account G, H

1

and H

2

defined previously.

The results presented at this paper have been

obtained from the tasks of research that have been

partially supported by the Spanish Ministery of

Science and Innovation through DPI2007-62267

proposal and by the Castilla y León Council with

SA030A07 project.

REFERENCES

Beck, J., Reagin, M., Sweeny, T., Anderson, R., Garner,

T. 2000. Applying a Component-Based Software

Architecture to Robotic Workcell Applications. In

IEEE Transactions in Robotics and Automation, vol.

16, pp. 207-217.

Curto, B., García, F. J., Moreno, V., González, J., Moreno,

A., 2001. Experience of a CORBA based architecture

for Computer Integrated Manufacturing. In ETFA’01,

8th IEEE International Conference on Emerging

Technologies and Factory Automation

, pp 765-769.

Figure 5: Implemented Supervisor System.

5 CONCLUSIONS

Ramadge, P. J., Wonham, W. M., 1987. Supervisory

Control of a Class of Discrete Event Processes. In

SIAM J. Control and Optimization, vol. 25, no. 1, pp.

206-230.

In this paper we propose a software framework

where the main aim is to make easier the

implementation of a supervisory control system over

a PLC. With this framework we want to emphasize

on the idea that the functionalities must be offered

with no effects on the robustness of the system

operation.

Chandra, V., Mohanty, S. R., Kumar, R., 2000. Automated

control synthesis for an assembly line using discrete

event system control theory. In IEEE Transactions on

Robotics and Automation.

Mušić, G., Matko, D., 2002. Discrete Event Control

Theory Applied to PLC Programming. In

AUTOMATIKA: Journal for Control, Measurement,

Electronics, Computing and Communications

, vol. 43

no. 1-2.

The system can be viewed as a well defined set

of services which are requested depending on the

production needs. Changes in the production process

can affect the order in which the services are

requested but not their implementation.

Phoha, V. V., Nadgar, A., Ray, A., Phoha, S., 2004.

Supervisory Control of Software Systems. In

IEEE

Transactions on Computer

, vol.53, nº9.

On the other hand, the flexibility obtained must

have nothing to do with the robustness demanded by

this kind of systems. Therefore we take into account

the possibility that certain event sequences could put

at risk the good working order of the system.

Cassandrass, C. G., Lafortune, S., 2007. Introduction to

Discrete Event Systems, Springer, 2

nd

edition.

APPLYING A SOFTWARE FRAMEWORK FOR SUPERVISORY CONTROL OF A PLC-BASED DISCRETE EVENT

SYSTEM

267