DISTRIBUTED ARRIVAL TIME CONTROL FOR VEHICLE

ROUTING PROBLEMS WITH TIME WINDOWS

Seok Gi Lee and Vittal Prabhu

Harold and Inge Marcus Department of Industrial and Manufacturing Engineering

The Pennsylvania State University, University Park, PA 16802, U.S.A.

Keywords: Distributed Arrival Time Control (DATC), Distributed Control, Scheduling, Dispatching.

Abstract: Competitiveness of a supply chains depends significantly on distribution center operations because it

determines responsiveness and timeliness of deliveries to customers. This paper proposes a control

algorithm for routing multiple out-bound trucks to customers spread over a wide geographical area, each

occupying different volume in a truck, and having a different delivery time-window. Overall operations are

also constrained by geographical locations of the customers in various zones and dissimilar truck capacities.

Performance of the algorithm is tested using data from a distribution center located in Latin America.

1 INTRODUCTION

Transportation is the most expensive logistics

activity. The overall goal in transportation should be

to connect sourcing locations with customers at the

lowest possible transportation cost within the

constraints of the customer service policy (Edward

H. Frazelle, 2002). Most important factors which

can affect transportation cost are the number of

trucks to deliver customer products, shipments

allocation on trucks which decide a route of a truck

and shipments loading on trucks as shown Figure 1.

The truck (vehicle) routing problem has been

recognized for over 40 years and is one of the most

important factors in distribution and logistics. In

particular, the importance of on-time delivery for

customers is growing up according to various and

complicated customer needs. In these conditions,

finding solution optimally is very hard because of

dynamics of a transportation environment. Many

heuristics approach which can be broadly classified

into two main classes, classical heuristics and meta-

heuristics, have been proposed for vehicle routing

problem in a last half century (Gilbert Laporte,

Michel Gendreau, Jean-Yves Potvin, Frederic

Semet, 2000).

Several meta-heuristic methods have been

proposed to solve the vehicle routing problem. The

important issues of meta-heuristics for the vehicle

routing problems is how they can diversify search

space and intensify routing solution to reduce

transportation cost. For example, tabu search and

simulated annealing algorithm tried to jump out of

the local minimum by search its neighborhood

space. To improve limitation of their neighborhood

search space, some advanced methods were

developed and plugged in search logic to diversify

neighborhood search space (Haibing Li, Andrew

Lim, 2003, J-F Cordeau, G Laporte and A Mercier,

2001).

Figure 1: Transportation problem.

Furthermore, research for system dynamism has

been conducted recently. Some measurements were

proposed to explain how dynamic vehicle routing

system (A Larsen, O Madsen and M Solomon, 2002,

Larsen A, 2000). These measurements can play a

crucial role in determining proper models or

algorithms to solve vehicle routing problem

according to the dynamic characteristics of the

system.

246

Gi Lee S. and Prabhu V. (2009).

DISTRIBUTED ARRIVAL TIME CONTROL FOR VEHICLE ROUTING PROBLEMS WITH TIME WINDOWS.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 246-251

DOI: 10.5220/0002211802460251

Copyright

c

SciTePress

`

In this paper, truck assignment and routing

algorithm (TARA) is proposed to meet not only

transportation cost needs but also customer service

needs. Core of TARA algorithm is constructed based

on distributed arrival time control (DATC) which is

a feedback control-based scheduling approach that

attempts to minimize the average of the square of the

due-date deviation for Just-in-Time system (Hong,

J., Prabhu, V. V., 2003).

2 PROBLEM DEFINETION

The problem, in terms of the distribution center and

customer delivery, could be described as follow. The

distribution center run 24 hours to process

customers’ transportation orders, but trucks operate

loading and control jobs from 4 AM to 10 PM at the

distribution center. During this time, there is no out-

of-order of trucks which is used for delivery. All

trucks are assumed to return to the distribution

center and to be ready for loading at 4 AM.

The problem has three major constraints related

with truck loading, delivery time and order

processing. For truck loading constraints, each truck

has own pallet capacity limit and maximum number

of the customer order in a truck is four. Also, there

are exclusive shipping requests which cannot share

trucks with other shipments. For delivery time

constraints, there are three different types of time

window in this problem. In a sense, a time window

implies the open time of a distribution center. A

customer can request three type of time window. At

first, for specific time of a specific date, delivery

should be as punctual as possible. This is similar to

Just-in-Time strategy with minimizing earliness and

tardiness. Secondly, delivery could be done within a

time window (w

min

, w

max

). Lastly, there could be no

time requirement from customers. It means that a

time window is within (0, 24) hour. Travel time

among each customer’s location including

distribution center is shown in Table 1. For order

processing constraints, customer orders arereceived

every day, except on Sunday, until 6 PM. The

scheduler generates the shipments of the next day. In

other words, every customer order must be shipped

the day after its arrival. Hence, if the distribution

center cannot ship an order due to no available

trucks, the customer order will be shipped the next

earliest truck-available date, which will turn out to

be a large deviation from the requested time

window.

The truck assignment and routing algorithm is

evaluated by two objective functions which are

related with the trucking cost and customer service.

The first objective function for trucking cost can be

determined as follow:

Minimize

11

mm

j

jjj

jj

nC nF

==

⋅

+⋅

∑∑

(1)

where

Sj

∈

∀

, S is the index set of trucks which

are used for delivery, n

j

is the number of trucks type

j, F

j

is the fixed cost for operating one truck and C

j

is the trucking cost of truck type j. The second

objective function related with customer service can

be represented by time window violation cost and

formulated as follow:

Minimize

1

n

i

i

ETC

=

∑

(2)

where ETC

i

= αxmax{0, w

i

min

– c

i

} + βxmax{0, c

i

–

w

i

max

} and c

i

is completion time of customer order i.

In this equation, α is the penalty cost for earliness

and β represents the penalty cost for tardiness of

time window for customer i.

Table 1: Customer location and travel time.

Location

Code

L10001 L10002 L10003 •

L10001 0.00 0.42 0.44 •

L10002 0.42 0.00 0.50 •

L10003 0.44 0.50 0.00 •

L10004 2.05 2.16 1.83 •

L10005 0.75 0.80 0.49 •

L10006 0.84 0.92 0.59 •

• • • • •

3 DISTRIBUTED TIME

CONTROL FOR TRUCK

ASSIGNMENT

DATC is a closed-loop distributed control algorithm

for manufacturing shop floor in which each part

controller uses only its local information to

minimize deviation from its part’s due-date (Hong,

J., Prabhu, V. V., 2003

). In DATC, the integral

control law is represented as follow:

∫

+−=

t

iiiii

adcdkta

0

)0())(()(

ττ

(3)

where k

i

is the controller gain, a

i

(0) is the arbitrary

initial arrival time, d

i

is the due-date and c

i

(τ) is the

predicted completion time for the ith job in the

DISTRIBUTED ARRIVAL TIME CONTROL FOR VEHICLE ROUTING PROBLEMS WITH TIME WINDOWS

247

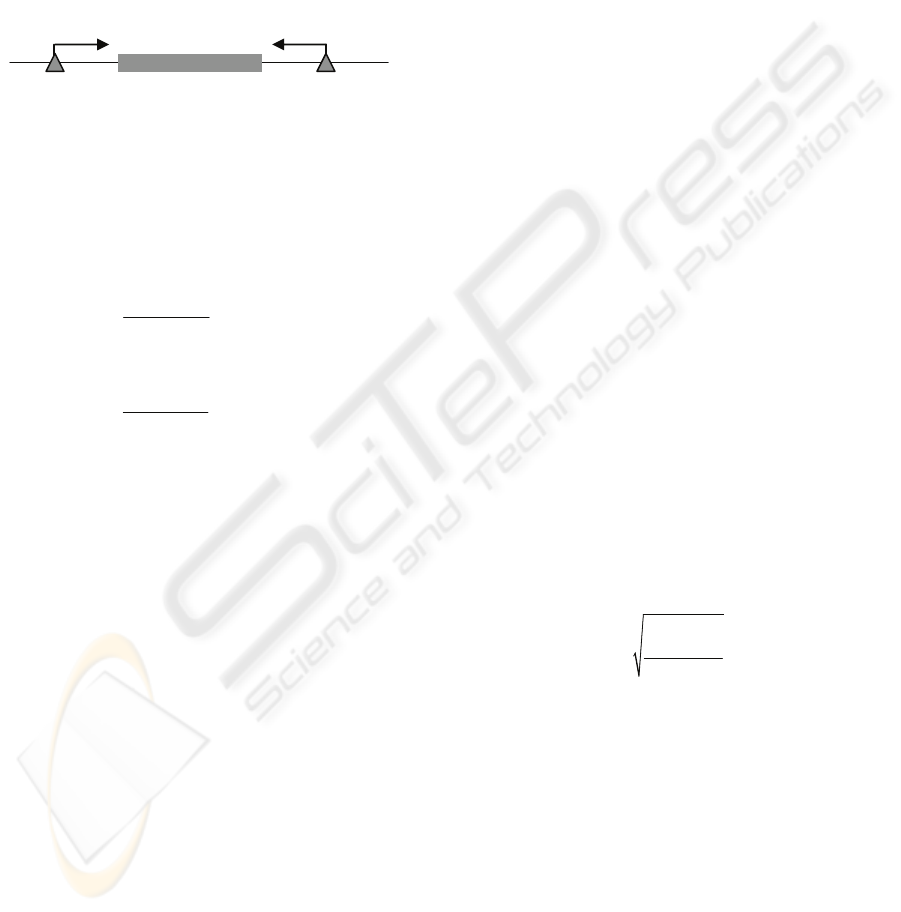

system. In vehicle routing problem with time

window, the controller gain value is defined by

function of relationship between completion time

and time window and it can be decided according to

two cases, earliness and tardiness. When earliness

occurs, the next arrival time of a job moves toward

minimum value of time window by above integral

control law. Similarly, in case of tardiness, the next

arrival time moves toward maximum value of time

window as shown in Figure 2.

Figure 2: Controller gain adaptation.

The momentum of each arrival time is controlled

by the controller gain, k

i

which is calculated

differently according to the earliness and tardiness as

described in equation (4) and (5).

k

cw

cw

KEk

ii

ii

ii

⋅

−

−

==

min

max

,

min

ii

wc ≤

(4)

k

wc

wc

KTk

ii

ii

ii

⋅

−

−

==

max

min

,

max

ii

wc ≥

(5)

As a result, in case of earliness, equation (3) can

be converted by equation (4) as follow:

)}1({)1()(

min

−−⋅Δ⋅+−= tcwKEtata

iiiii

(6)

Similarly, equation (3) is changed by equation

(5) for the tardiness case as follow:

)}1({)1()(

max

−−⋅Δ⋅+−= tcwKTtata

iiiii

(7)

where a

i

(t) is the arrival time at tth time step, Δ is

the time step and c

i

(t-1) is the completion time at (t-

1)th time step.

Overall TARA procedure is described as follow:

STEP 1 : Initialize customer and truck parameters

a

i

= minimum value of time window – t

1i

c

i

, u

j

= 0, p

j

= P

j

l

j

= 1 (Location 1 implies DC)

STEP 2 : Sort customer based on FCFS rule

STEP 3 : Truck assignment for each customer

For i = 1 to n Do

For j = 1 to m Do

j = Arg(min(E

j

)), subject to v

i

≤ p

j

e

j

= E

j

, p

j

= p

j

– v

i

, l

j

= l

i

u

j

= e

j

+ v

i

/R, where R is the unloading

rate in pallets/hour

c

i

= u

j

a

i

= a

i

+ k

i

x Δ x (d

i

- c

i

)

E

j

= u

j

+ t

ji

STEP 4 : Compute summation of total earliness and

tardiness for each i

STEP 5 : Initialize customer and truck parameters

STEP 6 : Go to STEP 2:

In these TARA steps, a

i

is arrival time of

customer i, c

i

is delivery completion time of

customer i, p

j

is the number of pallets it can be

loaded based on the current load of truck j, p

j

is the

maximum number of pallets it can be loaded by

truck j, l

j

is the current location of the truck j, l

i

is the

location of customer i, u

j

is the last unloading time

of truck j, v

i

is the number of pallet of customer i

and E

j

is time consumption of truck j from current

location to customer i. Also, by equation (6) and (7),

k

i

is KE

i

in case of earliness or KT

i

when the

completion time is greater than maximum value of

time window.

4 TRUCK ASSIGNEMNT AND

ROUTING ALGORITHM

PERFORMANCE

4.1 Performance Comparison

To measure the TARA performance, we used the

following scalar equation (8) for mean squared due

date deviation (MSD) which is used to characterize

the global dynamics (

Prabhu, V. V., 2003).

MSD =

2

1

()

n

ii

i

cd

n

=

−

∑

(8)

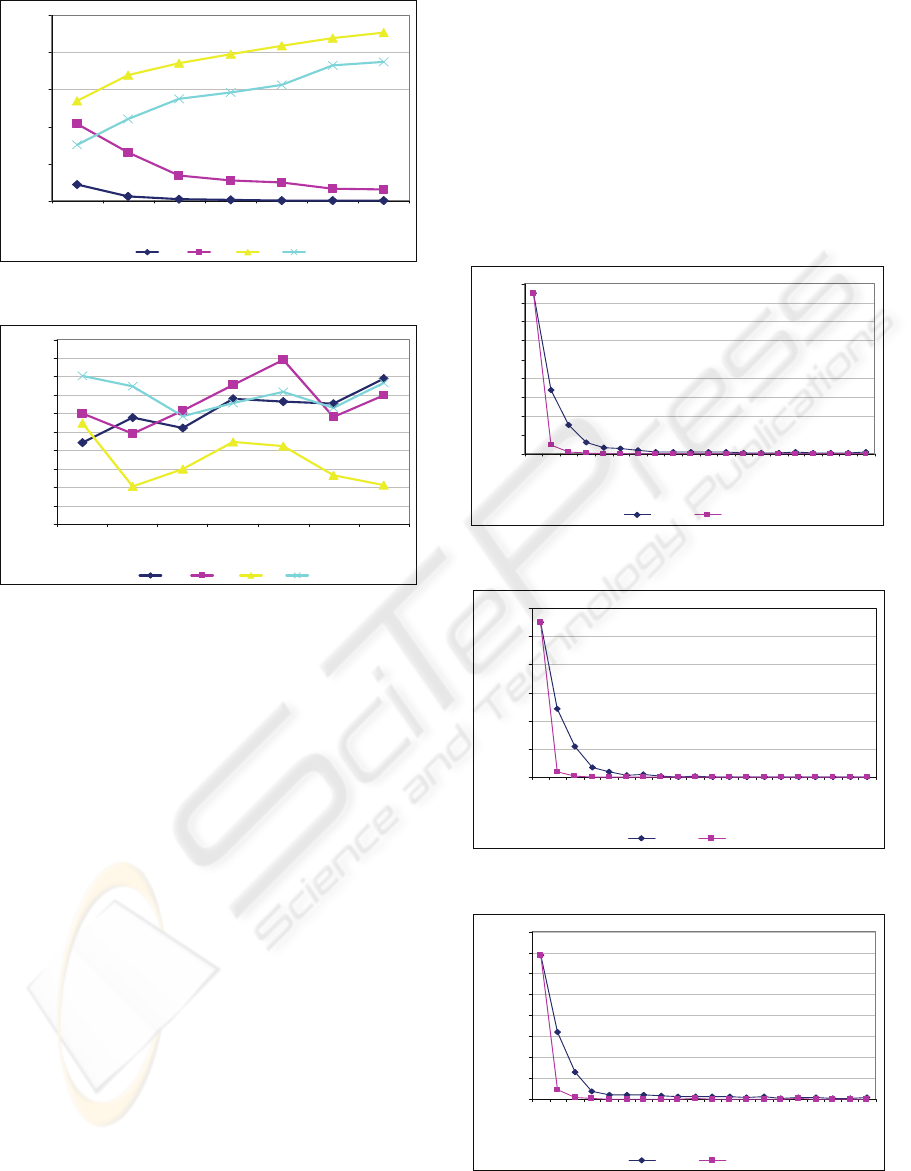

Four customer demand sets which have 24, 31,

43 and 54 orders in them were used for test. These

customer order data were real-world data used by

one of global health and hygiene companies. The

number of trucks was fixed as 12 and they have

equal capacity to load 60 pallets. According to

experiments, in case of set 1, 2 and 4, MSD became

zero within 20th iteration. For set 3, time violation

became the minimum value at 9th iteration. The

MSD results for four kinds of data sets are described

in Figure 3.

Furthermore, by using these experimental data,

TARA performance was compared to dispatch rules,

such as earliest due date (EDD), shortest processing

-

k

+

k

i

a

i

a

max

i

w

min

i

w

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

248

`

time (SPT) and latest processing time (LPT) as

shown in Table 2. For the EDD rule, customer

orders are arranged in ascending order by amount of

time difference between each order’s maximum time

window and distance from the distribution center.

Then each order is loaded in trucks one after another

and finally, total MSD is calculated. For the SPT

rule, orders are arranged in ascending order by

distance between the distribution center and each

order. Then, similar with the EDD rule, each order is

loaded in trucks and total MSD is calculated. In case

of the LPT rule, customer orders are arranged in

descending order by same measurement with the

SPT rule. The number of trucks was fixed as 12.

As a result, for average MSD of four data sets,

TARA obtained 196% better result than the EDD

rule. For the SPT and LPT rules, TARA showed

approximately 199.6% improved results.

Experimental Results of minimum travel

distance for each experiment set are shown in Table

3. Travel distance is estimated by assuming that the

average trucking distance is 60 miles per hour. For

set 1 and set 2 which have relatively small amount

of customer orders, TARA with static controller gain

have same or better performance than dynamic

controller gain. In case of large amount of customer

orders, TARA with dynamic controller gain gives

relatively better performance. However, for almost

all cases, dispatch rules have relatively better

performance than TARA. This is because, basically,

TARA controller proposed in this paper is designed

to minimize tardiness and earliness of customer

orders and it does not contain any device to consider

travel distance.

0

20

40

60

80

100

120

140

160

180

200

1 3 5 7 9 11 13 15 17 19 21 23 25

Ite ration

MSD

Set 1 Set 2 Set 3 Set 4

Figure 3: Mean squared due date deviation.

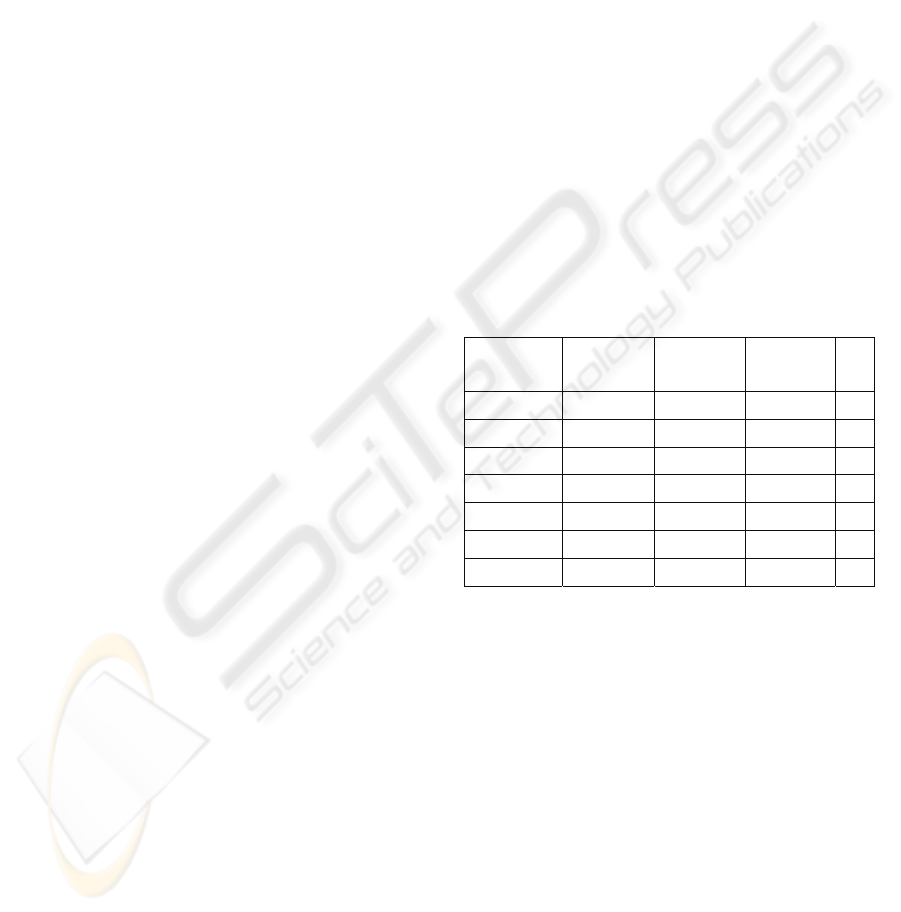

Table 2: Performance comparison – MSD.

Num

of

Order

TARA

EDD SPT LPT

Static Dynamic

24 0.394 0.000 0.676 5.720 5.367

31 0.000 0.000 0.601 5.636 4.912

43 0.015 0.086 0.544 5.377 4.552

54 0.225 0.000 0.637 5.368 4.153

Table 3: Performance comparison – Travel Distance.

Num

of

Order

TARA

EDD SPT LPT

Static Dynamic

24

1504 1504 1606 1409 1560

31

1635 1749 1861 1591 1905

43

2454 2427 2387 2105 2699

54

2959 2953 3320 2553 2926

4.2 Trucking Cost

Average total tardiness and average trucking cost

were measured by varying the number of truck for

TARA. To calculate trucking cost, fuel efficiency

was estimated by 15 miles per gallon and fuel price

was assumed by $3.5 per gallon. Also, fixed cost for

a truck which has 1-ton capacity was assumed $0.25

per mile based on the Excel software program

developed by the Texas A&M university (Ron

Torrell, Willie Riggs and Duane Griffith). The

number of customer orders and the controller gain

value was set to 43 and 0.6. Experimental results for

these two measurements are described in Figure 4.

As the number of truck increases, average total

tardiness increases. On the contrary, average

trucking cost decreases as the number of truck

increases.

0

5

10

15

20

25

45678910

Number of Trucks

Time Violation

900

950

1000

1050

1100

1150

1200

1250

Trucking Cost

Tim e V i ol at i on Trucking Cost

Figure 4: Trucking cost & time violation.

DISTRIBUTED ARRIVAL TIME CONTROL FOR VEHICLE ROUTING PROBLEMS WITH TIME WINDOWS

249

0

50

100

150

200

250

45678910

Number of Trucks

Time Violation (Hour)

TARA EDD SPT LPT

Figure 5: Time violation comparison.

800

850

900

950

1000

1050

1100

1150

1200

1250

1300

45678910

Number of Trucks

Trucking Cost

TARA EDD SPT LPT

Figure 6: Trucking cost comparison.

Also, time violation and the trucking cost

comparison among TARA and dispatch rules are

shown in Figure 5 and Figure 6. In case of time

violation, TARA and EDD had smaller time

violation value as increasing the number of trucks.

SPT and LPT, however, had increasing time

violation value as increasing the number of trucks.

In case of the trucking cost, it is hard to capture the

relationship between the number of trucks and the

trucking cost as shown Figure 6.

4.2 Dynamic Controller Gain Effects

As we explained in equation (4) and (5), TARA used

dynamic controller gain which is changed by status

of completion time. Actually, the basic distributed

arrival time control updates the arrival time

continuously with the static controller gain through

fixed iteration. However, by changing the controller

gain dynamically according to the status of

completion time, earliness and tardiness, the

convergence velocity and quality of MSD were

improved as shown in Figure 7-10. In case of the 24

orders set (set 1), MSD from the dynamic controller

gain reached zero at 14th iteration, but MSD from

the static controller gain was greater than zero and it

was not converged in zero. Similar results could be

observed in other data sets. For the 31 (set 2), 54 (set

4) order sets, MSD from the dynamic controller gain

were converged in zero at 8th and 21th iteration. In

case of the 31 order set, however, MSD from the

static controller gain was converged at 20th iteration

and the other one was greater than zero and not

converged. Although MSD by the dynamic

controller gain of the 43 order set (set 3) was not

converged, it was less than the result of the static

controller gain and reached at minimum value faster.

0

10

20

30

40

50

60

70

80

90

1 2 3 4 5 6 7 8 9 1011121314151617181920

Ite ration

MSD

Static K Dynamic K

Figure 7: Dynamic controller gain effect – set 1.

0

20

40

60

80

100

120

1 2 3 4 5 6 7 8 9 1011121314151617181920

Iter ation

MSD

Static K Dynamic K

Figure 8: Dynamic controller gain effect – set 2.

0

20

40

60

80

100

120

140

160

1 2 3 4 5 6 7 8 9 1011121314151617181920

Ite ration

MSD

Static K Dynamic K

Figure 9: Dynamic controller gain effect – set 3.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

250

`

0

20

40

60

80

100

120

140

160

180

200

1 3 5 7 9 11 13 15 17 19 21 23 25

Iteration

MSD

Static K Dynamic K

Figure 10: Dynamic controller gain effect – set 4.

5 CONCLUSIONS

Truck assignment and routing algorithm is an

effective algorithm based on distributed arrival time

control to solve the vehicle routing problem which

has various delivery time windows of customers. In

this work, TARA using the dynamic controller gain

has been developed to determine the best vehicle

routing plan for maximizing customer service level.

Basically, the controller gain used in basic DATC is

maintained static values through the whole

algorithm processes. The dynamic controller gain,

however, is updated continuously through whole

iteration according to the result of the completion

time, earliness and tardiness. Thus, we can improve

not only the convergence velocity of the solution but

also the quality of the solution compared with

dispatch rules simultaneously.

ACKNOWLEDGEMENTS

The research was partially supported by the Marcus

PSU/Technion Exchange Partnership.

REFERENCES

Prabhu, V. V., 2003, Stable Fault Adaptation in

Distributed Control of Heterarchical Manufacturing

Job Shops, IEEE Transaction on Robotics and

Automation

, 19(1), 142-149.

Hong, J., Prabhu, V. V., 2003, Modelling and performance

of distributed algorithm for scheduling dissimilar

machines with set-up,

International Journal of

Production Research

, 41:18, 4357-4382.

Edward H. Frazelle, 2002, Supply Chain Strategy,

McGraw-Hill.

Gilbert Laporte, Michel Gendreau, Jean-Yves Potvin,

Frederic Semet, 2000, Classical and Modern

Heuristics for the Vehicle Routing Problem,

International Transactions in Operational Research,

Res. 7, 285-300.

Haibing Li, Andrew Lim, 2003, Local Search with

annealing-like restarts to solve the VRPTW,

European

Journal of Operational Research

, 150, 115–127.

J-F Cordeau, G Laporte and A Mercier, 2001, A Unified

Tabu Search Heuristic for Vehicle Routing Problems

with Time Windows,

Journal of the Operational

Research Society

, 52, 928-936.

A Larsen, O Madsen and M Solomon, 2002, Partially

Dynamic Vehicle Routing Models and Algorithms,

Journal of the Operational Research Society, 53, 637-

646.

Larsen A, 2000, The dynamic vehicle routing problem,

PhD thesis, Technical University of Denmark.

Ron Torrell, Willie Riggs and Duane Griffith, 2008, Find

out how much truck costs per mile,

www.westernfamerstockman.com.

DISTRIBUTED ARRIVAL TIME CONTROL FOR VEHICLE ROUTING PROBLEMS WITH TIME WINDOWS

251