MAPPING DEVELOPMENT OF MES FUNCTIONALITIES

Vladimír Modrák

Faculty of Manufacturing Technologies

Technical University of Košice, Bayerova 1, Slovakia

Ján Manduľák

LPH Vranov N/T, S.R.O., Pod dolami 838, Slovakia

Keywords: Manufacturing management, Information system, Interface, functionality.

Abstract: This paper presents a view on MES and ERP functional areas in a hierarchy of enterprise information and

control systems. It starts with a background on ERP and MES Evolution. The work is based on the

exploration of MES and ERP functionalities development. Consecutively, aspects of ERP and MES

integration are treated. In the final section an impact of RFID technology on a validity data stored in MES

obtaining from a tracing of material flow in production processes is analyzed.

1 INTRODUCTION

In the present manufacturing paradigm,

manufacturing execution systems (MESs) play a

significant role. Offered software solutions

simultaneously close the gap between Enterprise

Resource Planning (ERP) systems and production

equipment control or SCADA (Supervisory Control

And Data Acquisition) applications. Current ERP

systems contain usually modules for material

management, accounting, human resource

management and all other functions that support

business operations. In the past years, the role of

ERP has been extended to cross-organizational

coordination. Nowadays, as optimization of

production activities is increasingly topical, a

cooperation of ERP and MES becomes a serious

concern of manufacturing managers. The paper is

structured as follows. Firstly, a brief view on MES

Evolution is presented. Then, MES functionalities

are partially analyzed and a general functionality

model is described. After that, technical aspects of

ERP and MES integration are treated. Finally,

decisive factors that influence the further

development of manufacturing execution systems

are discussed.

2 VIEW ON MES EVOLUTION

As ERP systems by nature are not suitable for

controlling day to day shop floor operations, for this

purpose a new type of industrial software with

acronym MES has emerged during nineties (Choi

and Kim, 2002). There is a more interpretation of

MES depending on different manufacturing

conditions, but the common characteristic to all is

that an MES aims to provide an interface between an

ERP system and shop floor controllers by supporting

various ‘execution’ activities such as scheduling,

order release, quality control, and data acquisition

(MESA #6, 1997). In a context of the MES

development and deployment it is important to point

out that Manufacturing Execution Systems were

originally designed to provide first-line supervision

management with a visibility tool to manage work

orders and workstation assignments. Consecutively,

MES expanded into the indispensable link between

the full range of enterprise stakeholders and the real-

time events occurring in production and logistics

processes across the extended value chain

(McClellan, 2004).

The phenomena of globalization forces

manufacturers to continuously improve their

performance. In this context, manufacturing and

operational excellence has become the key theme for

the manufacturing companies. To improve their

244

Modrà ˛ak V. and ManduÄ¿Ã ˛ak J.

MAPPING DEVELOPMENT OF MES FUNCTIONALITIES.

DOI: 10.5220/0002248902440247

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2009), page

ISBN: 978-989-674-001-6

Copyright

c

2009 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

performance, most manufacturers apply methods

and techniques which are focused on the elimination

of non-value adding activities. Information systems

can by supported in such programs or they can

provide a complementary way of improving

performance by increasing visibility on plant

performance. Accordingly, cooperation of ERP and

Manufacturing Execution Systems (MES) becomes a

serious concern of manufacturing managers. In that

sense, from MES applications is expected to support

real-time production control as well as data

collection and reporting to facilitate information

operability in a company.

3 MES FUNCTIONALITIES

The A concept of Manufacturing Execution Systems

is one of several major information systems types

aimed at manufacturing companies. MES can be in

simple way also defined as a toll for manufacturing

management. The functions of an MES range from

operation scheduling to production genealogy, to

labour and maintenance management, to

performance analysis, and to other function in

between. There are several general models of typical

MES functions that are principally divided into core

and support functions (see more in Modrák, 2005).

The core functions deal primarily with actual

management of the work orders and the

manufacturing resources. Other functional

capabilities of MES may be required to cover

support aspects of the manufacturing operations.

MESA International presents another approach

to MES functionalities that is more or less based on

the assumption of profitability to begin to deal with

wider model of basic elements to ensure

incorporating all-important functions into MES

(MESA #2,1997).

A point of debate about MES functionalities also

is connected with different types of manufacturing.

Understandably, from automation point of view a

discrete manufacturing presents much more

complicate concept comprising of various

technologies that are used to integrate manufacturing

system to one another. As the aim of this work is to

generalize MES functionalities it is also reasonable

to model of hierarchical levels and functions in a

common manufacturing company. A hierarchical

structure of main companies’ functions in this case

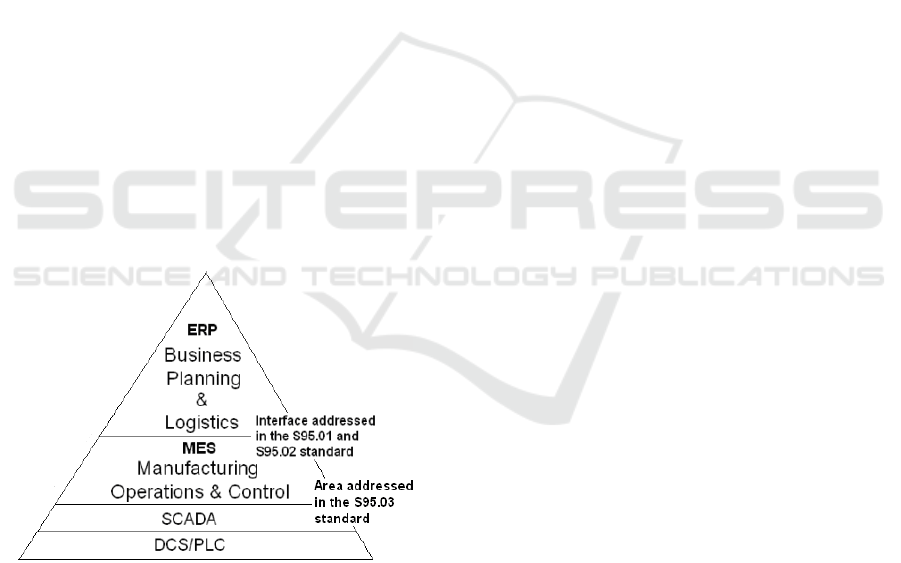

can be represented by four levels (see figure 1).

Figure 1: Functional levels in a manufacturing company.

Model of such structured company functions is often

divided into three levels that are the company

management, the production management, and the

production control (Gunther et al, 2008). In this

relation, functional areas of MES and ERP might not

be considered as closed structure, because it was

recognized that functions can run in the classic ERP

environment as well as in the MES environment.

Accordingly, under specific circumstance they may

overlap of both systems. Based on this assumptions

the following structure of MES and ERP functions

depicted in Figure 2 is mapped.

Figure 2: Intersections of MES and ERP functional areas

(adapted from Gunther et al, 2008).

Obviously, the scope of operations or functions

depends on number of subsystems, but the key

functions remain unchanging in their essence.

Because, there are no reference MES models that

can be used for general manufacturing

environments, overcoming of this aspect leads

through the presentations of sample solutions by

MAPPING DEVELOPMENT OF MES FUNCTIONALITIES

245

types of environment and other criterions. As

example can be used approach to modeling three

different management systems for maintenance,

quality and production (Brandl, 2002) based on the

S95 standard of ISA (ANS/ISA, 2000).

4 CHALLENGES OF ERP AND

MES INTEGRATION

Manufacturing execution systems besides their

typical functions were developed and used also as

the interface between ERP and process control, since

it was generally recognized that ERP systems

weren’t scalable. The seamless connections often

required skilled coding to connect to ERP and

process control systems (Siemens Energy &

Automation, Inc., 2006). Today, the availability of

Web-based XML communications successfully

bridges the gaps between MES and ERP systems.

Built on XML, the B2MML (business-to-

manufacturing markup language) standard specifies

accepted definitions and data formats for

information exchange between systems, and

facilitates information flow and updates between

ERP and manufacturing execution systems. It also

instigated redefinition the role of the MES. The ISA

SP-95 model (see Figure 3) breaks down business to

plant floor operations into four levels.

Figure 3: ISA SP 95 control hierarchy.

Levels 1 and 2 include process control zone. MES

layer consists of managerial and control functions

depending on different types of manufacturing.

Level 4 corresponds to the business planning and

logistics.

The goal of ISA-95 standard was to reduce the risk,

cost and errors associated with implementing

interface between ERP and MES. The ISA-95

“Enterprise - Control System Integration” is a multi-

part series of ANSI/ISA standards that define the

activity models and interfaces between

manufacturing functions and other enterprise

functions. Parts 1 (Models and Terminology), parts 2

(Objects Attributes) and part 5 (Business to

Manufacturing Transactions) define the exchange of

production data between business and plant systems.

B2MM provides a schema implementation of the

ANSI/ISA-95 and represents an independent

technology implementation of this standard.

B2MML has been developed by The World Batch

Forum (WBF) and adopted by players such as SAP

and Wonderware. Coupled together, B2MML and

ISA-95 permit designers to bridge ERP and MES

systems by using B2MML XML vocabulary.

Mentioned and other ISA standards significantly

facilitate the implementation of integrated

manufacturing systems. It is aimed to integrate ERP

systems with control systems like DCS and SCADA.

To support batch control level optimization, the

standard S88.01 (ANSI/ISA, 1995) has been

developed. It provides standard models and

terminology for the design and operation of batch

control systems. At the control level the key attribute

is integration of all process information into one

place. For this purpose are ordinarily used both a

programmable logic controllers and SCADA

software.

5 CHALLENGES OF ERP AND

MES INTEGRATION

An effectiveness of exploitation of new

manufacturing technologies depends on the way

how successfully will be synchronized newly

obtained data from a production control layer into

MES/ERP systems. This challenge escalates as the

RFID applications are increasing to a large number

of products and facilities and as they include

integration in broader Supply Chain Management

systems. According to Williams (2005), the

opportunities enabled by RFID are expected apart

from other effects in simplification of business

processes. Many manufacturing organizations have

processes where a product, asset, document or even

a person is "touched" by many different people at

different times. It causes limited view of information

that can introduce inefficiencies in the overall

process when information about other steps is

needed to execute the current step. Accordingly,

common MES/ERP systems can not have an access

to detailed information and they have no idea of

what is really happening to material flow on the

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

246

shop floor. Mentioned drawback leads to insufficient

coordination between material and accompanying

information flows and so-called bull-whip-effect.

When all data that information systems operate with

are “fed” to them by intermediary subject,

information on material flow is time dependent so it

is already outdated when inserted into the

information system by human operator. Until the

next synchronization information become more and

more outdated. Reducing the bull whip effect by

means of RFID system improves the efficiency of

execution/information systems not only within the

site but also across the supply chain. The results of

our experiments presented earlier (Modrák and

Moskvič, 2007) showed that application of RFID

technology for tracking and traceability of material

flow will impact the whole performance of

information systems in terms of information validity

and practically eliminate time dependence of amount

and quality of information available for ERP/MES

systems.

6 CONCLUSIONS

As it is conceded that production planning activities

have become more complex and therefore need to be

in principle optimized. Manufacturing Execution

Systems, which are positioned between the

Enterprise Resource Planning and control systems

levels, have significant potential to be effectively

used to optimize business processes on the shop

floor. Besides that fact, MES are being viewed as

critical in getting the most value out of existing

investments in automation. A frequent interest of

manufacturers concerns a balanced scale of MES

functionalities. As mentioned earlier, it depends on

more factors. For instance, when an existing ERP

system contains factory floor control functionality,

then functionality model of MES has only

supplement character. Thus, a scope of MES

functionality is evidently influenced by changes in

using automated identification (AID) technologies,

because they have positive impact on the plant floor

optimization. Therefore, mass use of RFID

technology can bring significant rationalizations in

the manufacturing automation in the near future.

This tendency was indirectly confirmed by such IT

players as Oracle, SAP, Microsoft and IBM, as they

all have accelerated efforts to meet the RFID

challenge (Rockwell Automation, 2004). In this

sense, rules concerning manufacturing execution

such as control, scheduling, routing, tracking, and

monitoring might all be modified responding to

RFID challenges.

REFERENCES

ANSI/ISA S88.01, 1995. Batch Control Part 1: Models

and Terminology, International Society for

Measurement and Control, RTP North Carolina, USA.

ANS/ISA-95.00.03, 2000. Enterprise Control System

Integration Part 3: Models of Manufacturing

Operations, Draft 7, International Society for

Measurement and Control, RTP North Carolina, USA.

Brandl, D., 2002. Making Sense of the MES at the MES

Layer” In ISA, Technical Conference, Chicago IL,

October.

Choi, B.K., and Kim, B.H., 2002. MES architecture for

FMS compatible to ERP, Int. Journ. of Computer

Integrated Manufacturing, 15, (3), pp. 274-284.

Gunther, O., Kletti, W., Kubach, U., 2008. RFID in

Manufacturing, Springer Berlin and Heidelberg

GmbH.

McClellan, M., 2004. Execution Systems: The Heart of

Intelligent Manufacturing, Intelligent Enterprise, Jun

12.

MESA #2, 1997. MES functionalities and MRP to MES

Data Flow Possibilities. White Paper 2, Update and

Revised March 1977, Manufacturing Execution

Systems Association, Pittsburgh, P.A.

MESA #6, 1997. MES explained: a high level vision.

White Paper 6, Manufacturing Execution Systems

Association, Pitsburgh, P.A.

Modrák, V., 2005. Functionalities and Position of

Manufacturing Execution Systems. In M. Koshrow-

Pour (Ed.) Encyclopedia of Information Science and

Technology. First Edition, Idea Group Reference,

Hershey, USA.

Moskvič, V., and Modrák, V., 2007. RFID In Automotive

Supply Chain Processes -There is a Case. In T. Sobh,

K. Elleithy, A. Mahmood, M. Karim (Eds.) Innovative

Algorithms and Techniques in Automation, Industrial

Electronics and Telecommunications. Springer, New

York, USA,

Rockwell Automation 2004. "RFID in manufacturing",

white paper. Retrieved from www.rockwel

automation.com/solutions/rfid/get/rfidwhite.pdf

Siemens Energy & Automation, Inc., 2006. Why integrate

MES and ERP? Because you can’t afford not to.

Siemens Whitepaper, 1-8.

Williams, D.H., 2005. Beyond the Supply Chain: The

Impact of RFID on Business Operations and IT

Infrastructure. Planetpal whitepaper. Retrieved from

http://www. planetpal.net /En/infos/art26_05_05.shtm

MAPPING DEVELOPMENT OF MES FUNCTIONALITIES

247