A SYSTEM-ARCHITECTURE FOR ROBOTIC

MOVEMENTS OF GOODS

Approaches Towards a Cognitive Material Flow System

Dennis Ommen, Carsten Beth, Jens Kamenik

OFFIS Institute for Information Technology, Escherweg 2, Oldenburg, Germany

Axel Hahn

Department of Computing Science, Carl von Ossietzky University, Ammerl

¨

ander Heerstrasse 114-118, Oldenburg, Germany

Keywords:

Network Robotics, Mobile Robots and Autonomous Systems, Robot Design, Development and Control, Intel-

ligent transportation technologies and systems.

Abstract:

Flexibility, throughput, maintainability, scalability, reliability and low cost: That are the main optimization

criteria of material flow systems (MFS). The most of this criteria are diametrical and so hardly to improve

considerably with today’s existing transportation devices and their static control structures. Hence a new

approach of a transportation systems with cooperating robotic units and a novel cognitive environment will be

presented. This approach will combine different research areas like robotics and wireless sensor networks to

achieve a higher degree of flexibility.

1 INTRODUCTION

This paper will discuss aspects that will lead to a

novel, cognitive material flow system (MFS). These

aspects are: modularity, energy consumption, dy-

namic sensor integration, and computational architec-

ture.

A few years ago carrying speed and throughput

were the main performance metrics in MFSs. In the

future properties like flexibility, modularity, reconfig-

urability and redundancy will play a decisive role.

Reasons are the growing number of different prod-

ucts and product variants and thereon shorter product

life-cycle and the growing complexity of products and

processes. At the same time the product quality shall

by high, the price low and the delivery time short. The

movements of goods in a transfer station thus have to

be organized in a flexible manner to fulfill these partly

conflicting requirements with minimal stock of inven-

tory.

Nowadays it isn’t possible anymore to build a

MFS for a transfer station which will last for 10 years

or longer without being rebuilt substantially. In the

future a MFS has to be reconfigurable by design, it

must be possible to change the layout with a small

amount of time and cost to be able to react on chang-

ing requirements (Windth, 2006). The static control

structure of former systems has proved to be too in-

flexible. Therefore a new dynamic control approach

an a new robotic system is needed to overcome these

issues.

To build such new systems it has to be investi-

gated (1) how to modularize the transportation system

and how to identify the modules of single transporta-

tion unit (horizontal/vertical actuators, energy supply,

controller, communication, etc.), (2) how these mod-

ules can be enabled to automatically acting as sin-

gle transportation units, (3) how the different trans-

portation units can cooperate with each other by using

agent-based technologies to achieve a common pur-

pose, (4) how to integrate all the necessary sensor in-

formation into a cognitive environment.

Paper Organization. The remainder of the paper is

organized as follows: Section 2 introduces the new

approach of a cognitive MFS. Section 3 discusses the

related work and will show a research trend. Sec-

tion 4 presents the cognitive MFS approach. The sec-

tions 5 and 6 highlights the systems requirements and

also approaches towards a cognitive MFS. Section 7

presents concluding remarks.

342

Ommen D., Beth C., Kamenik J. and Hahn A.

A SYSTEM-ARCHITECTURE FOR ROBOTIC MOVEMENTS OF GOODS - Approaches Towards a Cognitive Material Flow System.

DOI: 10.5220/0002249303420347

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2009), page

ISBN: 978-989-674-000-9

Copyright

c

2009 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 APPROACH

A cognitive MFS is characterized by (1) strict modu-

larization where all modules are able to take individ-

ual, autonomous decisions of there acting, (2) coop-

eration of the modules in order to form a larger en-

tity and/or to perform tasks collectively, (3) the in-

corporation of the environment in form of intelligent

sensors, (4) dynamic reconfigurability of the system

through adding, removing or rearrangement of mod-

ules, (5) goods accompanied by intelligent SW com-

ponents cooperating with the before-mentioned enti-

ties in order to reach their destination.

The approach of decentralized cooperating au-

tonomous logistic units, where goods and the trans-

portation system autonomously make decisions, can

be a way to realize the requirements drafted above

(Scholz-Reiter et al., 2007b), (Scholz-Reiter et al.,

2007a). Regarding where the decision is taken, the

approaches can be separated into two clusters (1)

good driven (Scholz-Reiter et al., 2006), (Scholz-

Reiter et al., 2007a): An embedded device attached to

the package escorts the goods to its destination. Dur-

ing the transportation process the embedded device

cooperates with the environment to achieve its goal.

(2) Transportation system driven: The environment

around the goods takes the decisions. Here a possible

process looks like that: With the arrival and identi-

fication of a good at the entry gate the environment

creates autonomously the specific transport order that

from now on escorts each autonomous transportation

unit that handles these goods.

These autonomous transportation units are able to

make their own decisions and to cooperate with each

other. They can decide which transportation order

they accept and how to deliver the good to the de-

sired sink. Furthermore they achieve a high degree

of freedom through the ability of cooperation with

other units. To raises the degree of flexibility even

more the transportation units consists of 1...n inter-

changeable modules. These modules are pluggable

in vertical and horizontal direction to build an unique

transportation unit. The abilities that these unique

transportation unit now has, is derived from the cur-

rently used modules (G

¨

unthner et al., 2008b). The

control paradigm of smart independent, autonomous

transportation units shall lead to positive emergence

with the promise to cope with the high dynamic of

logistic systems (Windth, 2006). The main goals of

such distributed systems are increased flexibility, car-

rying speed and throughput, increased maintainabil-

ity, scalability and reliability through redundancy and

decreased livecycle cost.

3 RELATED WORK

This section will provide an overview of the state of

the art of robotic MFSs. It will not only focus on sys-

tems that are available on the free market but also on

the current research. This paper will separate these

products/projects into the following three categories:

(1) central control and autonomous behavior: These

MFSs are controlled via a central instance, where all

the decisions regarding the transportations order are

scheduled. These robotic systems are usually appli-

cation specific and, hence there is no need for coop-

eration between the robots to fullfill a goal. (2) lo-

cal control with autonomous behavior: Because of lo-

cal control the presented system are scalable, flexible

and failsafe. Thereon, the installation and reconfigu-

ration costs are lower in comparison to central con-

trolled systems. The robots act autonomously and

don’t cooperate. (3) local control with swarm be-

havior: robots cooperate with each other to achieve

a common goal. This requires the ability to commu-

nicate with each other and to make local decisions.

Central Control with Autonomous Behaviour.

The Kiva warehouse management system by Kiva

Systems (Guizzo, 2008), (Wurman et al., 2008) is a

commercial system for commissioning of products in

stocks with small parts. The stock consists of many

adjustable shelves with a matrix like structure on a

flat ground. Small autonomous robots (Drive Units,

DU) are able to drive under a shelf, lift it up and

bring it autonomously to other locations, e.g. a pick-

ing station. Orders are accepted from a warehouse

management system by a central computer (Job Man-

ager, JM) which is responsible to schedule the DUs

and picking stations as well as the shelf space at

the station. After receiving a transportation request

from the JM the DUs are responsible for their own

task planning, path planning plus motions planning

and control. Communication between the agents is

done with XML messages at the higher level trans-

mitted by wireless technologies. Because of the agent

based architecture the system is highly scalable and

can grow with the requirements, where the central-

ized Job Manager is a limiting part. A disadvantage is

the limited field of application domains. The system

is mainly useful for order picking processes that have

a high degree on manual work.

Local Control with Autonomous Behaviour. Mul-

tishuttle is a product by Siemens Dematic AG devel-

oped together with Fraunhofer-Institute for Material

Flow and Logistics in Dortmund,Germany. The mod-

ular system consists of autonomous vehicles driving

A SYSTEM-ARCHITECTURE FOR ROBOTIC MOVEMENTS OF GOODS - Approaches Towards a Cognitive Material

Flow System

343

rail-bounded inside of a warehouse system. The vehi-

cles can drive at the horizontal direction and they can

autonomously load and unload product carrier (at the

same time). Rails are laid in several stacked levels.

They take care for both - guiding the vehicles and en-

ergy delivery. Movement at the vertical direction is

done by lifts. Transport orders are communicated to

the vehicles by WLAN. The rail-bound energy deliv-

ery leads to a lower weight and price. But for the same

reason the vehicles are bound to the warehouse, they

can’t deliver goods in the total area of the delivery sta-

tion. In contrast to traditional warehouse systems like

a shelf access equipment, the Multishuttle system is

scalable. Thereon, the throughput be increased with

some additional vehicles.

The system Servus form the Austrian company

Servus Robotics (Servus Robotics, 2006), (Robotics,

2005) is intended for intra-logistics assembly automa-

tion. Like Multishuttle the system is rail bounded.

The vehicles are able to act autonomously. They

accept transportation orders through an infrared or

WLAN interface. Additional information of the

goods, like necessary processing steps, is stored at the

vehicle. The goods themselves don’t need to be intel-

ligent. Additional actuators can be build upon the ve-

hicles, e.g. to be able perform processing steps while

the goods are carried. Energy is not supplied by the

rail, unlike the Multishuttle, instead each vehicle has

its own fast rechargeable energy supply.

Local Control with Swarm Behaviour. Another

project investigating in robotic conveyers is the

KARIS project of the Institute for Conveying Tech-

nology and Logistics (IFL) at the University of Karl-

sruhe, Gemany. They have presented a robotic trans-

portation system (Baur et al., 2008), that consists of

several homogeneous transportation units which are

able to drive at the floor or stand at the floor while

acting as a conveyer. The wheels thereby are turnable

at 360 degrees providing free movement at the hori-

zontal plane. A KARIS unit is able to carry payload

by its own or if the charge is too large or too heavy,

many KARIS units build a swarm and carry the pay-

load together. If a large throughput is required several

units can be combined to build a continuos conveyer

with sorter function. Swarm building and acting is the

actual research work at IFL.

The institute for Materials Handling, Material

Flow, Logistics (IML) in Munich (Gemany) pro-

posed a concept for future material handling systems

(G

¨

unthner et al., 2008b), (G

¨

unthner et al., 2008a) con-

sisting of low-scale autonomic transportation units.

All transportation vehicles are small and have a sim-

ple and basic design causing a low price because

of high volume production. For special roles they

shall be able to be equipped with manipulators like

a lift fork, roller or belt conveyer. They shall be au-

tonomous with their own intelligence and communi-

cation options. If a task can’t be achieved by a single

vehicle, more of them shall form a swarm and act to-

gether.

Figure 1: Trendline of robotic material flow systems.

Conclusion on the Related Work. As it is de-

picted in Figure 1 there is clear trend line towards au-

tonomous robotic systems that can act in a swarm to

achieve common goals in MFSs. The discussed re-

search projects KARIS is an elaborated robotic sys-

tem that shows that these systems can act in two

ways: as a discontinuous or continuous conveyer.

Nevertheless, this systems has no flexibility regard-

ing the transported goods. The concept of the IML

has this ability because of its changeable manipula-

tors. Thereon, it can pickup different kinds of goods,

like pallets and mixed cargo. But both approaches

are limited to operate on the floor. In the following

this paper will present an promising approach that self

adapts to the transported goods and the layout of the

transport area.

4 COGNITIVE MATERIAL FLOW

SYSTEMS

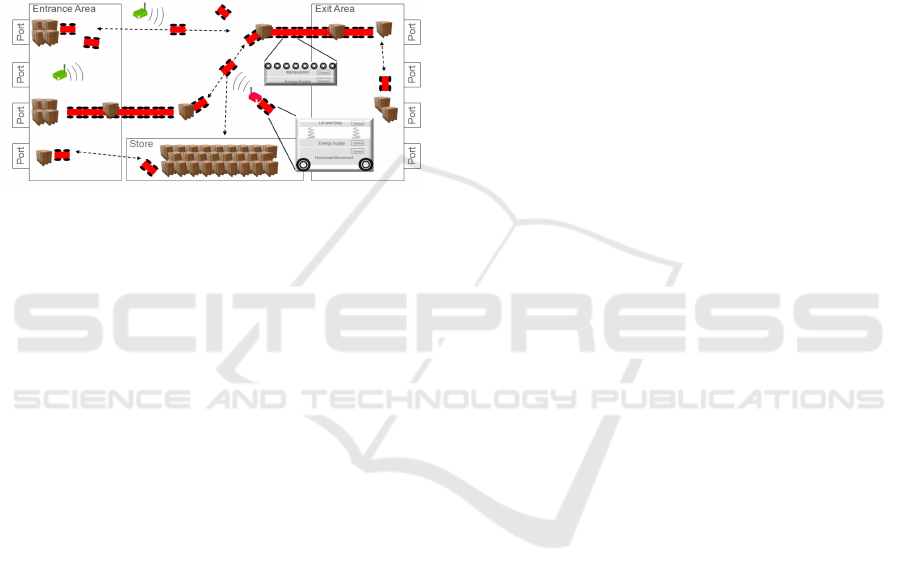

A transfer station scenario with cognitive transporta-

tion units (CTU) is drafted in figure 2. Here the sta-

tion consists of entrance and exit areas, a storing area

and a working area between the entrance and the exit.

Goods are delivered, e.g. by trucks at the ports of the

entrance area. On the other side goods are removed

at the ports of the exit area. The CTUs (red vehicles

in the picture) are responsible for good transportation

(goods are represented as pallets at the picture). Ac-

cording to the requirements CTUs can act as continu-

ous conveyors or discontinuous conveyors equipped

with different manipulation units depending on the

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

344

kind of goods. In general the CTUs are modular. Be-

cause of the unified model it is possible to combine

arbitrary modules in vertical and horizontal manner.

Communication between the CTUs and the environ-

mental sensors is done wireless. In figure 2 two types

of communicating sensors are shown. The red one is a

mobile sensor (CTU in its rule as a sensor); the green

one is a fixed location sensor. The shown scenario

raises some questions to the aspects of modularity,

energy supply, sensor data delivery, dynamic sensor

integration, and communication. These aspects are

highlighted in the following sections.

Figure 2: A cognitive material flow scenario.

5 COGNITIVE

TRANSPORTATION UNIT

Modularization. As it has been stated in the pre-

vious section the CTU consists of modules that have

different abilities. This key approach of modulariza-

tion gives cognitive MFSs the flexibility to adapt not

only to fluctuation in the load but also to adapt to

different kind of goods that need to be transported.

So needs a parcel an other manipulator as an mobile

shelve. The decomposition of the CTU leads to the

following kinds of modules: (1) A conveyer module

for fast transportation of goods in horizontal direc-

tion. If many of this modules stands next to each other

they can act like a continuous conveyer system. (2) an

elevating module, for movements in vertical direction

to lift or lowering goods. This module is needed, e.g.

to transport an mobile shelve or to compensate dif-

ference in the height during the pick up process of a

good. (3) A manipulator module can either work in

combination with the conveyer module or with the el-

evating module to grab or release a good. To be able

to handle different kind of goods, e.g. pallets or mo-

bile stock, there should also different kind of manip-

ulators. (4) A power supply unit, that energizes the

system. Like the other modules this is also designed-

for-purpose. So can the power supply unit be based on

batteries or can even be a stationary power supply to

support or load other CTUs. (5) The movement unit

allow the CTU to act as an discontinuous conveyer

system, with different kind of this modules the CTU

are able to drive on the floor and also to drive into a

stock.

Because the power supply is an mandatory on,

there are at least 20 CTU combinations possible,

which will leverage the MFS to respond in an even

more flexible way. The modules can either be stacked

vertical (on top of each other) , e.g. to build discon-

tinuous CTU (with modules (1)-(5) ) or horizontal to

build a continuous CTU with module type (1). There

should be no limitation regarding the used number

of modules to build an CTU. The modularization re-

quires new ways of communication, control and per-

ception between the CTU modules and then between

the CTUs themselves.

Towards a CTU System Architecture. The pre-

viously described modularization has also its impact

on the computational architecture of the CTU. Here

are different communication channels mandatory: (1)

The vertical channel handles the communication be-

tween the modules of the CTU. This communication

channel have hard criteria regarding the reliability of

data transmission and real-time requirements, e.g. be-

cause of used closed control loops that set the speed

of the CTU wheels. Thereon this channel is typically

wired and represented by a field bus with high band-

width, like CAN or Flexray. (2) A horizontal chan-

nel: This communication interface is used to interact

with (a) other CTUs and (b) the cognitive environ-

ment, which is discussed in detail in the next sec-

tion. A communication between the CTUs occurs,

when goods need to be transfered between them or

when transportation orders need to be negotiated or

for swarm cooperation. The channel (2) with its dif-

ferent interfaces is a wireless one, that has to ful-

fill special requirements regarding energy optimiza-

tion or real-time. Because of the numerous commu-

nication interfaces, that have divers API and physi-

cal characteristics, an abstraction layer is needed that

makes the communication to the CTU modules and

CTU itself transparent. This abstraction layer (mid-

dleware) has to support Quality of Service parameters

that specify the fault tolerance or real-time level of the

communication. Furthermore this Middleware has to

support different embedded devices, that are used in-

side the CTU modules or the sensors from the cogni-

tive environment. This can differ in used micropro-

cessor architecture, e.g. from 8-Bits to 32-Bits archi-

tectures and their program storage size (flash-size).

Energy Efficiency. As stated in (Overmeyer et al.,

2007) optimization under changing general condi-

A SYSTEM-ARCHITECTURE FOR ROBOTIC MOVEMENTS OF GOODS - Approaches Towards a Cognitive Material

Flow System

345

tions has still to be favorable for the overall logistic

system. A battery is a limiting factor for the time t

of useful work. The strategies the CTUs are using

to fulfill a task directly influence the energy drain of

the battery. For example, if the CTUs try to greed-

ily minimize the waiting time criterion in (Overmeyer

et al., 2007) they drive with the highest speed to the

nearest source, catch a palette and drive with highest

speed to the sink of the palette. If all CTUs choose

this egoistic strategy they start to block each other be-

cause the most efficient path from the source to the

sink is overused. At the end they may not be able

to fulfill the task at all because the strategy is to en-

ergy consuming for the whole system. For this kind

of system the optimization criteria has to be reformu-

lated in a way considering energy consumption. A

trade-off has to be found between the energy con-

sumption and the application needs. As an exam-

ple, for high prioritized costumers the focus lies on

speed and energy is less considered and for low pri-

ority costumers energy is considered more. For the

longest availability of the overall system a uniform

distribution of energy might be useful. But, this op-

timization may lead to the fact that all CTUs have to

recharge at the same time and the system is unavail-

able; an additional optimization criterion might then

be that the mean number of recharging CTUs is e.g.

not higher than 15% of all CTUs in the system. The

following assumptions are made: Batteries recharg-

ing takes a significant long time. During this period

the CTU is not able to do valuable work, e.g. it is

unavailable. Three states characterize the (simplified)

CTU: driving, turning and lifting. Every system state

has characteristic power consumption at a time t and

the overall system energy consumption at time t is:

E

AutSys

= E

Driving

(t) + E

Turning

(t) + E

Li f ting

(t) (1)

Additionally the power consumption depends on the

load (kg), the speed (

m

s

) and acceleration (

m

s

2

) of the

CTU. If the CTUs now receive a task they have to

(1) choose a strategy for the task and (2) estimate the

time they will spend in each system state, (3) calcu-

late the overall energy for the chosen strategy and (4)

compare the energy consumption with the given opti-

mization criterion - if this is violated go back to (1).

With this approach an energy optimized strategy for

logistic systems can be found.

6 COGNITIVE ENVIRONMENTS

The basic cognitive capabilities are perception, rea-

soning, learning and planning. A cognitive environ-

ment consists of systems that show a similar strate-

gic behavior like human individums do. For the mod-

elling of cognitive human processes, e.g. cognitive

systems, different architectures have been developed

(Laird et al., 1987) (Anderson and Lebiere, 1998). In

these architetures the perception (sensing) of the envi-

ronment and the storage (memory) of sensor data are

important basics for learning and reasoning. In for-

mer logistic systems like forklifts the only sensory in-

formation comes from the limited human perception.

The same problem have autonomous logistic systems

e.g. driver-less systems that rely on built-in sensor in-

formation. Their view of the environment is limited

to the perception ability of the integrated sensors.

Sensor Abstraction. In the proposed transfer sta-

tion scenario sensors are usable by everyone. This

expands the view of the environment to the whole

scenario. Every autonomous system is able to get

this view to raise the correctness of their decisions.

For example, in (Riedmaier, 2008) the only sensor in-

formation was the soil condition of the track. With

only this information the speed of forklifts could be

optimized and the handling of palettes could be in-

creased about 5%. In the proposed transfer station

scenario external sensors are attached to the walls able

to detect movement of non-cooperative and coopera-

tive systems. With the help of these sensors a CTU is

able to drive with high speed towards an intersection

where it otherwise would not be able to sense if an-

other robot is crossing it and, therfore had to reduce

the speed. To unify sensor communication wireless-

and wired communication media have to be integrated

into every sensor. So, every sensor can act as fixed ex-

ternal sensor or if necessary can be attached to an au-

tonomous robot to improve their sensing capabilities.

As the cognitive logistic system allows a task adapted

flexible restructuring, fixed sensors are a problem. To

allow flexibility, the CTUs are able to move the sen-

sors to a new position. From the modeling point of

view, sensors are agents running a sensing task for a

long time. In the restructuring process of the logistic

system they get a new task and autonomously decide

if they can fulfill this task (1) with their sensing ca-

pabilities and (2) at their actual position. If (1) is not

fulfilled they have to reject the task, if (2) is not ful-

filled they can require help from an autonomous robot

to replace them to a better position. Agents are the ab-

straction of the real embedded devices in the proposed

cognitive logistic system and consequentially sensors

are abstracted with agents as well - this unifies the

whole transfer station scenario world view. Further

usage of the network of sensors can be as a communi-

cation relay for the CTUs and sensors. Due to limited

propagation of radio waves in logistic in-door facili-

ties the assumption that all sensors can communicate

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

346

with each other is not true. Therefore, using the multi-

hop capability of modern wireless sensor networks is

a good way to extend the range of the sensors and the

CTU’s communication system.

Sensor Data Memory. Sensor data is important for

decision making of the control algorithms. There-

fore, it needs to be protected from communication

and sensor node failures. For industrial environments

WirelessHART (HART Communication Foundation,

2007) is a standardized protocol for reliable wireless

communication and can be used in the proposed trans-

fer station scenario. It provides robust self-organizing

and self healing mechanisms to encounter communi-

cation failures. But networked sensors have far more

potential, in a cognitive system they can be used as

distributed observers. A distributed observer is a sen-

sor with its own memory that stores a snapshot of

the past. It is similar to the human short-term mem-

ory (with low-capacity) and is used in many cognitive

modelling architectures (Laird et al., 1987) (Anderson

and Lebiere, 1998). This kind of sensors can answer

questions about situations of a larger context, which

is usful for coordination and optimization purposes.

Distributed sensors have an area to observe. For ex-

ample, a fixed sensor knows about the robot traffic in

his area and can therefore give a usage estimation of

the path belonging to his observation area. Techni-

cally, sensors now have to store their data instead of

just sending real-time data to the CTUs. The CTUs

then ask the sensors for certain events in their stored

history snapshot. For fault-tolerance reasons, sensors

are allowed to replicate their data to other fixed or mo-

bile sensors. They can use different replication strate-

gies to trade-off data availability for energy and vice

versa.

7 CONCLUSIONS AND FUTURE

WORK

Present state-of-the-art projects were considered as

too domain specific and not able to raise the flexibil-

ity of logistic systems comprehensively. Therefore,

this paper proposed modular principle that raises the

flexibility of the system. Energy is an important fac-

tor for battery driven autonomous robots, therefore

strategies for the trade-off between energy consump-

tion and timelines were discussed. Furthermore, a

unified sensor integration scheme was proposed that

raises the cognitive perception ability of the whole lo-

gistic system and a sensor data concept that enables

the idea of a distributed observer was shown. At the

moment the proposed models are being implemented

and in a next step they will be simulated. The goal

of the simulation is to find the best granularity of the

modularization and to find the best cooperating strate-

gies for autonomous logistic systems. As a next step

a test bed implementing figure 2 for validation of the

chosen strategies will be created.

REFERENCES

Anderson, J. R. and Lebiere, C. (1998). The Atomic Com-

ponents of Thought. Lea.

Baur, T., Sch

¨

onung, F., Stoll, T., and Furmans, K.

(2008). Formationsfahrt von mobilen, autonomen und

kooperierenden Materialflusselementen zum Trans-

port eines Ladungstr

¨

agers. Fachkolloquium der Wis-

senschaftlichen Gesellschaft f

¨

ur Technische Logistik e.

V., 4.

Guizzo, E. (2008). Three engineers, hundreds of robots, one

warehouse. IEEE Spectrum:, pages 26–34.

G

¨

unthner et al. (2008a). Vom Prozess zum Ereignis - ein

neuer Denkansatz in der Logistik. In Jahrbuch Logis-

tik, pages 224–228.

G

¨

unthner, W. A., Durchholz, J., Kraul, R., and Schnei-

der, O. (2008b). Technologie f

¨

ur die Logistik des 21.

Jahrhunderts. In Kongressband zum 25. Deutschen

Logistik-Kongress, pages 360–393.

HART Communication Foundation (2007). WirelessHART

Technical Datasheet. HART Communication Founda-

tion, 1.0b edition.

Laird, J. E., Newell, A., and Rosenbloom, P. S. (1987).

Soar: An architecture for general intelligence. Artif.

Intell., 33(1):1–64.

Overmeyer, L., Falkenberg, S., Heiserich, G., and Jungk, A.

(2007). Innovative Gestaltung von Intralogistik durch

Kopplung kleinskaliger Systeme. In 16. Deutscher

Materialfluss-Kongress, pages 171–179.

Riedmaier, S. (2008). Neue M

¨

oglichkeiten f

¨

ur Schmal-

gangstapler. Hebezeuge F

¨

ordermittel, 12:762–763.

Robotics, S. (2005). Na, Servus! Automation, 6.

Scholz-Reiter, B., Jagalski, T., and Bendul, J. (2007a).

Bienenalgorithmen zur Selbststeuerung logistischer

Prozesse. Industrie Management, pages 7–10.

Scholz-Reiter, B., Jagalski, T., and de Beer, C. (2007b).

Selbststeuerung logistischer Prozesse in Produktion-

snetzen. Industrie Management, pages 19–22.

Scholz-Reiter, B., Rekersbrink, H., and Freitag, M. (2006).

Kooperierende Routingprotokolle zur Selbssteuerung

von Transportprozessen. Industrie Management, 22.

Servus Robotics (2006). Wie von Geisterhand. Automation,

4.

Windth, K. (2006). Selbststeuerung intelligenter Objekte in

der Logistik.

Wurman, P. R., R., R. D., and Mountz, M. (2008). Coordi-

nating hundreds of cooperative, autonomous vehicles

in warehouses. AI Magazine, 29/1:9–19.

A SYSTEM-ARCHITECTURE FOR ROBOTIC MOVEMENTS OF GOODS - Approaches Towards a Cognitive Material

Flow System

347