MANAGING ENGINEERING KNOWLEDGE IN SPECIAL

MACHINE DESIGN COMPANIES

Pierre-Emmanuel Vinand, Franck Pourroy, Guy Prudhomme and François Villeneuve

Laboratoire G-SCOP, University of Grenoble, France

Keywords: Mechanical engineering design, Special machines, Knowledge Management.

Abstract: This paper deals with Knowledge Management (KM) in the specific industrial context of special machine

design. Our purpose is to study how relevant a KM approach in such an environment is. The theoretical

background highlights the concept of crucial knowledge and the codification and personalisation strategies.

From a field study, we show the existence of recurrences and experts in special machine engineering design,

justifying a KM approach. We also put forward a condition to make this approach effective: the existence

of a device enabling experts to work collaboratively.

1 INTRODUCTION

This paper is in line with the manufactured industrial

product design field. Manufactured products are

obtained by transforming raw material using

industrial techniques and processes. Designing such

products is nowadays a collaborative activity; this

involves all the life cycle stakeholders who have to

work together in order to define a product taking all

their constraints into account.

The design activity is composed of many

elementary activities whose goals are to propose

artefacts that model the product from different points

of view: functional, conceptual, structural…

In order to make these activities successful,

designers can rely on their own knowledge coming

from their expertise and previous projects. But they

also need information -technical, scientific,

organisational, working process…- they can find in

digital or paper resources. During design activities

designers also generate information and knowledge

which help them to solve problems they are

confronted with. It is this kind of knowledge and

information which supports designers during design

activities that we are interested in.

Studies whose objective is to manage

information and knowledge supporting elementary

design activities already exist in design literature

(Matta, 2008). Our work focuses on a special

machine context. A special machine is built to meet

the particular needs and constraints of a specific

client and only one device is usually produced.

Therefore, the questions that have to be addressed

are whether it makes sense to think about a

knowledge and information management approach

in such a context and subsequently how to make this

approach relevant.

The paper is organised as follows; we first give

some theoretical background and go in more details

on our research question. Then, we present a field

study within a company that produces special

machines, and we describe some specific

observations. Finally, we give some results of our

analysis; we show that a knowledge management

approach is relevant in the context of special

machines and we highlight founding elements to its

structuring and conditions of implementation.

2 THEORETICAL

BACKGROUND

Many research works deal with knowledge

management within companies. However, different

points of view are encountered about this object that

they call knowledge (Ahmed et al, 1999). Wilson,

who underlines a common confusion between

information and knowledge (Wilson, 2002), defines

knowledge as what we know: “knowledge involves

the mental processes of comprehension,

understanding and learning that go on in the mind

and only in the mind, however much they involve

interaction with the world outside the mind, and

123

Vinand P., Pourroy F., Prudhomme G. and Villeneuve F. (2009).

MANAGING ENGINEERING KNOWLEDGE IN SPECIAL MACHINE DESIGN COMPANIES.

In Proceedings of the International Conference on Knowledge Management and Information Sharing, pages 123-128

DOI: 10.5220/0002284501230128

Copyright

c

SciTePress

interaction with others”. This point of view, that we

adopt here, leads us to call into question the meaning

of knowledge management.

Knowledge management is claimed to be a way

of improving the efficiency of engineering design

activities by fostering knowledge formalization and

sharing (Gardoni & Dudezert, 2005). In the SECI

model, Nonaka and Takeuchi (Nonaka & Takeuchi,

1995) argue that in engineering, knowledge is built

during projects through social interactions between

the two dimensions of knowledge: tacit (knowledge

that is linked to people or organization) and explicit

(knowledge that has been identified and formalized).

It is to be noticed that the latter is rather what we

call here “information” according to Wilson’s point

of view. The resulting dynamic relies on four modes

of knowledge conversion: socialisation,

externalisation, combination and internalisation.

Hansen et al. (Hansen et al, 1999) define

codification and personalisation approaches as the

two main knowledge management strategies. On the

one hand, the codification strategy is based on

knowledge formalisation and relies on information

repositories which enable users to access “codified

knowledge”. The codification strategy mainly

addresses the externalisation, combination and

internalisation modes of Nonaka’s knowledge

conversion model. On the other hand, the

personalisation strategy enhances knowledge sharing

through a socialisation process and is based on

knowledge networks. The underlying knowledge

conversion mode is mainly the socialisation.

Some research works try to combine both the

personalisation and the codification strategies in

associating information repositories and knowledge

networks (Mentzas et al, 2001). With the aim of

reducing the codification effort, Beylier also

proposes an approach integrating both strategies

(Beylier et al, 2008). The principle is to distribute

codification effort while fostering collaboration

between several experts. This approach proved to be

efficient, but the results have shown that a

continuous coordination effort is necessary to ensure

a satisfactory codification process. Our strategy fits

into this scheme of associating an information

repository, a knowledge network and a collaborative

workplace.

In addition, engineers involved in a design

process may be considered as knowledge workers

(Petroni et al., 2008) and a large amount of

knowledge is used and created during their daily

work. Therefore, intending to account for the whole

of this knowledge would not be sensible. Grundstein

introduces the notion of “crucial knowledge” to

point at knowledge that is essential for decision-

making process and for the progress of the value-

adding processes (Grundstein, 2008). Locating this

crucial knowledge then becomes a key element in

the knowledge management approach.

Following this brief literature review, the issue

of how relevant a knowledge management approach

in the context of special machine design is, leads us

to locate the crucial knowledge, to identify among

this knowledge relevant candidates for a codification

strategy, and to characterize the knowledge network

that should complete the proposal.

3 FIELD STUDY

3.1 Industrial Context

The study was carried out within a company which

designs, manufactures and sets up special handling

machines. These handling machines are designed to

be used in a nuclear environment. They thus meet

specific standards and are subjected to particular

constraints in terms of reliability and safety

(personnel protection, mainly from radioactivity).

The handling machines are overhead cranes for

heavy loads (from 30 tons up to 500 tons).

All the designed and produced machines are

single. They are prototypes and thus there are no

mass production effects. The company answers a

specific invitation to tender where the entire

infrastructure around the overhead crane is to be

designed. In this context, the company is usually

associated with a consortium of companies. The

design and manufacture of such a unit extend over

several months, even over several years.

3.2 Our Investigation Process

The investigation work proceeded within the design

department of the company. We stood as external

observers. Two main sources of information and

knowledge came out from this phase of

investigation:

technical documents, i.e. documentary

resources;

discussions with the people handling the

technical study of the machine, i.e. human

resources.

Figure 1 gives a schematic representation of the

activities undertaken by the observer in relation to

these two information sources. These activities are

described thereafter.

KMIS 2009 - International Conference on Knowledge Management and Information Sharing

124

3.2.1 Documentary Resources

In order to better understand the specificity of the

industrial context, we get back to the technical

documents used by the designers for the design

phase of a new project.

A first category relates to the documents attached

to previous and in progress projects. Each project

involves one or more requirement lists, setting up

plans, overall plans, costing, detail designs,

dimensioning, calculation and testing reports. All

these documents relate to each study of overhead

crane. Each project represents many files to be

studied. We analyzed a total of 13 projects.

Figure 1: The observation system.

A second category of documents is often used by

the designers to support their activities. They are

documents transverse to the various projects, related

with the competences of overhead cranes designers.

These documents are for example standards,

calculation codes, etc.

3.2.2 Human Resources

In parallel with the analysis of technical

documentation, we worked with several actors who

are involved in these projects. Three of them will be

shown to have a special role in the design:

a manager of the design department who

validates and directs the various proposals of

the design department,

a person in charge of welding, metallurgy and

materials,

an engineering analyst.

3.2.3 The Observer’s Approach

The work we have achieved led us to stand as

observers in relation with the above mentionned

documentary resources as well as the staff involved

in the technical process.

At an early stage of our investigations, we shot a

series of interviews with the Design Office Manager

- amounting to a total of 10 hours. Our goal was to

build an overall vision of how the Design Office

Manager addresses the study of a new handling

machine. More specifically, we aimed to identify the

various stages the Manager considered as key issues

in processing a project study as well as the main

features to take into account when starting to design

a crane. At that stage, using the video enabled us to

keep record of all the critical information we might

have missed otherwise, and to go back with further

discussions when needed.

In a second stage, we worked with both the

documentary and human resources described earlier.

We tried to account for every piece of information -

be it documentary-based or interview-based - by

addressing issues such as “Why does this piece of

information need to be used?” “Why does this action

need to be taken?” This enables the observer to first

get acquainted with the information and then to

build his own knowledge before redefining it in

order to convey it and make it as communicable as

possible for the designer. This stage is known as the

codification stage. At that point, in-depth

discussions with the designer are necessary in order

to enrich the codification of the information.

Finally, the validation stage enables the observer

to ensure that the information is fully understood

and properly rewritten.

The discussions with the designers took place at

four specific levels:

first, the industrial field level – which involved

introducing the industry and the technical

dimension;

second, the project level – issues regarding

people involved in the project and how it is

carried out were addressed;

third, the module level - which is used in

overhead cranes;

and finally, the component level (the

components are parts of the modules).

The content of the interviews with the designers

became more and more accurate as the technical

documents were analysed and as explanations about

the information analysed were made necessary.

3.3 Observations

In this paper, we will not go in great details on all

the observations we have made for two years but

rather focus on a particular issue which illustrates

the results we present in section 4.

Existing information

(technical data, reports,…)

Special machine designers

Observer

(Mechanical engineer)

Discussions,

interviews…

Analysis

Validation

MANAGING ENGINEERING KNOWLEDGE IN SPECIAL MACHINE DESIGN COMPANIES

125

End truck

Hoist motion

Direction

motion

Translation motion

Trolley

Building

Figure 2: A typical overhead crane.

Figure 2 shows an overhead crane that is under

study in the company. The crane is composed of:

a structure - usually known as the frame -

composed of an end truck and a trolley

designed with steel giders that are

mechanically welded;

a translation motion system that allows the

motion between the end truck and the

building;

a direction motion system that allows the

motion between the trolley and the end truck;

the hoist system.

The hoist system consists in rolling a wire rope

on a rope drum. As this system proved quickly a key

module in handling nuclear loads and as it is the

“know-how” of the company, we decided to put the

emphasis on this module. Besides analysing the

design of the “hoist system”, we also analysed the

design of a number of its components.

Shell of the drum

Rotative axis of the drum

Right hub

flange

Left hub

flange

Welded seams

Figure 3: Schematic design of the drum.

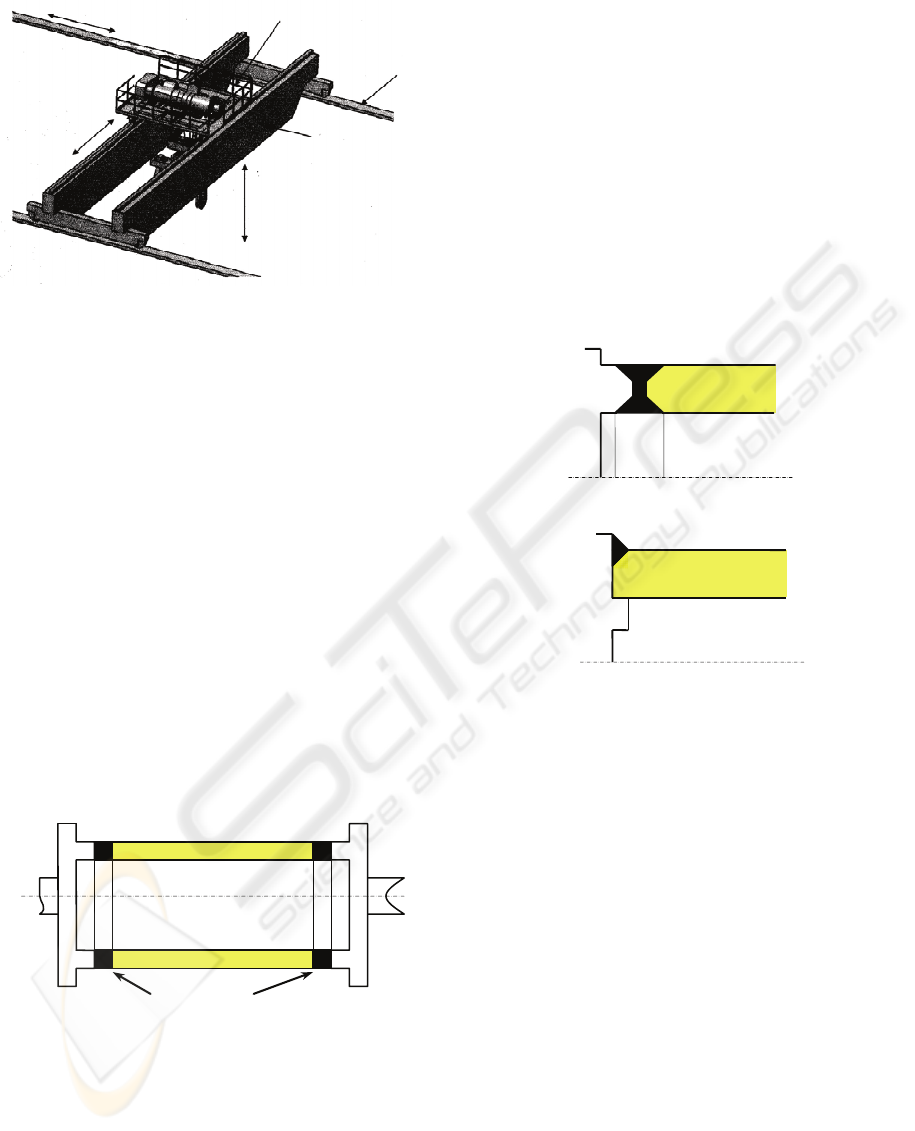

We only focus now on a key design rule for the

welded rope drum. This drum is made up of a

cylindrical hollowed shell and two cylindrical hub

flanges jointed to the shell as shown by figure 3. The

hub flanges are fit into the drum shaft.

Each of the two welded seams shown in figure 3

plays a major role for the drum design. All the

mechanical power developed by the drum shaft is

transmitted to the handled load through these joints.

Two categories of welded seam designs are

achieved: the welded butt seam and the welded T-

joint, as shown by figure 4. Both categories of

welded seams are not similar. As for the mechanical

strength is concerned, the welded butt joint is much

stronger than the T-joint. However, the welded butt

joint is much more difficult to achieve. As the shell

of the drum and the hub flange have to be processed,

as they also require more specific machining before

welding and need to be precisely positioned, the

welded butt joint proved more costly than the

welded T-joint.

Welded butt seam with a

double-V preparation

Shell of the drum

Rotative axis of the drum

Shell of the drum

Rotative axis of the drum

Welded T-joint with a

single-V preparation

Left hub

flange

Figure 4: Two categories of welded seams.

After having described the field study, we will

now present the results achieved so far regarding the

“Knowledge Management” in our industrial context.

4 RESULTS

Our field observations make it possible to highlight

some results of interest. These are structured around

three key issues: the identification of recurrences,

the role of technical experts, and the importance of

rules at the interface of expertise.

4.1 Many Recurrences

We first notice that in spite of the unique nature of

each project, the special machine design process

shows many recurrences:

at the customer level and the associated

requirements. The response to an invitation to

tender and the proposed technical solutions are

widely linked with the customer under

Left hub

flange

KMIS 2009 - International Conference on Knowledge Management and Information Sharing

126

consideration. It is known for example that for

the customer X a Y-type drum is required;

at the level of the approach to be used in

carrying out a new design study. In view of the

wealth of information, the uncertainties of a

project, the standards to be met, the designer

has the ability to develop an approach which,

on the whole, will be repeated over the

following projects, or whose specificities can be

spotted;

at the level of the architecture and of the

different modules of the system. For example,

all the handling equipments that we analysed

involve the same technology: a wire rope is

used to hang the load. The design of the hoist

module is repeated over the projects;

at the component level. For example, it was

observed that the hoist module always includes

a rope drum, a geared motor, a braking device,

a wire rope and a tackle block.

While these recurrences are more particularly

observed between the different design projects, some

others also exist at the inside of the projects. The

welded seam shown in the previous section is an

example of such recurrence. Defining a welded seam

is a common situation within a handling equipment

design. Welded seams are even a crucial issue in the

special machine domain which widely involves this

assembling technology.

In a special machine context, the existence of

these numerous and multi-level recurrences was far

than obvious. It is to be noticed that the designers

themselves were unaware of that at the beginning of

our study. This result is of great importance to

legitimise and to adjust the codification part of our

knowledge management strategy.

4.2 The Key Role of Technical Experts

During the observations, it also rapidly became

apparent that some of the participants in the

handling equipment design have a special role in the

process. Regarding the design of the drum for

example, three people were involved in the main

technical decisions: the experienced designer, the

engineering analyst, and the metallurgist. All are

known by their colleagues to be particularly skilled

in their domain. They are considered as experts and

take part in the design process in different ways:

they carry out their own design tasks, as the

other stakeholders of the design do;

they define the design approach which fits at

best with the requirements of the current

project. They put the project on the right track;

they provide the design teams with technical

advice when needed.

In order to achieve that, they mobilize different

kinds of knowledge, and more particularly:

knowledge in relation with regulation

(standards in force and, above all, action rules

that they built to use these standards);

technical knowledge (principles of solutions,

design rules, limitations…). An example is the

design rules they use to define the welded

seams for the drum;

knowledge in relation with the customers and

their expectations;

knowledge of the previous projects. This

includes the lessons learnt.

As for the recurrences previously pointed out, the

existence of these experts and the role they play are

of major interest for defining the knowledge

management approach. This participates in locating

the crucial engineering knowledge. This also gives

some elements for defining the required knowledge

networks (personalisation strategy).

4.3 Needs for a Collaborative Device

Considering the different kinds of welded seams

described in section 3.3, each of the three experts we

previously pointed out uses the same explicit rule:

the welded seam between the shell of the drum and

the hub flange must be a welded butt seam. But it

came out from the discussions that their related

knowledge was not the same:

from the design office expert point of view,

compared with a welded T-joint, a welded butt

seam improves the joint mechanical strength.

This gets rid of stress concentration areas which

could lead to a material breaking point;

from the engineering analyst point of view, the

strength of a welded butt seam is calculable

because of the material continuity between the

drum and the hub flange. As there is no

continuity with a welded T-joint it is impossible

to have a reliable modelling for strength

calculation;

from the metallurgist point of view, welding

crack initiation occurs when hydrogen atoms

are included in the welding. Welding

techniques exist to avoid embedding such

particles. But ultrasound or X-ray checking is

necessary after welding operations for

certification. Only a welded butt seam can be

checked by ultrasound or X-ray checking.

Therefore, while the action rule seems to be the

same, its justification by each expert is different. As

MANAGING ENGINEERING KNOWLEDGE IN SPECIAL MACHINE DESIGN COMPANIES

127

we attended to this work, a common and shared

welding design rule emerged from our instigation:

“A welded butt seam will be used when this welded

seam has to be checked. Such choice will make it

possible to validate the calculation hypothesis of

material continuity”.

An important corollary appeared immediately: “If

the specifications list or the calculation code do not

require checking the welded seam, then a less

expensive welded T-joint has to be chosen”.

This example shows that our presence as

observer (and knowledge management actor) gave

the experts the opportunity to share and define a

design rule at the interface of the three expertises.

An autonomous collaborative building of such a rule

requires a device (including areas, tools, methods…)

enabling experts to share their points of view. The

role of such a device is to help experts in

personalisation and codification strategies. We could

make the hypothesis of the relevance of the rule

justification as a means to support these strategies.

While the welding issue was the example we use

in this paper to put forward the necessity of a device

to allow codification and personalisation strategies,

we met other design situations (crane structure, hoist

system) where it could also be relevant.

5 CONCLUSIONS

In this paper, the analysis of a company producing

special machines has been conducted in order to

envisage how feasible knowledge management in

such context is. After discussing briefly the concepts

of information and knowledge and analysing the

present strategies relevant to implement a crucial

knowledge management approach, the context and

the investigations carried out have been described.

The observation analysis led us to some results

showing that a knowledge management approach is

relevant in the context of special machines.

First, in spite of the unique nature of each

project, the existence of numerous and multi-level

recurrences has been observed. This result is of great

importance to legitimise and to adjust the knowledge

management strategy.

Second, the recognized existence of experts and

the role they play are of major interest for defining

the knowledge management approach. This

participates in locating the crucial engineering

knowledge and gives some elements for defining the

required knowledge networks.

Third, we showed the necessity of a collaborative

device to allow codification and personalisation

strategies because it has been proved that different

experts in the same company should explicit

differently the same design rule.

To sum up, for knowledge management in a context

of special machine design, it is necessary to identify

expert people and crucial engineering knowledge, to

point out the recurrences and their level, and to give

means at disposal for confrontation between experts.

With this aim in view, works are in progress to

develop such an adapted collaborative device.

REFERENCES

Ahmed, S., Blessing, L., Wallace, K. M., 1999. The

relationships between data, information and

knowledge on a preliminary study of engineering

designers. In: ASME, Design Engoneering Technical

Conference. Las Vegas, 12-15 september 1999.

Beylier, C., Pourroy, F., and Villeneuve, F., 2008. A

collaboration-centred approach to manage engineering

knowledge: a case study of an engineering SME.

Journal of Engineering Design.

Briggs, H. C., 2006. Knowledge management in the

engineering design environment. In: AIAA,

Structures, Structural Dynamics,and Materials

Conference. Newport, USA, 1-4 may 2006.

Gardoni, M., Dudezert, A., 2005. Valuing Knowledge

Management Impact on Engineering Design

Activities. In: The Design Society, International

Conference on Engineering Design, Melbourne, 15-18

august 2005.

Grundstein, M., Rosenthal-Sabroux, C., 2008. GAMETH,

A Process Modeling Approach to Identify and Locate

Crucial Knowledge, In: Knowledge Generation,

Communication and Management. Orlando, USA,

june 29

th

- july 2

nd

, 2008.

Hansen M. T., Nohria N., Tierney T., 1999. What’s Your

Strategy for Managing Knowledge? Harvard Business

Review, 77(2), pp.106-116.

Matta, N., L’Hédi, Z., 2008. Applications of Knowledge

Engineering Approaches for Design. In A. Bernard, S.

Tichkiewitch, eds. Methods and Tools for Effective

Knowledge Life-Cycle-Management. Berlin: Springer.

pp.363-373.

Mentzas, G., Apostolou D., Young R., Abecker A. 2001.

Knowledge networking: a holistic solution for

leveraging corporate knowledge. Journal of

Knowledge Management, 5, pp.94-107.

Nonaka, I., Takeuchi, H., 1995. The Knowledge-Creating

Company. Oxford University Press. New-York.

Petroni, A., Colacino, P., 2008. Motivation strategies for

knowledge workers: evidences and challenges.

Journal of Thechnology Management & Innovation,

3(3), pp.21-29.

Wilson, T. D., 2002. The nonsense of knowledge

management. Information research, 8(1), paper n.144.

KMIS 2009 - International Conference on Knowledge Management and Information Sharing

128