IMPLEMENTATION OF A FUZZY LOGIC SYSTEM ON A FPGA

FOR A SERVO CONTROLLER

Arturo Téllez V., Luis A. Villa V., Herón Molina L. and Oscar Camacho N.

Centro de Investigación en Computación, Instituto Politécnico Nacional

Juan de Dios Batiz Ave. s/n, Nueva Industrial Vallejo, Mexico City, Mexico

Keywords: DC Servo Control, Fuzzy Logic Controller, Fuzzy Sets Adaptation, Combinatorial Design, FPGA,

Hardware.

Abstract: In this paper we propose a digital fuzzy logic system implemented on a field programmable gate array

(FPGA) in order to control a servo controller. The fuzzy logic controller (FLC) is designed as a

combinational circuit and does not depend on a clock signal. So the advantage is that the fuzzy system is

enough fast to control a servo controller. For the implementation of the membership functions (MF) we

propose to use dynamic MF, i.e. the parameters that define the each MF are adapted on line. Also, for the

design of fuzzy system a new methodology was developed so the design and implementation of the fuzzy

system is easy to do. The fuzzy system was programmed in MATLAB and was proved that the fuzzy system

is capable to control a servo motor. Finally the performance of the fuzzy system was proved directly on the

FPGA.

1 INTRODUCTION

There had been many implementations of hardware

FLC since the first one (Togai, 1986). Each one with

some differences related to the processing way.

A FLC can be implemented in three forms:

Runtime Computing (RTC), Lookup Computing

(LUC) or mixed. It can also be combined with

several computer architecture techniques like

combinatorial, sequential, pipelined and mixed

processing, implemented in a computer, a

microcontroller or any programmable device.

The use of FPGA in a reconfigurable device has

been suitable when talking about versatility to make

any digital design by means of costs and design

time. It is a dare to play with these architectures and

techniques to make an appropriated FLC design, by

which it is necessary to change the way of designing

algorithms to describe an improved FLC.

This paper shows a practical approach for the

design of a combinatorial FLC for a DC servo using

simple construction modules on a FPGA in order to

speed up the FLC prototyping.

2 FUZZY LOGIC CONTROLER

This FLC uses a Mamdani fuzzy model. The Fuzzy

system is described by the next equation:

(1)

Where is the system output,

, and

,

,...,

;

= center of the

output of each membership function. Each input is

assigned to a set of membership functions, for

instance,

represents all possible membership

functions for the first input variable. The FLC only

uses triangles, S and Z membership functions for

fuzzy sets.

This FLC has only two inputs and one output,

each input is described by three membership

functions which were implemented in hardware

according to equations 2- 4, which are shown in

Figure 1.

The Triangle function is described by:

89

Téllez V. A., Villa V. L., Molina L. H. and Camacho N. O. (2009).

IMPLEMENTATION OF A FUZZY LOGIC SYSTEM ON A FPGA FOR A SERVO CONTROLLER.

In Proceedings of the International Joint Conference on Computational Intelligence, pages 89-93

DOI: 10.5220/0002323700890093

Copyright

c

SciTePress

,

,

,

0,

(2)

The S function is described by:

,

,

0,

(3)

And the Z function is described by:

,

,

0,

(4)

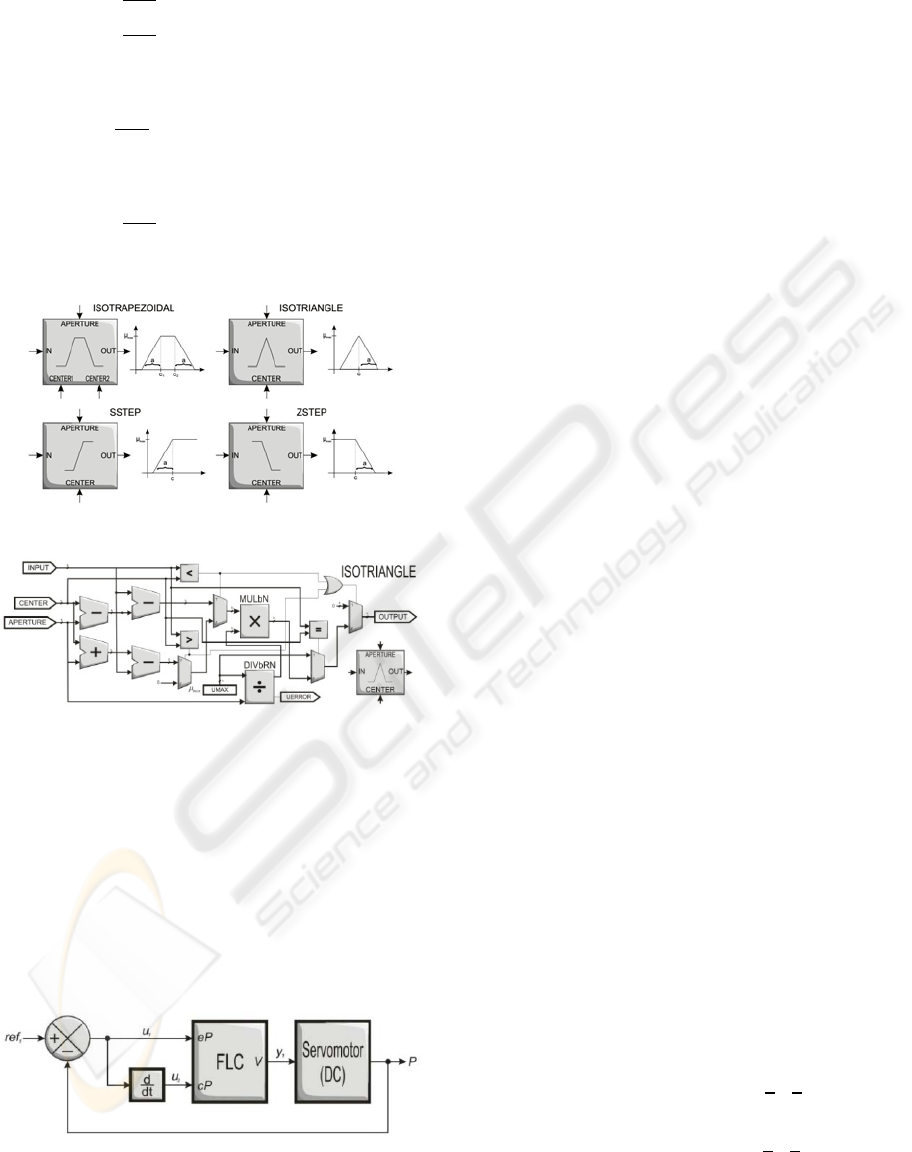

Figure 1: Several hardware suitable membership functions.

Figure 2: Design of an isosceles triangle as membership

function.

All the register transfer level (RTL) description,

which shows the design of data flow, was made with

VHDL. As shown in Figure 2, triangular function

uses division and multiplication algorithms. Also, S

and Z functions describe a similar performance.

Next section shows the design methodology that

was purposed for building combinatorial FLC, and

the architecture of each module of the fuzzy system

controller for the servo.

Figure 3: Fuzzy Logic Control System for a DC servo

motor.

3 DESIGN

FPGA technology facilities and advantages let the

designer to build any fuzzy system in short time. We

purpose a fast and simple approach for FLC design

which consists with eight steps in order to

implement it on FPGA:

1. Establish whatever the designer want to control

and which variables will be related. Define the

number of inputs and outputs of the FLC.

2. Define the universe of discourse for each input

and output variable based on the process

characteristics.

3. Define the number and shapes of fuzzy sets for

every variable based on the last step.

4. Establish the FLC configuration by means of

the fuzzy inference rules according to the

wished operation and based on the expert

knowledge about the process.

5. Build the fuzzifier using simple membership

functions connected in parallel.

6. Build the inference machine based on step 4,

by means of MIN- MAX modules.

7. Build the defuzzification stage by means of

multiplication and division modules using

parallelism.

8. Implement the design on FPGA.

Considering the FPGA limitations, it is possible to

build any fuzzy system.

STEP 1. Assume a fuzzy control system for a

DC servomotor which consists of two inputs and

one output, as shown in Section 2. First input

variable

is the rotor “position error” which is

the difference between current position and

desired position. Second input variable

is the

change of that position error (“change in

position”) in order to know if the error is

increasing or decreasing. The output variable

is the needed applied voltage to move the rotor

servo to a certain position (Figure 3).

STEP 2. Before choosing the number of

membership functions or fuzzy sets for this

system, it is needed to establish the size of the

discourse universe for every variable. Expert

should purpose those values. So, position error

must be expressed in radians () and it must

not be greater than half turn –

,

. And

change in position should accept non- abrupt

changes in error position –

,

; this

variable rises from position error derivative. For

every input it is required to get the minimum

possible error as possible or zero. This ranges let

IJCCI 2009 - International Joint Conference on Computational Intelligence

90

the FLC to control the servo rotor position by

means of varying the voltage supply from -5 to 5

volts.

STEP 3. Once the universe of discourse is

defined, the designer may purpose the number

and the shape (membership function) of the

fuzzy sets and establish their linguistic meaning.

By simplicity, for every variable, we purpose

three fuzzy sets that describe the triangular, S

and Z membership functions, and their linguistic

labels for every variable. For position error: NE

(negative error), ZE (zero error) and PE (positive

error); for change in error variable: NC (negative

change), ZC (zero change) and PC (positive

change); and for voltage variable: NV (negative

voltage), ZV (zero voltage) and PV (positive

voltage). The fuzzy sets distribution is a task for

the designer also.

STEP 4. The FLC configuration is made by

their rule set. The number of rules (Equation 5)

is defined by the number of fuzzy sets per input

variable (

number of fuzzy sets for input

position error,

number of fuzzy sets for input

change in position):

3

3

9

(5)

These nine rules are nine possible cases that may

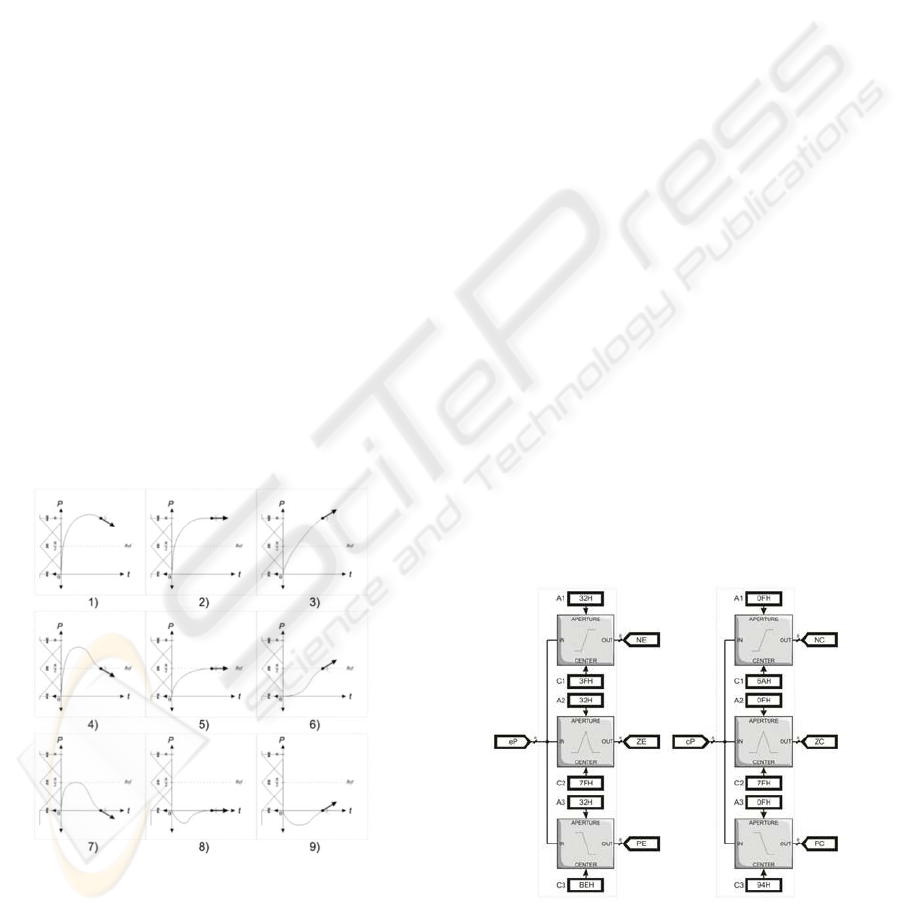

occur in the FLC inputs, shown in Figure 4.

Figure 4: Graphical representation of nine rule cases for

the servo application.

In order to get the right FLC configuration it is

needed to analyze the process entirely for covering

all the possible cases in which it exist a non- desired

operation. So, FLC can assure there is a concrete and

exact value in its output that contributes for a right

control action.

Then, the rule set can be built this way:

1.

IF

e

P

isNEAND

c

P

isNC THEN

V

isNV

2.

IF

e

P

isNEAND

c

P

isZC THEN

V

isNV

3.

IF

e

P

isNEAND

c

P

isPC THEN

V

isNV

4.

IF

e

P

isZEAND

c

P

isNC THEN

V

isNV

5.

IF

e

P

isZEAND

c

P

isZC THEN

V

isZV

6.

IF

e

P

isZEAND

c

P

isPC THEN

V

isPV

7.

IF

e

P

isPEAND

c

P

isNC THEN

V

isPV

8.

IF

e

P

isPEAND

c

P

isZC THEN

V

isPV

9.

IF

e

P

isPEAND

c

P

isPC THEN

V

isPV

STEP 5. Due to the use of RTC approach, it is

possible to build a combinatorial FLC that may

change its fuzzy set parameters on line,

regardless on their shape. Symmetric trapezoidal,

triangular, S and Z membership functions are

practical and suitable fuzzy sets for

implementing on FPGA.

STEP 6. All these membership functions,

shown in Figure 1, use the arithmetic operation

of division and multiplication for calculating

their corresponding slopes. In step 3, it was

chosen triangular, S and Z functions for the

fuzzy sets of every variable of the FLC fuzzifier,

so it is needed to establish their parameters

according to their corresponding range. This

range must be scaled according to the FLC bits

number. This way, fuzzifiers in Figure 5 show

parallel operation. Notice every fuzzy set

parameter can be changed simply by modifying

their register values.

Figure 5: Fuzzifiers for servo application. Every input

variable has three fuzzy membership values.

IMPLEMENTATION OF A FUZZY LOGIC SYSTEM ON A FPGA FOR A SERVO CONTROLLER

91

Figure 6: Inference Machine for servo application. All

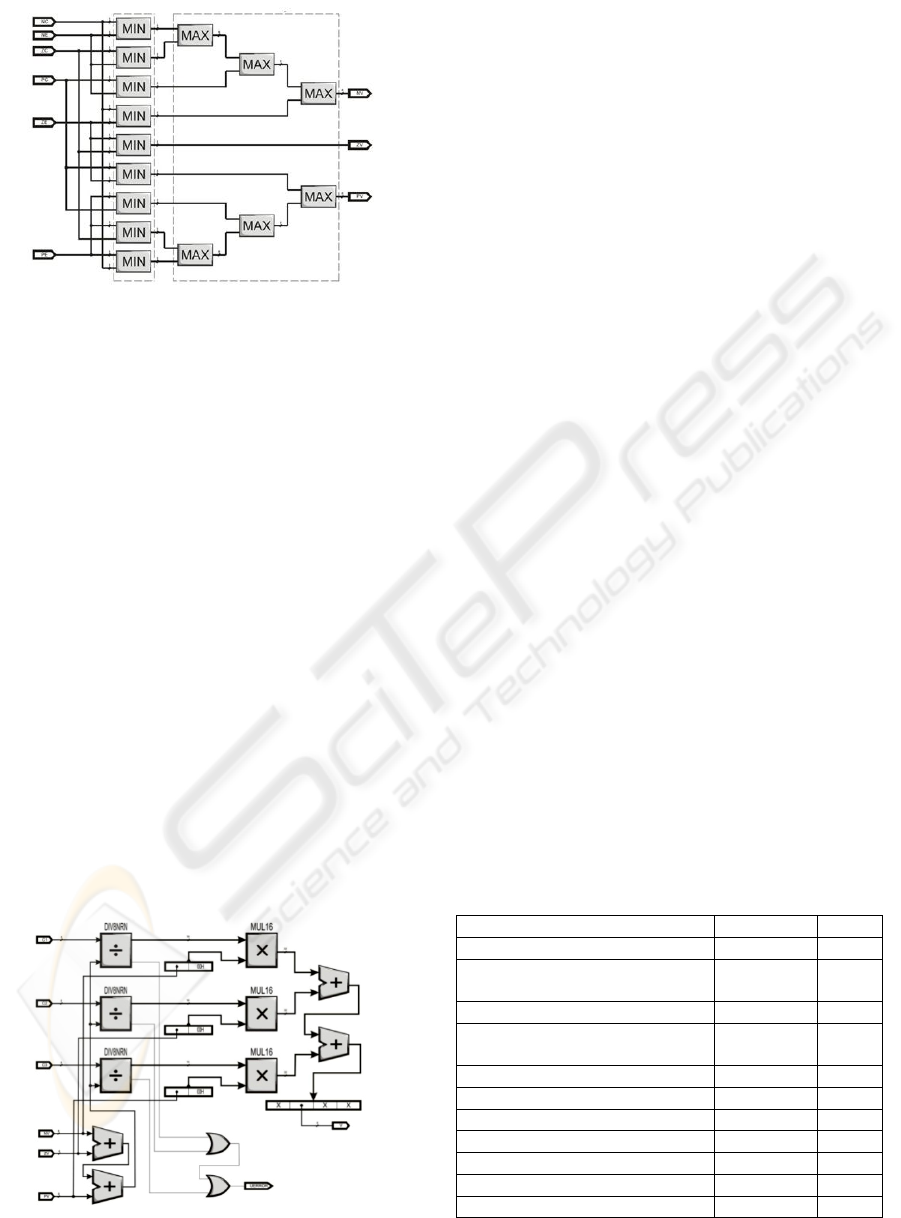

implied premises drive to a consequence.

STEP 7. Inference Machine is made using

Mamdani Implication Method, where all every

output relates all the implied premises using

simple MIN/ MAX operations according to the

rule set, established in step 4. Figure 6 shows this

rule set by means of combinatorial circuit

connections.

STEP 8. Defuzzification is needed for

converting all fuzzy values onto crisp values in

order to use them for a specific control action.

RTC combinatorial fuzzification stage let the

expert change the singleton positions over the

output discourse universe on line. This

defuzzifier uses centroid technique, where every

singleton position is divided (modified non-

restoring division) by the summation of the

membership values obtained from the inference

machine and this result is multiplied by every

fuzzy value obtained from the inference

machine. Finally every multiplication result is

summed in order to obtain the crisp output.

Figure 7 shows this RTL design for this servo

application.

Figure 7: Defuzzification stage for servo application.

Centroid calculation.

STEP 9. Finally, once this design is

synthesized for a FPGA it is ready to upload.

Designer should take in account the pins number

in order to fit the specific application. Due this

application has only two inputs and one output

there is not any problem to fit the most of recent

FPGAs.

4 RESULTS

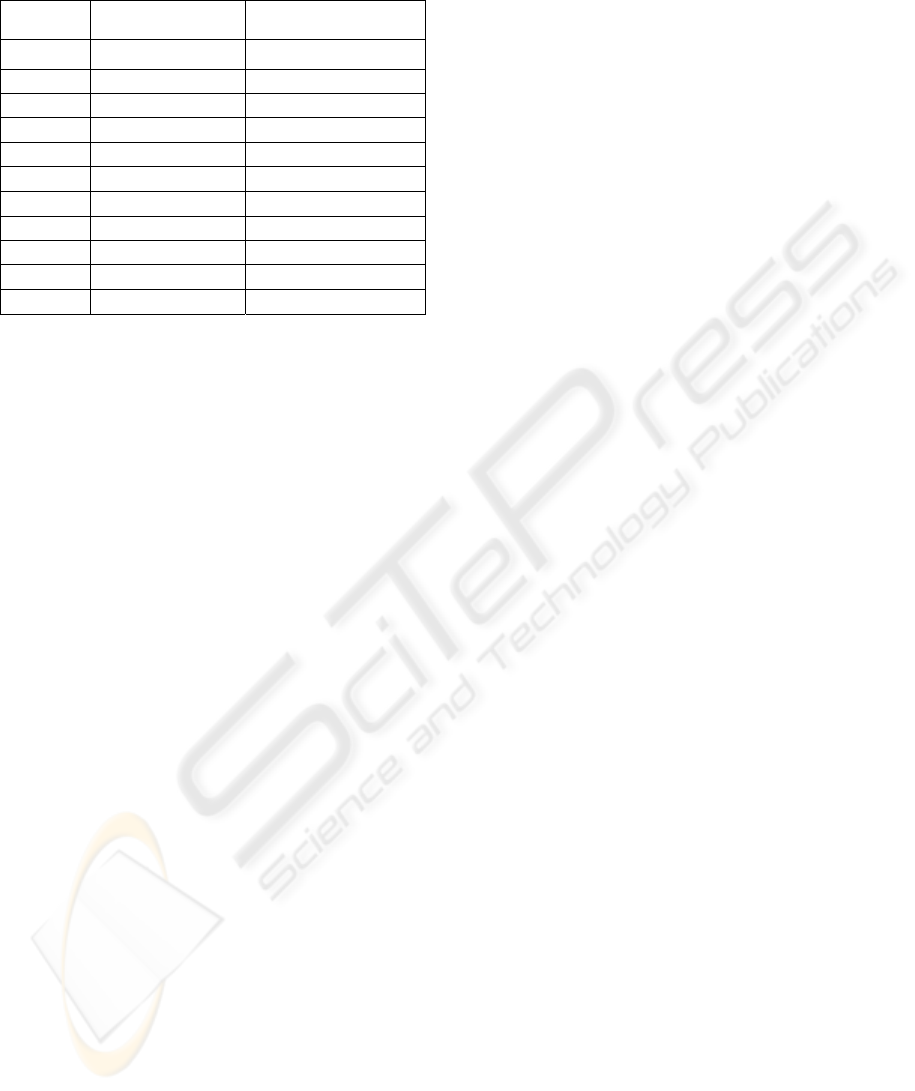

A general result for FPGA implementation was

obtained and this is resumed in Table 1 for Xilinx

Spartan FPGA starter kit. This results mean show

the delay time each module takes and the entire FLC

performance. Also, it is shown the total used LUTs

in FPGA resources.

Division algorithm is the slowest module in the

FLC. So, the more the division algorithm

performance improvement is made the more the

FLC performance will increase.

This fuzzy system was built in MATLAB Fuzzy

Toolbox first (FIS). Then it was chosen a set of

representative values called test bench and it is

applied to the FIS in order to prove the FLC

performance once it is implemented in FPGA kit.

DC servo FLC needs 84 ns to make an inference.

Then, its processing data rate is 11.9 MFLIPS. Table

2 shows a set of FLC implemented on FPGA with

RTC, LUT and mixed approaches, with similar FLC

configuration, but for different applications. Each

implemented FLC has similar and higher

performance compared with the purposed in this

paper, but the advantage of this method is the easy

scaling for system improvement or other application

designs.

Table 1: FPGA timing and resource results obtained for

DC servo control.

Algorithm Delay (ns) LUT

16 bits non-restoring division 48.50 644

Modified 8 bits non-restoring

division

28.83 208

8 bits multiplication 13.17 36

Isosceles triangle MF

36.70

14.51

251

S-step MF 36.70 249

Z-step MF 36.70 251

Fuzzifier 37.42 755

Defuzzifier 41.49 677

Mamdani inference machine 19.32 242

MIN-MAX operations 9.36 16

FLC 84.01 2689

IJCCI 2009 - International Joint Conference on Computational Intelligence

92

Table 2: Other hardware FLC with similar fuzzy systems.

Velocity performance comparison.

MFLIPS Device Autor

50.00 Undefined (Manzoul, 1995)

50.00 Undefined (Lund, 2000)

15.38 Xilinx XC3S1500 (Deliparaschos, 2005)

11.90 Xilinx XC3S200 (Tellez, 2008)

10.00 Xilinx XC3042,64 (Kim, 1997)

9.00 Xilinx XC4008 (Hung, 1994)

8.00 Altera EPF8820 (Aranguren, 1997)

5.56 Xilinx XC3S200 (González, 2007)

3.13 Xilinx XC3S1000 (Sánchez, 2007)

2.00 Xilinx XCV600E (Gaona, 2003)

0.08 VLSI (Togai, 1986)

5 CONCLUSIONS

A fuzzy logic controller was designed and

implemented on FPGA. Specifically the FLC was

implemented on a Xilinx design board. The

architecture of the system was implemented by

arithmetic modules by using combinational logic. In

order to implement the fast FLC prototyping we

proposed a methodology design of 8 basic steps. The

digital design was development with VHDL. Each

module was proved with ModelSim XE III Starter

version. The FLC has the characteristic that the

parameters of the membership functions are variable

on line. The complete fuzzy system for a servo

motor was probed with MATLAB and ModelSim.

ACKNOWLEDGEMENTS

Research supported by the Instituto de Ciencia y

Tecnología ICyTDF funding (Award No. PICCT08-

22) and by matching funding by IPN (Award No.

SIP/DF/2007/143).

REFERENCES

Téllez, A., 2008. Fuzzy Logic Controller Architecture

using Combinatorial Logic, Instituto Politécnico

Nacional. Centro de Investigación en Computación.

Mexico City.

Patyra, M. J.; Mlynek, D.M.; “Fuzzy logic:

implementation and applications;” Wiley; 1996.

Oberman, S. F.; Flynn, M. J.; “Division Algorithms and

Implementations;” IEEE Transactions on Computers;

Aug 1997; Vol 46, No. 8; pp. 833–854.

Togai M.; Watanabe H.; “Expert system on a chip: An

engine for real–time approximate reasoning;” IEEE

Expert Syst. Mag., 1986, pp. 55–62, Volume 1.

Manzoul, M.A.; Jayabharathi, D.; “FPGA for fuzzy

controllers;” Systems, Man and Cybernetics, IEEE

Transactions, 1995, pp. 213–216, Volume 25, Issue 1.

Lund, T.; Torralba, A.; Carvajal, R.G.; “The Architecture

of an FPGA–Style Programmable Fuzzy Logic

Controller Chip;” Computer Architecture Conference,

2000. ACAC 2000. 5

th

Australasian, 31 January–3

February 2000, pp. 51–56.

Deliparaschos, K.M.; Nenedakis, F.I.; Tzafestas, S.G.; “A

fast digital fuzzy logic controller: FPGA design and

implementation;” Emerging Technologies and Factory

Automation, 2005. ETFA 2005. 10

th

IEEE

Conference, 19–22 September 2005, Volume 1.

Kim Young Dal; Hyung Lee–Kwang; “High Speed

Flexible Fuzzy Hardware for Fuzzy Information

Processing;” Systems, Man and Cybernetics, Part A,

IEEE Transactions, January 1997, pp. 45–56, Volume

27, Issue 1.

Hung, D.L.; “Custom design of a hardware fuzzy logic

controller;” Fuzzy Systems. IEEE World Congress on

Computational Intelligence, Proceedings of the Third

IEEE Conference, 26–29 June 1994, pp. 1781–1785,

Volume3.

Aranguren, G.; Barron, M.; Arroyabe, J.L.; Garcia–

Carreira, G.; “A Pipe–line Fuzzy Controller in

FPGA;” Fuzzy Systems, 1997. Proceedings of the

Sixth IEEE International Conference, 1–5 July 1997,

pp. 635–640, Volume2.

Gonzalez, J.L.; Castillo, O.; Aguilar, L.T.; “FPGA as a

Tool for Implementing Non–fixed Structure Fuzzy

Logic Controllers;” Foundations of Computational

Intelligence, 2007. FOCI 2007. IEEE Symposium, 1–5

April 2007, pp. 523–530.

Sanchez–Solano, S.; Cabrera, A.J.; Baturone, I.; Moreno–

Velo, F.J.; Brox, M.; “FPGA Implementation of

Embedded Fuzzy Controllers for Robotic Applica-

tions;” Industrial Electronics, IEEE Transac-tions,

August 2007, pp. 1937–1945, Volume 54, Issue 4.

Gaona, A.; Olea, D.; Melgarejo, M.; “Sequential Fuzzy

Inference System Based on Distributed Arithmetic;”

Computational Intelligence for Measurement Systems

and Applications, 2003. CIMSA ’03. 2003 IEEE

International Symposium, 29–31 July 2003, pp. 125–

129.

IMPLEMENTATION OF A FUZZY LOGIC SYSTEM ON A FPGA FOR A SERVO CONTROLLER

93