SIMPLY FABRICATED PRECISE MICROFLUIDIC MIXER

WITH RESIST FLOW PATHS SEALED BY AN ACRYLIC LID

Toshiyuki Horiuchi, Hiroyuki Watanabe

1

, Naoki Hayashi

2

and Takuya Kitamura

3

1

Toshiba Mobile Display, Co., Ltd.,

2

CANON Inc.,

3

Nagano Electronics Industrial Co., Ltd.

Precision Engineering, Tokyo Denki University, 2-2, Kanda-Nishiki-Cho, Chiyoda-Ku, Tokyo, Japan

Keywords: Microfluidic mixer, Microfluidic device, Thick resist, Flow path, Aspect ratio.

Abstract: A microfluidic mixer was simply and easily fabricated using 380-μm thick patterns of negative resist SU-8

as flow paths and sealing the paths by an acrylic lid plate. The SU-8 was mainly composed of epoxy resin,

and it was hardened by the baking after the development. Because the too narrow flow paths were not

practical, the target width of the flow-path was set at 30-100 μm. The aspect ratio limit for 1:1 line-and-

space patterns increased when the pattern width became large and the lower numerical-aperture or higher F-

number projection lens was adopted. The maximum aspect ratio for line-and-space patterns with a width of

26-53 μm was 6.5-8, corresponding to the pattern width and the numerical aperture. After snail-shape flow-

path groove patterns were successfully fabricated, the resist block was covered by an acrylic lid plate and

sealed using screws. After microtubes were attached to the entrance and exit holes, red and blue colored

waters were injected into the two entrance tubes. As a result, two waters were mixed while passing through

the snail-shape paths, and dark purple water was ejected from the exit. It was successfully verified that the

easily and simply fabricated microfluidic mixer actually worked well.

1 INTRODUCTION

Among a lot of biodevices, microfluidic reactor,

mixer and other modules used for sensing and

analyzing are the most important and useful devices.

For this reason, various fabrication methods of

microfluidic devices are proposed. For example, fine

grooves are mechanically cut on the surfaces of

slide-glasses or quartz plates. Glassy materials are

chemically stable and not reactive. Accordingly,

they are suitable for the materials to fabricate

chemical-use devices. However, because the glassy

materials are fragile, it is difficult to make dense and

deep grooves. Moreover, it takes a long time to

machine the materials.

In most cases, microfluidic devices mentioned above

are thrown away after once they are used.

Accordingly, they should be easily fabricated with a

low cost. For this reason, various fabrication

methods using the technologies for applying to

Micro Electro Mechanical Systems (MEMS) are

developed. Most of MEMS microfluidic devices

directly use the resists such as poly-dimethyl-

siloxane (PDMS) (Lien, 2008) (Lei, 2008)

(Casquillas, 2008), SU-8 (Tsai, 2006) (Yang, 2007)

and poly-methyl-methacrylate (PMMA) (Nugen,

2009) as flow paths. Some of the proposed devices

used the combination of the plural resists (Kontakis,

2009) (Lo, 2008) (Ho, 2008).

On the other hand, similar flow paths are also

formed by etching silicon or glass substrates using

the resist patterns printed by lithography as the

etching masks (Avram, 2008) (Eun, 2008).

However, because most of the proposed methods

require complicated long processes, high fabrication

costs are anticipated. For this reason, a simple and

easy but highly accurate and useful fabrication

method of microfluidic devices is investigated here.

Dense and deep microfluidic patterns are printed

using thick SU-8 resist films mainly composed of

epoxy resin. It is not difficult to print high-aspect

patterns if the appropriate projection exposure

conditions are selected. Therefore, good flow paths

are fabricated by a simple lithography process. Once

the resist is sufficiently baked, it is hardened and

works like normal plastics. Accordingly, the baked

resist patterns are effectively used as flow paths of

throw-away microfluidic devices.

In this paper, investigation on the thick resist

patterning process is shown, and the aspect ratio

82

Horiuchi T., Watanabe H., Hayashi N. and Kitamura T. (2010).

SIMPLY FABRICATED PRECISE MICROFLUIDIC MIXER WITH RESIST FLOW PATHS SEALED BY AN ACRYLIC LID.

In Proceedings of the Third International Conference on Biomedical Electronics and Devices, pages 82-87

DOI: 10.5220/0002715100820087

Copyright

c

SciTePress

limit for 1:1 line-and-space patterns is clarified

correlating with the numerical aperture (NA) of the

projection lens. In addition, a precise microfluidic

mixer is actually fabricated. Two colored waters are

successfully mixed using the fabricated device.

2 PATTERNING CONDITIONS

In this research, negative SU-8 100 (MicroChem

Corp.) was used as a resist. Referring to the material

composition description provided by the supplier,

SU-8 is composed of Epoxy Resin of 35-75%,

Gamma Butyrolactone of 20-60%, Mixed

Tryarylsulfonium/Hexafluoroantimonate Salt of

3.5%, and Propylene Carbonate of 1-5%. Patterning

process conditions used in the experiments are

shown in Table 1. The SU-8 was coated on copper-

clad plastic substrates and silicon wafers in

thicknesses between 65-420 nm. Thick films were

obtained by double or triple repetitions of resist

coating and baking.

The copper-clad plastic substrates were used

because various electrode patterns are easily formed,

if necessary. Moreover, metals are directly

electroplated on them for fabricating the injection

molds. On the other hand, silicon wafers were used

to observe the cross sections of patterns by snapping

them along the crystal direction.

Table 1: Patterning conditions of SU-8.

Resist patterns were printed using a handmade

simple exposure system (Hirota, 2003). The

specifications are shown in Table 2. The system uses

a camera lens as a projection lens, and the numerical

aperture or the F-number is controllable.

It was clarified that the maximum aspect ratio

depended on the F-number, and the larger the F-

number was, the higher aspect ratio was obtained.

When the patterns were printed under various F-

number conditions, the highest aspect patterns

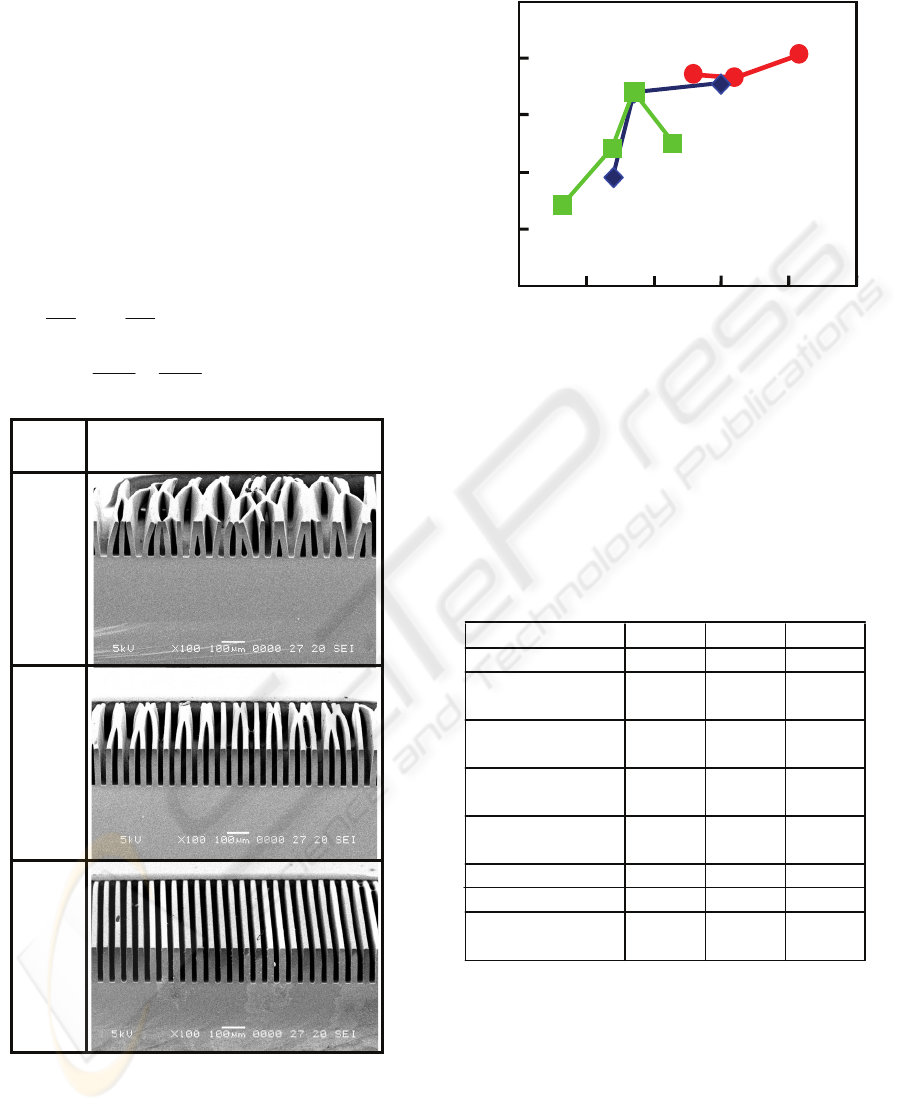

shown in Fig. 1 were printed (Horiuchi, 2008).

Table 2: Specifications of the exposure system.

Figure 1: High aspect patterns obtained under various

F-number conditions.

The critical factor deciding the aspect ratio was not

the pattern collapse but the depth-of-focus (DOF) for

securing sufficient image contrast throughout the

resist thickness. The pattern collapse was prevented

by giving sufficient exposure dose, as shown in Fig.

2. The highest aspect ratio for 1:1 line-and-space

patterns became as shown in Fig. 3, and they were

6.5-8.0 for F-numbers of 5.6-11.2,

(c)

F: 11.2

Width: 52.6µm

Thickness: 420 µm

Aspect ratio: 8.0

(b)

F-number: 8

Width: 42.1µm

Thickness: 300 µm

Aspect ratio: 7.1

A little resist remains at

the bottom.

(a)

F-number: 5.6

Width: 31.6µm

Thickness: 170µm

Aspect ratio: 5.4

Wavelength: 290-440 nm

Camera lens (Yashika), F=2.8-16

Ultra-violet lamp, LS-140UV

Reduction ratio

Item

Light source

1/19

2.2 mm square

Projection lens

X and Y: ±6.5 mm, Z: ±5mm

Field size

Specification

(Sumita Optical Glass)

Wafer stage

Process

Pre-bake

Step2: 50 min at 95°C in an oven

1/19 low-NA projection exposure,

Dip in SU-8 developer, 5-40 min

Step1: 20 min at 65°C in an

oven

Exposure

Rinse in 2-propanol, 1-2 min

Development

Condition

4-10 min

SIMPLY FABRICATED PRECISE MICROFLUIDIC MIXER WITH RESIST FLOW PATHS SEALED BY AN

ACRYLIC LID

83

respectively.

Because the high aspect ratio was obtained for the

quite large patterns compared with the critical-size

patterns, the redundancy to print the fluid-path

patterns was considered.

The pattern width w to obtain the highest aspect ratio

experimentally changed as shown in Table 3,

depending on the resolution R and the DOF of the

projection optics. Here, DOF

c

is the DOF for the

patterns with the critical width R, and they were

calculated by equations (1) and (2). The central

wavelength λ was assumed to be 365 nm. NA is the

numerical aperture of the projection lens. The

constants k

1

and k

2

were assumed to be 0.7 and 1.0.

1

0.7 0.7 2 1.4 .Rk F F

NA NA

λλ

λ

λ

== =×=

(1)

2

2

22

4.

c

λλ

DOF k F

NA NA

λ

=== (2)

Figure 2: Pattern collapse prevention by giving a large

exposure dose. F-number is 5.6.

Figure 3: Maximum aspect ratio dependence on resist

thickness and F-number.

From the calculated resolution limit R and the

pattern width w for obtaining the highest aspect

ratio, w/R was also calculated, as shown in Table 3.

The ratio w/R was almost constant without

depending on the F-number.

Table 3: Resolution versus pattern width and thickness for

obtaining the highest aspect ratio.

Although the DOF

c

for the critical size pattern was

calculated above, DOF

w

for the patterns with a

width of above w was far larger. Because the first-

order diffraction light angle from the periodical

patterns with a large width of w is R/w times smaller

than that from the critical-size periodical patterns,

the DOF

w

for the patterns with a width of w is

multiplied by w/R. Therefore, DOF

w

is calculated as

shown in Table 3. It was known that the DOF

w

was

sufficiently deep for printing such high-aspect

Ratio w/R

(Calculated)

F-number

NA

5.6 8 11.2

0.089 0.063 0.045

R (μm)

2.86 4.09 5.72

(Calculated)

DOF

c

(μm)

45.8 93.4 183

w (μm)

26.3 42.1 52.6

(Experimental)

Resist

170 300 420

thickness (μm)

Aspect ratio

6.5 7.1 8.0

DOF

w

(μm)

421 962 1680

(Calculated)

9.2 10.3 9.2

Exposure

time

5 min

7 min

6 min

26-μm line-and-space patterns

(170-μm thick resist)

0

100 200 300 400 500

0

2

4

6

8

10

F=11.2

F=5.6

Resist thickness (μm)

Maximum as

p

ect ratio

F=8

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

84

patterns in thick resist films. This performance is

caused by the utilization of the low-NA or large F-

number projection optics.

It was considered that too narrow flow paths were

irrelevant to fabricate practical microfluidic devices.

From the experience, minimum flow-path width for

fluids such as water and alcohol was estimated to be

30-100 μm. For this reason, considering the

resolution redundancy, F-number of 5.6 was selected

to fabricate an actual microfluidic device. Under this

condition, patterns with 26.3-36.8 μm were printed

well with a considerable exposure time margin, as

shown in Fig. 4. Patterning characteristics for wider

line-and-space patterns with a width of 105 μm were

also investigated. Figure 5 shows the results. Nice

patterns were obtained for long exposure time of up

to twice longer than the time for obtaining the

nominal width patterns, and groove patterns much

narrower than the nominal width were obtained for

the long exposure time.

Figure 4: Stable space-pattern-width controllability of

narrow high-aspect patterns.

Resistthickness

100μm

260μm

380μm

Exposuretime(min)

Spacepatternwidth(μm)

40

50

60

70

80

90

10

11

12

3

4

5

67

89

105‐

μmL&S

Figure 5: Change of large space pattern width depending

on the exposure time and resist thickness.

3 REPLICATION OF

MICRO-MIXER RESIST

PATTERNS

Considering the results obtained in the previous

chapter, actual microfluidic mixer patterns with a

snail-shape were printed using 380-μm-thick SU-8.

Printed patterns were shown in Fig. 6, and the

groove widths at the Y-shape entrance and the

confluent throat were measured as shown in Fig. 7.

Because the groove-width change became

smallest and the clearest pattern profiles were

obtained, 9 min was the optimum exposure time.

Bird’s eye view of the resist patterns at the entrance

and the exit are shown in Fig. 8. Printed patterns had

vertical and sharp sidewalls. The groove width and

the aspect ratio at the Y-shape entrance were 73μm

and 5.2, respectively, when the exposure time was 9

min. The vertical confluent groove had a width of

135 μm and aspect ratio of 2.8.

500

μ

m

(a) Exposure: 5 min

(b) Exposure: 6 min

(d) Exposure: 8 min

(c) Exposure: 7 min

(f) Exposure: 10min

(e)

Exposure: 9mi

n

Figure 6: Micro-mixer patterns fabricated under various

exposure-dose conditions.

Exposure time (min)

0

10

20

30

40

50

60

70

80

3 4 5 6

7

8 9

31.6-μm L&S

26.3-μm L&S

36.8-μm L&S

Resist thickness: 170 μm

Space pattern width (min)

SIMPLY FABRICATED PRECISE MICROFLUIDIC MIXER WITH RESIST FLOW PATHS SEALED BY AN

ACRYLIC LID

85

Exposuretime(min)

Groovepatternwidth(μm)

4 5

67

8 9

10 11

40

60

80

100

120

140

160

180

200

Confluentpart

Entranceneck

Figure 7: Width variances of micro-reactor patterns.

Figure 8: Entrance and exit patterns of a micro-reactor.

The minimum groove width was 73 μm.

4 ASSEMBLY OF A

MICRO-FLUIDIC MIXER

Using the snail-shape grooves shown in Fig. 6 and 8

as fluid paths, a micro-reactor was fabricated. The

resist grooves were tightly covered by an acrylic lid

plate to make the paths sealed. The lid plate had a

concave with a size a little larger than the outer edge

of the resist block, two entrance holes, and one exit

hole. The plate was machined using a simple

automatic 3-dimensional milling machine (Roland,

PNC-300 CAMM-3). Micro-tubes with an outer and

inner diameters of 500 and 300 μm were inserted

into the three holes and adhered, as shown in Fig. 9.

The tubes were made of poly-fluoro-acrylate (PFA).

Flowing and mixing capability was checked by

injecting colored waters from the two entrances

using syringes. The injected waters were colored red

and blue using watercolors. The colored waters were

successfully mixed while they passed through the

snail-shape paths, as shown in Fig. 10, and the

ejected water had an even dark purple color, that

means the red and blue waters were mixed well. The

waters did not leaked, and the flow paths made of

resist SU-8 were not damaged at all, and it was

verified that the simply and easily fabricated

microfluidic mixer was useful.

Figure 9: Outlook of the fabricated microfluidic mixer.

Figure 10: Successful mixing of two colored waters.

100

μm

(a) Red water injection. (b) Blue water injection.

(c) Injection of Red and blue waters.

A

B

1mm

(b) Main part.

10mm

(a) Total outlook.

(a) Entrance holes (b)Exit hole

100 μm

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

86

5 CONSIDERATION

First, advantages and disadvantages of the proposed

microfluidic mixer were considered. Because the

SU-8 patterns are easily printed and they are used as

the flow paths as they are, the fabrication process

was very simple and easy. Although reticles were

needed for projection lithography, very low-cost

film-reticles were applicable without any problems.

In addition, microfluidic mixers are generally used

by themselves, and accurate reticle alignment is not

needed. For this reason, projection exposure systems

may be very simple and plain. Even handmade

exposure systems or photo printers used for printing

off photographs from the negative films are useful.

The proposed microfluidic mixers are applicable

to some micro total analysis systems (μ-TAS). The

tolerances for various body fluids, juices and

chemical reagents have to be investigated hereafter.

The tolerances may not be universal comparing with

those of quartz and glass. However, probably, the

proposed microfluidic mixer will also have good

tolerances for most of the fluids including blood.

Next, fluidic parameters were studied. Although

the colored waters were manually injected using

syringes at the room temperature this time, and the

flow rate was not severely controlled, Reynold’s

number Re=Vd/(μ/ρ) was roughly estimated. It took

less than or equal to 0.1 s to flow the waters through

the device, and the flow path length between the

entrance and the exit was approximately 5.6 mm.

Therefore, the average flow rate V is roughly

calculated to be V=60 mm/s. On the other hand, the

path width d, fluid viscosity μ and the density ρ are

135 μm, ≈1 mPa·s and ≈1 g/cm

3

, respectively.

Therefore, Re is calculated to be ≈8. Accordingly,

the flow is supposed to be a laminar flow. In fact,

the red and blue waters divide the path into halves

between points A and B in Fig. 10(c).

It is not always necessary to make the groove so

deep. However, device sizes can be reduced by

using the deep grooves to secure the same cross

sectional area sizes and allocate the groove closely

each other.

6 CONCLUSIONS

A new method to fabricate microfluidic reactors or

mixers very simply and easily was demonstrated.

Negative SU-8 resist being composed of epoxy resin

with a thickness of 380 μm was used as flow paths.

Because even the 1:1 L&S patterns were printed

with very high aspect ratios of more than 5, deep

flow grooves were easily fabricated. A snail-shape

micro-reactor with a minimum flow-path width of

73 μm was actually fabricated. The resist flow paths

were sealed covering the resist block by an acrylic

lid plate with a concave a little larger than the resist

block and combining the substrate and the lid plate

by screws. Micro tubes were attached to the entrance

and exit holes, and red and blue colored waters were

injected through the micro-tubes using syringes. As

a result, the colored waters were successfully mixed

in a dark purple color, and ejected from the exit tube

without any leaks. The new method and structure for

the microfluidic devices are practical and effective.

ACKNOWLEDGEMENTS

This work was partially supported by Research

Institute for Science and Technology of Tokyo

Denki University Grant Number Q09M-05 in 2009.

REFERENCES

Lien, K. Y., Liu, C.J., Lee, G. B., 2008. MEMS 2008,

IEEE 21

st

International Conference on Micro Electro

Mechanical Systems, 66-69.

Lei, L., Mattos, I. L., Chen, Y., 2008. Microelectronic

Engineering 85, 1318-1320.

Casquillas, G. V., Bertholle, F., Berre, M., Meance, S.,

Malaquin, L., Greffet, J. J., Chen, Y., 2008.

Microelectronic Engineering 85, 1367-1369.

Tsai, N. C., Sue, Sue, C. Y., 2006. Biosensors and

Bioelectronics 22, 313-317.

Yang, R., Soper, S. A., Wang, W., 2007. Sensors and

Actuators A 135, 625-636.

Nugen, S. R., Asiello, P. J., Connelly, J. T., Baeumner, A.

J., 2009. Biosensors and Bioelectronics 24, 2428-

2433.

Kontakis, K., Petropoulos, A., Kaltsas, G., Speliotis, T.,

Gogolides, E., 2009. Microelectronic Engineering 86,

1382-1384.

Lo, C. S., Prewett, P. D., Davies, G. J., Bowen, J., Vanner,

K., 2008, Microelectronic Engineering 85, 1062-1065.

Ho, L. F., Chollet, F., 2008, Microelectronic Engineering

85, 1306-1310.

Avram, M., Iliescu, C., Volmer, M., Avram, A., 2008.

Digest of Papers, Microprocesses and Nanotechnology

2008, 21

st

International Microprocesses and

Nanotechnology Conference , 442-443.

Eun, D. S., Kong, D. Y., Chang, S. J., Yoo, J. H., Hong,

Y. M., Shin, J. K., Lee, J. H., 2008. Digest of Papers,

Microprocesses and Nanotechnology 2008, 21

st

International Microprocesses and Nanotechnology

Conference , 448-449.

Hirota, K., Ozaki, M., Horiuchi, T., 2003. Japanese

Journal of Applied Physics 42, 4031-4036.

Horiuchi, T., Watanabe, H., 2008. Journal of

Photopolymer Science and Technology 21, 77-83.

SIMPLY FABRICATED PRECISE MICROFLUIDIC MIXER WITH RESIST FLOW PATHS SEALED BY AN

ACRYLIC LID

87