PRACTICAL EDUCATION OF CONTROL ENGINEERING

Using Open OS, Free Software and Actual Plant

Sunao Tanimoto, Kiyoshi Yoshida

Nippon Institute of Technology, Miyashiro, Minami-Saitama, Saitama, 345-8501, Japan

Jyunichiro Tahara

Japan Agency for Marine-Earth Science and Technology (JAMSTEC), Japan

Keywords: Experiment Devices, Computer Control, Modern Control Theory, Plant Control, Linux, Octave, Control

CAD.

Abstract: The importance to educate control engineers is to make them experience the modern control theory by the

actual devices instead of pure digital simulator. During these applications, students will face to every

existing problem and digest the fruits of control theory by tangible impression. This paper reports the

development of experiment devices for computer control engineering education, where a pendulum is

controlled by a General Linux P/C through a DC motor every 1ms, realizing most kinds of advanced control

schemes linked with free control CAD, Octave. Controlled examples with various schemes are reported.

1 INTRODUCTION

Control engineering has an important role in

industries. Authors feel that the education for control

engineers has the problem that it mainly depends on

just the computer simulations. This seldom offers

tangible advanced control experiences to engineers

or students, and valuable theories are not applied to

actual fields well. To cope with this problem,

authors developed actual motor driven

pendulum/arm real-time control experimental

systems with an open source code OS; Linux,

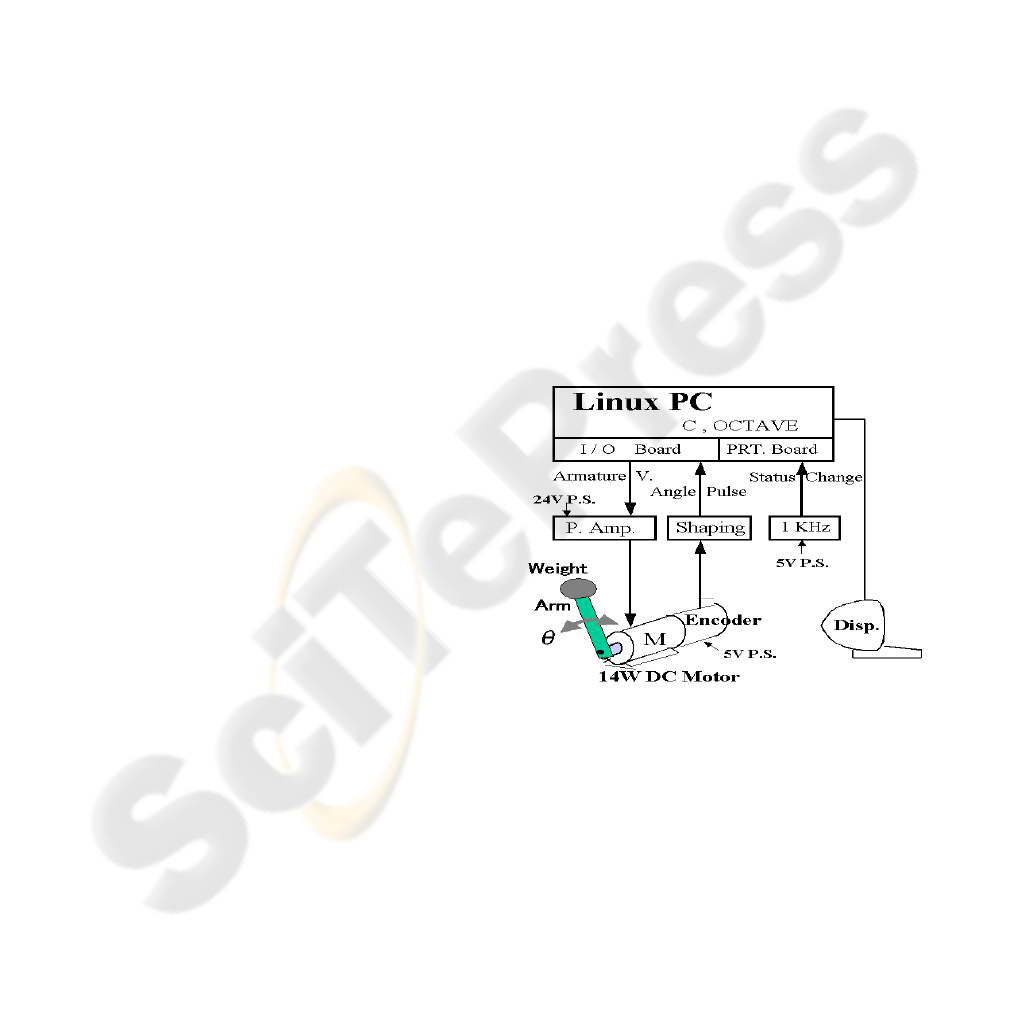

CAD/CAE; Octave and “C” Language (Figure 1).

Using the developed devices, students have flexibly

managed to realise tens of schemes of tangible

theories in the college lab. during last four years.

This paper explains the concepts and

specifications of developed devices, plant modelling

with mathematical linearization. Some developed

applications of modern control theory are introduced.

Finally, three types of discrete–time control methods

for industry uses are applied and their performances

are evaluated in each other.

Figure 1: System configuration.

2 DESIGN CONCEPT AND

SYSTEM CONFIGLATION

The basic component of plant control or Robot can

be reduced to control the position of a arm driven by

a motor. Key points of the design concept and the

spec. of this control system are discussed below.

265

Tanimoto S., Yoshida K. and Tahara J. (2010).

PRACTICAL EDUCATION OF CONTROL ENGINEERING - Using Open OS, Free Software and Actual Plant.

In Proceedings of the 2nd International Conference on Computer Supported Education, pages 265-270

Copyright

c

SciTePress

2.1 Design Concept

2.1.1 Real Time Control

Conventional real time control systems in industries

are controlled every 10 ms. Thanks to the progress

of computer capability today, it is possible to realize

1 ms DDC (Direct Digital Control) by just a P/C.

Once the developed control program is turned on,

the program senses the status change of 1 KHz

oscillator input. this program is executed every 1 ms,

without running OS area at all, achieving the perfect

real-time function.

The sampling time should not be disturbed by

the control calculation time. Because of the 2 GHz

P/C clock, most kinds of optimum calculation are

acceptable for control. Authors did not adopt

commercial real time OS to avoid their complexity

and ambiguity.

2.1.2 Accuracy, Simplicity and Reliability

Actual arm angle can be detected by 14,400 pulses

per rev. through I/O board of the P/C. Control input

to the motor armature is in analogue through 10-bit

DAC. A backlash-less motor without a gear is

adopted. No redundant devices are included.

A simple system configuration directly

corresponds to its reliability and accuracy. These

devices are neatly packed on a single board.

2.1.3 Maintainability

In plant control applications in industries, the

traceable-ness is quite important. Once a software

bug stalled the plant and destroyed the machinery,

the plant cannot be restarted without fixing the bug.

In case of Windows PC, whose source codes are

not disclosed, this bug cannot be fixed. Therefore,

Authors adopted Linux OS of open source code.

2.1.4 Flexible Control Design Capability

Although, AC motors are commonly used instead of

DC motors today, Authors adopted a DC motor for

the arm control, because a DC motor can be easily

expressed by differential equations, which results in

better understanding for users or students.

The controller is designed in C-language and its

PID control reference software is initially installed

by a author. Users can only modify this software for

their own purpose. The input and output of this

controller are the pulse count of the pendulum angle

and the armature voltage of the DC motor,

respectively.

2.1.5 Computer Aided Engineering

This system includes a control CAD/CAE called by

Octave of free software instead of expensive Matlab.

Users can get the chart of controlled result by storing

the control variables in the software table every 1

ms. Octave also offers tools of control theory such

as eigen value, Ricatti solution and transfer function.

Users can compare the actual control results with the

modelled theoretical result by both charts.

2.1.6 Exclusion of Non-linearity in Devises

Authors believe that the mechanical non-linearity

such as backlash, friction and dead time are difficult

to be evaluated and also its fine repeatability is not

realized in actual plants. In the devices here, those

non-linearity are excluded as much as possible. The

gearless motor and the directly coupled encoder with

fine resolution are adopted.

In case of developing those non-linear control

methods, non-linearity should be realized in the P/C

through its software with repeatability. And then,

developed control scheme for pure non-linearity will

be applied to the actual field, and analyzed.

2.1.7 Cost and Open Documents

4 same systems are developed. Its cost is $3,000/set

excluding authors’ labour. This reasonable cost can

mainly be realized by adopting the free software of

Linux and Octave. Its specification is open by

authors to any other groups for education and non-

business use.

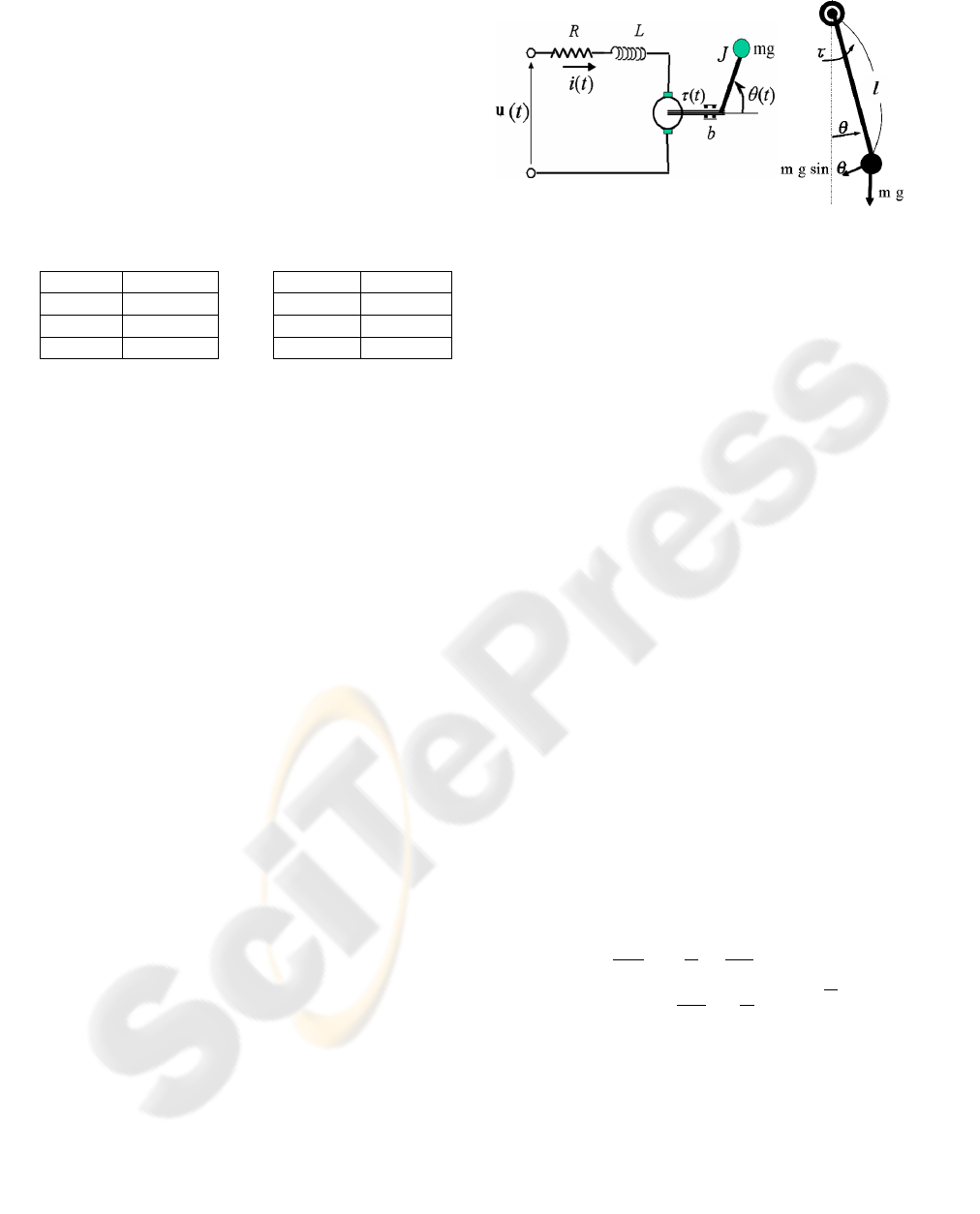

Figure 2: Control Block Diagram.

2.2 Hardware

This system consists of controlled process or plant

and a controller (Figure 2).

2.2.1 Process

a. Motor and Encoder

A small DC motor is adopted considering users’

safety. Rating specifications are on Table 1. Low

inertia-ed rotary encoder directly coupled with the

CSEDU 2010 - 2nd International Conference on Computer Supported Education

266

motor shaft is adopted. Pulse rate is 14,400

pulses/rev.

b. Amplifier and Power Supply

Large capacity-ed power amp. Is adopted

considering the motor stall current (table 2).

Switching power supply for the power amp. Is of

100w with 24vdc and 4.5a.

c. Oscillator

1 KHz oscillator is made as a sampler.

Table 1: Motor spec. Table 2: Amp. spec.

Power

14 W

Power

125 W

Voltage

DC100

Voltage

100 V

Speed

2500 pm

Current

15 A

Torque

0.054 m

2.2.2 Controller

a. P/C

P/C has a CPU of 2 GHz, 256MB memory and

80GB H/D.

b. I/O Board

1 ms sampling signal is input to the printer port .

Analogue i/o; PCI- 3523A has DAC with

12bits, ADC and a few DI/DO.

Encoder counter; PCI-6204 has a 32-bit

counter.

2.3 Software

Linux Fedora Core 1 is adopted for OS. Application

task can access I/O through developed sub-systems

without OS.

Octave for Linux is down loaded. Its application

manual is openly supplied by Internet.

Reference PID control program is prepared. It

has the strict correspondence with its documentation,

block diagram and naming rule. It has blocks of

control parameter initial input, periodical run loop,

data acquisitions, PID calculation, Output to i/o

board and data storing for Octave. Users can modify

this program for their own purposes.

3 PLANT MODELING

Once the plant H/W is designed, then the advanced

control needs its mathematical modelling

3.1 Mathematical Model of the Plant

A motor with a pendulum arm is shown by Figure 3.

Figure 3: DC motor and a pendulum.

These plants are mathematically expressed by

tmglttbtJ

sin

(1)

)(tiKt

T

(2)

)()()()( tKtRitiLtu

V

(3)

Definition of variables and parameters are as follow:

u

: Armature voltage

R

: Armature resistance

L

: Armature inductance

i

: Armature current

b

: Friction loss

J

: Arm inertia

: Motor torque

: Arm angle

l

: Arm length

m

: Mass of Weight

g

: Gravity acc. KT:Torque const.

KV:B.E.F. const.

3.2 Linearization of the Plant

This plant has a non-linear term of

sin

. We need

a linear model to apply the linear control theory. In

conventional method, this term is approximated

by

. Another method adopted here is the strict

linearization by non-linear term compensation.

3.2.1 Approximated Linear Model

Assuming

sin

, 3rd

order model is expressed by

the state variable expression bellow:

u

u

L

i

L

R

L

K

J

K

J

b

J

mgl

i

V

T

bxA

x

1

0

0

0

010

(4)

Incidentally, the inductance L in the DC motor is

ignored in many applications considering the large

amount of the inertia of the arm, which is called 2nd

order model.

PRACTICAL EDUCATION OF CONTROL ENGINEERING - Using Open OS, Free Software and Actual Plant

267

3.2.2 Strictly Linearized 2nd

Order Model

The original system has the serious non-linearity of

t

sin

.

Authors applied the input linearization to

delete non-linearity. (1) can be modified below:

)(sinsin

mglmglbJ

(5)

The term

tt

sin

is compensated to

the motor armature voltage every 1 ms (Figure 4),

getting the linear model as follow:

mglbJ

(6)

By adding this compensation, control theory in

textbooks can be applied without any contradiction.

ref

a

u

Linear

Controller

Motor and

Pendulum

aa

T

K

Rmgl

sin

ref

a

u

Linear

Controller

Motor and

Pendulum

Motor and

Pendulum

aa

T

K

Rmgl

sin

Figure 4: Real time input linearization.

Figure 5: Step response by PID controller.

3.2.3 Identification of the Plant

The derived 2nd

order model is identified to the

actual plant (Figure 5). Both model and actual plant

are controlled by the same PID controller. The

model is executed every 1 ms using Euler difference

method. Incidentally, the dead time of this system is

confirmed to less than 2ms.

4 CONTROL APPLICATIONS

Authors examined several control schemes in text-

books. Basically, control is executed every 1ms,

which is almost regarded as a continuous system.

Every nonlinear function such as dead time,

sampling period, discrete time, saturation, dead zone,

static friction is realized by “C” in P/C. The lists of

developed schemes are as follow:

PID control.

Position control.

Angle velocity control.

Dead time control.

Sampling control.

Control with low resolution sensor.

Control with less number of effective digits.

Modern control with 2nd order.

State feedback control.

Pole assignment control.

Optimum regulator.

Integral type control.

Observer coupled control.

Discretized State feedback control.

Modern control with 3rd order, under work.

Observer coupled control (armature current

observance).

4.1 PID Performance by Sampling

Time

In actual plants, control performance mainly

depends on the sampling period. Continuous

feedback control is desirable.

Authors checked how the control performance

depends on the sampling period quantitatively.

Maximum stable proportional gain Kp for the

horizontal pendulum position control depending on

every sampling period is shown by Figure 6.

0

50

100

150

200

250

300

1 5 10 20 40 80 160

Sampling Period [ms]

Gain Kp

Figure 6: Maximum proportional feedback gain vs.

sampling period.

4.2 Pole Assignment Control

During the state feedback control using 2nd order

CSEDU 2010 - 2nd International Conference on Computer Supported Education

268

plant model, poles are assigned with

4010,205 jjp

using Octave. Control

results are shown in Figure 7. This means the linear

modern control is realized theoretically enough.

205 jp

4010 jp

Figure 7: Pole assigned step responses.

4.3 Integral Type Optimum Regulator

As control theory says the optimum regulator is just

a gain feedback and offset cannot be deleted

depending on the weight matrix Q as follow:

dturu

TT

u

)(min

0

xQx

(7)

To delete this offset, optimum regulator with

integral element is tested. New integral variable is

defined and sate equation is modified as follow:

(8)

u

JR

K

KK

R

b

JJ

mgl

T

VT

0

0

001

0

11

010

x

(9)

Solving the Ricatti equation using Octave,

integral type method is executed getting a satisfied

result. Here, the optimum regulator without integral

variable is compared (Figure 8).

Figure 8: Optimum regulators, right: integral type.

4.4 Discrete Time Control

Performances

4.4.1 Three Kinds of Discretizations

In industry applications, DDC is adopted, where the

sampling time is from a few to 50 ms depending on

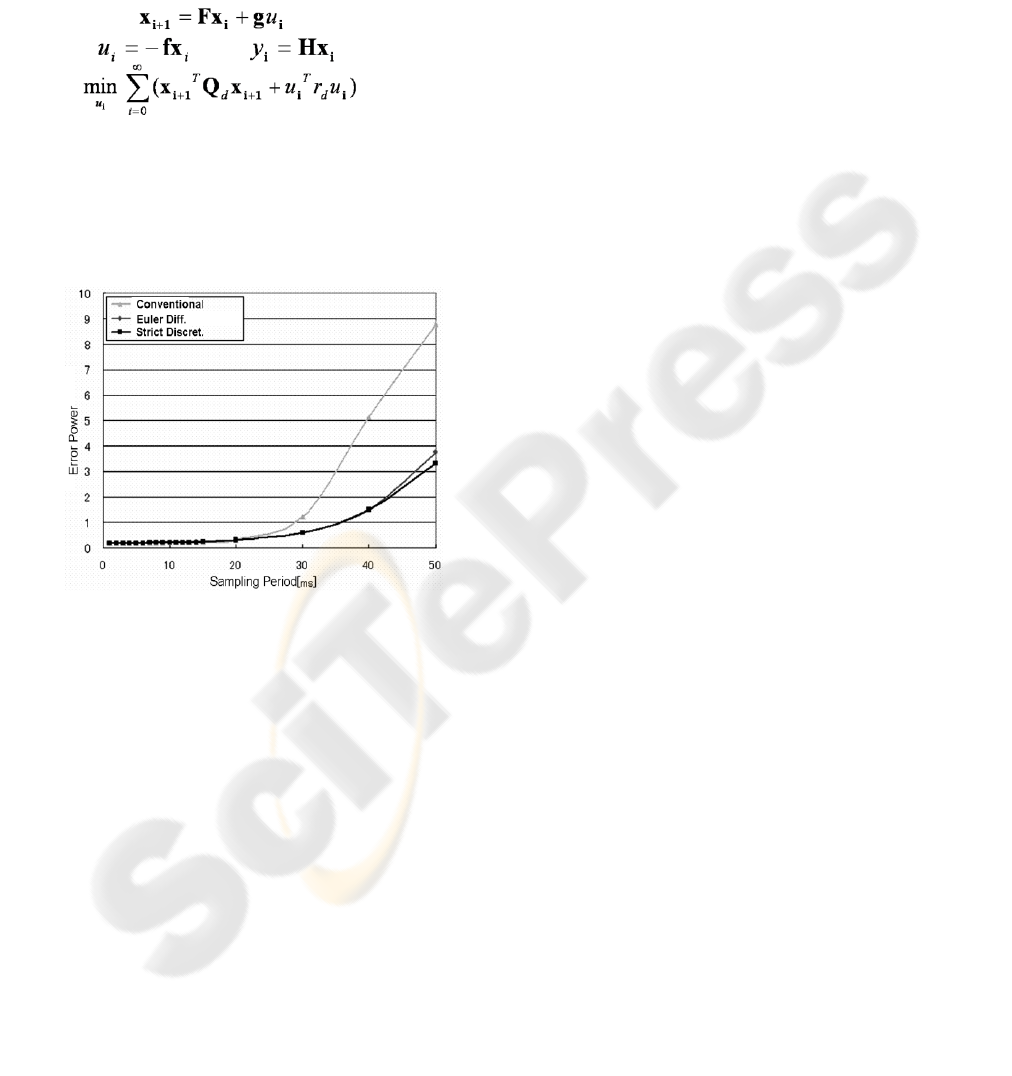

the plant dynamics. Figure 9 shows its discrete-time

control block diagram, where T

c

denotes the

calculation time in the sampling period. Authors

checked how the control performance depends on

the sampling period quantitatively in modern

control. Three kinds of discrete-time control

schemes are considered.

4.4.2 Conventional Method

The most common method is just to feedback the

state vector with gain matrix derived from the

continuous type Ricatti Equation as follow:

(10)

Figure 9: Discrete time Control System.

This method is not discrete and may be called by

periodical feedback. This is not optimum any longer,

which doesn’t utilize the information of sampling

period. But this is widely applied in industries

because it doesn’t need the plant discrete model.

4.4.3 Euler Difference Method

Euler Difference Method can easily discretize the

continuous plant model even in a plant controller.

Optimal feedback gain matrix

f

is obtained by

discrete-time Ricatti Equation through Octave.

(11)

4.4.4 Strict Discretization

The strict discretization needs to solve the continues

ubAxx

cxy

ii

u kx

dturu

c

T

c

T

u

)(min

0

xQx

ubAxx

cxy

ii

u kx

dturu

c

T

c

T

u

)(min

0

xQx

TuT

i

bxAIx

i1i

)(

ii

cxy

ii

u fx

)(min

0

ii1i1i

xQx

i

uru

d

T

d

T

u

TuT

i

bxAIx

i1i

)(

ii

cxy

ii

u fx

)(min

0

ii1i1i

xQx

i

uru

d

T

d

T

u

PRACTICAL EDUCATION OF CONTROL ENGINEERING - Using Open OS, Free Software and Actual Plant

269

state variable differential equation :

duee

t

)(

0

)(

b0xtx

t

AAt

(12)

i

A

i

A

1i

bxx udee

T

TT

)(

0

)(

(13)

Discrete-time state variable plant model is

derived:

(14)

Optimum feedback gain matrix

f

is also applied

here using Octave. This method is strict as a

discrete-time modification, but it is pretty difficult to

re-calculate F and g in on-line controller in case of

the product lot change or parameter change of

models in industries

Figure 10: Three performances comparison.

4.4.5 Comparison of Three Performances

Three types of above discrete-time methods have

been designed and executed. The step reference

change was given from horizontal arm angle to the

top dead point. Performances are evaluated by the

angle error power. Each weight matrix Q, r of the

evaluation function of quadratic form in optimum

regulator was chosen to get a good result for 1 ms

sampling period control. And this was fixed during

different sampling period tests.

There may be some discussion about fixing the

evaluation matrix for each to keep the fair

comparison. Basically, the control sampling time

should be related to the plant time constant. In

authors’ plants, velocity response time constant is

0.6 s.

Figure 10 shows the results where different

sampling periods were adopted for these three

methods. These tests gave us the considerable

information that the conventional method resulted in

poor performance especially when the sampling

period is moderately long ,above 20ms. This is why

this method does’t have the information of sampling

period

T

.

On the other hand, authors got relatively good

result by Euler method which is easy to apply

compared to the Strict descretization.

In each discrete time control method, it is

important that the sampling period should be small

under coping over data acquisition and output time

through network.

5 CONCLUSIONS

Authors developed practical educational devices for

students to make them experience the on-line real

time plant control.

Advanced control theories were applied and

those results were checked tangibly. Every trouble

derived from actual plant such as saturation of the

amplifier, cogging of the DC motor, vibration of the

plant, static friction and “C” coding is experienced

by students.

Authors are now working for 3rd order discrete

model with a observer which is giving us delicate

problems of sampling period and pole assignments

of the regulator and observer

Authors confirmed the importance of tangible

control experiment devices for the control

engineering education by the 4 year experience of

sending out about 40 students to industry fields.

REFERENCES

Hanyuda, S. et. al. 2007. Applications of Pendulum

Control System for Developed Educational

Experiment Devices, Risp International Workshop on

Nonlinear Circuits and Signal Processing, Shanghai,

pp.189-192, 2007/3

Tahara, J. et al. 2003. Design of Real Time Controller with

General Linux , Society of Signal Processing

Applications and Technology of Japan, pp 17-21

Vol.6, No.2, 2003/6

CSEDU 2010 - 2nd International Conference on Computer Supported Education

270