AN APPROACH TO TEACH MECHANICAL ENGINEERING IN

ORDER TO AVOID CURRICULUM FRAGMENTATION

AMONG TECHNICAL AND MANAGEMENT CLASSES

Adriano Fagali de Souza, Edgar Augusto Lanzer

Institute Superior Tupy – IST/SOCIESC, Albano Schmidt, 3333, Joinville-SC, Brazil

Carlos Mauricio Sacchelli, Leonidas Cayo M. Gilapa

CEFETSC, Joinville-SC, Brazil

Keywords: Engineering education, Disciplines integration, Current education demands.

Abstract: Today, engineering education, especially for technical subjects, is quite a challenge due to the high amount

of new technologies available in the modern world along with the market competition. The current

education system finds difficulties to follow the real speed of world’s development and its requirements.

Besides technological limits, a lack of integration between academic subjects is commonly observed. Many

times, students struggle to link themselves to the knowledge obtained in correlated subjects, and understand

how it all works together in real industry. Taken this issue into account, lecturers of Tupy Superior Institute

- IST/SOCIESC, a modern engineering school in the south of Brazil, developed a successful education

methodology for teaching engineering, by focusing on manufacturing plastic products. South of Brazil holds

one of the most important clusters for metal mechanic and plastic industry in Latin America. The proposed

educational method aims to improve students` view on process integration and minimizing the impact on the

real industrial world after leaving university. It is achieved by simulating a Virtual Industry which produces

plastic products. Each field in this manufacturing chain is considered one department of the Virtual

Industry, and it is managed by a group of students. The method integrates the mechanical graduation course,

propitiating a great improvement in the way of teaching engineering. The proposed approach of teaching

engineering has been proved to be very capable and adequate in enhancing students` knowledge, in

technical, scientific, management, human behaviour, working as a team. It also helps students` feeling about

the real industrial world. The proposed method aids in avoiding educational fragmentation and giving

support for engineering graduation in the contemporary world.

1 INTRODUCTION

Considering the high speed of the current

technological evolution, it is quite a challenge for

engineering professors and lectures to keep up dated

with the latest technical development, especially for

non-basic classes, usually faced by engineering

courses. There is a consensus among educators and

practitioners that engineering education must

significantly change in order to support the current

world’s demands. Learning-by-doing can be one

important concept to hold these new world

requirements (Carlson and Sullivan 1999). An

integrated laboratory for manufacturing education

has been proposed by (Shiue et al 1999), to enable

students for productive careers in industry by

applying education with hand-on projects.

Connecting technical topics like manufacturing

and design to others like management, process

planning and costing analyses is another challenge

for students. The influences in these fields are

crucial for industry; however, students have

struggled to realize this. It usually happens due to

the lack of integration between the classes in under

graduation degree. The current industrial world

claims for it.

In order to improve the way of teaching, some

proposals have been developed. (Meek et al 2003)

implemented a methodology to integrate classes of

the mechatronic under graduation at University of

Utah. In this proposal, groups of students work for

238

Fagali de Souza A., Augusto Lanzer E., Mauricio Sacchelli C. and Cayo M. Gilapa L. (2010).

AN APPROACH TO TEACH MECHANICAL ENGINEERING IN ORDER TO AVOID CURRICULUM FRAGMENTATION AMONG TECHNICAL AND

MANAGEMENT CLASSES.

In Proceedings of the 2nd International Conference on Computer Supported Education, pages 238-245

DOI: 10.5220/0002795602380245

Copyright

c

SciTePress

one year to develop robots which have to compete in

a sport game such football, basket, and others.

Wesselingh (2001) integrated some classes in a

chemistry engineering course in order to develop a

product made by students. Tolf et al (2003) present a

methodology for integrating two engineering classes

in order to solve project’s flaws.

Hargrove (2002) integrates some disciplines of

an engineering course to develop and construct a

vehicle for manipulating blocks of raw material,

aiming at following priorities: a) vehicle design, b)

sensors for the raw block detection, c) capacity of

choice, d) removing block approach.

Many authors discuss the lacks of engineering

education for technical disciplines. Integration and

relationship among groups is usually not mentioned.

There is also lack of integration in technical and

managing classes. According to Ziemian (2001), two

key issues continue to warrant attention and

improvement in engineering education:

a) Separation of the product design functions from

manufacturing steps.

b) Misunderstanding of manufacturing process as an

integrated system.

A network of different Computer Aided Systems

(also known as CAx, i.e.: CAD, Computer Aided

Design; CAE, Computer Aided Engineering; CAM,

Computer Aided Manufacturing, and others) has

been developed to support different tasks and

occupational profiles, ranging from product

development to manufacturing.

Dankwort et al (2004) discuss about ‘CAx

education’. According to the authors in the

contemporary industry the product development can

not seen on its own, as CAx and CAx education can

not be considered stand-alone. Historically CAD

was in the focus. Today, a network of CAx systems

support quite different tasks in product development

and manufacturing engineering. CAx education

always has to be tailored to a specific group of

person and/or jobs.

Many times engineers leave school knowing how

to push buttons and icons of a commercial CAx

software, but still don’t know how to apply the CAx

for aiding a whole manufacturing chain, and its

integration with the diverse fabrication stages,

through the integration of other CAx. They struggle

to extract all potential that these technologies can

offer. CAD is the most popular system in the CAx

family. Although the CAD technology is well

spread, the education of this subject at school still

has a lack of efficiency (Ye 2004; Briggs 2001).

Having this general context of engineering

education in mind a group of lecturers at Tupy

Superior Institute - IST/SOCIESC, Brazil, has

implemented an educational project in order to

improve the mechanical engineering education at the

college, focus on manufacturing plastic products,

applying diverse CAx technologies. This educational

project aims at integrating students and academic

classes, joining technical and managing fields in

order to close the manufacturing chain for a

proposed plastic product.

Students from all different phases of the under

graduation course are involved. The educational

project consists in a ‘Virtual Industry’, which

produces plastic products, accessing all the stages of

this manufacturing chain, such as: market survey,

product geometrical design, mold project, finite

element analyses, manufacturing process, costs,

production planning and industrial viability.

This educational project will allow students to

get a better feel on the influences of different fields

in engineering on the final product, considering

costs, demand, information exchange during product

development phase, and so on.

The current paper presents the proposed

educational project, which has been propitiating a

great improvement on the way of teaching

engineering and attending to industrial demand.

2 DESCRIPTION OF THE

EDUCATIONAL PROJECT

Academically the mechanical engineering under

graduation offered by IST is divided into 6 (six)

semesters, and was made to attend one of the most

important industrial clusters for plastic and metal

mechanic industry in Latin America, located in

south of Brazil. Both sorts of industries, in this

region, converging into plastic product development

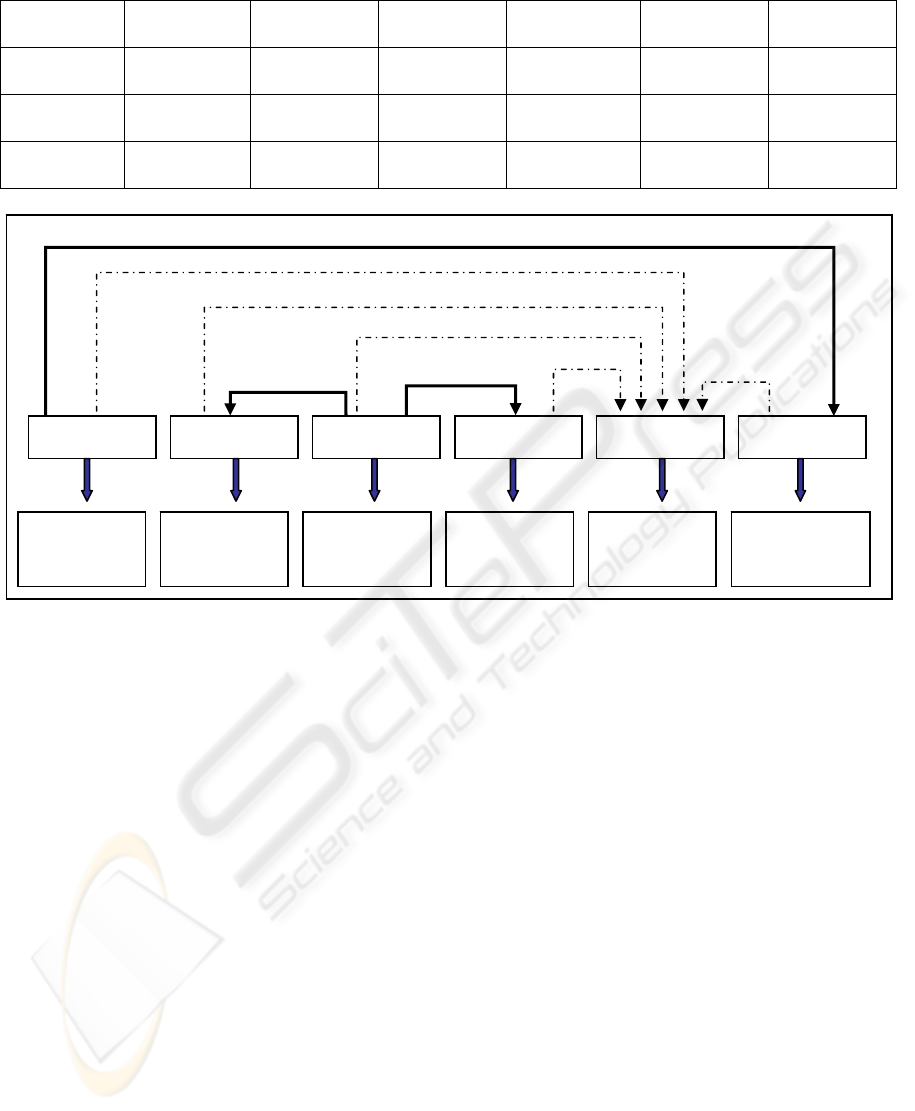

and molds manufacture. Figure 1 shows the main

technical fields involved in manufacturing chain for

mold and plastic transformation (Souza et al 2006).

Considering this atmosphere, the mechanical

engineering course at IST purposes to make

engineers who attend the regional demand for plastic

and metal mechanic industry. The pedagogic project

emphasizes the development of knowledge and

abilities rooted in: product development, mold

design, mold manufacturing, organization and

managing, production planning, further ordinary

skills. The activity intends to simulate an industry

that produces plastic products. A group of students

from each semester of the course runs one process

involved in this manufacturing chain, as following:

AN APPROACH TO TEACH MECHANICAL ENGINEERING IN ORDER TO AVOID CURRICULUM

FRAGMENTATION AMONG TECHNICAL AND MANAGEMENT CLASSES

239

Figure 1: Manufactured chain focused (Sousa et al., 2006).

- Semester 1: Identifying products demands and

specifications.

- Semester 2: Drawing the mold and product

using CAD 2D software.

- Semester 3: Modeling the product and the

respective mold by CAD 3D. Simulation analyses

are also done by the students from this semester by

using CAE software.

- Semester 4: Fabricating the mold by using a

CAM software.

- Semester 5: Analyzing the cost of the product

and the investment return based on the information

got from the other semesters.

- Semester 6: Constructing the process planning

for production the respective product, considering

demand all characteristics involved.

Virtual Industry activity can implicates one or

more disciplines from each of the 6 phases of the

graduation course. Each phase represents one sector

of the Virtual Industry. Thus, 6 industrial sectors

compound the Virtual Industry and its

manufacturing chain.

Considering the complexity and expenses of this

chain, the tasks such as plastic transformation

process; mold manufacture; and try-outs, cannot be

accomplished. However, simulations of the

manufacturing process are done by CAD/CAM/CAE

systems, together to financial analyses.

2.1 Work Methodology

Each phase of the under graduation course

represents one industrial sector; therefore the Virtual

Industry has six sectors which represent its whole

manufacturing chain. And in each phase of the under

graduation course 8 (eight) teams are formed by

students. Each group has about 4 (four) students.

Therefore, there are 8 (eight) Virtual Industries

running and each Virtual Industry has 6 (six) sectors,

as presented in table 1.

The sector of the Virtual Industry has to network

with one another in order to develop the proposed

product.

During the team formation, lectures from

respective classes are stimulated to look for

individual student’s abilities, considering three main

characteristics: manager ship ability; communication

ability; and technical ability. After that, the teacher

has to form teams made up of: one chief manager;

one communicator response; and students

responsible for technical know how. The entire

group is duly responsible for all assigned tasks.

The activity of the Virtual Industry starts with

one product being produced. Each sector has to

communicate with counterparts in order to obtain

production information on the product, such as:

geometrical data; manufacturing process; production

management; individual costs; investment viability

and others.

All the 8 (eight) Virtual Industries have to

develop similar activities, considering the product to

be manufactured, production batch and others.

General variables along the development process

can be defined by the team and explained in a final

report.

In this activity a meeting is holding with lectures

involved before the beginning of each school period.

This meeting is used for set the dates and

deliverables. Suggestions and improvements are

suitably discussed.

2.2 Deliverables and Requirements

Each sector of the Virtual Industries has to generate

and exchange information about its respective

production activities. That information is divided in

technical and management data. Technical data

correlates mainly to:

- Product design, as geometry and special

features.

- Design of the mold necessary for its production.

- Technical 2D draft for production line.

- NC programs for the mold manufacture.

- Analyses and simulations.

Software CAD/CAM/CAE are the most used tools in

this stage.

Manufacture chain of plastic products fabricated by moulds

Product

development

Materials analyses

Mould

manufacture

Inspection and

try-out

Transformation

processes

Mould

design

CSEDU 2010 - 2nd International Conference on Computer Supported Education

240

Table 1: Manufacture sector of each Virtual Industry.

Phases of

the course

Phase 1 Phase 2 Phase 3 Phase 4 Phase 5 Phase 6

Industrial

sector

Marketing

survey

Drafting

department

Design

department

Manufacture

department

Financial

department

Industrial

department

Phases of

the course

Phase 1 Phase 2 Phase 3 Phase 4 Phase 5 Phase 6

Industrial

sector

Marketing

survey

Drafting

department

Design

department

Manufacture

department

Financial

department

Industrial

department

Figure 2: Flow of information, requirements, suppliers and deliverables from each phase.

Management data correlates mainly to:

- Market research and product definition.

- Demand forecast.

- Expenses in each phase to accomplish the

related work, concerning: number of workers;

labor costs and its legislative fees; computers

and software requirements; direct cost of heavy

machines, maintenance, equipment amortization

and depreciation; staff training; raw material;

and so on.

If convenient, students can also contract outside

services. It must be listed in final report.

Many times, a specific sector requires

information from the other sectors. Therefore, in

order to complete the production cycle, all data

involved must flow accordingly to its requirements.

Figure 2 illustrates the requirements, suppliers and

deliverables from each sector of the Virtual Industry.

Virtual Industry activity takes up a full educational

period. Students have to meet the whole team and

exchange information regarding the project. E-mail

is also used as an instrument for data exchange.

Working in concurrent engineering technique is

stimulated by the lecturers. A group which identifies

and makes optimization along the process increases

their final grade. Reports on the work flow have to

be elaborated as well.

2.3 Activities Definition

For a first view, the project development can be

summarized in: identify a plastic product to be

manufactured; develop the mold required for its

fabrication; fabricate the mold; production and

financial analyses. The specific activity for each

phase is related to the class on the respective phase.

Table 2 presents the activities, the respective phase

of the course and the classes correlated.

The activities are detailed as follows:

Activity 1 - Product definition: In order to be

realizable, only one product is previously defined for

the eight Virtual Industries. However, the details of

this product are broken up into eight categories, for

each industry, as following:

1- Product for men;

2- Product for women;

3- Product for both men and women;

4- Product for social class A;

Phase 1 Phase 2 Phase 3 Phase 4 Phase 5 Phase 6

Mould Design

Mould cavity

Product demand

Sector Cost

Sector

Cost

Sector Cost

Sector Cost

Sector

Cost

Product

viability and

demand

Mould draft

and bill of

materials

Product and

mould

design

Mould

manufacture

Product end-

cost

Process

planning

AN APPROACH TO TEACH MECHANICAL ENGINEERING IN ORDER TO AVOID CURRICULUM

FRAGMENTATION AMONG TECHNICAL AND MANAGEMENT CLASSES

241

Table 2: Activities of each phase representing the industrial sectors.

Activity Activity definition and deliverables Phase Class

1

Product definition 1 and 3 Mold development

2

Mold design 3D modeling 3

Mold development.

Computer Aided

Design- CAD II

3

2D mold drafting and materials 2

Computer Aided

Design- CAD I

4

Individual costs 1 to 6 -

5

Demand and product viability 1 Managing system

6

Manufacture of the mold 4

Computer aided

manufacturing CAM

7

Product end-cost 5 Industrial cost

8

Production planning 6

Production Planning

and control

9

Final presentation 1 to 6 -

5- Product for social class B;

6- Product for social class C;

7- Product for elderly;

8- Product for children.

The product geometry has to be modeled in a 3D

CAD software (Unigraphics NX4). Students should

concern about product ergonomic features and

market acceptance.

Activity 2 - Mold design: Using the 3D CAD

product modeled in activity 1, its injection mold has

to be designed. The shrinking of plastic material,

coolant system, injection points, pressure of

injection, mold split line, the plastic flow analyses,

and others project characteristics should be taken

into account. The CAD is used to create the cavity of

the molds and flow analyses are taken using the

CAE software MoldFlow V5.

Activity 3 - Manufacture 2D draft and bill of

materials: This phase of the course is starting

knowing 2D mechanical drafts. They receive 3D

CAD model and generates the 2D draft required to

follow the production line on the shop-flour. They

are also responsible for doing the bill of material

required for the mold construction.

Activity 4 - Individual costs: All the phases have

to understand very well all the costs involved in the

related stage. The equipments, labor expenses,

investments end so on. The costs of all phase are

used to make the end-product cost.

Activity 5 - Demand and product viability: A

market survey is done in order to estimate the

product demand to aid the production planning

ahead. The economical viability of the product is

also checked.

Activity 6 - Manufacture of the mold: The

fabrication of the mold by a CNC machine center is

programmed. The students receive the 3D CAD

geometry of the mold and generate the NC program

using the Unigraphics NX 4 CAM module. They

have to generate the NC programs and simulate the

roughing, semi-finishing and finishing operation for

manufacturing the mold. The time expend, the

machine and the cutting tool used have to be defined

by the group.

Activity 7 - Product end-cost: Using the cost

information from all the phases, join information

about the investments, returns expected, operation

and commodity expenses, the product end-cost is

defined.

Activity 8 - Production planning: The information

about product demand together to the industry

design is used to create a production planning.

Activity 9 - At the end of the academic semester,

each team (Virtual Industry) has to present a report

of the entire project and “release” its product. They

have to present the project. Grades are given to

compound the end-grade of each correlated

discipline.

2.4 Schedule

The activity is taken along one educational semester

– four months. Due to sort time, the complexity of

the project, and the deep relationship among the

phases to exchange data, the schedule should follow

strictly as previewed. Otherwise, some correlated

activities might not have sufficient time to

accomplish its task. Table 3 illustrates the schedule.

CSEDU 2010 - 2nd International Conference on Computer Supported Education

242

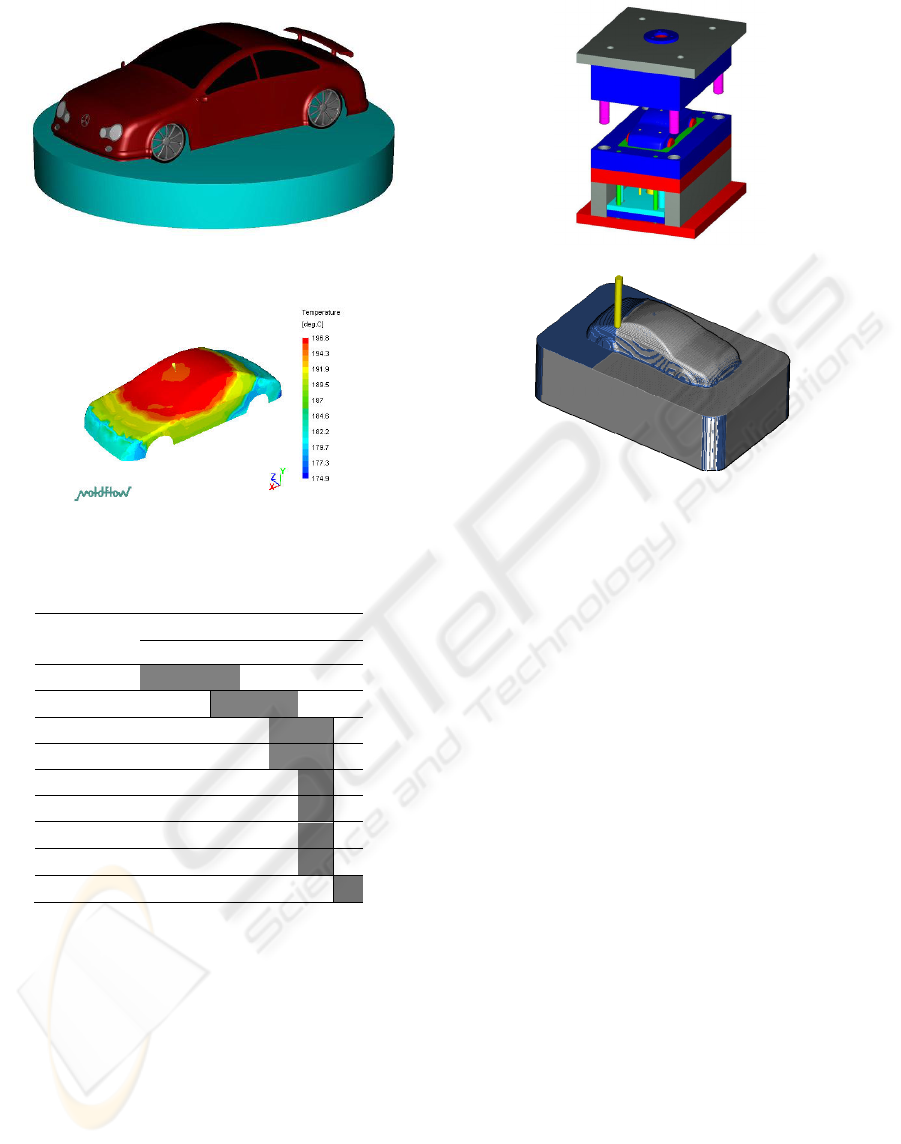

Fig. a. Product modeled in a 3D CAD Fig. b. 3D mold design

Fig. c.: Plastic flow analyses by CAE Fig. d. Mold manufacturing by CAM

Figure 3: Sample of project development by one of the Virtual Industries. Technical tasks.

Table 3: Project schedule.

Activity

Schedule (Month)

1 2 3 4

1

2

3

4

5

6

7

8

9

3 RESULTS AND DISCUSSION

For illustrating propose, a product developed by one

of the Virtual Industries has been chosen. Figure 3

presents the main results concerning technical

issues, developed by the integration of students in

phases 2, 3 and 4, of the graduation course.

One important result of the students’ integration

can be observed in this particular project. After the

group in phase 3 modeled the product geometry, the

group of manufacturers (phase 4) identified a

geometrical limitation. The product had a fillet

radius of 2 mm which could be very hard to

manufacture. So the group decides to modify the

fillet radius to a reasonable value for manufacturing,

5 mm.

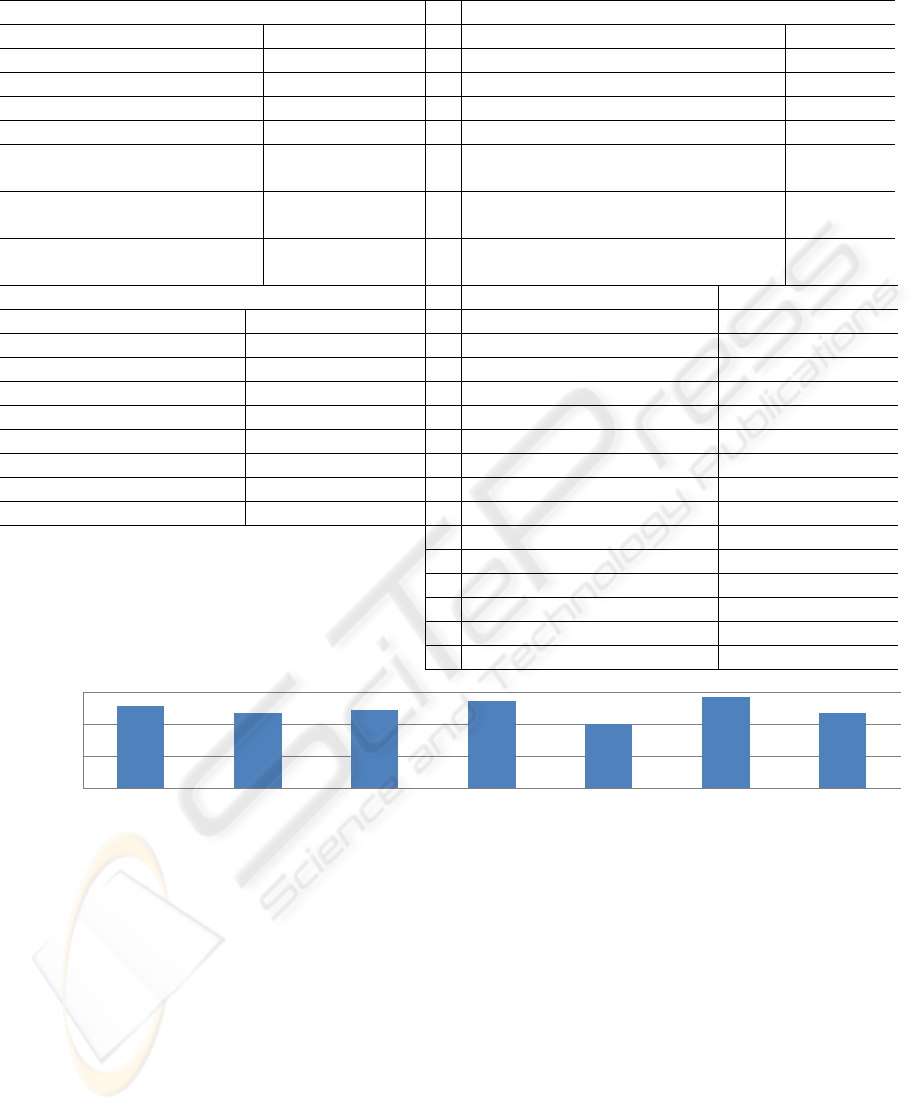

Table 4 presents the main data developed for

management tasks, involving students from Phase

number 1, 5 and 6 of the engineering graduation.

Besides the usual management, costs, and process

planning information, the students had the

possibility to amplify their feel considering

information gathered from all manufacturing chain,

which would have been difficult to get without this

project.

In order to have a feedback about the proposed

method of teaching, a simple questionnaire was

completed by the students after the graduation

course. Grades from 0 to 6 (6 is the best great) show

the students’ view about this activity, in a general

context, as presented by Figure 4.

Besides, the proposed method influences the

teaching methodology due to drive the lectures to

enclose their subjects to the industrial application

and improve the students’ concept of working in a

team. However the project acceptance is a challenge

for the leaders, to make lectures and students aware

how vital their involvement are for the project to

keep going on.

AN APPROACH TO TEACH MECHANICAL ENGINEERING IN ORDER TO AVOID CURRICULUM

FRAGMENTATION AMONG TECHNICAL AND MANAGEMENT CLASSES

243

Table 4: Sample of production and cost definition development by one of the virtual industries.

Production Cost-Volume-Profit Analysis

Monthly production (unit) 35.000 Cost-Volume-Profit Analysis 1,40

Year production (unit) 420.000 Variable cost ($/unit) 0,25

Cost production ($/unit) 1,17 Month fixed cost ($) 32.039,9

Mark Up-20% ($/unit) 1,40 CM - Contribution margin ($/unit) 1,15

*taxes -33,25%($/unit) 0,47 CM (%) 115%

Selling price (unit) 1,86

Countable break-even point

(unit/month) 27.915

Monthly production (unit) 35.000

**Economic break-even point

(unit/month) 37.464

Year production (unit) 420.000

Financial break-even point

(unit/month) 26.011

Financial analysis

Period/Investment

-415.000,00

Annual net income 675.813,60 1 yr. 228.457,56

Fixed costs 384.479,88 2 yr. 228.457,56

Variables costs 105.600,00 3 yr. 228.457,56

Gross profit 185.733,72 4 yr. 228.457,56

Depreciation 83.039,88 5 yr. 228.457,56

pre-tax profit 268.773,60 6 yr. 228.457,56

Income taxes (15%) 40.316,04 7 yr. 228.457,56

Net profit 228.457,56 8 yr. 228.457,56

Incomes 228.457,56 9 yr. 228.457,56

10 yr. 228.457,56

Present value 1403773

Net present value 988773

Internal rate return 1

Value 160918

Payback=Period 2

0

2

4

6

Work informatio n Organization of the

teams

Motivation Comunication

among the phases

The time for

developing the

work

Improviment of the

student view about

manufacturing chain

Support materials

Grades

Figure 4: An average evaluation of the proposed method from the students’ point of view.

4 CONCLUSIONS

The proposed approach to teaching engineering has

been proved to be adequate to enhance the students’

learning, besides technical and scientific, knowledge

about management, human behavior, network and

teams spirit, getting the filling about the real

industry atmosphere.

This interdisciplinary educational activity allows

future engineers feel the importance of the

integrating different stages of a manufacture chain

and how the concurrent engineering could help the

processes, improving product cycle development. It

also propitiates students a holistical overview on the

whole cycle of product development, management

and economical issues, technical problems and the

impact of each manufacturing stage on the end-

product.

This activity promotes a personal growth for the

students, once they have experienced how to work in

a work team. They have to manage conflicts,

capacity and limitation according to different way of

thinking. The students’ motivation on this work

could be observed when the students put in extra

time to develop a project in which they believe to be

worthwhile.

CSEDU 2010 - 2nd International Conference on Computer Supported Education

244

Before this methodology was implemented,

many times students finished the course knowing

quite well strict subjects. However, they are not

aware of all the others issues surrounding the

subject, such as cost involved in each industrial

sector, production time, the relation with other

sectors, and the problems that might arise in a real

application. The activity also improves students’ feel

on how all product data can influence the whole

manufacturing process.

The main difficulties and challenges to be

overcome are:

- Make lectures fully aware how vital their

involvement is for the project to keep going on.

- The time table is very strict. Each and every

phase depends on one another.

- Any phase not well carried-out can bring

setbacks and failure to the project.

Even with the above difficulties this approach to

teach engineering motivates students, avoiding

teaching-learning fragmentation and has duly proved

its potential.

ACKNOWLEDGMENTS

The authors thank Instituto Fábrica do Milénio-IFM

and Sociedade Educacional de Santa Catarina-

SOCIESC.

REFERENCE

Carlson, L. E.; Sullivan, J. F. (1999). Hands-on

Engineering: Learning by doing in the Integrated

Teaching and Learning Program. Int. J. Engng. Ed.

Vol 15, N1, 20-31.

Shiue, Y.; Beard, B. B.; Santi, M.; Beaini, J. E., Integrated

Laboratory for Manufacturing Education. (1999). Int.

J. Engng. Ed. Vol 15, N1, 51-57.

Meek, S.; FIEL, S.; Devasia, S. (2003). Mechatronics

education in the Department of Mechanical

Engineering at the University of Utah. Mecharonics,

13, 1-11.

Wesselingh, J. A. (2001).Structuring of products and

education of product engineers. Power technology,

119, 2-8.

Toft, Y.; Howard, P.; Jorgensen D. (2003). Human-

centred engineers- a model for holistic

interdisciplinary communication and professional

practice. International Journal of Industrial

Ergonomics, 31, 195-202.

Hargrove, J. B. (2002). Curriculum, equipment and

student project outcomes for mechatronics education

in the core mechanical engineering program at

Kettering University. Mechatronics, 12, 343-356.

Ziemian, C. W. (2001). A System Approach to

Manufacturing as Implemented with a Mechanical

Engineering Curriculum. Int. J. Engng. Ed. Vol 17,

N6, 558-568.

Souza, A. F, Sacchelli, C. M.; Scalice, R. K.; Gilapa, L.;

Lacerda, M. M. (2006). Management Analyzes of

Production of Injection Molds. IV Mechanical

Enginnering Congress. Recife-PE, Br.

Dankwort, C. W.; Weidlich, R.; Guenther, B.; Blaurock, J.

E. (2004). Engineers' CAx Education - it's not only

CAD. Computer-Aided Design, 36, 1439-1450.

Ye, X.; Peng, W.; Chen, Z.; Cai, Y. (2004). Today's

students, tomorrow's engineers: an industrial

perspective on CAD education. Computer-Aided

design, 36, 1451-1460.

Briggs, C. (2001). On the role of CAx in Design

Education. Int. J. Engng. Ed. Vol 17, N4-5,455-459.

AN APPROACH TO TEACH MECHANICAL ENGINEERING IN ORDER TO AVOID CURRICULUM

FRAGMENTATION AMONG TECHNICAL AND MANAGEMENT CLASSES

245