3D INSPECTION SYSTEM IN CERAMIC TILES SURFACES WITH

RANGE IMAGES

G. Pab

´

on-Rodr

´

ıguez, G. Andreu-Garc

´

ıa, A. Rodas-Jord

´

a

J. Valiente-Gonz

´

alez and F. Acebr

´

on-Linuesa

Computer Vision Group, Universidad Polit

´

ecnica de Valencia, Spain

Keywords:

Surface inspection, Computer vision system, 3D defect detection, Quality control, Range images.

Abstract:

In this paper we propose a system to characterize 3D defects of range images, which can be combined with

traditional surface inspection methods in an industrial environment for ceramic tiles inspection. Our applica-

tion has the advantage of learning the geometric features of the ceramic pieces, creating a unique 3D model

against which we compare the test pieces. In addition to this, the system includes a robust learning phase,

which discards tiles with defects impossible to see from a human expert and a more stringent inspection in

areas with low uncertainty. Experiments with real data were performed. Our data consist of tiles of different

types, shapes and silk-screen of ceramic tiles. Results are promising for tiles with a straight orientation, over

99 % of defects are correctly classified.

1 INTRODUCTION

This paper is concerned with the problem of auto-

matic inspection of ceramic tiles using computer vi-

sion. Our objective is to propose a suitable vision sys-

tem to detect and quantifier topographic surface de-

fects in tiles with nonplanar surfaces, irregular shapes

and glazed surfaces.

Decorative ceramic tile are manufactured in vast

quantities. According to (Smith, 2000) a large

range of tile designs are currently produced. These

tiles can have different shapes varying from conven-

tional simple planar designs to highly complex three-

dimensional forms and, in finish, from uniform color

to irregular pseudo-random designs or natural random

patterns typical of polished stone.

Most of ceramic tile automated inspection system

have predominantly been aimed at the inspection of

planar tile surfaces of uniform colouring. The de-

tection of defects in the case of nonplanar tiles or

tiles with pseudo-random patterns is more complex.

In (Boukouvalas et al., 1995) a successful applica-

tion of various image analysis techniques for the in-

spection of uniform planar tiles is described. In the

case of more complex patterned planar tile designs,

an off-line training stage has been proposed in or-

der to detect in both regular and random patterns.

However, such an approach is not able to explicitly

distinguish three-dimensional topographic, from two-

dimensional chromatic defects.

An automatic system to inspect and classify ce-

ramic tiles according to the integrity defects at the tile

corners is described in (Valiente et al., 1998). The

system detects the lack of material in the corner of

the tile basing on the differences of color among the

zone damaged and the remainder of tile, but if the

zone where there is a lack of material has been col-

ored the system does not work correctly.

Almost all the methods revised, like (Boukouvalas

et al., 1999), (Boukouvalas and Petrou, 2000), (L

´

opez

et al., 2001) and (L

´

opez et al., 2005) detect chro-

matic defects but not topographical ones. In (Smith,

2000) a technique that is able to isolated mixed topo-

graphic and chromatic surface features has been de-

veloped. They proposed a photometric stereo tech-

nique for the acquisition of quality data in the inspec-

tion of ceramic tiles, possessing both topographic and

albedo features. The method is able to separate a sur-

face topographic description from a coincident albedo

pattern. In the paper does not expose any method to

quantify the defects.

Our goal is to propose a suitable computer vision

system to detect and obtain measures of magnitude

of topographic surface defects. The system has to

inspect all the surface and to work with nonplanar

surfaces, irregular shapes and glazed surfaces. The

system has to offer solutions that can be used in real

world, this is in ceramic industry. A supervised ap-

158

Pabón Rodríguez G., Andreu-García G., Rodas-Jordá A., Valiente-González J. and Acebrón-Linuesa F. (2010).

3D INSPECTION SYSTEM IN CERAMIC TILES SURFACES WITH RANGE IMAGES.

In Proceedings of the International Conference on Computer Vision Theory and Applications, pages 158-163

DOI: 10.5220/0002827101580163

Copyright

c

SciTePress

proach to classifier requires a great number of defec-

tive samples, which can be difficult to obtain. So we

need to implement an inspection method based only

in good samples for training purpose. Contrary to

supervised classification novelty detection only need

normal samples. With novelty detection method the

system will have the advantage of being able to detect

new types of defects that were unknown at the time of

training.

In our proposed, a pattern 3D is obtained to each

tile model with uncertainly criterion that permit tak-

ing account the real inaccuracy in tile manufacturing.

Edge detection, matching and image registration tech-

niques to align tiles are used. Finally generates a 3D

pattern of a defect-free ceramic tile and via novelty

detection the defects are identified. Experiments with

commercial tiles show the good system performance.

2 ACQUISITION ENVIRONMENT

The surface inspection requires acquiring images that

are more suitable than the human visual perception.

Range images are a special class of digital images. A

range image reproduces the 3D structure of a scene.

Currently exists a variety of range measuring tech-

nologies to acquire 3D information about our world.

Laser range scanners can provide extremely accurate

and dense 3D measurement over a large working vol-

ume.

Our acquisition system is located in an opaque box

to not be affected by external light and put together a

commercial acquisition system based in ranger C55

camera, linear laser of 635nm and a conveyor belt.

The ranger C55 can be classified as MultiScan camera

where high speed 3D and gray-scale data are output

according to the line scan method. The object is illu-

minated from a position angle 45 degrees with a laser

line projector and viewed with the camera from a po-

sition on vertical to conveyor belt, see Figure 1. The

Figure 1: Left image represents the acquisition environment

camera, conveyor belt and lineal laser light. In the right

image can see the 3D line projection on tile.

lineal profiles acquired to obtain 3D shapes are based

on the method called laser triangulation. Ranger C55

Figure 2: Example of 3D image tile obtained with our envi-

ronment acquisition.

resolution is 1536*512 pixels and can acquired until

35000 profiles per second.

An example of the 3D image tile used in this work

can see in Figure 2. The images used in this work

are acquired while the conveyor belt was working and

with a final resolution of 0.06 mm in the Z direction

(direction vertical to conveyor belt).

3 VISUAL INSPECTION VIA

NOVELTY DETECTION

Supervised classification has been demonstrated as a

powerful approach when both training data and test-

ing data are well-conditioned. However, supervised

approach often involves a lengthy training stage and,

more importantly, it requires a substantial number of

defective samples, which for some applications can

be difficult to obtain.

In a novelty detection task, the classifiers task is

to identify whether an input pattern is part of the data

or it is in fact unknown. As for defect detection, it

involves assigning a normal or abnormal label to a

pattern (e.g. a surface or a pixel). Contrary to su-

pervised classification, novelty detection only needs

the normal samples for training purposes and usually

uses a distance measure and a threshold for decision

making. Recently, (Markou and Singh, 2003) gave a

detailed review of novelty detection approaches, us-

ing statistical and approaches.

Statistical parametric approaches are commonly

used in visual inspection (Xie, 2008). The fundamen-

tal assumption is that the data distribution is Gaus-

sian in nature. Each pattern is usually represented as

a point in a d-dimensional feature space, where d is

the length of the feature vector. The objective is then

to establish decision boundaries in the feature space

and reject patterns that fall in regions of low density.

The decision boundaries are determined by the prob-

ability distribution of the patterns at training stage.

3D INSPECTION SYSTEM IN CERAMIC TILES SURFACES WITH RANGE IMAGES

159

The available performance measure for novelty

detection methods is the probability of false positives

(FP) that is rejection of good samples. Increasing the

acceptance decision boundary will then obviously de-

crease the risk. However, it is also clear that the prob-

ability of false negatives depends on the acceptance

region. In some applications, the decision boundary

is simply set as the maximum range of normal sam-

ples in the training stage.

Figure 3: Uncertainty image U obtained for arrow and apple

models. The darker areas indicate greater uncertainty and

the white area shows the areas marked as smoothing areas

by our system.

3.1 The 3D Tile Pattern

The aim is to obtain a 3D tile pattern with ability to

discriminate defective tiles and accept at the tiles con-

sidered non-defective. All tiles with free surface de-

fects and those tiles with subtle changes on original

design must be considered as non-defective tiles.

The tiles are manufactured automatically and the

ornamental designs are stamped on them with a rel-

ative accurate. Due to this fact there is no a precise

correspondence between points with the same coor-

dinates of two tiles, but most likely if there is cor-

respondence with points in your neighborhood. This

disagreement between regular samples is referred by

us as inter-discrepancy between samples, but it is not

considered as defects.

Another direct consequence of the manufacturing

process is that the material is not distributed with pre-

cisely on the surface. Small differences in the amount

of varnish not affect the quality of tile but if it com-

putes the absolute differences between two tiles then

it could be detected as defects. This fact is referred by

us as intra-discrepancy.

These aspects force us to implemented a pattern

that has account the uncertainly. Only true regular

tiles samples (free-defect) can be used to obtained

a 3D pattern. The use of the window concept and

Neighborhood criteria allow us to successfully ad-

dressing the inter-discrepancy and make an analysis

of how smooth or rough are the decorative designs,

this aspect is necessary to obtain measurements of

the intra-discrepancy. These two aspects are not con-

sidered real defects but inequalities of the production

process.

Let a T

i

range image that represents a tile, it de-

notes by t

i

lk

/t

i

lk

∈ T

i

the profile obtained to pixel with

coordinates (l,k) in the plane (x,y) of the image. Set-

ting a 3 ∗ 3 window pixels, it denotes by N

i

lk

the 8-

nearest neighbor to pixel with coordinate (l, k) in-

cluded itself. For each T

i

one image of intra average

A

i

is computed using a 3 ∗ 3 window, then each ele-

ment a

i

lk

∈ A

i

can be computed as:

A

i

=

a

i

lk

| a

i

lk

=

1

9

∑

(p,q)∈N

i

lk

t

i

lk

(1)

In a similar way, for each T

i

one image of intra max-

imum X

i

and one image of intra minimum M

i

, using

the 3 ∗ 3 window, are obtained as follow:

X

i

=

x

i

lk

| x

i

lk

= max(t

i

pq

| ∀t

i

pq

∈ N

i

lk

)

(2)

M

i

=

m

i

lk

| m

i

lk

= min(t

i

pq

| ∀t

i

pq

∈ N

i

lk

)

(3)

The criterion to detect defect cannot be equal to all

tile surface. In tile regions with smooth decorative el-

ements a severe criterion can be used. But in rough re-

gions, regions with wave or regions with many edges

the criterion has to be smoothing to avoid false detec-

tion. In order to identify the smoothing of the regions

a binary image S

i

will be used to implement the pat-

tern, the elements s

i

lk

∈ S

i

are computed as:

s

i

lk

=

(

1, if

∑

(p,q)∈N

i

lk

(t

i

lk

−t

i

pq

) = 0

0, if

∑

(p,q)∈N

i

lk

(t

i

lk

−t

i

pq

) 6= 0

(4)

The criterion of above expression is: if the 8-

nearest neighbors have the same value then the region

is considered as an homogeneous region. This can see

a very restrictive criterion but is important to be sure

about the variability that is appropriate to tolerate in

each zone tile

Two aspects are taken into account to design the

uncertainly image U; the intra-discrepancy through

theA

i

and A

j

images and la inter-discrepancy through

the S

i

and S

j

images. The images U can be defined

as,

U =

n

u

lk

| u

lk

=

1

n

u

ji

lk

o

(5)

being n the number of true samples selected to com-

pute the uncertainly image and the u

ji

lk

values obtained

as,

u

i j

lk

= max

1≤ j≤n

"

∑

j+1≤i≤n

C(a

j

lk

− a

i

lk

)(s

j

lk

∧ s

i

lk

)

#

(6)

where,

VISAPP 2010 - International Conference on Computer Vision Theory and Applications

160

C(x) =

1, if x = 0

0, if x 6= 0

(7)

The values of the u

i j

lk

pixels represent the amount of

regular tiles that have voted this area as homogeneous.

The uncertainly image U is a measurement about how

many training tiles (without defect) consider that a tile

region is homogeneous. Examples of uncertainty im-

age can see in figure 3, where white area are homoge-

neous region.

Figure 4: Sequence of steps to obtain 3D pattern Ω.

Let a training set data of tiles and their ranger

image set T = {T

i

}

n

i=1

= {T

1

,··· ,T

n

}, and evalu-

ated the corresponding A

i

,X

i

,M

i

and S

i

, the images

A,D,X and M can be deduced as follow,

A =

(

a

lk

| a

lk

=

1

n

n

∑

i=1

a

i

lk

)

(8)

D =

(

d

lk

| d

lk

=

1

n

s

n

∑

i=1

(a

lk

− a

i

lk

)

2

)

(9)

X =

x

lk

| x

lk

= max

1≤i≤n

(x

i

lk

)

(10)

M =

m

lk

| m

lk

= min

1≤i≤n

(m

i

lk

)

(11)

The Ω pattern can be set as a set of five images

Ω = {A,D,X,M,U} that representing the images of

the average, the deviation standard, the maximum, the

minimum and the uncertainty. The figure 4 shows a

diagram with the steps necessary to obtain the pattern.

An aspect very important is how can be selected the

set tile T appropriated to obtained the Ω pattern.

3.2 Selecting True Regular Samples

A selecting true regular samples process previous to

obtain the pattern is take out. The objective of this

process is to select between the classified tiles as reg-

ular tiles (free-defect) by the human operator that, one

time are evaluated by the vision system, also will be

considered as regular tiles. The tiles that satisfy the

above criterion are referred by us as true regular sam-

ples. Obviously those tiles that are in the final se-

lection are tiles with a minimal inter-discrepancy be-

tween them. The figure 4 shows all the process.

Considering a set T = {T

1

,·· · ,T

m

} of regular

samples candidates to be selected as regular true

samples, a subset of m − 1 pseudo-pattern Ψ =

{Ψ

1

,...,Ψ

m−1

} are obtained where Ψ

i

is computing

using all the samples of the T set except the sample i

in a process of leaving-one-out.

Each Ψ

i

is defined as Ψ

i

= {A

Ψ

i

,D

Ψ

i

} where A

Ψ

i

and D

Ψ

i

are obtained using the expressions (8) and (9)

respectively and with m − 1 samples.

For each sample T

i

a discrepancy map R

i

is ob-

tained using the pseudo-pattern Ψ

i

. The discrepancy

map to R

i

can be deduced as follow:

r

i

lk

=

0, if (a

Ψi

lk

− d

Ψi

lk

) ≤ t

i

lk

≤ (a

Ψi

lk

+ d

Ψi

lk

)

1, in other case

(12)

The pixels with r

i

lk

= 0 are considered no-

disagree. If all the pixels of tile T

i

have been con-

sidered as no disagree then T

i

is a true regular sam-

ples and T

i

will selected to figure up the pattern Ω. In

other case when ∃r

i

lk

∈ R

i

| r

i

lk

6= 0 the T

i

is rejected

to compute the pattern Ω.

Figure 5: A numerical example of different values to esti-

mate the defects.

3.3 Defect Maps

For each test tile a defect maps Θ

i

is obtained using

the pattern Ω = {A,D,X,M,U} defined in previous

sections.

Given T

i

a data test and Ω the 3D tile pattern, the

step in order to obtain the defect maps Θ

i

is as follow:

Step1. Compute A

i

,X

i

, and M

i

, applying (8), (10)

and ( 11).

Step 2. Estimate R

i

from A

i

and D

i

, applying (12).

Step 3. Calculate θ

i

lk

∈ Θ

i

as follow:

3D INSPECTION SYSTEM IN CERAMIC TILES SURFACES WITH RANGE IMAGES

161

θ

i

lk

=

0, if m

i

lk

≤ t

i

lk

≤ x

i

lk

r

i

lk

(x

i

lk

−t

i

lk

), if t

i

lk

> x

i

lk

r

i

lk

(m

i

lk

−t

i

lk

), if t

i

lk

< m

i

lk

(13)

Then Θ

i

is an image than contain pixels to zero and

pixels greater than zero. The pixels θ

i

lk

∈ Θ

i

are pixels

defects free if θ

i

lk

= 0, in other case, the pixels with

θ

i

lk

> 0 are pixel with defects and the positive value is

the first approximation to quantify the defect.

Obtained Θ

i

the image U is used to weigh the de-

fects. The aim is that small values in Θ

i

are very sig-

nificant if its on smoothing area and on rough area

only big values are considered as defect. In this sense

the image U is considered with an image of weights.

To remove noise in Θ

i

a morphological operator

was applied, with a disk shape of radius 5 pixels as

structuring element. Finally the defect pixels are clus-

tered with criterion of 8-connected pixels and a mea-

surement about the defect area is obtained. An exam-

ple of this region is shown in figure 5. Considering

this area, and the profiles of pixels inside of area, a

measurement of volume of defects is estimated. Us-

ing the measurement of volume and area and the im-

age U different criteria to quantify and to classify the

defects can be thought out.

4 EXPERIMENTS AND RESULTS

For the experiments was necessary to set up an image

database based on real samples from the tile indus-

try. We have used in our experiment a data set of 210

tiles extracted directly from the factory, the produc-

tion line, so we work with real data and real defects.

The database is comprised by two model named for

us ”arrow” and ”apple”, see figure 6. We considered

these two models appropriate to test our proposal, be-

cause its have different forms and contain on its sur-

face as smooth as rough areas.

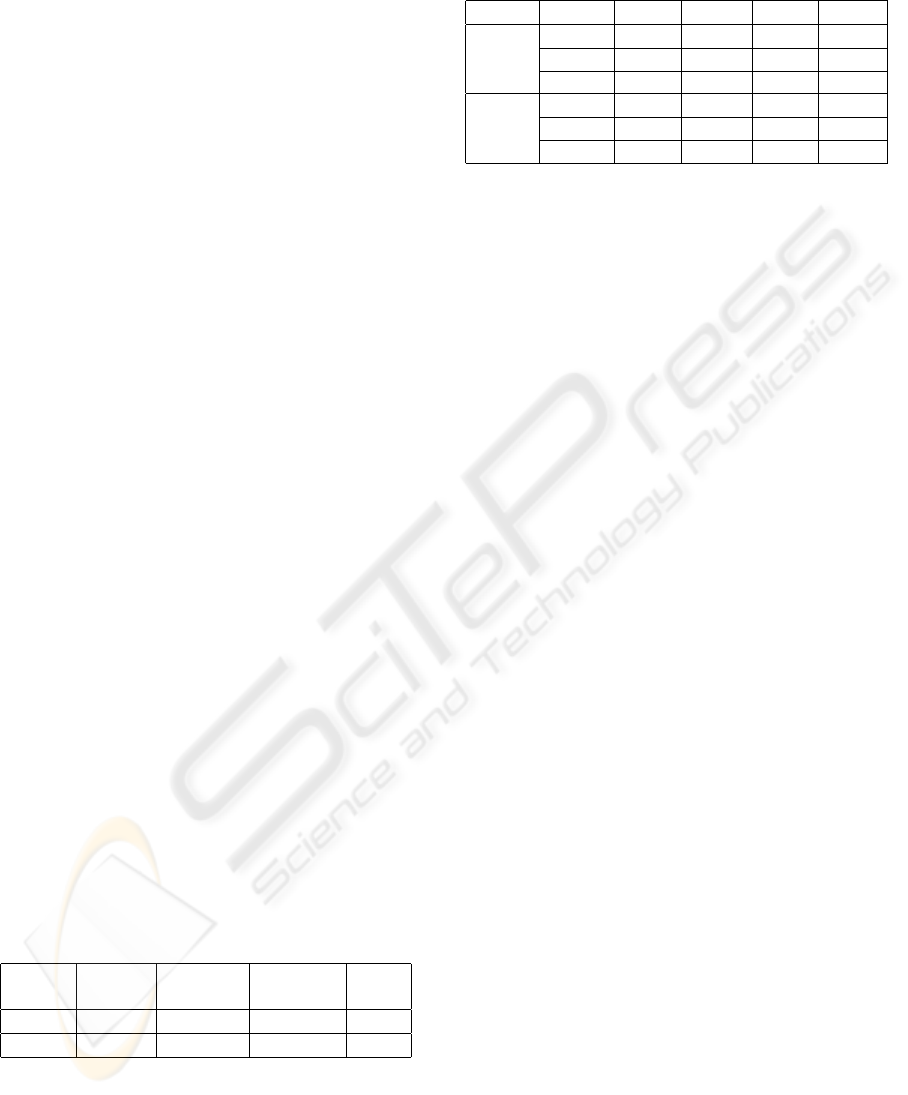

Table 1: Composition and distribution of tiles in the

database used in the experiments.

Tile Pattern Test free Test with Total

Model tiles defect defect tile

Arrow 13 35 63 111

Apple 8 31 60 99

For each tile model, arrow and apple, a process of

selecting true regular samples was carried out, as is

described in section 3.2. Table 1 shows the tile distri-

bution for each model in database, in this table can see

a total of 111 arrow tiles and 99 apple tiles was used.

At the beginner of the selecting process 15 free defect

Table 2: Summary result.

Tile degree TP % TN % FP % FN %

0

◦

100 98.4 0 1.6

Arrow 10

◦

97.9 95.2 2.1 4.8

−10

◦

100 95.2 0 4.8

0

◦

100 100 0 0

Apple 10

◦

89.7 96.7 10.3 3.3

−10

◦

94.8 93.3 5.2 6.7

tiles was candidate to obtain the the 3D pattern but

after of the selecting process only 13 arrow tiles and

8 apple tiles were used to compute the pattern Ω the

other free defect tiles was used to test the system. The

defect of test samples was lumps, depressions,orange

peel, material lack and too varnish.

Three different orientations were taken into ac-

count to do the experiments: i) 0 degree, this is the

best position to acquire images during the test and

implies that the tiles will be placed on the conveyor

belt completely parallel to the bands. ii) 10 degree,

this implies that the tiles it is placed an angle α to the

central of belt such that 0 < α ≤ 10. iii) -10 degree,

this implies that the tiles it is placed an angle α to the

central of belt such that 0 > α ≥ −10.

In all stage of the process three orientation was

taken into account for thus, pattern Ω will be pro-

jected to three orientations so three different patterns

were obtained for each model Ω

10

◦

, Ω

0

◦

and Ω

−10

◦

and all the test on the tiles were repeat for each ori-

entation. During the test process the system select

automatically the pattern with the more appropriate

orientation have account the orientation of test data.

The increment of FP and FN in the rotated tiles

are due to greater deformation that is produced at the

laser line in capture stage.

All test pieces were successfully tested by the sys-

tem; the results were summarized in table 2. In test

stage, for each tile it image is acquired and the pro-

cessing steps represented in figure 4 are made as fol-

low:

i) The tile contour (signature) is computed in order

to find differences between the angles of the test im-

ages and pattern tiles. The maximum curvature points

are control points to generate a transformation matrix

and determine the correspondence between the test

tile points and the three pattern of model.

ii) Knowing the coordinates of a set points in the

test tile image, an affine transformation (Gottesfeld,

1992) is determined to re sample the geometry of the

test tile image.

A detailed performance is showed in Table 2

where the detection rate for each model is presented

as: true positives (TP), false positives (FP), true neg-

VISAPP 2010 - International Conference on Computer Vision Theory and Applications

162

Figure 6: From left to right: Original tiles, Range images and Defect marked on uncertainty image.

atives (TN) and false negatives (FN). This approach

keeps the success rate on expected levels, but de-

creases to 94% when test tiles is rotated. The weight

factor of a defect increases when its position is be-

tween areas of high and low uncertainty, see figure 5.

Our proposed approach add the quantification of

detected defects in contrast to other systems e.g.

(Smith, 2000). We achieved our goal inspecting the

entire surface of tiles and to work with no planar sur-

faces, irregular shapes and glossy or glazed surfaces.

The proposed system has a final resolution of 0.06

mm in the Z direction. This extracts a set of features:

quantity of defective pixels tile, centroid, bounding

box, area, volume, perimeter, confidence measure,

and dispersion each tile defect. Also, it can detect

silk-screened defects because the color affects some

depth measurement. Experiments with commercial

pieces show reconstruction errors caused by the com-

bination of color and varnish.

5 CONCLUSIONS

A system for industrial inspection of ceramic tiles is

presented, showing a sophisticated inspection strat-

egy, with promising results. The proposed algorithm

use range images, to improve small defects detection

so difficult to see for human eyes.

Our algorithm is aimed to characterize 3D de-

fects of range images with novelty detection tasks,

which that only needs the normal samples for train-

ing purposes and usually uses a distance measure and

a threshold for decision making. We tested success-

fully the algorithm in some orientations with test tiles

from different shapes and textures. With novelty de-

tection method the system will have the advantage of

being able to detect new defects that were unknown at

the time of training.

Our future efforts: improve the response of the al-

gorithm about color, shadows, brightness effects and

time response time. This will include a stage that au-

tomatically corrects the false measurements deep in

the 3D reconstruction.

ACKNOWLEDGEMENTS

This work has been supported partially by research

project DPI2007-51166596-C02-01 (VISTAC).

REFERENCES

Boukouvalas, C., Kittler, J., Marik, R., Mirmehdi, M., and

Petrou, M. (1995). Ceramic tile inspection for color

and structural defects. In Proceedings of AMPT95.

pages 390–399.

Boukouvalas, C., Kittler, J., Marik, R., and Petrou, M.

(1999). Color grading of randomly textured ceramic

tiles using color histograms. In IEEE Transactions on

Industry Electronics. pages 219–226.

Boukouvalas, C. and Petrou, M. (2000). Perceptual correc-

tion for color grading of random textures. In Machine,

Vision and Applications. pages 129–136.

Gottesfeld, L. (1992). A survey of image registration tech-

niques. ACM Computing Surveys. pages 327–376.

L

´

opez, F., Acebr

´

on, F., Valiente, J., , and Perez, E. (2001). A

study of registration methods for ceramic tile inspec-

tion purposes. In Proc. of the IX Spanish Symposium

on Pattern Recognition and Image Analysis. pages

145–150.

L

´

opez, F., Valiente, J., Baldrich, R., and Vanrell, M. (2005).

Fast surface grading using color statistics in the CIE

Lab space. In Iberian Conference on Pattern Recogni-

tion and Image Analysis. In LNCS 3523. pages 666–

673.

Markou, M. and Singh, S. (2003). Novelty detection: a

review - part 1: statistical approaches. In Signal Pro-

cessing 83. pages 2481–2497.

Smith, M., S. R. (2000). Automated inspection of textured

ceramic tiles. In Computers in Industry 43. pages 73–

82.

Valiente, J., Acebr

´

on, F., and L

´

opez, F. (1998). An Au-

tomatic Visual Inspection System for Ceramic Tile

Manufacturing Defects. In Proc.. IASTED Int. Conf.

on Signal Processing and Communications. pages

257–260.

Xie, X. (2008). A Review of Recent Advances in Surface

Defect Detection using Texture analysis Techniques.

In Electronic Letters on Computer Vision and Image

Analysis. pages 1–22.

3D INSPECTION SYSTEM IN CERAMIC TILES SURFACES WITH RANGE IMAGES

163