REUSABLE STATE MACHINE COMPONENTS FOR

EMBEDDED CONTROL SYSTEMS

Krzysztof Sierszecki, Feng Zhou and Christo Angelov

Mads Clausen Institute for Product Innovation, University of Southern Denmark, Alsion 2, Soenderborg, Denmark

Keywords: Embedded control systems, Component-based design, Reusable and reconfigurable components, State

machines.

Abstract: The paper presents a software design method for embedded applications, featuring reconfigurable

components such as a State Machine (SM) function block operating in conjunction with a composite Signal

Generator (SG) function block. The method emphasizes separation of concerns, whereby the State Machine

realizes the reactive aspect of system behaviour in separation from the transformational aspect, which is

delegated to the Signal Generator. Instances of these function blocks can be used to configure event-driven

state machines executed periodically in the context of control system tasks (actors). When activated, the SM

determines the control step that has to be executed in response to a particular event. The control step is then

indicated to the SG, which generates the corresponding control signals. The SM has been implemented

using a new Binary Decision Diagram (BDD)-based design pattern, resulting in a simple, yet powerful

component capable of processing both discrete and continuous signals, which can be used to efficiently

implement control actors for sequential and hybrid control applications.

1 INTRODUCTION

The conventional implementation of state machines

is based on manual encoding of an abstract model

representing either the behaviour or the structure of

the state machine. In the former case, the

behavioural model, i.e. the state transition graph, is

converted into code using various kinds of design

patterns, such as the switch-case design pattern

(Samek, 2002). In the latter case, the software

implementation models the hardware structure of the

state machine. The resulting program computes the

state transition logic functions and executes the

actions that are associated with various states. In

particular, that is how sequential control programs

are developed for industrial automation systems,

where control logic is encoded using domain-

specific languages, such as those defined in

standards IEC 61131-3 (John and Tiegelkamp, 2001)

and IEC 61499 (Lewis, 2001).

In both cases, conventional design methods have

a major shortcoming: the resulting implementation is

not reusable, because the logic of the state machine

is built into the code. Consequently, a new program

has to be developed whenever an application is

created or modified. This is a time-consuming and

error-prone process whose complexity grows rapidly

with the number of states and state transitions. To

some extent, the situation can be alleviated via

automated program generation using validated

models, but code reusability is still a problem.

This problem can be solved by developing

reusable state machine components, featuring

standard state machine drivers operating on re-

configurable data structures (Wang and Shin, 2002),

(Wagner and Wolstenholme, 2003). The resulting

software artifact can be viewed as an object of type

‘state machine’, which may have multiple instances

defined by the contents of the encapsulated data

structures (configuration tables). These can be

configured and re-configured using a dedicated

configuration tool. In this way, conventional

software development is replaced by the

configuration of reusable components and

consequently, manual coding of state machines can

be largely reduced and even eliminated.

This design philosophy has been adopted and

further refined in a reconfigurable state-machine

component for embedded control systems (Angelov

et al., 2005). With that component, it is possible to

invoke signal-processing function blocks (FBs)

within the states of the execution control state

166

Sierszecki K., Zhou F. and Angelov C. (2010).

REUSABLE STATE MACHINE COMPONENTS FOR EMBEDDED CONTROL SYSTEMS.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 166-171

DOI: 10.5220/0002879101660171

Copyright

c

SciTePress

machine. However, the complexity of the

component model is relatively high because it

combines both reactive (state-based) and

transformational behaviour in the context of hybrid

control systems. This has motivated the development

of the master-slave model presented in (Angelov et

al., 2008) where system tasks (actors) are configured

using stateful components of lower complexity, i.e. a

state-machine function block coupled to a modal

function block. However, in this model the state

machine can process only binary event signals that

are generated by pre-processing function blocks

such as comparators, counters, timers, etc., which

may result in increased complexity of the

corresponding function block networks.

The above problem has been addressed with a

design method featuring a new State Machine

function block operating in conjunction with a

composite Signal Generator, which is presented in

this paper. The discussion is illustrated with a

running example – a state machine used to

implement one of the control actors of a Medical

Ventilator Control System (Zhou et al., 2009).

The rest of the paper is structured as follows:

Section 2 presents the design model of a state

machine composed of State Machine and Signal

Generator components and focuses on the

implementation of a reconfigurable function block

of class State Machine, using a design pattern that

integrates pre-processing and control functions.

Section 3 presents briefly the design pattern of the

Signal Generator function block. A summary of the

proposed software design method and its

implications is given in the concluding section of the

paper.

2 RECONFIGURABLE STATE

MACHINE FUNCTION BLOCK

Embedded control system actors may exhibit

complex stateful behaviour. Such actors can be built

from reconfigurable software components, i.e. State

Machine (SM) and Signal Generator (SG) function

blocks. This approach emphasizes separation of

concerns: the SM implements reactive behaviour by

selecting the control step to be executed in response

to a transition event defined in terms of one or more

event signals that are sampled when the host actor is

triggered. The control step is specified in terms of

one or more output signals. These are generated by

invoking a sequence of function blocks inside the

SG - a composite component, which implements the

transformational aspect of actor behaviour - from

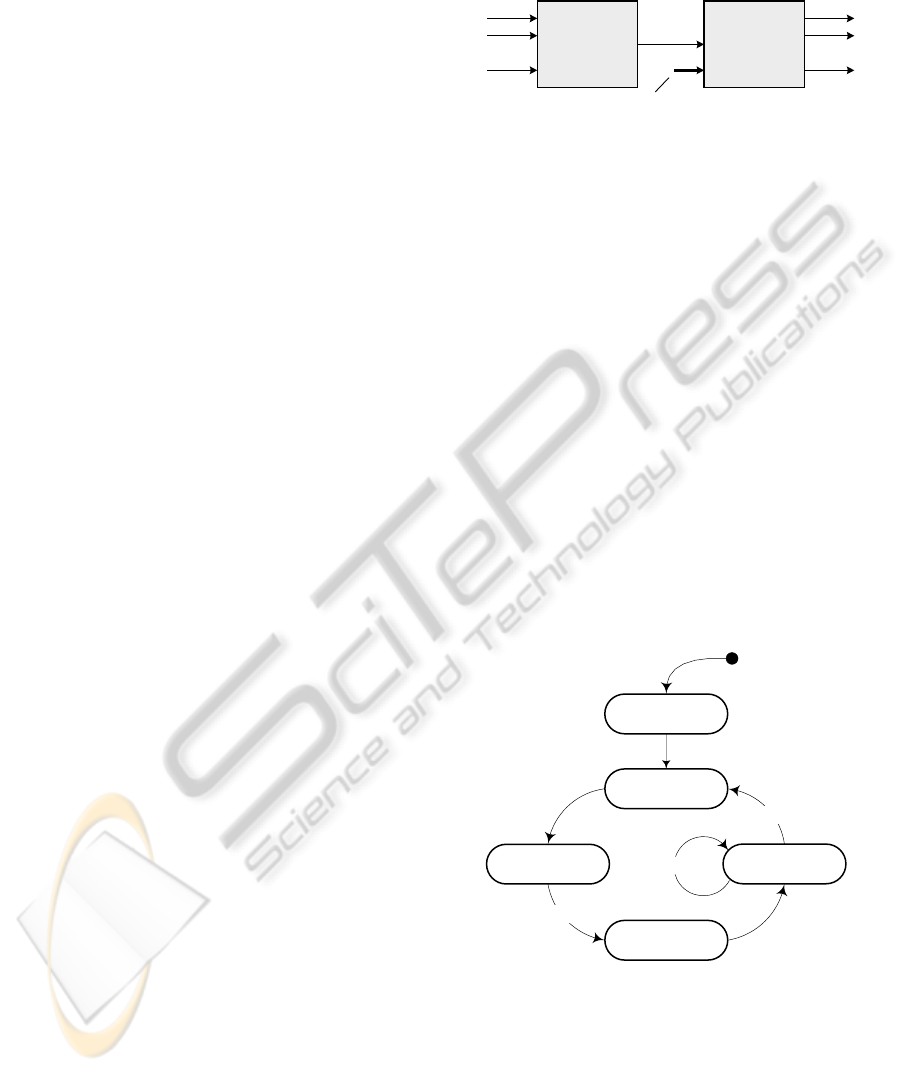

input signals to output signals (see Fig. 1).

SM

SG

..

..

..

..

Event

signals

Output

signals

Input signals

Control

step

Figure 1: State Machine and Signal Generator function

blocks.

The SM function block can be implemented

using a new version of the State Logic Controller

(SLC) design pattern originally introduced in

(Angelov et al., 2005). The SLC employs a data

structure that represents the state transition graph of

a Moore machine realizing the desired control

behaviour. It can be efficiently encoded as a table

containing binary decision diagrams that represent

the next-state mappings of various states s in the set

of states S, and the corresponding control steps, in

accordance with the state transition graph.

The next-state mapping of a state s is defined as

the subset Fs = {s’} involving those states that are

immediate successors of s. Hence, a state transition

graph can be symbolically represented by specifying

the next-state mappings of all states s ∈ S, whereby

the transition arcs are defined as tuples (s, s’ |

s’ ∈ F

s

) that are associated with the corresponding

transition events and event-priority symbols.

init

close_IV

open_EV

close_EV

pid_control

inspFlag

inspFlag

expFlag

s

1

s

2

s

3

s

4

s

5

1

2

s

0

Y

1

Y

2

Y

3

Y

4

Y

5

Figure 2: Medical Ventilator Control System: control actor

state machine.

This technique will be illustrated with a running

example, i.e. a control state machine encapsulated in

the Volume Control Ventilation (VCV) actor of a

Medical Ventilator Machine (Zhou et al., 2009), see

Fig. 2. Its state transition graph can be represented as

follows:

REUSABLE STATE MACHINE COMPONENTS FOR EMBEDDED CONTROL SYSTEMS

167

Fs

0

= s

1

/ Y

1

[c]

Fs

1

= s

2

/

Y

2

[c]

Fs

2

= s

3

/ Y

3

[c]

Fs

3

= s

4

/ Y

4

[e

1

], s

3

/ NOP [!e

1

]

Fs

4

= s

5

/ Y

5

[c]

Fs

5

= s

2

/ Y

2

[e

2

, 1], s

5

/ Y

5

[e

1

, 2],

s

5

/ NOP [!e

1

, !e

2

],

where s

0

denotes the initial pseudo-state, s

1

–

s

5

denote operational states; Y

1

– Y

5

denote the

corresponding control steps – initialization (init),

close inspiration valve (close_IV), open expiration

valve (open_EV) close expiration valve (close_EV),

PID control of inspiration valve (PID_control); e

1

and e

2

denote events represented by signals inspFlag

and expFlag respectively, and c denotes the default

clock event; bracketed expressions denote the

corresponding triggering events or <event – event-

priority> pairs (when necessary).

Next-state mappings can be conveniently

represented by means of binary decision diagrams,

as shown in Fig. 3 for the example state machine. In

these diagrams, circular nodes denote event signals

that have to be tested in order to determine the

current state/step to be executed from among the

subset of successors of the previous state/step. These

are tested in a predefined sequence that reflects the

priority of the corresponding transitions.

e

1

Y

1

Y

2

e

2

Y

3

Y

4

NOP

Y

5

Y

2

Y

5

NOP

e

1

1 0

01

1

0

FS

0

FS

1

FS

2

FS

3

FS

5

FS

4

s

0

s

2

s

3

s

4

s

5

s

3

s

2

s

5

s

5

s

1

Figure 3: Binary decision diagrams for next state (step)

mappings.

For example, it is possible to make a transition

from s

5

to either s

2

or s

5

, whereby the former

transition has higher importance, i.e. lower event

priority than the other one. That is encoded in the

BDD whereby the event signal e

2

is checked first

and the transition to s

2

– taken if e

2

is true; the

transition to s

5

will be taken only if e

2

is false and e

1

– true. In case neither of the event signals is present,

the parsing of the BDD ends up in a no-operation

(NOP) node, meaning that no transition is taken and

the previous state has to be maintained in the current

period without executing a control action.

Table 1: Step Sequence Table (the BDD Table).

Node

SuccTrue /

NextStateM

SuccFalse Mapping

0 Y

1

1

x

FS

0

1 Y

2

2

x

FS

1

2 Y

3

3

x

FS

2

3 e

1

4 5

FS

3

4 Y

4

6

x

5 NOP 3

x

6 Y

5

7

x

FS

4

7 e

2

1 8

FS

5

8 e

1

6 9

9 NOP 7

x

The binary decision diagrams of the next-state

mappings can be encoded in a Step Sequence Table,

(also called the BDD Table) as shown in Table 1. It

consists of the columns Node, successorTrue /

NextStateMapping and successorFalse, whereby the

first column contains symbols denoting BDD nodes,

and the other two columns – pointers to rows

containing the corresponding BDD elements. The

rows are grouped into segments containing the next-

state mappings of states s

0

– s

5

.

The Step Sequence Table can be interpreted

much in the same way as its graphical counterpart.

This can be done by a standard routine – a State

Machine Driver (SMD), which is activated

periodically by the host actor. Within each cycle, the

SMD processes the BDD segment containing the

successor states/steps of the state visited in the

previous cycle, in order to determine the current

state/step. If a state transition has taken place, the

control step index variable is updated accordingly,

and the associated Signal Generator function block

is subsequently invoked to execute the

corresponding control step. However, it is executed

only when the state is visited for the first time; it will

not be executed in subsequent cycles if the state is

maintained, unless a self-transition is explicitly

specified (execute-once semantics).

The above discussion is based on the assumption

that event signals are Boolean variables supplied by

external components, e.g. pre-processing function

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

168

blocks such as digital and analogue signal

comparators, timers, event counters, etc. However,

this may result in relatively complex function block

networks modelling application actors. That problem

can be eliminated by executing pre-processing

operations as internal functions of the state machine

function block. In that case, the condition nodes of

the BDD may be interpreted as various types of

compare, event counting and timer operations whose

result is tested in order to make a branching decision

within the BDD.

Each node of the BDD is thus associated with an

operation that has to be executed by the State

Machine Driver when processing the node. To that

end, an operation code is used to specify the node

operation, e.g. a control step executed in a state

node. Likewise, it is necessary to specify operation

codes (or function pointers) for various Boolean test,

compare, and counter/timer operations executed in

condition-testing nodes of the BDD.

The BDD table of the state machine function

block can be encoded using records of the following

format:

BDD_Record = Operation, CondTest |

Operation, ControlStep;

Operation = CondOp1 |

... | CondOpk|

CtrlStepOp;

CondTest = Operand1, Operand2,

SuccessorTrue,

SuccessorFalse;

ControlStep = ControlStepIndex,

NextStateMapping;

where the Operation code specifies one of the

following node-processing operations:

Boolean operations

Compare Integer operations

Compare Real operations

Count Events operation

Control Step operation

In case of condition evaluation, the CondTest

part of the BDD record contains operand fields,

which are interpreted in the context of the executed

node-processing operation as follows:

Boolean operations use Operand1 and

Operand2 as pointers to the tested variable

locations.

Compare Integer and Compare Real operations

use Operand1 as a pointer to the first

compared variable and Operand2 – as a

pointer to the second compared variable or

constant.

The Count Events operation uses Operand1 as a

pointer to the counted event variable. The

initial value of the event counter and the event

counter itself are passed as parameters via the

Operand2 field.

The remaining two items of the condition-test

record are used to implement branching decisions, as

follows:

Successor1 is used as a pointer to the next line

to be processed if the test/compare/counter

operation returns True.

Successor0 is a pointer to the next line to be

processed if the test/compare/counter

operation returns False.

In case of control step execution, the Operation

field is accompanied by a ControlStep field

comprising:

ControlStepIndex – an index of the control step

that has to be executed in the current state. A

NOP encoding of the control step index

denotes no operation.

NextStateMapping – a pointer to the first line of

the corresponding next-state mapping.

The above operations are executed by the State

Machine Driver while processing binary decision

diagrams, as follows:

Boolean operations and compare operations are

implemented by means of C-library compare

routines, which return True or False depending on

the result.

The Count Events operation interprets Operand1

as a pointer to the input variable of the event

counter. If that is a NULL pointer, the event counter

is driven by the periodic timing events triggering the

host actor, and operates as a timer measuring time

intervals that are multiples of the actor period. The

initial value of the event counter and the counter

itself are passed as a pointer to a dedicated data

structure in the second operand field. The operation

returns False if [counter] != 0 after decrementing the

counter; if [counter] = 0, the operation re-initializes

the counter and returns True.

The control step index is supplied to the SG as an

input parameter used to invoke the corresponding

sequence of function blocks in order to generate the

required control signals. If the SM state in the

current cycle is the same as in the previous one

(NOP BDD node), a NOP control step index is

generated, in accordance with the adopted execute-

REUSABLE STATE MACHINE COMPONENTS FOR EMBEDDED CONTROL SYSTEMS

169

once semantics. However, a self loop may be used if

a control step has to be executed repeatedly in

successive periods (e.g. PID in state s

5

of Fig. 2).

The algorithm given below can be used to

implement a state machine driver for a reusable and

reconfigurable function block of class State

Machine:

void StateMachineDriver(void *FB)

{

// Restore execution history

BDD_Record *r = FB->tableRecord;

// Determine current step and update

// output

do {

// Condition-testing node?

if (r->operation != CTRL_STEP_OP)

{

if ((r->operation)(r->operand1,

r->operand2))

{ // True

r = r->successorTrue;

}

else { // False

r = r->successorFalse;

}

}

else {

// Control step node?

// Update control step index

FB->ctrlStepIndex =

r->ctrlStepIndex;

// Save execution history

if ( r->ctrlStepIndex != NOP )

FB->tableRecord =

r->nextStateMapping;

return; // Leave the driver

}

} while( TRUE );

}

The SM function block instance is invoked with

a pointer to an execution record of type

StateMachine denoted as FB, which contains

relevant data, such as output buffer for the control

step index variable as well as a tableRecord history

variable, i.e. a pointer to the first line of the next-

state mapping segment, to be processed during the

next activation of the SM function block.

3 SIGNAL GENERATOR

FUNCTION BLOCK

The Signal Generator is a composite function block

containing instances of function blocks that are to be

invoked within statically defined execution

schedules - control step (CS) sequences, in order to

generate the control signals associated with the

corresponding control steps.

To that end, the control step index generated by

the SM is used to access a table containing records

such as < CSsequenceStart, CSsequenceLength >,

where each line corresponds to one particular control

step. These two parameters are used to access a

Function Block Table (FBT) where each line

corresponds to a function block instance specified by

the record < FBfunction, FBinstance >.

In particular, the CSsequenceStart is used to

access a FBT record specifying the first function

block instance of a control step sequence, and

CSsequnceLength – the number of function block

instances that have to be invoked in order to execute

the control step. Hence, the FBT can be viewed as a

concatenation of control step sequences that are

specified by the corresponding sub-networks of the

function block network encapsulated in the Signal

Generator.

It is possible that several control steps generate

one and the same continuous control signal, e.g. a

control signal that is generated in both manual and

automatic mode of operation. In that case, a

Multiplexor FB shall be used, whereby different

Multiplexor functions are invoked to switch the

corresponding input signals to the multiplexor

output.

Discrete (on/off) control signals can be generated

by means of another kind of function block that may

be invoked within the Signal Generator – the

Discrete Control Function Block (DCFB). The

DCFB employs the concept of control memory

storing binary control words: a particular word is

accessed using the corresponding control step index,

and is subsequently stored in the DCFB output

buffer.

Discrete control signals can also be generated by

means of a digital multiplexor function block. In this

case, the control step index is used to select an input

binary word to be switched to the multiplexor output

in order to generate the corresponding on/off control

signals. This solution is preferable for applications

featuring a small number of discrete control steps, as

is the case with the example state machine of Fig. 1.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

170

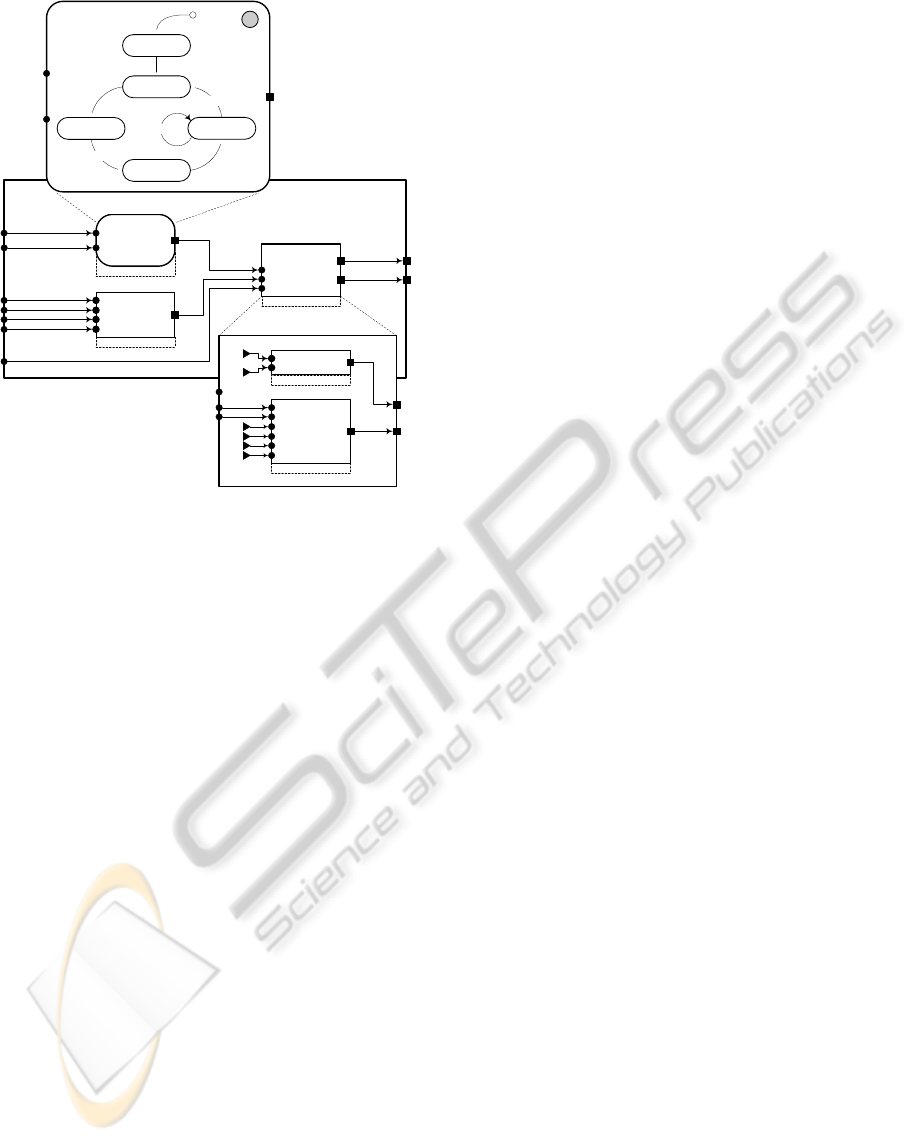

driver

driver

arith

step

setPoint

ctlX3.p1Flow

ctlX2.flowSet

ctlX1.inspFlag

ctlX2.I

ctlX2.E

ctlX2.respRate

State Machine

ctrlSM

ctrlSG

calcuSP

SPArithmetic

U16-float

Signal

Generator

expValveOutput

pidControlValue

init

close_IV

open_EV

close_EV

pid_control

inspFlag

inspFlag

expFlag

H

1

2

Ts

Kd

Ki

Kp

1

0

(EXPOPEN)

(EXPCLOSE)

setPoint

p1Flow

ctrlExpValve

2Multiplexer

U8-U8

ctrlInspValve

PID

float-float

action

expValveOutput

pidControlValue

ctlX1.expFlag

s

0

Figure 4: Control actor state machine implementation.

The Signal Generator of the example state

machine is shown in Fig. 4. It incorporates two

function block instances, i.e. a Multiplexor FB

instance generating on/off control signals for the

control steps open_EV and close_EV, and a PID FB

instance generating the signal pid_control and

close_IV. The PID function block encapsulates three

functions: initialize(), PID() and stop(). The first one

is invoked when executing the init control step and

the other two – when executing the control steps

pid_control and close_IV (by applying a zero

voltage to the inspiration valve of the ventilator).

The combination of state machine and signal

generator can be used to engineer sequential and

modal continuous control systems, as well as

systems generating continuous control signals in

some states and discrete on/off control signals in

other states, as shown in the example.

4 CONCLUSIONS

The paper presents a software design method for

embedded control applications, which employs two

types of reconfigurable component that can be used

to configure control system tasks (actors) – State

Machine and Signal Generator function blocks. The

State Machine function block realizes the reactive

(control flow) aspect of actor behaviour, in

separation from the transformational (data flow)

aspect, which is assigned to the Signal Generator.

The presented version of the State Machine

function block is capable of processing any kind of

input signal – Boolean, binary-coded or analogue in

order to compute Boolean event variables needed to

implicitly select the state to be activated, and to

explicitly select the control step to be executed in

that state. The index of the control step is then

indicated to the Signal Generator, in order to activate

the corresponding FB sequence used to generate the

corresponding control signals.

The State Machine has been implemented as a

reusable and reconfigurable function block using a

new BDD-based State Logic Controller design

pattern, resulting in a simple, yet powerful

component that can be combined with a

reconfigurable Signal Generator to efficiently

implement state machines of arbitrary complexity

for a broad range of sequential and hybrid control

applications.

REFERENCES

Samek, M., 2002. Practical Statecharts in C/C++:

Quantum Programming for Embedded Systems, CMP

Books.

John, K-H., Tiegelkamp, M., 2001. IEC61131-3:

Programming Industrial Automation Systems,

Springer.

Lewis, R., 2001. Modeling Control Systems Using IEC

61499, Institution of Electrical Engineers.

Wagner, F., Wolstenholme, P., 2003. Modeling and

Building Reliable, Re-usable Software. In 10th IEEE

International Conference and Workshop on the

Engineering of Computer-Based Systems. Huntsville,

USA.

Wang, S., Shin, K.G., 2002. Constructing Reconfigurable

Software for Machine Control Systems. In IEEE

Trans. on Robotics and Automation, vol. 18, No 4

Angelov, C., Sierszecki, K., Marian, N., 2005. Design

Models for Reusable and Reconfigurable State

Machines. In Lecture Notes in Computer Science, v.

3824, Springer

Angelov C., Ke, X., Guo Y., Sierszecki K., 2008.

Reconfigurable State Machine Components for

Embedded Applications. In SEAA 2008, 34th

EUROMICRO Conference on Software Engineering

and Advanced Applications, IEEE Computer Society

Zhou, F., Guan, W., Sierszecki, K., Angelov, C., 2009.

Component-Based Design of Software for Embedded

Control Systems: the Medical Ventilator Case Study.

In ICESS 2009, International Conference on

Embedded Software and Systems, IEEE Computer

Society

REUSABLE STATE MACHINE COMPONENTS FOR EMBEDDED CONTROL SYSTEMS

171