PREDICTION OF TEMPERATURE INSIDE A REFRIGERATED

CONTAINER IN THE PRESENCE OF PERISHABLE GOODS

Javier Palafox-Albarrán, Reiner Jedermann and Walter Lang

Institute of Microsensors Actuators and Systems (IMSAS), University of Bremen

Otto Hahn Allee NW1, D-28359 Bremen, Germany

Keywords: System Identification, Temperature, Organic Heat, Feedback-hammerstein.

Abstract: This paper presents an alternative method to predict the temperature profile in a spatial point of the interior

of a refrigerated container with the aim of improving the logistics of perishable goods. A SISO gray-box

model in which the organic heat is represented by a non-linear feedback system and the cooling process

represented by a linear system is proposed. Parameter adaptation and prediction algorithms for the model

are modified to reduce the matrix dimensions, implemented in Matlab and applied to experimental data for

validation. Apart from being highly accurate, the predictions comply with the desired figures of merit for

the implementation in wireless sensor nodes, such as high robustness against quantization and enviromental

noise. Simulation results concludes that if the cargo emits organic heat, the proposed model is faster and

more accurate than the linear models.

1 INTRODUCTION

Research has been done in the past to estimate the

temperature profile inside refrigerated containers.

Several options have been investigated:

mathematical approaches as presented in (Shaik,

2007), K-ε models as proposed in (Rouaud, 2002),

and several numerical models as reviewed in

(Smale, 2006). With the exception of

(Moureh,2004), in which the effect of the pallets is

considered; usually the focus is put on the cold air

flow as the main factor governing the temperature

pattern inside a container and the effects due the

cargo presence is sub estimated.

To take into account the effect of the cargo in the

temperature, in (Babazadeh, 2008) it is proposed the

use of wireless sensor nodes (WSN) to measure the

ambient parameters in the surroundings of a spatial

point of interest and the use of system identification

to estimate the parameters of a linear Multi-Input

Single-Output (MISO) system. It concluded that in

order to have a good estimation, it is necessary to

have a high number of training samples and many

inputs to the system.

In this paper an alternative Single-Input Single-

Output (SISO) grey-box model is presented to

predict the temperature inside the container under

the presence of perishable goods with the aim of

reducing the complexity and preserving the

accuracy. The proposed model provides a

meaningful description of the factors involved in the

physical system including the effect of transporting

living goods such as fruits and vegetables. The

starting point is based on the physical relations;

subsequently, a tuning parameter for the specific

case of bananas is found by simulations.

2 MODEL OF THE SYSTEM

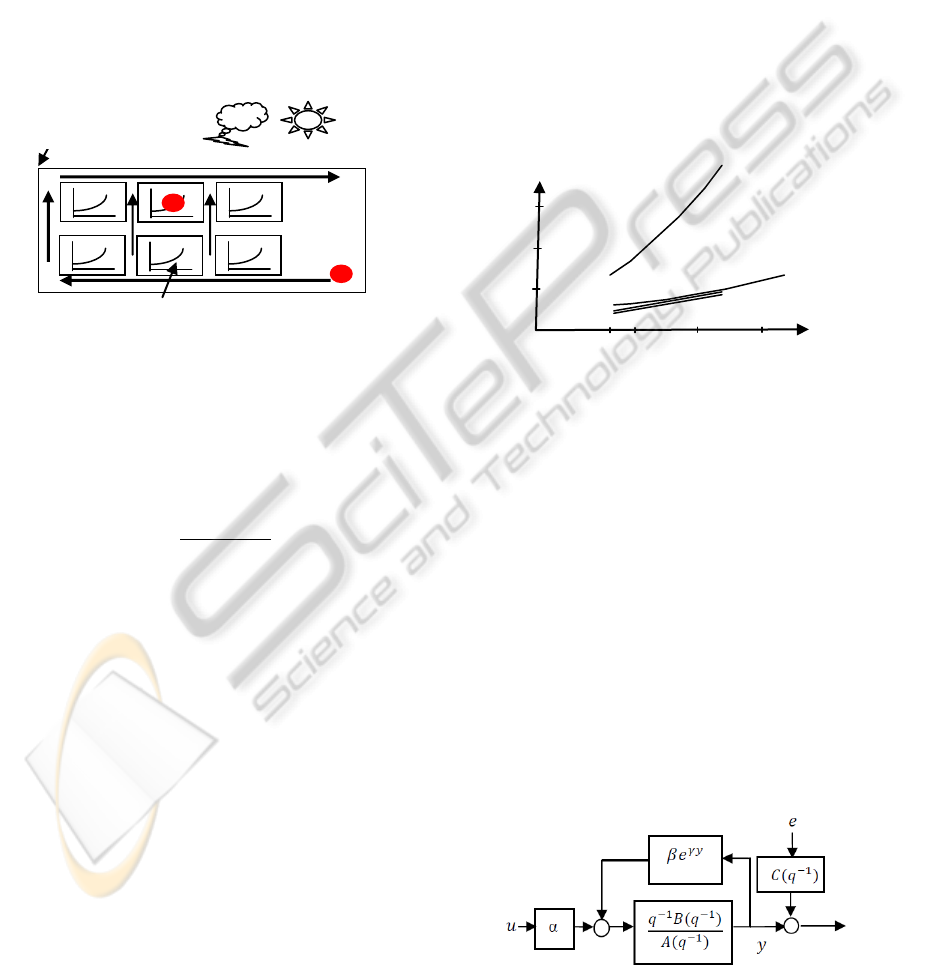

The factors affecting the temperature distribution

inside a refrigerated container are illustrated in

Figure 1. The cold air flows from bottom to top

through the gratings in the floor and through the

spaces between the pallets, and eventually it is

drawn off the channel between the pallets and the

container ceiling.

A naive representation of the container can be

done by a SISO linear dynamic system in which the

input is the air supply and the output is the spatial

20

Palafox-Albarrán J., Jedermann R. and Lang W. (2010).

PREDICTION OF TEMPERATURE INSIDE A REFRIGERATED CONTAINER IN THE PRESENCE OF PERISHABLE GOODS.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 20-27

DOI: 10.5220/0002880100200027

Copyright

c

SciTePress

Temperature

o

C

Yellow

Green

Heat

W/ Ton

3

00

2

00

1

00

point of interest. However, in reality it is only a

simple model of the main contributor to the

temperature pattern, the air flow. Several other

factors affect the speed of the cooling down.

To improve the accuracy of the model, other

contributors are considered as well: first is the heat,

produced by respiration of living goods such as

fruits and vegetables; second is the thermal loss,

affecting the correct cooling of the goods; finally,

unpredictable temperature variations due to highly

changing external climatic conditions during

transportation.

Figure 1: Factors affecting the temperature inside a

refrigerated container.

The linear SISO black-box model representing

the air flow is represented mathematically by a

linear dynamic system H, which in the discrete

domain is given by the Equation 1.

1

=

1

1

1

(1)

Where

and

are the orders of the system

polynomials,

1

,

1

are the polynomial

coefficients, and is the delay operator in discrete

domain.

An attenuator, α ,models the isolation loses of

the air supply temperature and is modeled to affect

the input of the dynamic system. The external

climatic conditions are unknown in advance,

therefore considered a statistical process. The output

of the Moving Average (MA) process, which is in

fact white noise (WN) filtered by the filter C

represented in Equation 2 added to the output of the

dynamic system, models them.

(

1

) = 1 +

1

1

+ +

(2)

To model the organic heat, it is necessary to use

experimental data. Figure 2 (Mercantila, 1989)

shows a family of curves for organic heat in the case

of bananas. A proportional relationship between of

the organic heat and the rippening state is observed.

Equation 3 represents the organic heat relation

with respect to the temperature.

is the heat

production in Watts, is a constant which is fixed

for a certain type of fruit and rippening-state in 1/

O

C,

is the fruit temperature in

O

C, and is a scaling

factor which depends of the amount of food and is

given in kilograms.

=

(3)

Figure 2: Heat Production of bananas.

Finally, the block diagram to represent the input-

output relations of all the factors is built. It is shown

in Figure 3. The air flow dynamics are represented

as a feed-forward block as it is the most important

contributor. The isolation losses affect the correct

cooling of the goods before the dynamic system and

the noise effect has an additive effect on the output.

The contribution of the organic heat depends on

the cooling temperature inside the container.

Simultaneously, it has a small additive effect in the

input of the linear dynamic system as the air flows

through the pallets and is slightly warmed. It is

represented by a static exponential feedback. The

resulting block diagram, in which a linear dynamic

system has a non-linear feedback corresponds to a

Feedback-Hammerstein (FH) configuration (Guo,

2004).

Figure 3: Model of the system.

Organic heat

Isolation losses

Disturbances

PREDICTION OF TEMPERATURE INSIDE A REFRIGERATED CONTAINER IN THE PRESENCE OF

PERISHABLE GOODS

21

3 PARAMETER ADAPTATION

ALGORITHM

In (Guo, 2004) a Parameter Adaptation Algorithm

(PAA) was developed to identify the parameter-set

of a FH system. It uses an intermediate variable

and converts the non-linear system into a pseudo-

linear one. Its principal advantage is that the

conventional recursive matrix-based linear system

identification algorithms as those presented in

(Landau, 2005) can be applied to estimate the

parameter matrix . The recursive form of those

algorithm is given by Equation 4. Where () is the

prediction error as described in Equation 5, P(t+1)

is an adaptation matrix to perform the minimization

of ε using Recursive Least Squares method, and φ(t)

is the observation matrix that contains the input and

the output data.

+ 1

in Equation 6 is the so

called Forgetting Factor (FF).

(t+1)=(t)+(P

t + 1

φ(t))

()

(4)

() = () ()

φ(t-1)

(5)

P(t+1)=

()()φφ

(

()

φ

φ+(+1)

)

(+1)

(6)

+ 1

=

+ 1

(7)

Guo considers the non-linearity as a polynomial

of order l as shown in Equation 8; however, the

dimensions of the matrices in the algorithm would

be significantly too large to be applied in platforms

where power consumption is an important figure of

merit.

y

=

y

k

=0

(t)

(8)

To reduce the dimensions of the matrices, was

proposed the use of the exponential Equation in

Equation 3 instead. γ is to be determined and it

remains constant, while β is a parameter to be

identified as it depends on the amount of fruit being

transported. The linear term of the Equation 8 needs

to be extracted to be included in the polynomial

1

of the equivalent SISO pseudo-linear

system. Expanding it into a Taylor series and

rearranging, the summation of the non-linear

coefficients of the exponential function can be

calculated using Equation 9. The non-linear

coefficients and an offset are on the left hand of the

equation.

()

!

∞

=2

+1 =

()

()

(9)

The equivalent pseudo-linear system for an

exponential non-linearity is shown in Equation 10.

1

y

t

=

1

+

1

1

() +

1

1

+

1

(10)

The resulting coeficients of the polynomials

(

1

) and

1

are given by Equation 11 and

12.

=

()

(11)

1

=

2

2

+ +

(12)

And the intermediate variable is shown by

Equation 13.

=

1

+ (

()

())

(13)

The choice of the forgetting factor in the

algorithm is often critical. In theory, it must be one

that converges. On the other hand, if it is less than

one the algorithm becomes more sensitive and the

estimated parameter changes quickly making the

convergence faster. A more complex solution is to

allow it to vary with time, lower than one at the

beginning but tending to one.

Figure 4: Types of forgetting factors.

Figure 4 illustrates three different types of FF. The

first case is obtained by making

, and

in

Equation 7 equal to one. It is called Decreasing Gain

(DG). In the second case, the Constant Forgetting

Factor (CFF)

is set to a value smaller than one

and

set to one. Finally, the Variable Forgetting

Factor (VFF) uses a value of

smaller than one

and recalculates

for each iteration.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

22

Table 1: Elements of the elements in the algorithm matrices.

Symbol

Arrangement of the elements into the matrices

φ(t)

···

+ 1

,

1

, (

),

1

. . .

),

···

+ 1

()

1

,

1

,

1

,

2

1

1

,

1

(t)

+ 1

,

, (

),

1

. . .

)

()

1

,

1

,

1

,

2

1

1

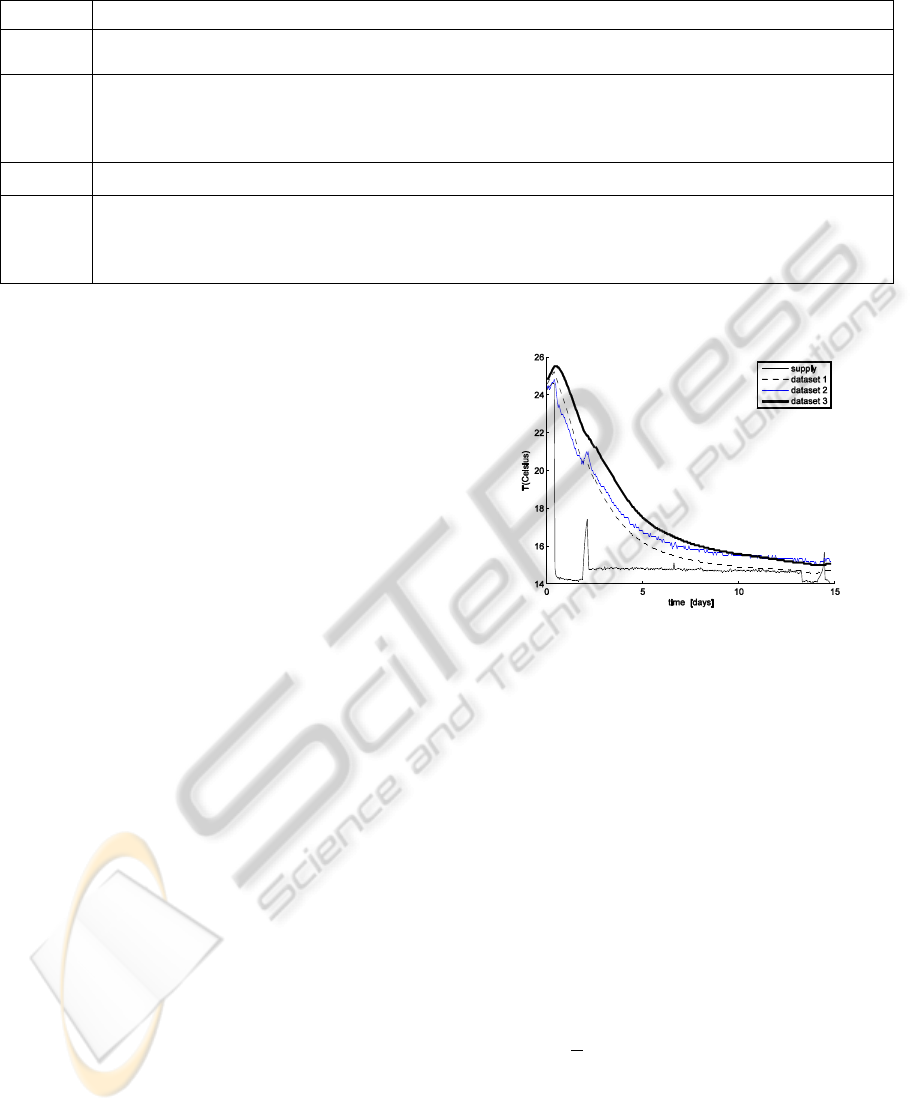

4 PREDICTION ALGORITHM

The predictions are made using the estimated

parameters in the model. Figure 5 shows

experimental data sets from a container transporting

bananas. It can be observed how the air supply is

kept constant after some days. For the prediction

algorithm, () is set to the value of the last sampled

input temperature of the parameter adaptation

process. Similarly, the initial predicted output value

is set to the last acquired value of the output.

Equation 14 to 17 describes the prediction

algorithm. m is the number of iterations used for the

PAA.

=

(14)

() =

(15)

()=

(m) φ

(t-1)

(16)

=

1

+ (

()

())

(17)

5 DETERMINATION OF γ

In considering a linear system, an exponential

discrete time decaying system like the one presented

in Figure 5 can be described as of the order of one

with its unique pole on the real positive axis. The

closer the pole to one the higher the delay of the

system.

Figure 5: Banana data sets.

To find a trustworthy parameter that

characterizes the respiration heat of bananas. The

presented Feedback-Hammerstein model of linear

order one and the FH parameter adaptation and

prediction algorithms are run using given

experimental data sets. The Mean Squared Error

(MSE) of the prediction over n samples, equivalent

to fifteen days, is stored for several values of γ and

fixed number of training days. If the stored values of

the MSE are plotted, the local minimums are

determined by the observation of the MSE vs. γ

curves. In Figure 6, it can be seen that in the above

mentioned plot for five days of training and for the

data set 1, a local minimum exists for a value γ of

0.0587.

=

1

(

)

2

=

(18)

PREDICTION OF TEMPERATURE INSIDE A REFRIGERATED CONTAINER IN THE PRESENCE OF

PERISHABLE GOODS

23

Figure 6: Prediction accuracy vs. γ.

6 RESULTS

For validation of the model and algorithms several

figures of merit are considered. The accuracy and

the speed of convergence are of paramount

importance; however, quantization and noise

robustness are also highly desirable for

implementation in a WSN. Only the linear orders of

one and two are considered to avoid computation of

complex conjugate poles that would characterize

oscillations.

To observe the speed of convergence and the

accuracy of the predictions with respect to the

number of training days, parameter estimation and a

prediction in Matrix form are done (See Table 1) for

a fixed number of training days. Subsequently, MSE

vs. Training days graphs are plotted. Assuming a

quantization level of 0.2

O

C, a Matlab script was

written to assign the nearest value of the

quantization grid to the input and the output datasets.

The results of the predictions using the quantized

datasets are overlapped with the results of non-

quantized.

Similarly, to determine the noise robustness,

MSE versus the signal to noise ratio (SNR) is

plotted. Several noise levels of white noise were

added to the output of the data set 1, and the

resulting signals were applied to PAA and prediction

algorithms with fixed number of training days.

SNR(dB)=10log

(19)

Simulations were done for two types of data sets.

First, the experimental data of bananas were used to

include the presence of organic heat. Secondly, the

data sets corresponding to a cheese experiment,

which does not present organic heat, were

considered. A summary of all simulation results is

presented on Table 2.

6.1 FH vs. Linear Models

in the Presence of Organic Heat

From the simulations it is observed in Figures 7 and

8 that if linear methods are applied to the banana

datasets, the accuracy of the results for different

sensor positions of are not sufficient. Quantization

robustness is improved with the linear order of one

and the speed of convergence is better using CFF. In

the best of cases acceptable prediction accuracy can

only be achieved after more than five days of

training.

It is also observed in Figures 8 and 9 that FH

identification algorithms are the best to achieve fast

convergence speeds. In the best cases, less than 3

days of training is sufficient to achieve good

predictions. However, the plots are made for the data

from three days onwards to avoid the visualization

of the effects in MSE due to the set point variations

in the reefer supply temperature. Linear system

orders of one are in all cases better than order of

two, both in the speed of convergence and the

quantization robustness. Decreasing Gain must be

optimal to preserve the accuracy and the

quantization robustness.

Figure 7: ARX of order one in the presence of organic

heat.

Concerning the noise models, results of the

simulation of Feedback-Hammerstein with MA

process are worse than when modeled as white noise

(WN). It affects the accuracy and the quantization

robustness

0 0.05 0.1 0.15

0

0.2

0.4

0.6

0.8

1

MSE

Values of

MSE of FH ARX PAA with respect to gamma

3 4 5 6 7 8 9 10

0

1

2

3

Training Days

MSE

Order of one and DG

Non-quantized

Quantized

3 4 5 6 7 8 9 10

0

1

2

3

Training Days

MSE

Order of one and CFF

Non-quantized

Quantized

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

24

Figure 8: FH of order one in the presence of organic heat.

Figure 9: FH of order two in the presence of organic heat.

6.2 FH vs. Linear Models

in the Absence of Organic Heat

In the case of cheese data set, the linear methods

accuracy results are better than that of the Feedback-

Hammerstein as can be observed in Figure 10.

Modeling noise as white gives better quantization

robustness than modeling it as MA process.

The use of forgetting factors does not have a big

impact in the results of ARX predictions; however,

Constant Forgetting Factor is slightly better for

ARMAX predictions. Linear orders do not affect

the simulated predictions, but an order of two is

selected because it can model more accurately if the

behavior of the system is not purely decaying.

Figure 10: Comparison of FH and linear methods in the

absence of organic heat.

Figure 11: Comparison of linear methods with MA and

WN models.

6.3 Noise Robustness

The noise was added to validate FH and linear

models; also for both of them the accuracy is

compared with and without the MA model.

Maximum Signal-to-Noise Ratio to obtain a good

prediction is observed to be around 43 dB for all of

them with the exception of ARX which has a

maximum value of 47 Decibels as shown in Table 2.

6.4 Prediction Improvement

The described approach was originally developed

based on an experiment in 2008 with records for 3

sensors (data set A). Two new data sets with 16

sensors each, which were recorded in 2009

(Jedermann, 2010) in two separate containers (data

set B and C), were used to cross validate the

approach.

3 4 5 6 7 8 9 10

0

0.5

1

Training Days

MSE

Order of one and DG

Non-quantized

Quantized

3 4 5 6 7 8 9 10

0

0.5

1

Training Days

MSE

Order of one and CFF

Non-quantized

Quantized

3 4 5 6 7 8 9 10

0

0.5

1

Training Days

MSE

Order of two and DG

Non-quantized

Quantized

3 4 5 6 7 8 9 10

0

0.5

1

Training Days

MSE

Order of two and CFF

Non-quantized

Quantized

3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8

0

0.5

1

Trainining Days

MSE

Linear ARX of order of one

Non-quantized

Quantized

3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8

0

0.5

1

Trainining Days

MSE

FH of linear order of one

Non-quantized

Quantized

3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8

0

0.5

1

Time (Days)

MSE

Linear ARX of order of two

Non-quantized

Quantized

3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8

0

0.5

1

Time (Days)

Average Error

Linear ARMAX of order of two

Non-quantized

Quantized

PREDICTION OF TEMPERATURE INSIDE A REFRIGERATED CONTAINER IN THE PRESENCE OF

PERISHABLE GOODS

25

Table 2: Summary of simulation results.

Accuracy

Number

of

matrix

elements

Convergence

speed

Quantization

Robustness

Critical

SNR

Estimation

for linear

dataset

Best

Forgetting

Factor

Best

Linear

order

ARX

CFF

2

3

Bad

Good

47dB

Good

ARMAX

CFF

2

3 +

Bad

Bad

43 dB

FH and WN

model

DG

1

3

Good

Good

43 dB

Bad

FH and MA

model

DG

1

3 +

Good

Bad

43 dB

Figure 12: Noise Robustness for FH method

FH algorithm of linear order of one was applied

to all data sets; neither quantization nor forgetting

factor is used. For the initial parameter settings, the

pole and zero of the feed-forward linear system was

set to 0.9 and 0.0; β was set to 2.

The previously obtained value of γ equal to

0.0587 is used to predict the temperature inside the

containers for many spatial positions. The results are

compared to the predictions for the datasets shown

in Figure 5 and resumed in Table 3. A good average

is observed for the three containers; however, in

some positions the predictions are not as accurate as

is observed in the Maximum column.

Table 3: MSE prediction results for a unique value of γ.

Container/Result

Maximum

Minimum

Average

Data set A

0.1893

0.0173

0.0778

Data set B

1.4558

0.0550

0.4130

Data set C

0.8888

0.0101

0.2798

A second approach is to select γ according to the

position of the pallets inside the container. The

method to find γ, described previously, is applied to

all the new container datasets.

It is observed that an improvement in the

accuracy of the predictions can be made if two

different values of γ are selected: one for pallets

close to the door-end, and one for pallets close to the

reefer supply. In Table 4 it is resumed the prediction

results if values of 0.0525 and 0.055 are set

respectively.

Table 4: MSE prediction results for values of γ according

to the position inside the container.

Container/Result

Maximum

Minimum

Average

Data set A

0.1893

0.0173

0.0778

Data set B

0.4767

0.0279

0.0946

Data set C

0.5747

0.0201

0.1743

7 CONCLUSIONS

A model to represent the factors affecting the

temperature inside a refrigerated container

transporting perishable goods was proposed. It

models the effect of organic heat using a static non-

linear feedback system, the refrigeration by a linear

dynamic feed-forward system, and the disturbances

by stochastic processes. This complex model can

provide an accurate description of the factors

involved in the physical system.

The selected identification method was adapted

specifically to reduce the dimensions of the

matrices. The non-linear exponential function is

used instead of a polynomial to preserve the

simplicity of the parameter adaptation and the

prediction algorithms. The disadvantage of the

10 20 30 40 50 60 70

0

5

10

15

20

25

Signal to Noise Ratio(dB)

MSE

FH ARX Prediction Error vs SNR

Non-quantized

Quantized

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

26

simplification is that depending on the kind of fruits

to be transported, it is required to tune the algorithm

by a correct selection of γ which has to be known in

advance. An improvement can be observed in the

accuracy of the predictions if γ is set according to

the position of the pallets inside the container.

From the simulation results it is concluded that

the FH identification algorithm is efficient when the

cargo emits organic heat. The method of FH of order

1 is optimal to achieve all figures of merit. It makes

accurate predictions only after three days of training

and maintains low dimensions of matrices.

However, if the linear method is applied to the

banana datasets, a comparable accuracy can only be

achieved after more than five days of training. Also,

it is concluded that when the goods to transport are

free of organic heat, such as in the case of cheese, it

is preferable to use a linear system instead.

ACKNOWLEDGEMENTS

The authors would like to express their gratitude to

Prof. Rainer Laur, Dirk Hentschel, Mehrdad

Babazadeh, and Chanaka Lloyd for all their help.

This research was supported by the German

Research Foundation (DFG) as part of the

Collaborative Research Centre 637 “Autonomous

Cooperating Logistic Processes”. Further project

information can be found at

www.intelligentcontainer.com.

REFERENCES

Babazadeh, M., Kreowski, H.-J., Lang, W, 2008. Selective

Predictors of Environmental Parameters in Wireless

Sensor Networks. In International Journal of

Mathematical Models and Methods in Applied

Sciences Vol.2, pages 355-363.

Guo, F., 2004. A New Identification Method for Wiener

and Hammerstein System. Ph.D. Thesis, Institut für

Angewandte Informatik Forschungzentrum Karlsruhe.

Karlsruhe.

Jedermann, R., Becker, M., Görg, C., Lang, W., 2010.

Field Test of the Intelligent Container, In European

Conference on Wireless Sensor Networks

EWSN2010, 16-19 February 2010 in Coimbra,

Portugal.

Landau, I.D., Zito G., 2006. Digital Control Systems:

Design, identification and implementation. Springer.

London, 1st edition.

Mercantila. 1989. Guide to food transport: fruit and

vegetables. Mercantila Publ. Copenhagen.Moureh J.,

Flick, D., 2004. Airflow pattern and temperature

distribution in a typical refrigerated truck

configuration loaded with pallet. In International

Journal of Refrigeration, V. 27, Issue 5, pages 464-

474.

Palafox J., 2009. Prediction of temperature in the transport

of perishable goods based in On-line System

Identification. M.Sc. Thesis, University of Bremen.

Bremen.

Rouaud, O., Havet, M., 2002. Computation of the airflow

in a pilot scale clean room using K-ε turbulence

models, In International Journal of Refrigeration, Vol.

25, Issue 3, pages 351-361.

Shaikh, N. I., Prabhu, V., 2007.Mathematical modeling

and simulation of cryogenic tunnel freezers. In Journal

of Food Engineering, Vol. 80, Issue2, pages 701-710.

Smale, N. J., Moureh,J., Cortella, G., 2007.A review of

numerical models of airflow in refrigerated food

applications. In International Journal of Refrigeration,

Vol. 29, Issue 6, pages 911-930.

LIST OF ABBREVIATIONS

ARMAX

ARX

CFF

DG

FF

FH

MA

MSE

PAA

WN

WSN

Auto Regressive Moving Average

with External input.

Auto Regresive with External input.

Constant Forgetting Factor

Decreasing Gain

Forgetting Factor

Feedback Hammerstein

Moving Average

Mean Squared Error

Parameter Adaptation

AlgorithmWhite Noise

Wireless Sensor Node

PREDICTION OF TEMPERATURE INSIDE A REFRIGERATED CONTAINER IN THE PRESENCE OF

PERISHABLE GOODS

27