AN ESTIMATION PROCEDURE TO DETERMINE THE EFFORT

REQUIRED TO MODEL BUSINESS PROCESSES

Claudia Cappelli

1

, Flávia Maria Santoro

1

, Vanessa Nunes

1,2

Márcio de O. Barros

1

and José Roberto Dutra

1

1

Postgraduate Information Systems Program – UNIRIO, Av. Pasteur 458, Urca – Rio de Janeiro, RJ, Brazil

2

COPPE/UFRJ – Systems Engineering and Computer Science Program, Rio de Janeiro, RJ - P.O. Box 68511, Brazil

Keywords: Business process modeling (BPM), Estimation.

Abstract. Business processes modeling projects are increasingly widespread in organizations. Companies have several

processes to be identified and modeled. They usually invest much in hiring expert consultants to do such

job. However, they still find no guidelines to help them estimate how much a process modeling project will

cost or how long this will take. We propose an approach to estimate the effort required to conduct a BPM

project and discuss results obtained from over 50 projects in a large Brazilian company.

1 INTRODUCTION

Business process modeling (BPM) projects are

increasingly widespread in organizations, often

driven by Business Process Management initiatives

(Indulska et al., 2009). The expected benefits from

these projects are as follows: (i) Provide tools and

analysis contributing to process improvement,

focusing on eliminating waste, reducing costs and

mitigating risks; (ii) Allow, through process

mapping, for learning about "how to perform the

work", guaranteeing autonomy to new employees,

since knowledge would not be concentrated on older

employees; (iii) Facilitate process management,

contributing to increase customer satisfaction level.

Well-known project management practices are

generally applied in conducting BPM projects. One

of the first activities to be undertaken is to identify

project scope and establish deadlines. Project

duration must be validated according to the effort

required to complete modeling and an estimated

allocation of professionals over time. Companies

have several processes to be identified and modeled.

They usually invest much in hiring expert

consultants to do such job. However, they still find

no guidelines to help them estimate how much a

BPM project will cost, how long or how many

resources it will take. Differences in process type,

goals, performers’ profiles, and professionals

responsible for modeling render a new project

always different from previous ones, thus increasing

the uncertainty of such estimates. We argue that,

from a historical database of observed efforts

invested in BPM projects, the organization can

extract indicators closer to reality and, therefore,

increase the reliability of its estimates.

Among various process modeling methods, the

framework adopted in this work is the workflow-

oriented method proposed by Sharp (2001). Several

diagrams are used in order to model the business

processes, with activities, roles, organizational units,

objectives, products, etc.. There are a number of

tools and notations available for this purpose. The

modeling tool referenced in this work is ARIS

(Scheer, 1999) which, among others, includes the

following models: Value-added Chain (VAC);

Event-driven Process Chain (EPC) and Function

Allocation Diagram (FAD).

The aim of this paper is to present an approach

for effort estimation on BPM projects and discuss

results obtained from real project data from over 50

projects in a large Brazilian company. The paper is

structured in the following manner: Section 2

presents business process modeling concepts;

Section 3 presents the Estimating BPM Project

Effort process and Section 4 argues its limitations;

Section 5 presents related work; Section 6 shows

conclusions and future work.

178

Cappelli C., Maria Santoro F., Nunes V., de O. Barros M. and Dutra J. (2010).

AN ESTIMATION PROCEDURE TO DETERMINE THE EFFORT REQUIRED TO MODEL BUSINESS PROCESSES.

In Proceedings of the 12th International Conference on Enterprise Information Systems - Information Systems Analysis and Specification, pages

178-184

DOI: 10.5220/0002884201780184

Copyright

c

SciTePress

2 BUSINESS PROCESS MODEL

DATABASE

Nearly 50 actual BPM projects were developed in a

large Brazilian petroleum company for

approximately two years, each with its specific

goals. These projects were conducted according to

an institutionalized method based on the framework

presented in section 2 and adherent pattern notation.

Teams were generally comprised of a number of

part-time modelers and one project manager.

We have recorded effort and cost estimates for all

these projects. At the beginning, managers used their

experience with projects in other companies and

knowledge about the analysts whole would take part

in the project to estimate a new project’s effort. At a

second stage, they began to use data collected from

previous projects performed within the company.

2.1 Classifying Business Processes

Thanks to the projects described in the former

section, we had a great deal of information on

conducting BPM projects. This information included

people involved in each project, scope and project

scheduling. This data formed a rich database, which

we have mined to build the effort estimation model.

However, though the information was available, it

was not structured so as to allow immediate

analysis: it was distributed along several documents,

such as Gantt charts, meeting summaries, and many

other types of documentation. Our first step was to

collect and organize this data into logical groups and

attributes. We have managed to collect information

about 48 projects classified into three groups:

• Administrative Projects (ADM):

processes related

to administrative tasks, performed at offices

usually distant from the operational plant. Involve

collecting information on market demand,

controlling the execution of recurrent inspections

and maintenance tasks, organizing training

sessions or workshops, collecting and

communicating production-related information to

high management. Administrative processes

usually have a simple workflow, consisting of

tasks not described in great detail. Information on

13 administrative processes were collected;

• Operational Projects (TOP):

on the flip side of the

administrative processes, operational processes

are directly related to production and to the daily

operation of the production plant. These

processes are typically performed by technical

personnel, who interact directly with equipment

gauges and valves installed in the production site.

Operational processes are usually described by

huge workflows with very detailed procedures to

perform each comprising task, along with

exception routes to be followed when the process

does not behave as expected. Information on 10

operational processes were collected;

• Technical management projects (TMP): these

processes are in the middle ground between the

administrative and operational processes. While

administrative processes are mostly concerned

with clerical activities and reporting, TMP are

concerned with production continuity and

improvement. They typically involve managing

resources required to conduct the operation,

tracking new production methods and equipment

performance, evaluating new production site

performance, and so on. These are distinct from

operational processes in the sense that they do not

involve directly manipulation of equipment used

in production. TMP are usually mid-sized

processes, if compared to their peers from the

former groups, and are strongly subjected to

automation. Information about 25 technical

management processes were collected.

2.2 Describing Business Processes

After classifying each BPM project as ADM, TOP

or TMP, we collected the following information on

each process: Project identifier; Project name;

Project class; Business unit; Project start and finish

date; Project manager; Analysts; Dedication for each

analyst; Project participation start and finish date for

each analyst; Number of workflows comprising the

process (# EPCs); Number of non-decomposable,

atomic activities in the workflows of the process (#

FADs); # risks; # indicators; # systems; # business

requirements; # business rules; # screens; #

equipments; and Interface diagram.

The former attributes were collected for all BPM

projects comprising our database. Afterwards, we

eliminate outliers due to the following reasons:

• One ADM process had too many activities (#

FAD). While the average ADM process has 46

activities, the eliminated one had 183 activities

(the second larger ADM process had only 79

activities);

• One TMP process was paused throughout a long

time frame. Modeling team changed after this

period, and the new team had to learn about the

process from the start;

• Two TMP processes were too small (5 and 10

AN ESTIMATION PROCEDURE TO DETERMINE THE EFFORT REQUIRED TO MODEL BUSINESS PROCESSES

179

activities) and performed in a very short time

frame (about one month each);

• One TOP and two TMP processes were discarded

due to strong reuse from other processes.

3 ESTIMATING BPM PROJECT

EFFORT

The objective of an effort estimation technique is to

determine the number of man-days required to

accomplish a certain task. To create a new effort

estimation technique, one must rely on the following

project management relationship, which describes

the dependencies among duration, work to be done,

and number of workers.

U

W

D =

(1)

where D represents task duration, represented in a

time unit; W is the amount of work required for a

single worker to accomplish the task, also measured

in a time unit; and U represents the number of

workers available to participate in the task. Given

that D times U is a measure of effort (number of

workers for a certain period), we have the equality

E=W. Based on our project database, we have to

build models both for project work and effort. Given

completed projects, we fit estimation equations to

describe the amount of work for a given project

based on its attributes. When considering a new

project, we have to estimate its attributes, apply to

the work model, and calculate its effort.

In the following sections, we develop a model to

describe the work involved in a BPM project

(section 4.1), the effort for each project composing

our database (section 4.2), and estimation models for

our three project classes (sections 4.3 to 4.5).

3.1 Describing Project Work

Since we had many attributes to estimate the amount

of work required for a given BPM process, our first

initiative was to reduce the volume of data before

creating an effort model. To identify which

information is more relevant to the estimation

procedure, we have interviewed some of projects

managers comprising our database. Their feedback

was very important, and is summarized below.

Project managers emphasized that the cost of a

BPM project would probably be related to the

number of activities, the complexity of such

activities, and the degree of detail in which these

should be described. The number of activities is

represented by the number of FAD’s in a process.

So, this attribute should be part of the effort model.

Project managers have also stated that activity

complexity was related to process type. This

relationship was proved by data, as shown in Table

2, which depicts the average time required to model

each activity for each process class (and standard

deviation). ADM processes were found to be the

hardest to model, while TOP projects were found to

be the easiest.

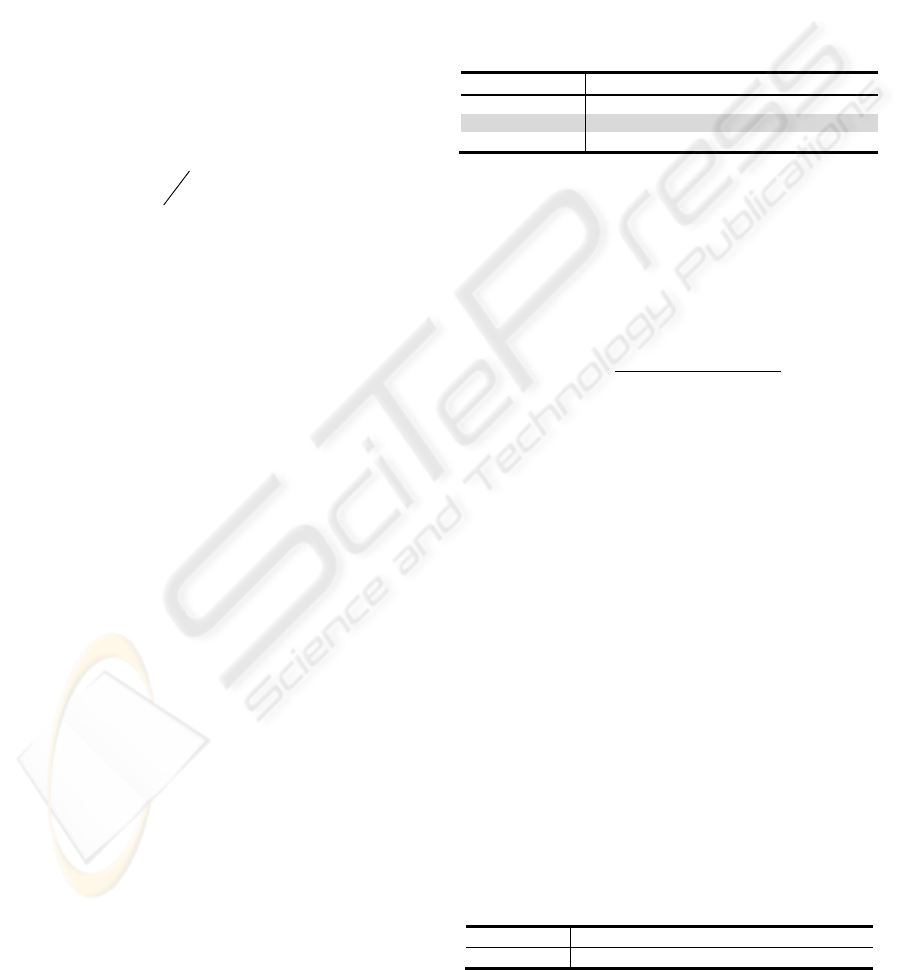

Table 2: Relationship between the time required to

perform a BPM project and its number of activities.

Type µ

Time/FAD

σ

Time/FAD

ADM 0,74 0,41

TMP 0,53 0,28

TOP 0,47 0,30

Managers supported this conclusion, mentioning

that TOP projects are well-known by a number of

people who work directly on the process. Due to the

differences, we have decided to separate the effort

model according to project type.

Finally, to estimate the degree of detail modeled

for each activity in a given project, we have defined

a derived attribute from several attributes composing

our database. The number of elements

(NEL) is a

count of distinct complementary information

produced by a BPM project, usually related to

project goals, which determine what kind of

information is to be modeled. This information

includes elements described in Section 3.2. For

instance, if a project lists the risks and the

application systems related to a given process, we

count as two elements (NEL=2).

Managers have expressed that the effective count

of elements might not be relevant, since it would be

directly related to the number of activities. Again,

data supported this claim. Table 3 presents the

correlation (Spearman’s rank order coefficient)

between the effective count of elements (ECT)

identified by a BPM project and the number of

activities in the same process (high correlation for

ADM and TOP and moderate correlation for TMP).

Since ECT is highly correlated to the number of

activities and given the difficulties of having this

information a priori, we have decided not to take it

into consideration in our effort estimation model.

Table 3: Correlation between the effective count of

elements (ECT) and the number of activities (FAD).

ADM TMP TOP Overall

ρ

ECT, FAD

85% 65% 87% 78%

Thus, the amount of work to be accomplished in

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

180

order to execute a BPM project p depends on the

class of the process under analysis and is based on

two variables: FAD

p

and NEL

p

.

W

p

= f (FAD

p

, NEL

p

) (2)

Sections 4.3, 4.4, and 4.5 present the analytical

formulation of the f() function for each process class

and the limits of its application. However, to derive

these formulations we must compare the amount of

work required to accomplish the BPM project to the

time that was effectively required to complete the

work. The following section addresses estimating

the time required for each process.

3.2 Describing Project Effort

To calculate the effort (man-days) invested in each

project comprising our database, we have multiplied

the number of workers participating in a project by

the amount of time during which it was performed.

Our BPM projects were performed by two types

of workers: analysts and managers. By analyzing our

data, we have perceived an almost constant

participation of managers, dedicating about 20% of

their work-time for each project. Thus, managing a

BPM project can be deemed a constant effort and the

varying workforce is described solely by the number

of analysts involved in the project.

In our experience, it was common practice to

assign an analyst to more than one BPM project at a

time. This concurrent work is very important, since

BPM projects usually have periods in which the

results produced by the analysts are being validated

by the client, leaving the team available to work on

other processes. On the other hand, we do not have

precise data about the dedication of each developer

to each project in our database. Instead, we know the

periods in which each analyst worked for each

process and the fraction of an 8-hour workday that

s/he worked during this period for all projects in

which the analyst was involved.

To estimate the dedication of each analyst to each

BPM project, we have assumed that an analyst

assigned to more than one project would equally

divide the work time among these projects. Thus, if

a part-time analyst (50% of an 8-hour workday) has

worked for two projects in a given week, s/he

dedicated 25% of a man-week to each project. By

doing so, we have calculated a derived attribute for

each project in our database: the adjusted number of

modelers (AM), calculated as per equation 3 below.

.

#

..

1

1

,

∑∑

==

−

=

p

p

N

f

sd

a

aa

da

a

pp

p

projects

dedication

sf

AM

(3)

where s

p

is the start date for project p, f

p

is the finish

date for project p, dedication

a

represents the whole

dedication (for all projects involved) of a given

analyst a as a fraction of an 8-hour workday; and

#projects

a,d

represents the number of projects in

which an analyst a worked concurrently in day d.

Thus, the effort required to accomplish a given

BPM project p, measured in full-time 8-hour man-

days, is calculated by multiplying AM

p

by project

duration, as presented in equation 4.

pppp

AMsfE ).(

−

=

(4)

Given E

p

for each project in our database, we can

fit proper a f() function for each project class, as

presented in the following sections.

3.3 Estimating BPM Projects

Prior to estimate a BPM project, there is a need to

identify the end-to-end process model, by

developing the VAC, in order to provide an

overview of the main processes. Then, each macro-

process of the VAC is decomposed in individual

business processes. To estimate the amount of

activities for each individual business process,

consider that each process will be detailed in a single

workflow. If it is not possible to deduce the amount

of activities for each individual process, it can be

done by analogy, using the knowledge database,

searching for projects with similar characteristics

and obtaining an average amount of activities.

3.4 Estimating ADM Projects

Following outlier elimination, we had 12 ADM

BPM projects in our database. Table 4 presents

summary information on these projects.

Table 4: Summary information on ADM projects.

AVG SD Min Max

FAD

P

46 20 14 79

NEL

P

4 n/a 2 5

D

P

77 27 42 132

E

P

33 27.6 12.3 104.4

E

P

/FAD

P

0.74 0.41 0.25 1.48

The best fit for equation f() (see equation 2) for

ADM projects was a combination of a third order

polynomial over the number of activities and a linear

equation of the number of elements (see Equation 5).

This equation has shown good fitness for all ADM

projects (R

2

> 91%).

7.31.108.516.00014.0

23

−−+−=

ppppp

NELFADFADFADE

(5)

AN ESTIMATION PROCEDURE TO DETERMINE THE EFFORT REQUIRED TO MODEL BUSINESS PROCESSES

181

Thus, our estimation procedure for ADM BPM

processes can be summarized as:

• Estimate the number of activities for the project

under interest. Usual ADM processes range from

15 to 80 activities;

• Estimate the number of elements to be addressed

while modeling process. ADM processes usually

describe from 3 to 5 distinct elements (systems,

indicators, business requirements/rules, screens,

and interface diagrams);

• If the number of activities is lower than 80 and

the number of elements is lower than 6, apply

equation (5) to estimate the effort required to

conduct the project, in man-days. Accept

estimations up to E

p

+ FAD

p

* 0.41, allowing

one standard deviation for project risks;

• If the number of activities is greater than 80 or

the number of elements is higher than 5, we are

not able to determine a fitting equation. In such

cases, the equation (5) may yield inadequate

values and an estimation range is acceptable

from 0.74 * FAD

p

to 1.56 * FAD

p

, that is:

µ

E

* FAD

p

≤ E

p

≤ (µ

E

+ 2 * σ

E

)* FAD

p

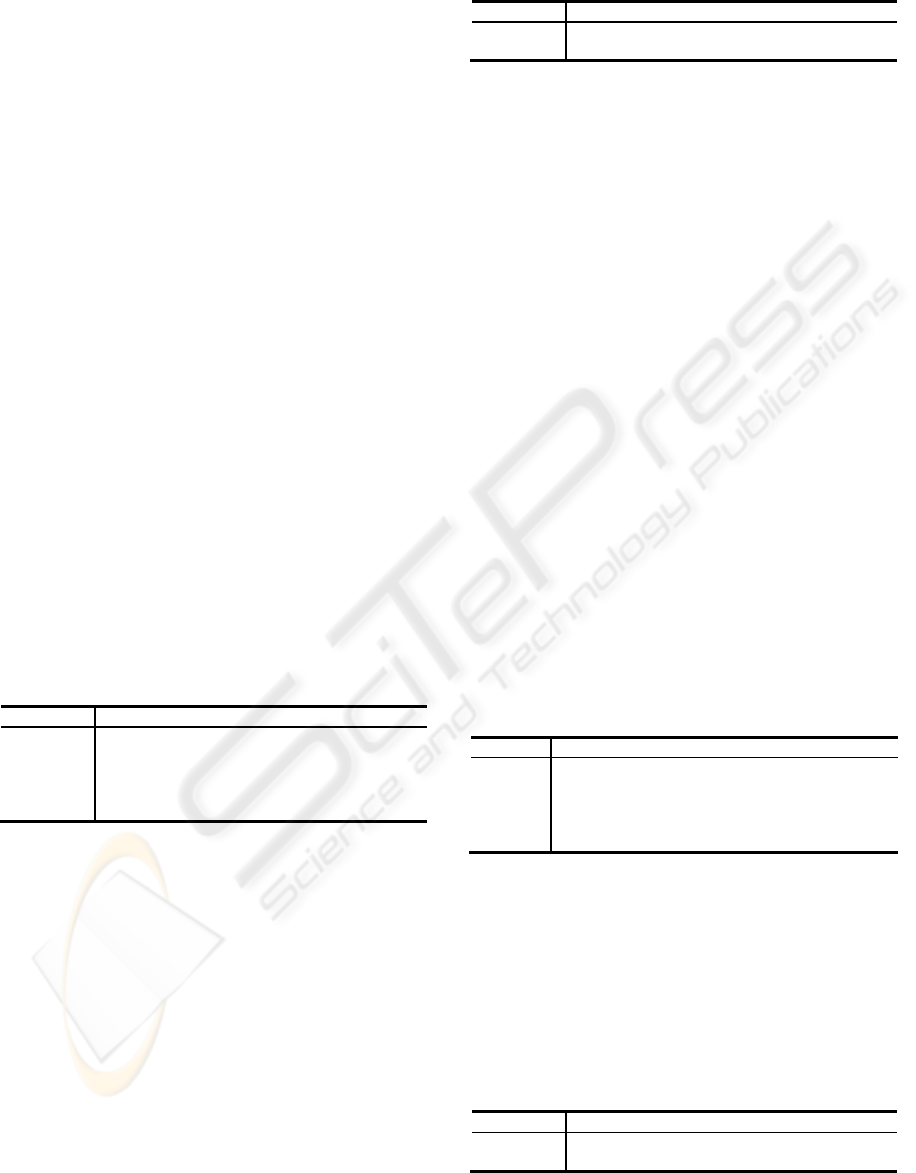

3.5 Estimating TOP Projects

After outlier elimination, we had 9 TOP projects in

our database. Table 5 presents summary information

about these projects.

Table 5: Summary information about TOP projects.

AVG SD Min Max

FAD

P

332 252 37 722

NEL

P

6 n/a 4 7

D

P

146 51 78 229

E

P

129 95 27 301

E

P

/FAD

P

0,38 0,09 0,27 0,53

The best fit for equation f()for TOP projects was

again a combination of a third order polynomial over

the number of activities and a linear equation over

the number of elements, like equation (5). Such

equation has shown good fitness for all TOP projects

(R

2

> 95%). However, due to negative parameters in

the third and first power of the polynomial, this

formulation would yield very low (even negative)

estimations for mid-sized processes addressing in

few elements. Since this unexpected behavior was

promoted due to spikes in process data, we have

decided to smooth the observed effort data using a

third order averaging process. Table 6 presents

summary information about these projects after the

smoothing.

Table 6: Summary for TOP projects after smoothing.

AVG SD Min Max

E

P

105 74 27 217

E

P

/FAD

P

0,31 0,03 0,27 0,38

The best fit for equation f()after smoothing was a

combination of a second order polynomial over the

number of activities and a linear equation over the

number of elements (equation 6). Such equation has

shown good fitness for all TOP projects (R

2

> 98%).

13.304.3175.000015.0

2

+++=

bppp

NELFADFADE

(6)

Thus, our estimation procedure for TOP BPM

processes can be summarized as follows:

• Estimate the number of activities for the project.

Small TOP processes usually have from 50 to

250 activities, whereas large processes have 600

or more;

• Estimate the number of elements to be addressed

while modeling. Small TOP processes usually

describe from 5 or 6 distinct elements, while

large TOP processes address 6 or 7 elements;

• Apply formula (6) to estimate the effort required

in man-days. Accept a 10% range to allow room

for project risks.

3.6 Estimating TMP Projects

Following outlier elimination, we had 20 TMP

projects whose data is presented in Table 7.

Table 7: Summary information on TMP projects.

AVG SD Min Max

FAD

P

54 25 13 109

NEL

P

3 n/a 2 7

D

P

63 42 16 151

E

P

26 15 8 56

E

P

/FAD

P

0.53 0.28 0.16 1.13

The available data for TMP processes was much

noisier when compared to data for ADM and TOP

processes. Therefore, the best fit for equation f()for

TMP projects was poor (R

2

≈ 28%). As in the TOP

process, we have proceeded smoothing the observed

effort data by using a third order averaging process.

Table 8 presents summary information about TMP

projects after the smoothing.

Table 8: Summary for TMP projects after smoothing.

AVG SD Min Max

E

P

24 7 10 38

E

P

/FAD

P

0,5 0,16 0,25 0,92

The best fit for equation f()after smoothing was a

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

182

power function over the number of activities (7).

Equation 7 has shown fair fitness for all TMP

projects (R

2

>65%).

72.007.2

62.0

+=

pp

FADE

(7)

We have also found that the number of elements

has had limited influence in the effort model

(correlation between effort estimation error and the

number of elements was as small as 4%). Thus, the

number of elements is not used in the fitting

equation. Our estimation procedure for TMP BPM

processes can be summarized as:

• Estimate the number of activities for the project

under interest. TMP processes usually have from

20 to 100 activities;

• Apply formula (7) to estimate the effort required

to conduct the project, in man-days. Accept a

20% range to allow room for project risks.

4 LIMITATIONS AND LESSONS

LEARNED

Estimation models are highly dependent on available

data quality. We have spent a long time cleaning the

information conveyed in our database and analyzing

the best way in which this could be used to derive

the models. Nevertheless, the resulting models are

still limited by our restricted data: we ar not able to

describe a fitting equation for large (> 80 FAD)

ADM processes, for ADM processes addressing

more than 5 distinct elements; accuracy for small

TOP processes is very limited, and data for TMP

processes is noisy enough to inhibit a precise model.

The model could be richer if more data were

available and if this data were collected more

accurately. Thus, data must be collected from new

BPM projects and inserted in the database to allow

further revisions on equations. Particularly, resource

allocation must be collected more precisely, for

example, using timesheets.

Finally, our data may be biased because it was

collected from projects performed by the same team.

Though the analysts have changed considerably

throughout the 2 years, managements have remained

almost the same. Again, data from new projects can

improve equations and clear this potential bias.

5 RELATED WORK

To our knowledge, no published work exists that

presents techniques to estimate the effort required

accomplishing a BPM project. Some authors have

written about the similarities between software and

process modeling projects (Vanderfeesten et al.,

2008) and compared software and process model

metrics (Gruhn and Laue, 2006; Cardoso, 2005).

Louis at al. (1991) talk about people knowledge,

Hughes (1996) considers the experts for estimation.

Bielak (2000) and Moses and Clifford (2000)

discuss the importance of historical data to

improvement in estimate accuracy.

6 CONCLUSIONS AND FUTURE

PERSPECTIVES

Business process modeling is a key element when

discussing organizational management and IT

strategies. Nevertheless, estimating the effort to

model business processes has become a great

challenge due to the lack of guidelines to support

such task. We have presented an estimation

procedure approach to determine the effort required

to model business processes using data collected for

approximately two years in about 50 projects. Data

about real effort and resources in each project were

stored in a database thus rendering possible the use

of such information in this work.

By grouping projects in related process types, we

have collected information that was registered in an

unstructured way. Through a combination of

statistical analysis and expert opinions, we have

developed estimation models for each process type

group, considering the limitations discussed.

As future work, we intend to evaluate the

proposed models by applying them on new BPM

projects to calibrate the parameters and adjust the

formulas, if necessary.

REFERENCES

Bielak J. “Improving size estimates using historical data”

In: IEEE Software, Vol.17, Issue 6, p. 27-35, 2000.

Cardoso, J.. How to measure the control-flow complexity

of web processes and workflows. In The Workflow

Handbook, pages 199–212, 2005.

Gruhn, V., Laue, R. Complexity metrics for business

process models, in: 9th International Conference on

Business Information Systems, Austria, 2006.

Hughes R. T. “Expert judgement as an estimating method”

In: Information and Software Technology 38, Elsevier,

p.67-75, 1996.

Indulska, M., Recker, J. C. and Rosemann, M., Green, P.

Business process modeling: current issues and future

challenges. International Conference on Advanced

AN ESTIMATION PROCEDURE TO DETERMINE THE EFFORT REQUIRED TO MODEL BUSINESS PROCESSES

183

Information Systems, 8-12 2009, The Netherlands.

Louis M. Taff, James W. Borchering, and W. Richard

Hudgins, Jr. "Estimeetings: Development Estimates

and a Front-End Process For a Large Project" In: IEEE

Transactions on Software Engineering, v.17, n8, 1991.

Moses, J. Clifford, J. “Learning how to improve effort

estimation in small software development companies”

In: Computer Software and Applications Conference

(COMPSAC), The 24th Annual International, Taipei,

Taiwan, p. 522-527, 2000.

Scheer, A. W., ARIS – Business Process Frameworks, 2nd

ed., Springer, 1999.

Sharp, A.; McDermott, P. Workflow Modeling: Tools for

Process Improvement and Application Development.

Norwood: Artech House, 2001.

Vanderfeesten, I., Cardoso, J., Mendling, J., Reijers, H. A.

and van der Aalst, W.M.P., Quality metrics for

business process models. In: Fischer, L. (Ed.), BPM

and Workflow Handbook, Future Strategies Inc.,

Lighthouse Point, FL, USA. pp. 179-190, 2008.

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

184