INTERACTION OF A FLEXIBLE ROBOT WITH ITS

ENVIRONMENT

Michael Kastner, Hubert Gattringer, Hartmut Bremer

Institute for Robotics, Johannes Kepler University, Altenberger Strasse 69, 4040 Linz, Austria

Martin Ramsauer, Paolo Ferrara

FerRobotics Compliant Robot Technology GmbH, Altenberger Strasse 69, 4040 Linz, Austria

Keywords:

Fludic Muscles, Pneumatic Robot, Contact Detection, Interactive Programming, Human Robot Interaction.

Abstract:

Uncomplicated and safe programming interfaces as well as flexible programs themselves become important

when robots are used for small lot size tasks or are operated by personnel without special robotics education.

This work takes a look at safe and easy interaction of a flexible articulated robot arm – actuated by fluidic

muscles – with its environment. A contact detection scheme for stiff collisions at speeds between 50 and

250 mm/s is presented and measurement results are disucussed. Moreover, a programming by demonstration

concept is described on the basis of a pick and place task. Both strategies (implemented on a seven axis

handling robot) rely on physical models to allow an operation without extra sensors.

1 INTRODUCTION

Programming a robot requires a high level of subject-

specific knowledge and concentration. Human errors

can cause great damage to the robots environment –

including people. Studies showed that most robot re-

lated accidents occur during programming or fault re-

covery (Clark and Lehto, 1999). For small lot sizes,

frequent reprogramming and adaptation increases the

occurance of these scenarios, thus heightening the

overall probability of harm to process equipment and

personnel.

Fluidic muscles are interesting actuators for de-

vices interacting with humans, because of their com-

pliance. See (Daerden and Lefeber, 2002) for an tech-

nology overview and (Van Damme et al., 2005) for

more on soft manipulators. Besides safety considera-

tions coveredin (Bicchi and Tonietti, 2004), this com-

pliance can also be used to let the robot be more aware

of its surroundings.

For this paper we consider a robot actuated by

commercially available muscles (Hesse, 2003) of the

McKibben type. We show how the physical model

of the robot and its actuators can be used in two sce-

narios of robot environment interaction. This is done

without the need for any sensors in addition to the

ones present in the control loops (see Figure 1b).

In the first setting, the robot moves along a trajec-

tory at rather low speed and should be able to detect a

(stiff) collision with its surrounding at the tool with-

out causing damage. This sense of touch is meant to

free the programmer from the necessity to provide the

exact data of the process setup to the robot. Measure-

ment results for different speeds and spatial directions

are discussed.

The second part describes the direct interaction of

the operator with the robot to allow the programming

of a simple pick and place task completely by demon-

stration.

2 SYSTEM ARCHITECTURE

The robot configuration (1a) comprises seven rota-

tional joints. Five are actuated pneumatically. Of

these, three (1, 2 and 4) are driven by the one degree

of freedom muscle setup detailed below. The hand

joint (6, 7) is operated by a combination of three flu-

idic muscles and a cardan mechanism. The remaining

two joints (3, 5) contain standard brushless DC mo-

tors with harmonic drive gearing.

As shown in Figure 1b, a pneumatic muscle drive con-

sists of two muscles (Figure 1c) in an antagonistic

setup connected by a sprocket chain. The linear mo-

230

Kastner M., Gattringer H., Bremer H., Ramsauer M. and Ferrara P. (2010).

INTERACTION OF A FLEXIBLE ROBOT WITH ITS ENVIRONMENT.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 230-233

DOI: 10.5220/0002918402300233

Copyright

c

SciTePress

Pressure

Sensors

Position

Sensor

Control

System

2 x

1 2

Tank

a) b)

d)

c)

Nonlinear Springs

4

5

3

2

1

7

6

B

Y

T

Y

T

Z

T

X

B

X

B

Z

F

1

F

2

Figure 1: Kinematic setup (joints, base and tool coordinate systems) of the considered robot

R

omo (a), mostly actuated by

pneumatic drives like (b). The drives utilize fluidic muscles (c) and their characteristic is similar to the scheme shown in (d).

tion of the actuator is transformedinto a rotation by an

according sprocket wheel supported by a ball bearing.

The absolute rotation angle is measured by a cable

extension sensor. Airflow to and from the muscles is

regulated by proportional directional valves. The air

pressure inside each actuator is measured by a sensor

mounted near the inlet. All sensors are connected to

16 bit A/D converters.

The compliance of the system stems from the soft

muscles and the compressible work medium air. In

this respect the actuation is roughly equivalent to two

nonlinear springs with adjustable pre-tensioning (see

Figure 1d).

3 MODELING

3.1 Fluidic Muscles

The static relations between force F, contraction h

and pressure p of the fluidic muscles (Festo MAS,

Figure 1c) are provided in the form of datasheet di-

agrams by the manufacturer. For this work, we used

approximations of the form

F = a(h) p+ b(h), (1)

where a(h) and b(h) are polynomials of order three

and six. Their coefficients have been identified in ex-

periments. One model muscle was used for each dif-

ferent diameter.

When two fluidic muscles are combined into an

antagonistic setup, the resulting actuator torque is

Q

M

(∆p, q) = r

S

(F

2

− F

1

), (2)

with the sprocket wheel radius r

S

and the muscle

forces F

1

and F

2

(see Figure 1b). Q

M

can be written

as a function of the pressure difference ∆p = p

2

− p

1

and the joint angle q, to which the contractions h

1

and

h

2

are geometrically linked.

3.2 Multi Body System

For modeling the mechanical part of the robot, the

equation of motion of the multibody system

M(q)

¨

q+ g(q,

˙

q) = Q

M

(3)

is used. Here, q and its time derivatives are the vec-

tors of the joint angles, velocities and accelerations

respectively, M is the mass matrix, g a term that in-

cludes gravitational forces, coriolis forces and so on.

A calibration term is also part of g. The entries of

the vector Q

M

are the torques of the joint actuators

(mostly muscle pairs like in eq. 2). We calculated

and implemented this model by using the projection

equation in subsystem formulation (Bremer, 2008)

N

∑

k=1

∂˙y

k

∂

˙

q

T

(M

k

(y

k

) ¨y

k

+ g

k

(y

k

, ˙y

k

) − Q

k

) = 0 (4)

which allowed us to combine smaller segments k (one

driveand the attached arm each) of the robot in a mod-

ular way. y are describing coordinates used for the

separate subsystems while the rest of the notation is

analogous to the one used in Equation 3. Geometry

and inertia data were exported from the CAD con-

struction files, damping terms were identified on the

real system.

4 CONTACT DETECTION

A robot manipulator is moving along some path (Fig-

ure 2). At an unknownlocation, it will collide with its

INTERACTION OF A FLEXIBLE ROBOT WITH ITS ENVIRONMENT

231

t

d

TCP path

Environment

Robot manipulator

Figure 2: Contact detection scenario.

surrounding. This is deliberate but must be handeled

in a manner as not to inflict damage. An algorithm

should be found to allow the robot an autonomous

(i.e. without the use of any extra sensors) detection

of such a collision.

After the detection, the robot should abort the ma-

neuver,report the incident to the sequence control and

hold its current position. Due to the limited band-

width of the pneumatic robot system, it is impossible

to avoid the peak in the contact force upon collision.

This has to be dealt with by choosing an appropri-

ate approaching velocity. After the impact, the robot

should not push against the surrounding.

The focus for this task is on two stiff clashing ob-

jects. (Haddadin et al., 2008) cover similar topics for

an electrically actuated robot with focus on safety.

4.1 Contact Force Estimation

In the contact case, the model multibody dynamics

Equation 3 does not hold any longer. There is a re-

maining term

Q

C

= M(q)

¨

q+ g(q,

˙

q) − Q

M

(q, p) (5)

that we interpret as a vector of external contact

torques acting on the joints. Deviations from the

model are also included there as well as measurement

errors. The velocities

˙

q and accelerations

¨

q are esti-

mated from the position sensor data.

As already mentioned,we are interested in the tool

contact scenario. Therefore, we use the relation for

the virtual work

δx

T

TCP

F

C

= δq

T

Q

C

(6)

and

δx

TCP

=

∂x

TCP

∂q

δq =

∂v

TCP

∂

˙

q

δq (7)

to get an equivalent tool center force estimation,

F

C

=

∂v

TCP

∂

˙

q

T

!

−1

Q

C

. (8)

The vector x

TCP

= [x y z]

T

contains the cartesian co-

ordinates of the tool center point, v

TCP

is the accord-

ing absolute translational speed. From the kinemat-

ics of the robot (Figure 1a), one can see that for a

reasonable tool geometry, joints 6 and 7 are insensi-

tive to contact forces because of the small lever arms.

More noise than information would be added, which

is why we did not include these joints in our algo-

rithm. Joints 3 and 5 are also excluded as they are

not actuated pneumatically. The Jacobian using the

velocities then reads

∂v

TCP

∂

˙

q

=

∂v

x

∂ ˙q

1

∂v

x

∂ ˙q

2

∂v

x

∂ ˙q

4

∂v

y

∂ ˙q

1

∂v

y

∂ ˙q

2

∂v

y

∂ ˙q

4

∂v

z

∂ ˙q

1

∂v

z

∂ ˙q

2

∂v

z

∂ ˙q

4

. (9)

4.2 Detection Criterion

We base the decision whether a tool impact occured

or not on the two basic ideas that in the contact case

1. the model Equation 3 changes to Equation 5 and

2. the controller (which was designed for free trajec-

tories) performance declines significantly result-

ing in a limited tracking accuracy.

The most simple way to utilize the first idea is to com-

pare the projected contact force

F

C

= F

C

· t

d

(10)

(t

d

is the tangent vector of the desired path, Figure 2)

to some threshold L in the form

C =

1 if F

C

> L

0 otherwise

(11)

where C = 1 means that contact is detected. Practi-

cally, it was impossible to find an L value resulting

in a low amount of false positives and negatives over

the desired workspace and speed range. This seems to

stem from the fact that the actuator model described

in Section 3.1 neglects too many effects (like drift and

hysteresis) to provide an accurate force measure.

To just detect the impact, we modified the criteron

to use

˙

F

C

(s) =

s

(s+ λ)

2

F

C

(s), (12)

an estimation of the force derivative with some addi-

tional low-pass filtering applied.

We also conducted experiments with the second

aforementiond idea. Including the controller error on

acceleration level in the form

D =

˙

F

C

(

¨

x

d

−

¨

x)

k

˙

xk

· t

d

(13)

showed the best results when again compared to some

constant level L. Index d denotes desired values. For

very low speeds (below 50 mm/s) the only robust de-

tection found was via the position error (x

d

−x) which

led to a rather big delay in the detection. In most

cases, this will render the detection useless as such

slow movements are typically used for delicate han-

dling scenarios.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

232

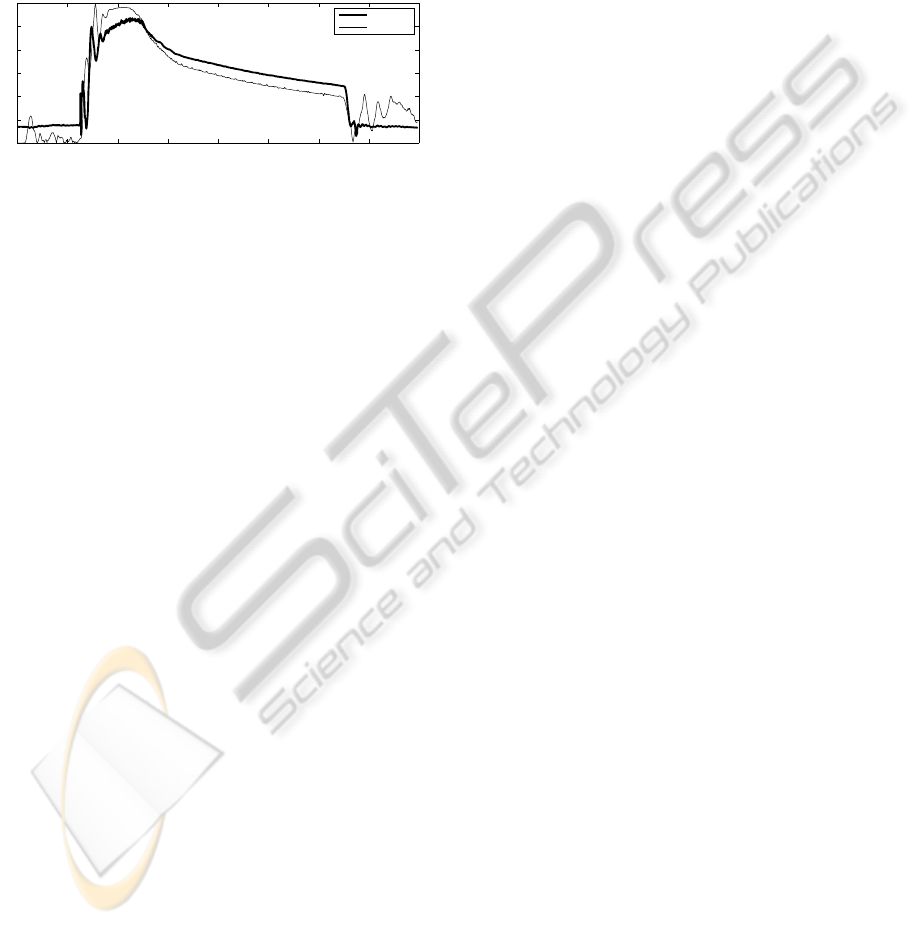

4.3 Measurement Results

We evaluated the detection by driving the manipula-

tor against a workbench at various speeds (50, 100,

150 and 250mm/s), in different directions (X+, Y+,

Z- – see Figure 1a – and mixed diagonal) and with

0.5 or 5 kg of payload mass. Each combination was

measured ten times.

0 2 4 6 8 10 12 14 16

0

10

20

30

40

50

60

measured

estimated

Figure 3: Example of estimated normal contact force in N

over time in s – compared to external sensor measurement.

Although the force characteristic (measured with

a three axis force sensor) varied over the different

scenarios, the detection was successful for nearly all

cases without adapting the threshold. Most problem-

atic was the combination of low speed and small pay-

load. Here we found at the same time false negatives

(5 for X+) and positives (3 for Y+). Other than that,

only one detection of over 300 failed.

The contact force – excluding impact peaks – al-

ways stayed below 20 N (and mostly below 10 N for

speeds below 150mm/s).

5 SHOW-DO PROGRAMMING

In guidance mode, a human can grasp the robot and

move it freely through the workspace. The robot is

still supported by the torques resulting from the model

in Equation 3 but any additional effort from the con-

troller is limited to very low values. Due to the soft

joints, one can interact with the robot along the com-

plete structure.

The guidance mode can be used to quickly move

the robot out of the way, to interactively teach posi-

tions or to record complete continuous path segments.

In our showcase we used a handle with two buttons,

mounted on the lower arm of the robot, to let the user

teach complete pick and place applications – similar

to a macro recorder known from personal computer

software. Tool actions trigger special behaviour – for

example the ”pick” macro at execution time moves

the manipulator in tool direction until it touches the

workpiece and does not solely rely on the recorded

position information.

The interaction with the robot proved to be intu-

itive and all kinds of people were quickly able to per-

form programming tasks.

6 CONCLUSIONS

In this paper we show how to use models of the me-

chanical system and the actuators of a pneumatically

drivenrobot for interaction with the environment. The

illustrated approach worked well when the human op-

erator compensated the remaining model uncertain-

ties. The completely autonomous interaction also

showed good results for the simple case of contact de-

tection.

A first effort to employ the presented interaction

possibilities for more intuitive programming led to

promising feedback from users.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the Austrian

Center for Competence in Mechatronics (ACCM) for

their support.

REFERENCES

Bicchi, A. and Tonietti, G. (2004). Fast and ”soft-arm” tac-

tics [robot arm design]. Robotics & Automation Mag-

azine, IEEE, 11(2):22–33.

Bremer, H. (2008). Elastic Multibody Dynamics: A Direct

Ritz Approach, chapter 4: Rigid Multibody Systems,

pages 59–113. Springer-Verlag GmbH.

Clark, D. R. and Lehto, M. R. (1999). Handbook of Indus-

trial Robotics, chapter 36: Reliability, Maintenance

and Safety of Robots, pages 717–754. John Wiley &

Sons, 2 edition.

Daerden, F. and Lefeber, D. (2002). Pneumatic artificial

muscles: Actuators for robotics and automation. Eu-

ropean journal of mechanical and environmental en-

gineering, 47:11–21.

Haddadin, S., Albu-Sch¨affer, A., De Luca, A., and

Hirzinger, G. (2008). Collision detection and reaction:

A contribution to safe physical human-robot interac-

tion. In Intelligent Robots and Systems, 2008. IROS

2008. IEEE/RSJ International Conference on, pages

3356–3363.

Hesse, S. (2003). The Fluidic Muscle in Application. Festo

AG & Co.KG.

Van Damme, M., Daerden, F., and Lefeber, D. (2005). A

pneumatic manipulator used in direct contact with an

operator. In Proceedings of the 2005 IEEE Interna-

tional Conference on Robotics and Automation.

INTERACTION OF A FLEXIBLE ROBOT WITH ITS ENVIRONMENT

233