ESTIMATION AND COMPENSATION OF DEAD-ZONE INHERENT

TO THE ACTUATORS OF INDUSTRIAL PROCESSES

Auciomar C. T. de Cequeira, Marcelo R. B. G. Vale, Daniel G. V. da Fonseca

Laboratory of Automation in Petroleum, Federal University of Rio Grande do Norte, Campus Universitário, Natal, Brazil

Fábio M. U. de Araújo, André L. Maitelli

Department of Computing and Automation, Federal University of Rio Grande do Norte, Natal, Brazil

Keywords:

Parameters estimation, Nonlinearity, Inverse compensation, Dead-zone, Hammerstein model.

Abstract:

The oscillations present in control loops can cause damages in industry. Canceling, or even preventing such

oscillations, would save up to large amount of dollars. Studies have identified that one of the causes of these

oscillations are the nonlinearities present on industrial processes actuators. This paper has the objective to

develop a methodology for removal of the harmful effects of nonlinearities. Will be proposed a parameters

estimation method to the Hammerstein model, whose nonlinearity is represented by dead-zone. The estimated

parameters will be used to construct the inverse model of compensation. A simulated level system was used

as test platform. The valve that controls inflow has a dead-zone. Results analysis shows an improvement on

system response.

1 INTRODUCTION

Inside industrial process there are hundreds of control

loops, which are mainly composed by sensors, actua-

tors, Programmable Logic Control (PLC) and Super-

visory Control and Data Acquisition (SCADA). The

control efficiency is, therefore, important to ensure

a high quality product and low cost production. So,

finding and solving control loop problems of a pro-

cess implies in reject reduction, better product ho-

mogeneity, lower production costs and higher rates

of production. Even an 1% energy or control effi-

ciency improvement means a huge economy in indus-

trial process, of millions of dollars (Desborough and

Miller, 2002).

Several studies related to control loop perfor-

mance indicate that the majority present deficient be-

havior, showing oscillations at process output. One of

those researches (Desborough and Miller, 2002) eval-

uated 26 thousand control loops and classified them

this way:

• 16% as excellent;

• 16% as acceptable;

• 22% as fair;

• 10% as poor;

• 36% as open loop.

Among the causes for this deficient performance

are included bad tune of controllers, wrong process

project, the incoming oscillatory perturbations and

the nonlinearities of the actuators. And those non-

linearities cause dead-band in actuators as well.

An audit made by a big producer of valves has

shown that 30% of the products presented about 4%

or more of dead-band and approximately 65% of the

valves had a dead-band higher than 2% (FISCHER,

2005). As most of the actions of regulatory control

consist of small variations in the order of 1% or less,

the control loops would not act effectively in the pro-

cess for responding to these small variations. For a

good performance, it is recommended that the con-

trol valve dead-band is about 1% or less (Campos and

Teixeira, 2007).

A point to mention is that 20 to 30% of the oscil-

lations in control loops are caused by nonlinearities

of the valves (Ulaganathan and Rengaswamy, 2008),

among which we can point out the static friction, hys-

teresis, backlash and dead-zone as the best known.

The compensation of the effects of such nonlineari-

ties would help in solving the problem of poor perfor-

62

C. T. de Cequeira A., R. B. G. Vale M., G. V. da Fonseca D., M. U. de Araújo F. and L. Maitelli A. (2010).

ESTIMATION AND COMPENSATION OF DEAD-ZONE INHERENT TO THE ACTUATORS OF INDUSTRIAL PROCESSES.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 62-70

DOI: 10.5220/0002953000620070

Copyright

c

SciTePress

mance of about a quarter of the controllers present in

the industry.

The aim of this study is therefore to minimize or

cancel the oscillations observed in the outputs of in-

dustrial processes, which are caused by dead-zone in-

herent to the actuators of control loops.

The industrial processes were represented by the

Hammerstein model. Inverse models of nonlinearity

will be built based on dead-zone parameter estima-

tion. The intention is to make these inverse models

capable to compensate the nonlinearity, reducing the

oscillations and its harmful effects. It will be pro-

posed a method of parameter estimation for a Ham-

merstein model that contains as the non-linear part a

dead-zone.

2 MATHEMATIC MODELS

This section describes the mathematic models utilized

in dead-zone estimation and compensation methodol-

ogy. This methodology uses the Hammerstein model

to represent the industrial processes containing dead-

zone. Thereby, the linear part of Hammerstein model

is represented by Output Error model and the non-

linear part is represented by dead-zone. Besides the

Hammerstein model, this section also describes the

inverse model for dead-zone compensation. This one

will reduce prejudicial effects of nonlinearity.

It should be clear that the mathematic models de-

scribed in this section are simplified descriptions of

real physical phenomena.

2.1 Hammerstein Model

The nonlinear Hammerstein model is composed by

a static nonlinearity preceding a linear dynamic

(Aguirre, 2007). This model is called block-oriented

or block-structured model (Chen, 1995). Thus, both

the non-linearity and the dynamics are represented by

blocks, as shown in Figure 1. Here, the NL block

represents the static nonlinearity function and the L

block represents the linear dynamic of modeled pro-

cess. The signs u(k), y(k) and e(k) are the nonlin-

earity input, the output and the noise of the system,

respectively. The signal x(k) is called internal vari-

able of the Hammerstein model (nonlinearity output

and linear dynamic input), and, in general, it cannot

be measured, making it difficult to estimate the pa-

rameters in the same models.

Although very simple, this structure may repre-

sent several actual physical processes, such as indus-

trial processes with variable gain and control systems

NL L

u(k) x(k) y(k)

e(k)

+

+

Figure 1: Hammerstein model.

with linear processes and nonlinear actuators (the lat-

ter falls within the subject matter in this work). There-

fore Hammerstein models are popular in control engi-

neering.

2.2 Output Error Model

There are some mathematical representations that are

especially suitable for system identification, using

classic algorithms to the estimation of its parameters.

Along with the ARX and ARMAX models, the Out-

put Error model is one of the most used structures. In

this study, this model represents the linear dynamic of

the Hammerstein system (block L of Figure 1) and it

is represented in Figure 2. In the same model, it is as-

sumed that the noise disturbs the output in an additive

manner, as equations below.

y(k) = q

−d

B(q)

A(q)

x(k) + e(k) (1)

A(q)y(k) = q

−d

B(q)x(k) + A(q)e(k) (2)

A(q) and B(q) are polynomials of order n

a

and n

b

,

respectively, and are defined below. d represents the

pure delay system and q

−1

is the shift operator, so

x(k)q

−d

= x(k − d).

A(q) = 1+ a

1

q

−1

+ ... + a

n

q

−n

a

B(q) = b

0

+ b

1

q

−1

+ ... + b

m

q

−n

b

x(k)

B(q)

A(q)

y(k)

e(k)

+

+

Figure 2: Output Error model.

The Output Error model is much more realistic

than the ARX and ARMAX because the modeling of

noise does not include the dynamics of the process

1/A(q) (Nelles, 2000). So, the parameter estimation

task becomes more difficult. As shown in Equation

(2), the noise is not white but colored due to the pres-

ence of the polynomial A(q). For this reason, the least

squares method cannot be used. A non-polarized al-

gorithm should be used so that the estimation is not

biased.

ESTIMATION AND COMPENSATION OF DEAD-ZONE INHERENT TO THE ACTUATORS OF INDUSTRIAL

PROCESSES

63

The Equation (2) can be rewritten in the form of

summations, already introducing the delay in the in-

put signal.

y(k) =

n

b

∑

i=0

b

i

x(k− d − i) −

n

a

∑

j=1

a

j

y(k− j)

+

n

a

∑

j=1

a

j

e(k− j) + e(k)

(3)

The signals y(k), x(k) and e(k) are the same as

the Hammerstein model (Figure 1), and have been de-

fined previously.

2.3 Dead-zone

The dead-zone is a static nonlinearity with no mem-

ory that describes the insensitivity of components for

small signals. It can be seen as a static relationship be-

tween input and output signals, in which, for a range

of input values, there is no answer. Once the output

appears, the relationship between input and output is

linear.

Figure 3 shows a graphical representation of the

dead-zone, where u(k) is the input and x(k) is the out-

put. The limits b

r

and b

l

represent the range where

the output signal remains unchanged, and m

r

and m

l

indicate the slope of the lines. By definition b

r

> 0,

b

l

< 0, m

r

> 0 and m

l

> 0, and in general, neither the

limits nor the slopes are equal.

u(k)

x(k)

m

r

b

r

b

l

m

l

Figure 3: Dead-zone graphic.

Analytically, the dead-zone can be written as fol-

lows:

x(k) =

m

r

[u(k) − b

r

], if u(k) ≥ b

r

0, if b

l

< u(k) < b

r

m

l

[u(k) − b

l

], if u(k) ≤ b

l

(4)

One way to write the behavior of the dead-zone so

that it is linear in the parameters is:

x(k) = X

r

(k)m

r

[u(k) − b

r

] + X

l

(k)m

l

[u(k) − b

l

] (5)

where X

r

(k) and X

l

(k) are auxiliary functions that

take the value 0 (zero) or 1 (one) according to the fol-

lowing conditions:

X

r

(k) =

1, if u(k) ≥ b

r

0, otherwise

(6)

X

l

(k) =

1, if u(k) ≤ b

l

0, otherwise

(7)

2.4 Inverse Model for Dead-zone

Compensation

It is known that the nonlinearities are among the key

factors that limit the static and dynamic performance

of control systems, preventing high precisions when

using linear controllers. In order to cancel the harmful

effects generated by the dead-zone, it is proposed to

implement its inverse model.

The Figure 4 shows the structure used in this

work for the cancellation of this nonlinearity. The

inverse nonlinearity (INL block) was allocated be-

fore the nonlinearity (NL block) to cancel out its ef-

fects. When implemented with the real parameters,

such compensation cancels completely the effects of

dead-zone. Therefore, if the dead-zone is fully com-

pensated, the input signal u

c

(k) must be equal to the

signal x(k).

INL NL L

u(k) x(k)u

c

(k) y(k)

e(k)

+

+

Figure 4: Block diagram of nonlinearity compensation.

The graphical relationship between the input sig-

nal u

c

(k) and output signal u(k) is shown in Figure

5.

u

c

(k)

u(k)

1

m

r

1

m

l

b

r

b

l

Figure 5: Graphic of dead-zone inverse compensation.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

64

The dead-zone inverse model is represented by

Equation 8. The parameters b

r

, b

l

, m

r

and m

l

are the

same used in modeling of dead-zone.

u(k) =

1

m

r

[u

c

(k) + m

r

b

r

], if u

c

(k) > 0

0, if u

c

(k) = 0

1

m

l

[u

c

(k) + m

l

b

l

], if u

c

(k) < 0

(8)

For a linear parameterization of inverse compen-

sation, we have:

u(k) = χ

r

(k)

1

m

r

[u

c

(k) + m

r

b

r

]

+χ

l

(k)

1

m

l

[u

c

(k) + m

l

b

l

]

(9)

where χ

r

(k) and χ

l

(k) are auxiliary functions defined

as:

χ

r

(k) =

1, if u

c

(k) > 0

0, otherwise

(10)

χ

l

(k) =

1, if u

c

(k) < 0

0, otherwise

(11)

The inverse model equation is similar to the dead-

zone model. The variables m

r

, m

l

, b

r

and b

l

have the

same meaning of Equation (5). The difference lies in

the definition of auxiliary functions χ

r

(k) and χ

l

(k).

To check the accuracy of the inverse model, in

other words, to conclude that x(k) = u

c

(k), three sit-

uations will be analyzed: u

c

(k) > 0, u

c

(k) < 0 and

u

c

(k) = 0. For this proof, the function of the inverse

of the dead-zone will be called ZI(·).

Lemma 1. (Dead-zone Inverse) when implemented

with real parameters m

r

, m

l

, b

l

and b

r

, the dead-zone

inverse (8) cancels the effect of dead-zone (4), that is

u(k) = ZI(u

c

(k)) ⇒ x(k) = u

c

(k),∀k ≥ 0.

Proof. Suppose u

c

(k) > 0. For u

c

(k) > 0, the auxil-

iary function χ

r

(k) (10) will be equal to 1 and χ

l

(k)

(11) will take value 0. Therefore, u(k) (9) will be:

u(k) =

1

m

r

[u

c

(k) + m

r

b

r

] =

u

c

(k)

m

r

+ b

r

(12)

As it was admitted that u

c

(k) > 0, and by definition

m

r

> 0, the portion

u

c

(k)

m

r

is also positive. So, u(k) >

b

r

. The auxiliary function X

r

(k) (6) will take value

1, while X

l

(k) (7) will be 0. Substituting (12) in (5)

with the appropriate values of the auxiliary functions

we have:

x(k) = m

r

u

c

(k)

m

r

+ b

r

− b

r

(13)

Making the simplifications, we conclude that x(k) =

u

c

(k).

Suppose that u

c

(k) < 0. For u

c

(k) < 0, the auxil-

iary function χ

r

(k) (10) will be equal to 0 and χ

l

(k)

(11) will take value 1. As a result, u(k) (9) will be:

u(k) =

u

c

(k) + m

l

b

l

m

l

=

u

c

(k)

m

l

+ b

l

(14)

As it was admitted that u

c

(k) < 0, and by defini-

tion m

l

> 0, the portion

u

c

(k)

m

r

will be negative. So,

u(k) < b

l

. The auxiliary function X

r

(k) (6) will take

value 0 while X

l

(k) (7) will be equal to 1. Substituting

(14) in (5) with the appropriate values of the auxiliary

functions we have:

x(k) = m

l

u

c

(k)

m

l

+ b

l

− b

l

(15)

Making the simplifications, we conclude that x(k) =

u

c

(k).

Suppose that u

c

(k) = 0. For u

c

(k) = 0, the auxil-

iary functions χ

r

(k) (10) and χ

l

(k) (11) are equal to

0 and the signal u(k) will take value 0 too. Since,

by definition, b

r

> 0 and b

l

< 0, the signal u(k) will

be b

l

< u(k) < b

r

, and according to Equation (4) the

signal x(k) = 0. Therefore, x(k) = u

c

(k).

3 PARAMETER ESTIMATION

METHODOLOGY

There is a lot of work in literature regarding the iden-

tification of the Hammerstein model. Many works re-

quire that the nonlinearity is approximated by a static

and continuous function, usually a polynomial. The

convergence is guaranteed. However, in the case of

this paper, the nonlinearity is represented by discon-

tinuous models.

The methodology proposed here is based on

(Vörös, 1997, 2003). The author developed an it-

erative (Vörös, 1997) and recursive (Vörös, 2003)

method to estimate parameters of the Hammerstein

model with discontinuous nonlinearities. He relates

the problem of identification because of the impossi-

bility of measuring the internal variable of the Ham-

merstein model. Instead of measuring this variable,

its estimate is used based on the estimated parame-

ters in the previous step of the recursion. There is no

proof of convergence for this identification method of

Hammerstein with internal variable estimation. How-

ever, it is satisfactory for most practical applications

(Vörös, 2006).

There are certain situations that the least squares

method is polarized or tendentious. One of these sit-

uations occur when the noise or error in the regres-

sion equation is not white, which is the case of the

ESTIMATION AND COMPENSATION OF DEAD-ZONE INHERENT TO THE ACTUATORS OF INDUSTRIAL

PROCESSES

65

Output Error models. To solve the problem of polar-

ization, non-polarized estimators must be used, like:

extended least squares, generalized least squares, in-

strumental variables estimator (Aguirre, 2007). The

method chosen for this study was the recursive instru-

mental variables estimation (RIV) with forgetting fac-

tor. The equations that are utilized in this estimation

method are written below (Ljung, 1987):

K(k+ 1) =

P(k)z(k+ 1)

λ+ φ

T

(k+ 1)P(k)z(k+ 1)

(16)

P(k+ 1) =

1

λ

P(k) − K(k+ 1)φ

T

(k+ 1)P(k)

(17)

ˆy(k+ 1) = φ

T

(k+ 1)

ˆ

θ

(k)

(18)

ˆ

θ(k+ 1) =

ˆ

θ(k) + K(k + 1) [y(k+ 1) − ˆy(k+ 1)]

(19)

where K is the estimator gain calculated from the co-

variance matrix P, ˆy is the estimated value of system

output y,

ˆ

θ is the vector of estimated parameters, φ is

the vector of regressors, z is the vector of instrumental

variables and λ is the forgetting factor.

3.1 Equations Development

The vector of instrumental variables was chosen so

that the estimated system output ˆy and the system in-

put u were utilized. The equation can be seen below.

z(k) =

h

ˆy(k− 1) · · · ˆy(k− n

a

),

u(k− d) ··· u(k− d − n

b

)

i

(20)

Substituting Equation (5) in Equation (3) we have

equation (21), which describes the total behavior of

the system with its both linear and non-linear charac-

teristics.

y(k) =

n

b

∑

i=0

b

i

n

X

r

(k− d − i)m

r

[u(k− d − i) − b

r

]

+X

l

(k− d − i)m

l

[u(k− d − i) − b

l

]

o

−

n

a

∑

j=1

a

j

y(k− j) +

n

a

∑

j=1

a

j

e(k− j) + e(k)

(21)

It is observed that, if we multiply the coefficients

b

i

by the term in braces, there will be a number of pa-

rameters like n

a

+ 4(n

b

+ 1) to be estimated, besides,

they are connected to each other (b

i

m

r

, b

i

m

r

b

r

, for

example). To avoid this large amount of parameters,

the key term separation principle was used (Vörös,

1995). In this new formulation, the internal variable

b

0

x(k− d) is separated from the others, which gener-

ated the following equation, with the number of pa-

rameters equals to n

a

+ n

b

+ 4:

y(k) = b

0

n

X

r

(k− d)m

r

[u(k− d) − b

r

]

+X

l

(k− d)m

l

[u(k− d) − b

l

]

o

+

n

b

∑

i=1

b

i

x(k− d − i) −

n

a

∑

j=1

a

j

y(k− j)

+

n

a

∑

j=1

a

j

e(k− j) + e(k)

(22)

For Equation (22), the vector of regressors and the

vector of parameters can be respectively defined such

as:

φ

T

(k) =

h

− y(k− 1),...,−y(k − n

a

),

X

r

(k− d)u(k− d), −X

r

(k− d),

X

l

(k− d)u(k− d), −X

l

(k− d),

x(k− d − 1),...,x(k− d − n

b

)

i

(23)

θ

T

=

h

a

1

,...,a

n

a

,b

0

m

r

,b

0

m

r

b

r

,

b

0

m

l

,b

0

m

l

b

l

,b

1

,...,b

n

b

i

(24)

The internal variables x(k − d − 1),...,x(k − d −

n

b

) cannot be measured directly. Estimates of their

values will be used, based on the parameters of the

previous step of the recursive estimation. In other

words, the estimated values of m

r

, b

r

, m

l

and b

l

will

be used in Equation (5) for the construction of the re-

gressors x(k− d − 1), ..., x(k− d− n

b

).

The dead-zone parameters are estimated with b

0

.

To obtain the separated values, it is necessary to know

the parameter b

0

. For this, it was admitted that the

plant gain is known. By the final value theorem

(Nelles, 2000):

∑

n

b

i=0

b

i

1+

∑

n

a

j=1

a

j

= K

p

(25)

where K

p

is the plant gain. So, b

0

is:

b

0

= −

n

b

∑

i=1

b

i

+ K

p

1+

n

a

∑

j=1

a

j

!

(26)

We can conclude that, in order to discover the sep-

arated value of each dead-zone parameter,simply per-

form the following divisions:

m

r

= b

0

m

r

/b

0

b

r

= b

0

m

r

b

r

/b

0

m

r

m

l

= b

0

m

l

/b

0

b

l

= b

0

m

l

b

l

/b

0

m

l

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

66

Although all parameters are estimated, these last

four parameters are the ones used to construct the in-

verse model of compensation.

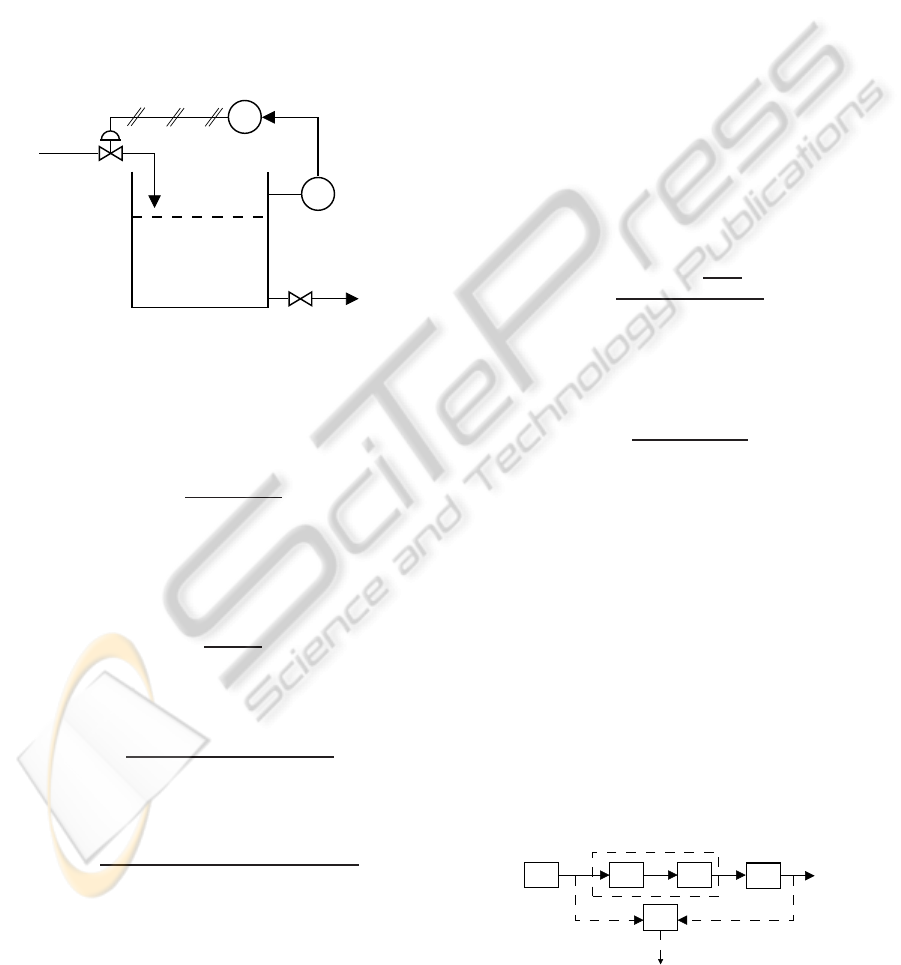

4 TEST PLATFORM

The testing process is a level system in which we want

to control tank height and it can be seen in Figure 6.

It consists of an incompressible fluid reservoir having

a flow input q

in

controlled by a pneumatic valve that

has an associated nonlinearity, and a flow output q

out

dependent on the height.

LC

LT

q

in

q

out

Figure 6: Level system.

The valve is a pneumatic actuator of fluid flow

control and has associated dynamics (Wigren, 1993).

It was assumed that it has linear opening characteris-

tics and the model can be seen as follows:

G

v

(s) =

25

s

2

+ 5s+ 25

(27)

The reservoir contains incompressible fluid and it

is classically found in literature. The model used here

is a linearization of a more complex model (Ikonen

and Najim, 2002), and its transfer function is:

G

t

(s) =

2

s+ 0,9

(28)

The continuous model of the entire system, con-

sidering the transport delay of d = 3, is:

G(s) =

50e

−0,3

s

3

+ 5,9s

2

+ 29,5s+ 22,5

(29)

The discrete model of the level system using a

zero-order hold and a discretization time of 0,1s is:

G(z) = z

−3

0,00713z

2

+ 0,02441z+ 0,0053

z

3

− 2,328z

2

+ 1,899z− 0,5543

(30)

5 SIMULATION AND RESULTS

References generated in the process and the measure-

ments of tank height are expressed in percentage. As

a excitation sign the PRS (pseudo random signal) was

used within a range of values averaging 50% and

varying uniformly from 45 to 55% being the chosen

values kept constant in a minimum of 10 sampling

periods. The forgetting factor was kept constant dur-

ing the first 2000 sampling periods having a value of

0,995, and after this time, it changed exponentially to

1, according to Equation (31), with λ

0

= 0,995.

λ(k) = λ

0

λ(k− 1) + (1− λ

0

) (31)

The noise was considered as a white additive one,

with average zero and Gaussian variance of 0, 03. The

initial values of the parameter vector θ were 10

−3

and

covariance matrix P was initialized as a diagonal ma-

trix whose elements were equal to 10

6

.

In order to quantify the efficiency of controls with

and without compensation, two metrics of perfor-

mance evaluation were implemented (Goodhart et al.,

1991). The first one considers the variance of the con-

trol signal,

ε

1

=

∑

u(k) −

∑

u(k)

N

2

N

(32)

and the second metric evaluates the deviation of the

process output regarding the reference according to

the integral absolute error (IAE),

ε

2

=

∑

|r(k) − y(k)|

N

(33)

N being the number of samples.

The evaluations were divided into 3 tracks. In the

first one, the reference is kept constant at a value of

50% from 1 to 60s. At the 10s instant, a -10 ampli-

tude disturbance occurs and ceases to exist at the 40s

instant. In track 2, the reference is changed to 49% at

60s, and at 80s, in the last track, it is changed to 51%.

The block diagram for the estimation process can

be seen in Figure 7. Block E represents the genera-

tor of excitation signal PRS, NL block represents the

dead-zone nonlinearity, blocks A and T are respec-

tively the dynamics of the valve and tank and repre-

sent the linear part of the Hammerstein model. The

RIV estimation method with the presence of the for-

getting factor is represented by block M.

NL A T

Valve

E

M

u x y

b

θ

Figure 7: Block diagram of the level system estimation.

ESTIMATION AND COMPENSATION OF DEAD-ZONE INHERENT TO THE ACTUATORS OF INDUSTRIAL

PROCESSES

67

The block diagram of the compensation is shown

in Figure 8. Block C represents a PI controller, which

was tuned empirically so that, for the level system

without the presence of nonlinearities, the plant re-

sponse would behave without a large overshoot and

with no regime error (less than 2%). Mathemati-

cal manipulations were made so that a control sig-

nal equals to zero would correspond to a level of

50%. Block INL represents the inverse nonlinearity,

and was allocated before its respective nonlinearity.

The others blocks have the same meanings described

above.

NL TC INL A

u x yu

c

−

r

+

e

Valve

Figure 8: Block diagram of the level system with nonlinear-

ity compensation.

The dead-zone in the actuator of this process was

built with the following parameters: m

r

= 3, m

l

= 3,

b

r

= 1 and b

l

= −1. The graphics containing the

parameters estimation results of linear dynamics and

dead-zone can be seen in Figure 9. The parameter

values obtained at the end of the recursive estimation

process are shown in Table 1. The actual values of

each one are also in Table 1 for comparison.

Analyzing the estimation graphics, it is observed

that all the parameters have converged up to 7500s,

the last ones being the coefficients of the polyno-

mial B(q). The values obtained in the estimation pro-

cess are shown in Table 1, and have small errors (the

biggest errors are in the order of 10

−2

) in relation to

the real values. The algorithm showed good conver-

gence for the noise presence.

Table 1: Parameters of level system with dead-zone.

Parameters Estimated Value Real Value

a

1

-2.3271 -2.328

a

2

1.8968 1.899

a

3

-0.55309 -0.5543

b

0

0.00718 0.00713

b

1

0.02424 0.02441

b

2

0.00542 0.0053

m

r

3.0256 3

m

l

2.993 3

b

r

1.0214 1

b

l

-0.99561 -1

The controller was empirically tuned to k

p

= 0.5

and k

i

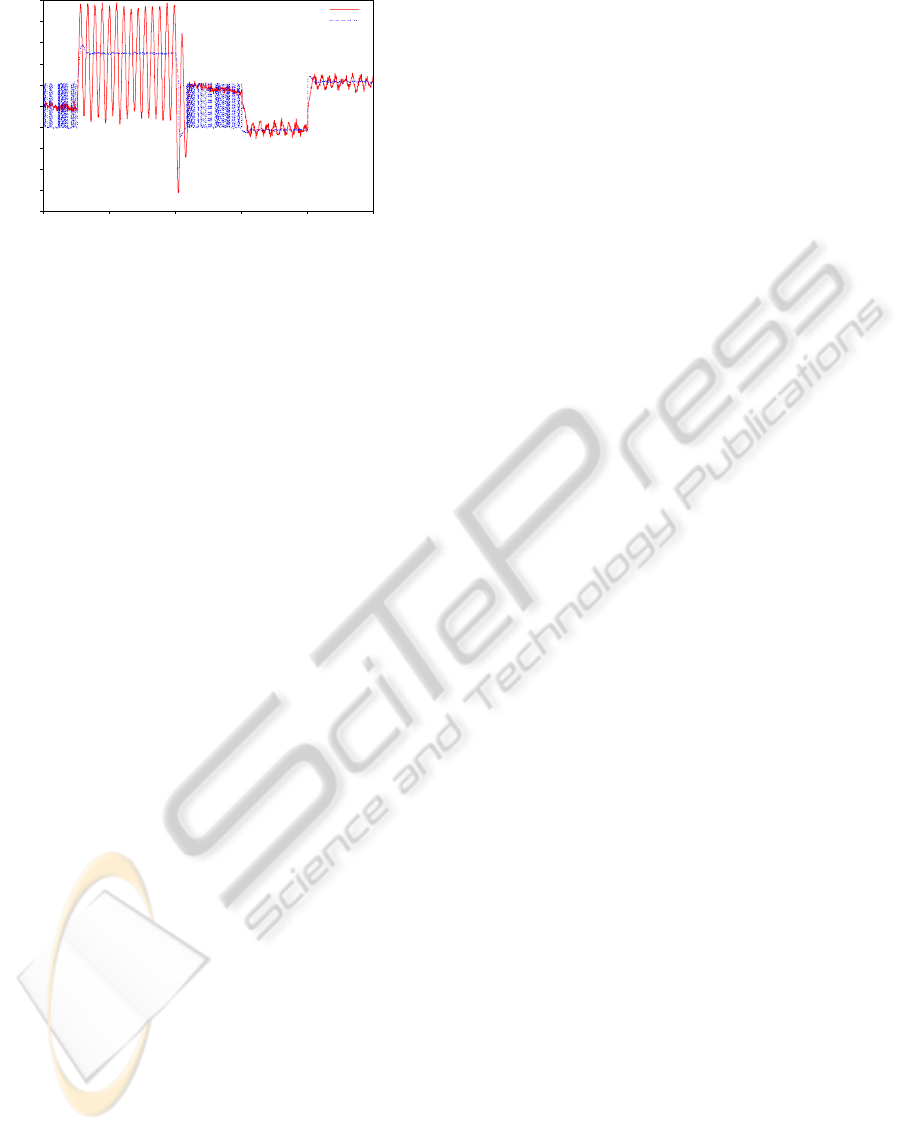

= 0.7. Figure 10 contains the graphics of plant

level output for the linear case, that is, without the

presence of dead-zone. Figures 11 and 12 represent,

−2.50

−2.00

−1.50

−1.00

−0.50

0.00

0.50

1.00

1.50

2.00

0 5000 10000 15000 20000

Time (s)

a

1

a

2

a

3

(a) Polynomial A(q).

−0.01

0.00

0.01

0.02

0.03

0.04

0 5000 10000 15000 20000

Time (s)

b

0

b

1

b

2

(b) Polynomial B(q).

−2.00

−1.00

0.00

1.00

2.00

3.00

4.00

5.00

6.00

0 5000 10000 15000 20000

Time (s)

m

r

m

l

c

r

c

l

(c) Dead-zone.

Figure 9: Parameter estimation of level system with dead-

zone.

respectively, the cases of plant output with the pres-

ence of dead-zone with and without the compensator

block. The control signals for these last two cases are

shown in Figure 13.

For track 1, the control without compensation was

rather oscillatory during the existence of the distur-

bance (10 to 40s) with the tank level ranging approx-

imately from 45 to 55%. After the disturbance, the

level returned to the reference and remained without

oscillations. This was due to mathematical manipula-

tions that keep the reservoir level by 50% for a valve

input signal equal to zero. In tracks 2 and 3 the refer-

ence is changed respectively to 49 and 51%. In these

two tracks, it is observed the existence of oscillations

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

68

maintained in the output with amplitude around the

reference of ±1%. As for the control with compen-

sation, the behavior of the plant output is very similar

to the case where there is not the dead-zone presence.

Thereby, and according to Table 2, the control with

compensation had better IAE indices (ε

2

) for the 3

tracks compared to the control without compensation.

Table 2 also shows the index ε

1

of control signal

variance evaluation for the two cases with the pres-

ence of dead-zone. Note that, in the case with com-

pensation, the inversenonlinearity (INL block) output

was considered as controlsignal, and not the output of

PI controller. Based on the graphic of Figure 13, the

control signal with the inverse nonlinearity is more

aggressive in relation to the sign of pure PI control

for the dead-zone region. This is caused by the dis-

continuity present in the graphic of the inverse dead-

zone (see Figure 5) around de zero point. Whenever

the PI output inverts its sign (from positive to nega-

tive or vice versa), a jump in the output compensation

occurs. Even with this discontinuity, the control with

compensation had a smaller variance in its signal to

the 3 tracks of the evaluation.

Table 2: Metrics for performance evaluation of nonlinear

system with and without compensation.

Track

With Comp. Without Comp.

ε

1

ε

2

ε

1

ε

2

1 3.0574 1.7683 2.4786 0.3696

2 0.1242 0.3722 0.0492 0.2028

3 0.1201 0.4188 0.0547 0.2439

6 CONCLUSIONS

In this work, it was developed a method of estima-

tion and compensation of dead-zone that is present in

the actuators of various industrial processes. It was

used, as a testing process, a simulation of a level tank,

which has a valve with a dead-zone to control the in-

put flow.

First it was developed an estimation method of

parameters for a Hammerstein model, in which the

nonlinear part is represented by dead-zone. As linear

dynamic, the Output Error model was used, which is

a more complex model and the estimation task be-

comes more difficult when compared to the estima-

tion of ARX and ARMAX models, because the noise

is much more influential in the process. The method

used the key term separation principle, reducing the

number of parameters to be estimated.

In practice, the process operator defines the dura-

tion and type of measures that can be collected from

44.00

46.00

48.00

50.00

52.00

54.00

56.00

0 20 40 60 80 100

Level (%)

Time (s)

Reference

Output without dead−zone

Figure 10: Plant output without dead-zone.

44.00

46.00

48.00

50.00

52.00

54.00

56.00

58.00

60.00

0 20 40 60 80 100

Level (%)

Time (s)

Reference

Output without compensation

Figure 11: Plant output with dead-zone and without com-

pensation.

44.00

46.00

48.00

50.00

52.00

54.00

56.00

0 20 40 60 80 100

Level (%)

Time (s)

Reference

Output with compensation

Figure 12: Plant output with dead-zone and with compen-

sation.

the process. In fact, large variations in the excitation

signal are very useful in identifying systems. How-

ever, they are not often allowed by the operators.

Then, the identification should be made using normal

operation data.

After being estimated, the parameters that make

up the dead-zone were used to construct the inverse

model of compensation. In general, the controller

with compensation was more aggressive than the con-

trol without compensation during the dead-zone re-

gion. However, the plant output is much less oscil-

lating in the compensated case. Performance metrics

ESTIMATION AND COMPENSATION OF DEAD-ZONE INHERENT TO THE ACTUATORS OF INDUSTRIAL

PROCESSES

69

−5.00

−4.00

−3.00

−2.00

−1.00

0.00

1.00

2.00

3.00

4.00

5.00

0 20 40 60 80 100

Time (s)

Control without compensation

Control with compensation

Figure 13: Control signals for the nonlinear system.

quantify the control actions and the error at the plant

response. Therefore, the purpose of minimizing or

even canceling the oscillations was achieved.

The estimation and compensation techniques de-

veloped here can be applied to any industrial plant

that is represented according to Hammerstein model,

which has the dead-zone as nonlinearity.

It is intended, as future work, to estimate and com-

pensate the backlash nonlinearity. In addition, we in-

tend to implement the proposal in a Programmable

Logic Controller (PLC). This will bring this work to

a possible application in the real world.

ACKNOWLEDGEMENTS

Especial thanks for ANP PRH-14, CNPq and Petro-

bras.

REFERENCES

Aguirre, L. A. (2007). Introdução à Identificação de Sis-

temas: Técnicas Lineares e Não-Lineares Aplicadas a

Sistemas Reais. Editora UFMG, 3 edition.

Campos, M. C. M. M. and Teixeira, H. C. G. (2007). Con-

troles Típicos de Equipamentos e Processos Industri-

ais. Editora Edgar Blücher.

Chen, H.-W. (1995). Modeling and identification of paral-

lel nonlinear systems: structural classification and pa-

rameter estimation methods. Proceedings of the IEEE,

83(1):39–66.

Desborough, L. and Miller, R. (2002). Increasing customer

value of industrial control performance monitoring -

honeywell’s experience. In AIChE Symposium Series

2001, number 326, pages 172–192, Arizona.

FISCHER (2005). Control Valve Handbook. Emerson Pro-

cess Management, Iowa, USA.

Goodhart, S. G., Burnham, K. J., and James, D. J. G. (1991).

A bilinear self-tuning controller for industrial heating

plant. IEEE Conference Publication, 2(332):779–783.

Ikonen, E. and Najim, K. (2002). Advanced Process Identi-

fication and Control. Marcel Dekker, New York.

Ljung, L. (1987). System Identification: Theory for the

User. Prentice-Hall.

Nelles, O. (2000). Nonlinear System Identification.

Springer, Berlin.

Ulaganathan, N. and Rengaswamy, R. (2008). Blind identi-

fication of stiction in nonlinear process control loops.

In American Control Conference, pages 3380–3384.

Vörös, J. (1995). Identification of nonlinear dynamic sys-

tems using extended hammerstein and wiener mod-

els. Control Theory and Advanced Technology,

10(4):1203–1212.

Vörös, J. (1997). Parameter identification of discontinuos

hammerstein systems. Automatica, 33(6):1141–1146.

Vörös, J. (2003). Recursive identification of hammerstein

systems with discontinuous nonlinearities containing

dead-zones. IEEE Transactions on Automic Control,

48(12):2203–2206.

Vörös, J. (2006). Recursive identification of hammerstein

systems with polynomial nonlinearities. Journal of

Electrical Engineering, 57(1):42–46.

Wigren, T. (1993). Recursive prediction error identifica-

tion using the nonlinear wiener model. Automatica,

29(4):1011–1025.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

70