ASSEMBLY SYSTEMS FOR LOW PRODUCT DEMAND

Estimation of Final Results

Waldemar Grzechca

Institute of Automatic Control, The Silesian University of Technology, ul.Akademicka 16, 44-100 Gliwice, Poland

Keywords: Assembly line balancing, Single line structure, Assembly round table, Quality of results.

Abstract: The paper considers assembly systems for low product demand. In the last five decades a large variety of

assembly line structures and solutions procedures have been proposed to balance assembly line. Author of

this paper compares single assembly line and assembly rotating round table. Estimation of final results of

balance of both structures is discussed. It is shown that implementation of different structures are

appropriate for low product demand. Numerical example of design assembly single line and assembly

rotating round table helps to understand mentioned structures.

1 INTRODUCTION

Since always people created new items for their own

needs and if these appeared to be helpful they tried

both to improve them and manufacture them faster.

In order to balance supply and demand the

development of technology was a must. Definition

of production can be therefore understood as

transforming raw materials into a complete valuable

product. This transformation combines various tasks

of human work, automation and technology. It

consists of steps after which the temporary product

is closer to the final state. All these processes

combined together define the assembly line which

formal definition states: Industrial arrangement of

machines, equipment, and workers for continuous

flow of workpieces in mass-production operations.

An assembly line is designed by determining the

sequences of operations for manufacture of each

component as well as the final product. Each

movement of material is made as simple and short as

possible, with no cross flow or backtracking. Work

assignments, numbers of machines, and production

rates are programmed so that all operations

performed along the line are compatible. Automated

assembly lines consist entirely of machines run by

other machines and are used in such continuous-

process industries as petroleum refining and

chemical manufacture and in many modern

automobile-engine plants. Although it does not seem

difficult by the definition it is a complex field of

research. One of the reasons may be the fact that the

first automated production line was implemented in

20

th

century, actually in the year 1913 in Ford Motor

Company, USA. In assembly systems the most

often used is the flow line – a particular example of

such a structure is the assembly line. Balancing of

such a line consists of assigning various tasks to

work stations (Salveson, 1955). The objective of

balancing leads to defining the cycle time with

constant number of work stations or inversely

calculating the number of stations with given cycle

time. In order to start balancing we need to have a

finite set of work stations, tasks with corresponding

times and relationships between them i.e. in a form

of a precedence diagram. Balancing of an assembly

line is the answer to the question - how to allocate

resources on a flow line in order to finalize the end

product most effectively. Effectively in this case

means assigning tasks equally between stations to

minimize idle times and equalize work load. A

balanced line needs to fulfill (Sury, 1971), (Scholl,

1998), (Beker and Scholl, 2005):

•

prece

dence diagram restrictions

ast one)

m

2 ASSEMBLY LINE STRUCTURE

There exist also a classification regarding plant

layout which is used to describe the arrangement of

• p

ositive number of stations (at le

• cycle time c greater or equal maximu

station time.

259

Grzechca W. (2010).

ASSEMBLY SYSTEMS FOR LOW PRODUCT DEMAND - Estimation of Final Results.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 259-264

DOI: 10.5220/0002956302590264

Copyright

c

SciTePress

physical facilities in a production plant (Scholl,

1998). Five types of layout can be distinguished:

• serial lines,

• U-shaped lines,

• parallel lines,

.

Lines

line production

systems. It is determined by the flow of materials. It

lures,

o changing demand rates.

• parallel stations,

• two-sided lines

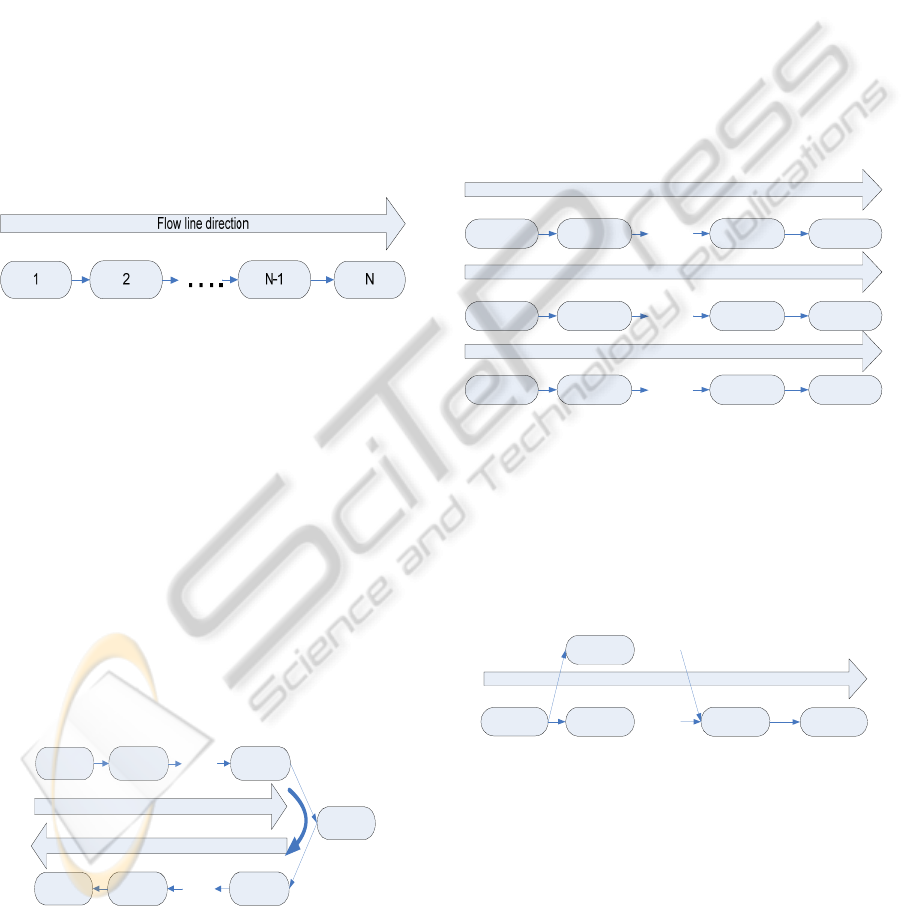

2.1 Serial (Single)

This is a very basic layout of a flow

is mostly used for small size products. These lines

have several disadvantages:

• monotone work,

• sensibility due to fai

• inflexibility due t

Figure 1: Serial line.

2.2 U-shape

ms of a serial line it

was redesigned to a form of U-shape (U-line). In

d Lines

In order to deal with the proble

such a line operators can work at more than one

station simultaneously. For example first operator

may both load and unload product units. As they are

included in more tasks during production process

they are gaining very important experience and

enlarge horizons. It is very helpful in case of just-in-

time production systems as it improves flexibility

which is crucial in dynamically changing demand

rates. What more, stations are closer together what

results in better communication between operators

and in case of emergency they are able to help each

other effectively.

1

2.3 Parallel Lines

In order to deal with problems described in case of a

serial line it might be a good idea to create several

lines doing the same or similar tasks.

Figure 2. U-line structure.

The advantages of such a solution (Sauer, 1997):

• increased flexibility for mixed-model

systems,

• flexibility due to changing demand rates,

• lowered risk of machine breakdown

stopping the whole production,

• cycle time can be more flexibly chosen

which leads to more feasible solutions.

The optimal number of lines is however a subject of

discussion for every single case separately.

2

M-1

M

…

.

N N-1 M+1

….

Flow line direction

Flow line direction

Figure 2: U-line structure.

1 2

N-1

N

….

Flow line direction

1 2 N-1 N

….

1 2 N-1 N

….

Flow line direction

Flow line direction

Figure 3: Parallel lines.

2.4 Parallel Stations

As an extension of serial lines bottlenecks are

replaced with parallel stations. Tasks performed on

parallel stations are the same and throughput is this

way increased (Askin and Zhou, 1997).

1

2

N-1

N

….

Flow line direction

….

2

Figure 4: Parallel stations.

2.5 Two-sided Lines

This kind of flow lines is mainly used in case of

heavy workpieces when it is more convenient to

operate on both sides of a workpiece rather than

rotating it. Instead of single working-place, there are

pairs of two directly facing stations such as 1 and 2.

As an example car line can be considered, and

mounting some parts like: side – doors (left, right

side), muffler (i.e. right side) or lights with no

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

260

preference to the side. Such a solution makes the

line much more flexible as the workpiece can be

accessed either from left or right (Bartholdi, 1993).

In comparison to serial lines:

• it can shorten the line length,

• reduce unnecessary work reaching to the

other side of the workpiece.

1 3 N-3 N-1

….

Flow line direction

2 4 N-2 N

….

Figure 5: Two-sided line.

3 LOW MIX PRODUCT DEMAND

The volume of production is not a widely discussed

topic over the literature. There are numerous articles

about mixed-model assembly systems however they

do not investigate the problem of low product

demand. A formulation of a problem given in

(Bukchin et. al, 2002) should give an idea about it. J.

Bukchin indicates that it’s long gone, when

everybody was buying a black painted Ford T as

long as it was cheap. Back than, high productivity

was achieved by introducing a perfectly single

model with no additional features.

Nowadays, the life cycle of a product is relatively

short and the demand for varied product is high.

Consequently, a set of similar products needs to be

assembled in relatively low volume. The goal to

such an approach is flexible responding to shorter

product life cycles, low to medium production

volumes, changing demand patterns and a higher

variety of product models and options.

The conditions for such an installation are:

• assembly-to-order production,

• low product demand (low volume

production),

• number of tasks greater than number of

stations,

• lack of mechanical conveyance,

• Highly skilled workers.

It might be extended with conditions given by

(Heike et. al, 2001):

• flexible fixtures,

• flexible tooling,

• delivery of material.

Such conditions give a good base for an assembly

system robust to demand changes. Having a good

balancing algorithm is a goal in this case.

When the demand for a set of similar products is

insufficiently high in order to install a complete

assembly line a solution given in (Battini et. al,

2007) might be used. Most of the authors use

combined precedence diagrams in order to reduce

multiple models into a single model. As the plant

layout, they majority uses a straight line in some

cases allowing parallel workstations for omitting the

bottleneck effects. What more, some allow

duplicating stations in series. Authors investigation

U-shaped lines indicate their benefits over

traditional serial lines. Some of them are:

• improvement in labour productivity,

• job enlargement for human operators,

• great interaction between operators,

• reduction in number of required workstations,

• lead time contraction,

• increase of flexibility.

They suggest (Aase et. al, 2004) this kind of lines in

case of number of tasks less than 30 and 10 stations.

Fixed position layout should be taken into account

dealing with heavy workpieces as it is more

convenient to switch operators places rather than i.e.

rotating the part (Heike et. al, 2001). Generally,

when set-up times required between different

versions are significantly high a job shop layout

suits the best (McMullen, 2007).

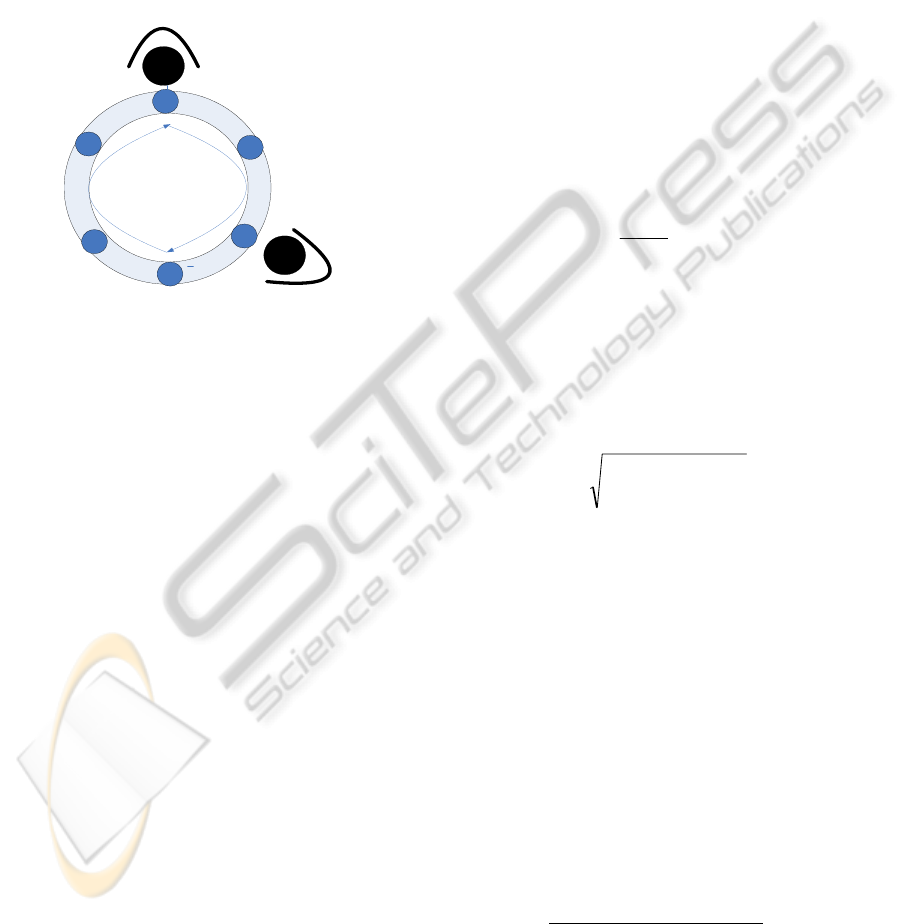

4 ASSEMBLY ROTATING ROUND

TABLE

The model and the procedure discussed in this

section bases on (Battini et. al, 2007). D. Battini

introduces a mixed-model assembly system

consisting of a rotating assembly table with a fixed

number of stations. It is a semi-automated system

therefore some stations are occupied by human

operators, some by machines and other are free.

Human operators are indicated by “O” while

automated ones as “A”. The resource assignment is

assumed to have no limitations, every operator or

machine can be placed at any station of the table.

The product assembled with such a system is

assumed to be homogenous with some additional

features that enable creation of joint precedence

diagram with known tasks’ durations. The rotating

table is a multi-turn one, as a matter of fact a batch

of one single product is completed in n number of

turns, with n ≥ 2. The table is an example of unpaced

ASSEMBLY SYSTEMS FOR LOW PRODUCT DEMAND - Estimation of Final Results

261

synchronous line controlled assembly system. It

means that all the tasks performed by operators need

to be completed before the shift of the table. It is

assumed that it has a pneumatic motion and all

operators need to press a button as an information

that they finished their task. If all the tasks are

finished the table switches their position with switch

time t

s

≥ 2s (move time between 2 stations). Every

switch of the table moves the workpiece to

following station – one station at each table switch.

1

2

3

4

5

6

OP1

OP2

Figure 6: Example of rotating assembly round table (two

human operators and six stations).

The assumption of rotating round table are:

1. The assembly rotating round table is multi-

turn type.

2. Precedence diagrams of all model types can

be accumulated into a single combined

precedence diagram.

3. The line production policy is “assembly-to-

order”.

4. Workpieces are fixed on the table and there is

only one workpiece at the station of the table

at a time.

5. Each station has only either one operator or

one actuator.

6. Idle operators cannot be used to help the

operators of other stations

7. The table switches only when all the opened

stations have finished their job.

8. The first task of the cycle is the load of all the

workpieces of the same batch on a table and

is always assigned to first operator.

9. The last task of the cycle is the download of

the assembled units and can be assigned to

any operator.

The objectives for this assembly system are:

1. Optimize the load balancing of each station

activated in the rotating table

2. Optimize the resource positioning in order to

minimize the entire make span of the

assembly batch, and consequently, the

average cycle time.

The goal of this paper is to compare serial assembly

system and rotating round table.

5 ESTIMATION OF FINAL

RESULTS OF BALANCING

PROBLEM

Some measures of solution quality have appeared in

line balancing problem. Below are presented three of

them (Scholl, 1998).

Line efficiency (LE) shows the percentage

utilization of the line. It is expressed as ratio of total

station time to the cycle time multiplied by the

number of workstations:

100%

Kc

ST

LE

K

1i

i

⋅

⋅

=

∑

=

()

(1)

where:

K - total number of workstations,

c - cycle time.

Smoothness index (SI) describes relative

smoothness for a given assembly line balance.

Perfect balance is indicated by smoothness index 0.

This index is calculated in the following manner:

∑

=

−=

K

1i

2

imax

STSTSI

(2)

where:

ST

max

= maximum station time (in most cases

cycle time),

ST

i

= station time of station i.

Time of the line (LT) describes the period of

time which is need for the product to be completed

on an assembly line

:

(

)

K

T1KcLT +

=

⋅

−

(3)

where:

c - cycle time,

K -total number of workstations.

The average cycle time for rotating round table is

calculated due to the formula:

K

X}t)]S(t{max[

Z

1lASk:k

k

sZK

Z

∑∑

=∈

⋅+

=C

(4)

where:

C – average cycle time,

t(S

k

) – station load,

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

262

AS

Z

– set of stations activated in turn z,

Z – 1,..,Z are table runs,

K – total number of stations,

t

s

– switch time of the table,

X

k

– distance in switches between the major

load station and each activated in turn z.

6 NUMERICAL EXAMPLES

In this chapter an illustrative example of serial

assembly line and assembly rotating round table is

shown. An 8 tasks example of final product is

considered. In both cases for founding end solution

of balance a heuristic procedure (Update

Immediately First Fit – Number of Followers) was

implemented.

1

2

3

4 5 6

7 8

Figure 7: Precedence graph of numerical example.

Table 1: Operation time of numerical example.

Task i

Time t

i

Task i Time t

i

1 18 5 7

2 13 6 14

3 6 7 11

4 9 8 2

6.1 Serial Assembly Line

We consider serial assembly line with two workers it

means with workstation. It is a problem knows as

Simple Assembly Line Balancing Problem Type 2

when the number of stations is given and value of

cycle time is calculated.

1

N

i

i

t

c

K

=

⎡⎤

⎢⎥

⎢⎥

⎢⎥

=

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎣⎦

∑

(5)

where:

c – cycle time of serial assembly line,

t

i

– operation time of task i.

Figure 8: Serial two stations line.

Figure 9: Balance of serial line for calculated example.

The calculated cycle time is 40 (the total operation

time is 80) so we got final solution of balanced line:

Station 1 {1, 4, 3, 7) and Station 2 {5, 2, 6, 8). The

solution is optimal (mostly we obtain using heuristic

method only feasible solution) and calculated

measures are: SI = 0, LE = 100% and LT = 80).

6.2 Assembly Rotating Round Table

We consider now assembly rotating table with 2

human operators and six workstations. We obtain

final results for 6 cases it means we calculate

average cycle time for six different location of

human workers. Starting from position 1 and 2 we

relocate second operator to location 3, 4, 5 and 6.

Operator 1 is always assigned to station 1.

Relocation of Operator 2 causes that the distance

between both workers changes.

OP1

1

2

3

4

5

6

OP2

Figure 10: Location of human workers at assembly

rotating round table (1

st

case) and direction of movement.

Using heuristic described in (Battini et. al, 2007) we

obtained results which are presented in Table 2:

ASSEMBLY SYSTEMS FOR LOW PRODUCT DEMAND - Estimation of Final Results

263

Table 2: Operation time of numerical example.

OP 1 OP2 Cycle Turns

1 Station 1 Station 2 53 2

2 Station 1 Station 3 61 3

3 Station 2 Station 3 53 2

4 Station 1 Station 4 56 3

5 Station 2 Station 4 61 3

6 Station 3 Station 4 53 2

7 Station 1 Station 5 58 3

8 Station 2 Station 5 56 3

9 Station 3 Station 5 61 3

10 Station 4 Station 5 53 2

11 Station 1 Station 6 70 2

12 Station 2 Station 6 58 3

13 Station 3 Station 6 56 3

14 Station 4 Station 6 61 3

15 Station 5 Station 6 53 2

The best average cycle time for assembly rotating

round table is 53 and it occurs always when

Operator 1 and Operator 2 are located next to other.

In this case we need to execute only two turns. The

final solution is: Operator 1 executes tasks 1 and 6

and Operator 2 executes tasks 2, 3, 4, 5, 7 and 8.

Additionally we can calculate the time when final

products is ready to unload from assembly system.

In our case the ready product leaves the system in

216 units of time. We should remember that

assembly rotating system is mostly effective in case

when product demand is equal to the total number of

stations.

7 CONCLUSIONS

In the paper two assembly systems were considered.

First assembly lines were presented. Next assembly

rotating round table was shown. The problems

seems interesting for low product demand. Known

procedures of solving balance of line structures

allow to get very easy optimal or near optimal

solution for two stations line. Investigated assembly

rotating round table allows to quick changes of

assembling different product. Heuristic procedure

improves the result of average cycle time from 70 to

53. This kind of assembly table takes benefits from

layout described in section 4 dealing with their

disadvantages such as monotony, boredom,

operators overload and communication. Different

measures of final result (smoothness index, line

efficiency, line time or average cycle time) simplify

the choice of the most appropriate solution. We

should underline that assembly rotating round table

system don’t need additional sequencing procedure.

Mixed product assembly deals with many

precedence relations but we choose only this one

with maximal number of tasks and connection.

Therefore we calculated the balance of whole model

with maximal task time operations. It allows to

choice appropriate cycle time of turn. In serial lines

we need to sequence the mix product model and

sometimes to stop the line (different model cycle

time) or to add additional parallel station.

This research was supported in part by grant of

Ministry of Science and Higher Education BK

209/Rau1/2009 t.5

REFERENCES

Aase, G. R., Olson, J. R., Schniederjans, M. J., 2004, U-

shaped assembly line layouts and their impact on labor

productivity: an experimental study, European

Journal of Operational Research, 156, 698–711

Askin, R. G., Zhou, M., 1997, A parallel station heuristic

for the mixed-model production line balancing

problem, International Journal of Production Research,

35(11), 3096-3106

Beker, C., Scholl, A., 2005, A survey on problems and

methods in generalized assembly line balancing,

European Journal of Operational Research, 168, 694–

715

Bartholdi J. J., 1993. Balancing two-sided assembly lines:

a case study, International Journal of Production

Research, 31(10), 2447-2461

Battini, D., Facio, M., Ferrari, E., Persona, A., Sgarbossa,

F., 2007, Design Configuration for a Mixed Model

Assembly System in Case of Low Product Demand,

The International Journal of Advanced Manufacturing

Technology, 34(1), 188-200.

Bukchin, J, Dar-El, M, Rubinovitz, J., 2002, Mixed model

assembly line design in a make-to-order environment,

Computers & Industrial Engineering, 41, 405-421

Heike, G., Ramulu, M., Sorenson, E., Shanahan, P.,

Moinzadeh., K, 2001, Mixed model assembly

alternatives for low-volume manufacturing: the case of

the aerospace industry, International Journal of

Production Economics, 72, 103-120

McMullen, P. R., 1997, A heuristic for solving mixed-

model line balancing problem with stochastic task

durations and parallel stations, International Journal

of Production Economics, 51(1), 77–190

Salveson, M. E., 1955. The assembly line balancing

problem, Journal of Industrial Engineering, 62-69

Scholl, A., 1998. Balancing and sequencing of assembly

line, Physica- Verlag

Sauer, G. A., 1998, Designing parallel assembly lines.

Computer Industrial Engineering, 35(3–4), 467–470

Sury, R. J., 1971. Aspects of assembly line balancing,

International Journal of Production Research, 9, 8-14

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

264