A BLUETOOTH SENSOR NETWORK BASED ON

THE IEEE 1451 STANDARD

A Sensor Network Solution to Evaluate the Wellbeing of the Passenger

and Improve Safety in Cars

Jesus Murgoitio Larrauri, Beñat Arejita Larrinaga, Maider Larburu Lopez

and Javier Sanchez Cubillo

Robotiker-Tecnalia, Parque Tecnológico, Edificio 202, Zamudio E-48170 (Bizkaia), Spain

Keywords: Sensor network, IEEE 1451, Bluetooth, NCAP, STIM, TEDS, Plug & play.

Abstract: The use of sensors is very widespread in a lot of different environments and applications. Each situation

needs a different solution and for that reason the use of a scalable and easily manageable sensor network is a

must as applications are becoming increasingly complex. In many cases the perfect solution is the one based

on a wireless sensor network; it provides flexibility, ease of management of the system and expandability.

But in order to provide interoperability between different sensor manufacturers and to give a transparent and

independent interface, the use of a standard is mandatory. This standard system is provided by the IEEE

1451 family of standard protocols. In this project a Bluetooth based sensor network has been implemented

using the IEEE 1451 family of standard protocols. The goal of this network is to aid data acquisition from a

number of sensors within a car, in order to monitor the wellbeing of the passengers and improve safety and

comfort.

1 INTRODUCTION

The Bluetooth sensor network that is presented in

this paper has been developed for an automotive

environment in order to increase the safety and the

passengers’ comfort and to monitor their wellbeing.

For this purpose several sensors installed within a

car have been controlled using an IEEE 1451

standard based sensor network.

The sensor network has been implemented

within a Medea+ project known as Caring Cars, with

satisfactory evaluation.

As a result, several electronic boards have been

developed based on the HCS08 microcontroller

family, which are provided with Bluetooth

capabilities. The firmware of these devices has been

implemented using the APIs and data structures

defined in the IEEE 1451.0 standard.

In parallel, several software libraries and their

respective APIs have been created in order to control

these devices from a Linux based PC.

2 CARING CARS

The main goal of the Caring Cars project was to

increase car safety by enabling wellbeing

applications in an automotive environment.

The main target was in-car safety and wellbeing

to address the huge indirect costs of transportation in

the EU. Reports by the European Environment

Agency estimate the indirect costs of transportation

at about 8% of GDP, a substantial part of which is

caused by accidents. Each year an estimated 127

thousand people are killed and about 2.4 million are

injured on roads in Europe.

So, the main goal of project was to address these

costs by turning the car into a safer environment.

To achieve the previously mentioned general

goal, the project designed an open automotive

infrastructure, mainly based on a sensor network in

cooperation with a car gateway. This sensor network

consists of the sensors already available in vehicles

augmented with new sensors.

61

Murgoitio Larrauri J., Larrinaga B., Larburu Lopez M. and Sanchez Cubillo J. (2010).

A BLUETOOTH SENSOR NETWORK BASED ON THE IEEE 1451 STANDARD - A Sensor Network Solution to Evaluate the Wellbeing of the Passenger

and Improve Safety in Cars.

In Proceedings of the International Conference on Wireless Information Networks and Systems, pages 61-66

DOI: 10.5220/0002959100610066

Copyright

c

SciTePress

The Car gateway manages and coordinates in-car

devices and establishes a connection with the

external world signalling for enriched information

exchange. In this way it will be possible to improve

car safety and thus reduce the costs of transportation

activity.

By adding external communication to the

infrastructure envisioned by the project it will also

become possible to use the same infrastructure to

support health care applications.

This project had partners from both industry and

academia to form a well balanced consortium that

has experience in providing car manufacturers and

manufacturing cars while possessing technical

expertise in the relevant technical fields. The

consortium used this experience and knowledge to

raise car safety to the next level.

3 IEEE 1451

The IEEE 1451 family of standard protocols is

aimed at giving a standard set of commands and data

structures to facilitate the self-management of sensor

networks and transducers. It provides the application

layer not only with a transparent interface to handle

sensors and actuators but also a communication

interface that is independent to the communication

protocol used in the physical layer.

The standard defines two main entities; the

Network Capable Application Processor (NCAP)

and the Smart Transducer Interface Module (STIM).

In order to achieve this, the standard family is

divided into different subfamilies: IEEE 1451.0,

IEEE 1451.1, IEEE 1451.2, IEEE 1451.3, IEEE

1451.4, IEEE 1451.5, IEEE 1451.6 and IEEE

1451.7.

The following figure shows an overview of this

family of IEEE international standards and how each

previously mentioned sub-family is related to each

of the others, mainly the IEEE 1451.0 and IEEE

1451.5, which are the only ones that have been used

within this work.

One key feature of the IEEE 1451 is the

Transducer Electronic Data Sheet, TEDS. This kind

of file is used to help to implement plug & play

features for the management of the transducers and

the transducer network itself.

Figure 1: IEEE 1451 family of protocols.

In this project only the 1451.0 and 1451.5

subfamilies have been used. The first one defines all

the data structures, commands, TEDS and

communication, transducer services and HTTP

access APIs and the second one defines the interface

for IEEE 1451 wireless communications (802.11.x,

802.15.1, 802.15.4).

4 BLUETOOTH SENSOR

NETWORK

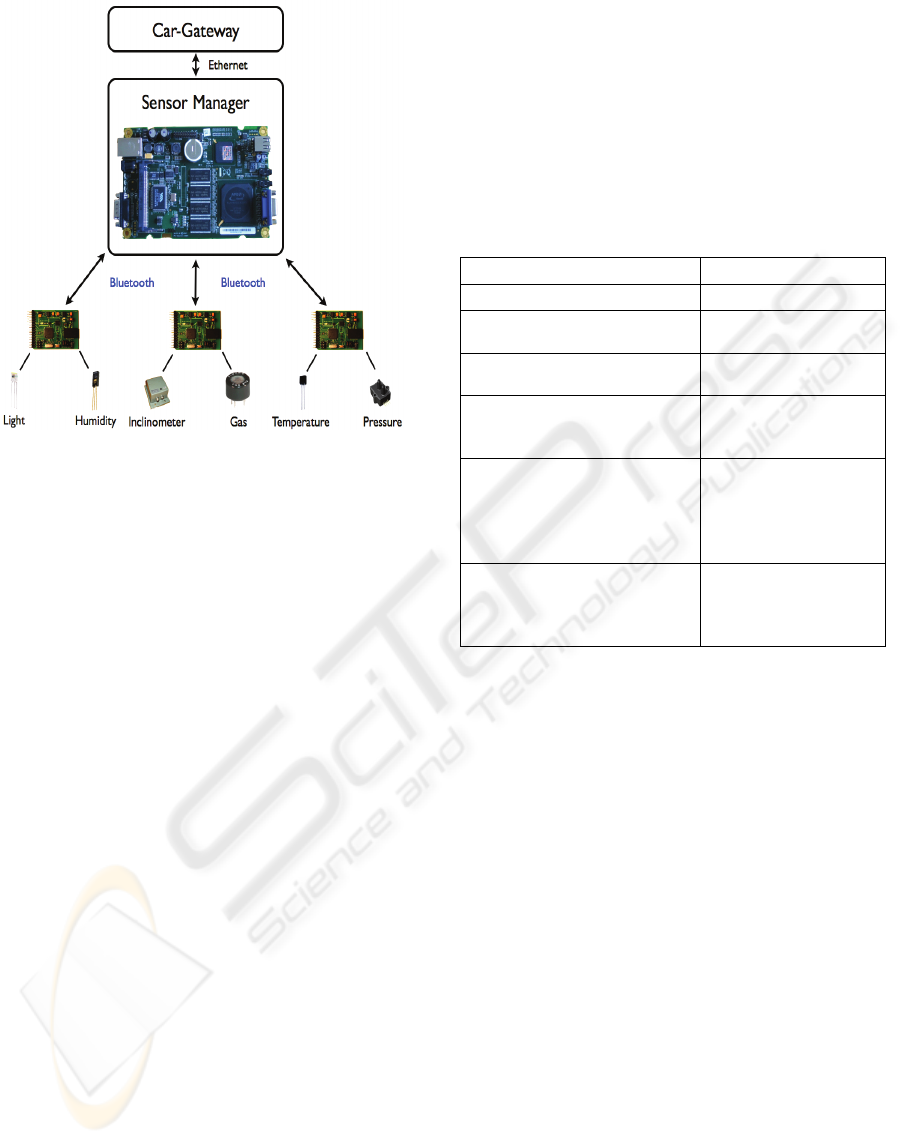

The sensor network that has been implemented,

consists of three main elements. At the highest level

of the hierarchy is the car-gateway which is in

charge of collecting all the data from the sensor

network and storing it in the data base.

One step below in the architectural hierarchy is

the sensor manager, which is focused on collecting

all the data from the sensor nodes using a Bluetooth

communication and then sending the collected

information to the car-gateway via Ethernet.

Finally, there is one more element at a lower

level of the architectural hierarchy, the sensor node.

This works as an interface to the sensors themselves.

It is able to control eight different sensors and send

the gathered information to the sensor manager via

Bluetooth using the IEEE1451.0 TransducerServices

API and ModuleCommunication API.

4.1 Network Architecture

The network architecture which has been used is

illustrated in figure 2.

Figure 2 shows the main elements of the system:

the car-gateway, the sensor manager and the sensor

nodes.

WINSYS 2010 - International Conference on Wireless Information Networks and Systems

62

Figure 2: General architecture of the sensor network.

For the Caring Cars project, seven different

transducers have been used: gas detection,

temperature, pressure, inclination, humidity, light

plus a special ECG signal sensor.

All these transducers have been distributed

within a car, making three different groups each

controlled by a sensor node (STIM). The data

acquired by the nodes is sent to the sensor manager

using a previously established Bluetooth connection

while the communication parameters and the

connection itself are established by the sensor

manager.

4.2 Car-Gateway

The Car-Gateway is the top element of the

architecture and it is a Linux based Car-PC. Its

responsibility is to run the main application, storing

the information sent by the Sensor Manager via

Ethernet and evaluating the information of the

sensors in the system, and finally taking the right

decision in order to help to increase car safety and

passenger comfort.

Thus, an interface based on HTTP protocol

between Car-gateway and NCAP is used to provide

the 1451.0 functionality to any particular application

requiring sensor data.

4.3 Sensor Manager, NCAP

The Sensor Manager is a mini-PC (alix 3c3) with

Linux operative system. It uses the created libraries

and APIs to manage the sensors and the

communication with the sensor nodes in a

transparent way, as defined in the IEEE 1451.0 and

IEEE 1451.5 standards.

In order to have an overview of functionalities

provided by the implemented solution (first version),

the following table summarizes some of the most

important of these:

Table 1: Some of the implemented functions.

Function name Description

TedsManager_readTeds Reads TEDS files

TimDiscovery_reportTims

Reports available

STIMs

TransducerAccess_open

Opens the access of the

specified channel

TransducerAccess_startStream

Starts the data stream

from a specified

channel

Comm_init

Initializes

the communication

parameters

and establishes the

Bluetooth connection

NetComm_open

Opens

the communication

interface of the IEEE

1451 layer

Several others have also been completed for this

functional solution, e.g. to report available channels

in a STIM, close the access of the specified channel,

stop the data stream of a specified channel, or read a

message that is in the bluetooth layer from the IEEE

1451 layer.

The NCAP current hardware device (alix 3c3)

selected is based on one “AMD Geode LX800” CPU

(500 MHz) and 256 MB DDR DRAM. Although

nowadays this device is working correctly and is

considered a good option at this development stage,

because of certain new features and corresponding

performance it should be evaluated prior to a more

consolidated version, and it is planned to design a

new NCAP hardware device which is more adjusted

to the final constraints and which features only the

necessary interfaces in order to obtain cheaper

market solutions. From this point of view, hardware

architecture options based on ARM are being

considered for the future.

4.4 Sensor Nodes, STIM

The sensor nodes are eight bit microcontrollers

based on the Freescale HCS08 family. The current

A BLUETOOTH SENSOR NETWORK BASED ON THE IEEE 1451 STANDARD - A Sensor Network Solution to

Evaluate the Wellbeing of the Passenger and Improve Safety in Cars

63

STIM version is able to control eight different

transducers and they have a Bluetooth chip, the

LMX9838, connected to the microcontroller by a

serial communication interface, and it has the

Bluetooth protocol stack implemented until the SDP

layer.

The firmware in the microcontroller sends the

information via serial lines in messages defined by

the Bluetooth chip manufacturer (national

semiconductor).

The established Bluetooth connection uses the

RFCOMM protocol to emulate a serial point to point

communication between the sensor nodes and the

sensor manager using radio signals.

From the point of view of the protocol between

NCAP and STIM (Bluetooth), it has to be mentioned

that some problems related to connection time have

been detected. Therefore the current version of the

overall network requires more than the previously

expected time for all of the transducers’ data to

reach the NCAP and be monitored. This time

sometimes exceeds 30 seconds. It has been checked

and some interesting results have been obtained, in

that the connection time increases significantly when

more wireless devices, e.g. mobile phones, are

working in the surroundings.

As Bluetooth communication protocol was

selected because the transducers involved for

CaringCars project were related to wellbeing

evaluation within the car, this means that time

constraints for connection between STIMs and

NCAP were not very strict, the obtained results were

sufficient. Otherwise, this issue is being tested in

order to make improvements to future versions.

In any case, the IEEE1451 standard enables easy

changes to be made from one communication

protocol to another more convenient one, if this is

required due to time constraints or any other

requirement, using the same transducer descriptors

(TEDS). This is because the 1451.0 is providing a

common interface to manage every different type of

STIM, although it should also be mentioned that

only this Bluetooth STIM type has been fully tested

up to now.

4.5 Sensors and TEDS

The IEEE 1451.0 standard defines the so called

Transducer Electronic Data Sheet or TEDS. These

files are data structures divided in perfectly defined

different fields. The information within these fields

describes the sensor itself.

Using the information of these files the

application layer can easily know every parameter of

the sensor that is controlling, for instance calibration

information, the sensor’s measuring ranges or the

maximum working temperature of the sensor.

One of the most useful characteristics of these

files is that they can store the information for the

conversion from the sensor’s output voltage value to

its corresponding physical units. These

characteristics make the management of the

transducers easier, providing the application with a

transparent interface to work with, regardless of the

physical characteristics of the transducer in question.

Some of the data provided by a calibration

TEDS for the LM35 temperature sensor used in

CaringCars project were as follows:

/* Total Length */

/* TEDS identification header */

/* Length of TEDS */

/* --------------- */

/* Last calibration date */

/* Length of field */

/* --------------- */

/* Calibration interval */

/* --------------- */

/* Linear conversion */

/* --------------- */

/* Set of coefficients */

/* --------------- */

/* Checksum */

The strangest sensor used in this project was the

ECG signal sensor. It is not very usual to obtain the

ECG signal in a car environment but on the other

hand this signal could give a lot of information about

the wellbeing and comfort of the passengers.

To obtain this signal three conductive material

stripes have been added to the surface of the steering

wheel. These stripes are placed in a manner that

ensures that the necessary signals can be obtained in

order to achieve the ECG signal which is so desired.

The use of such an unusual sensor in an

automotive environment has been facilitated thanks

to the sensor network and the IEEE 1451 family of

standard protocols.

4.6 Results

As a result of this project, some IEEE 1451 standard

compatible electronic boards have been

manufactured which are able to communicate using

the very well known Bluetooth protocol. Thus, a

functional sensor network has been implemented

WINSYS 2010 - International Conference on Wireless Information Networks and Systems

64

based on Bluetooth communications and IEEE 1451

family of standard protocols.

A common API and its respective libraries have

been developed in order to be able to control the

sensor nodes in a transparent way not only for the

management of the sensors, but also for the

communications used in the physical layer.

Finally a functional sensor network has been

implemented in a car environment satisfactorily

controlling a number of sensors between which the

ECG has been the most unusual but also the most

valuable sensor to monitor the wellbeing and

comfort of the passenger.

The following image shows the demonstrator

panel, formed by one NCAP and two STIMs where

each STIM module is able to connect to two

transducers, fabricated in order to explain the main

feature provided by this technology, which is the

easy way to interchange transducers connected to

different channels in any sensor node hardware

module (STIM), simply by downloading the proper

descriptor (TEDS) from the NCAP to the

corresponding STIM.

On the other hand, some limitations, problems

and/or disadvantages have been detected too. Firstly,

the current development is able to connect just two

channels per STIM physical node, although this is

only due to RAM memory space constraints. This

problem will be solved for the next version.

Figure 3: Demonstrator panel.

Furthermore, a longer delay to establish

Bluetooth connection in order to start

communications has been detected, mainly for

environments with more wireless technologies

working at the same time. This was detected because

when mobile phones were switched off this

connection time was reduced.

Another limitation related to Bluetooth protocol

is that one NCAP is able to connect a maximum of

seven STIMs. As the fabricated STIM can be

connected to eight transducers, nowadays one NCAP

would be able to provide data from up to 56

transducers. Obviously, any sensor network based

on this technology could have as many NCAPs as

required.

Finally, it should be mentioned that current

NCAP hardware is a commercial device and,

although the corresponding firmware will be easily

portable, new hardware devices based on a more

suitable hardware will be designed in the future.

5 CONCLUSIONS

From the functional point of view, and taking into

account that this is the first fabricated version, the

goals of this sensor network have been satisfactorily

achieved although with certain limitations to be

resolved in the future.

This solution applied to this project has helped to

implement an application that is able to control and

manage a number of sensors in a transparent way,

regardless of the physical communication used in the

lower layers and regardless of the physical

characteristics of the sensors.

The use of Bluetooth communications has

helped to implement the sensor network in a car

environment easily due to the wireless characteristic

of the communication. The bandwidth and data

transfer rates provided by Bluetooth have been

sufficient to satisfactorily measure all the required

sensors for wellbeing evaluation, once the first

connection has been established.

On the other hand the use of IEEE 1451 family

of standard protocols has been very useful. The data

structures, the transducer access interface and the

transparent communication interface provided by the

standard family have been the key features for the

success of the entire sensor network.

Some days in connecting several STIMs and

NCAP by Bluetooth protocol have been detected

A BLUETOOTH SENSOR NETWORK BASED ON THE IEEE 1451 STANDARD - A Sensor Network Solution to

Evaluate the Wellbeing of the Passenger and Improve Safety in Cars

65

mainly when more wireless technologies are

working at the same time.

Besides, due to some limitations related to not

having enough RAM memory space in the current

STIM version, a new STIM hardware version will be

proposed.

Therefore, future improvements for the next

version will aim at improvement according to the

main two aspects: providing more RAM memory in

order to be able to connect more transducers per

STIM node (at least eight channels), and reducing

connection time using Bluetooth protocol when any

STIM and NCAP are switched on.

A new hardware device based on a more suitable

hardware will be also designed for NCAP in the

future.

REFERENCES

The Institute of Electrical and Electronics Engineers,

2007. IEEE Standard for a Smart Transducer

Interface for Sensors and Actuators—Common

Functions, Communication Protocols, and Transducer

Electronic Data Sheet (TEDS) Formats.

The Institute of Electrical and Electronics Engineers,

2007. IEEE Standard for a Smart Transducer

Interface for Sensors and Actuators—Wireless

Communication Protocols and Transducer Electronic

Data Sheet (TEDS) Formats.

Song, E. Y. Lee, K. B. 2008. STWS: A Unified Web

Service for IEEE 1451 Smart Transducers, IEEE

transaction on Instrumentation and Measurement.

Volume 57, Issue 8, Pages 1749-1756.

Lee, K. B. Schneeman, R. D. Distributed Measurement

and Control Based on the IEEE 1451 Smart

Transducer Interface Standards, IEEE transaction on

Instrumentation and Measurement. Volume 49, Issue

3, Pages 621-627.

Bluetooth Special Interest Group. Specification of the

Bluetooth system, URL www.bluetooth.com.

The Institute of Electrical and Electronics Engineers. IEEE

Std 802.15.1-2005, Wireless Medium Access Control

(MAC) and Physical Layer (PHY) Specifications for

Wireless Personal Area Networks (WPANs), 14 June

2005.

The Institute of Electrical and Electronics Engineers. IEEE

Std 802.15.4-2006, Wireless Medium Access Control

(MAC) and Physical Layer (PHY) Specifications for

Low-Rate Wireless Personal Area Networks (WPANs),

8 September 2006.

CaringCars – International project web site. URL:

http://www.hitech-projects.com/euprojects/caringcars/

CaringCars – Spanish consortium project web site. URL:

http://www.tid.es/netvehicles/caringcars/portal/home.

htm

WINSYS 2010 - International Conference on Wireless Information Networks and Systems

66