USING MODELICA MODELLING LANGUAGE FOR PHYSICAL

PLANT PARAMETERS EVALUATION AND OPTIMIZATION

A Case Study

Eurico Seabra and José Machado

Department of Mechanical Engineering, CT2M Research Center, University of Minho, 4800-058 Guimarães, Portugal

Keywords: Modeling, Simulation, Modelica Modeling Language, Hybrid Plants, Dependable Controllers.

Abstract: Modelica Modeling language is powerful and suitable for modeling mechatronic systems, being possible to

interact different technological aspects and deal, simultaneously with different technologies (mechanical,

electrical, pneumatic, hydraulic,..). In this paper it is discussed, in a case study, the possibility of using this

language for modeling an automation system (controller and plant) in closed loop behavior and also in

defining some parameters of the automation system in order to optimize some behavior aspects of the

system as, for instance, the time cycle of the automation system. Some aspects relied with controllers

dependability are also discussed and it is showed how Modelica modeling language can help controllers’

designers improving controllers dependability, when are used Simulation Techniques.

1 INTRODUCTION

There is a rapidly increasing use of computer

simulations in industry to optimize products, to

reduce product development costs and time by

design optimization, and to train operator. Whereas

in the past it was considered sufficient to simulate

subsystems separately, the current trend is to

simulate increasingly complex physical systems

composed of subsystems from multiple domains.

In such a complex industrial process, simulation

tools are extremely useful since they can contribute

to higher product quality and production efficiency

in several ways. For example, modifications in a

plant could be tested (both statistically and

dynamically) in advance in a simulator saving much

of the trial and error procedure that is used

nowadays; the optimization of plant behavior

parameters can be performed too. Besides, a

dynamic simulator of the plant and of its control

would allow for a thorough study of different control

strategies, and would be an efficient way to tune

controllers for new equipments. Finally, a simulation

tool can also be a way of training not only the

operators but also the production engineers and

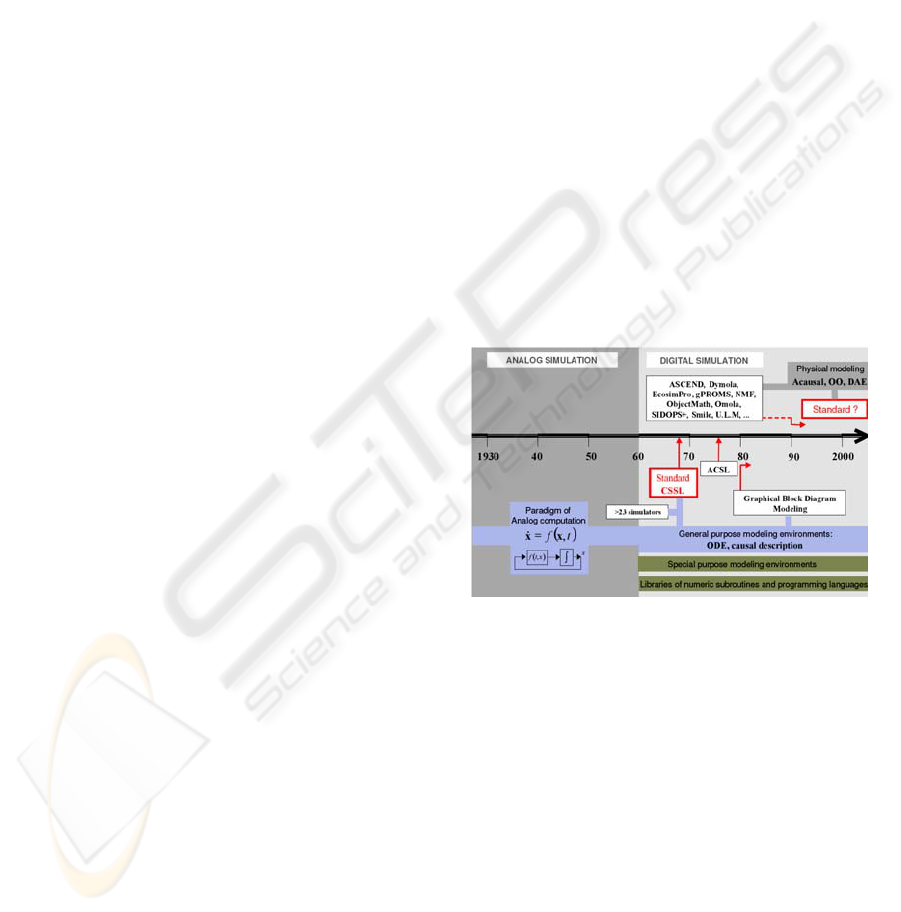

technicians. Some tools have been developed in

order to simulate the behavior of automation systems

(figure 1).

Figure 1: Evolution of modeling and simulation tools.

Graphical block diagram modeling is widely

used in control engineering (Karayanakis, 1995).

Some examples of languages and environments

supporting this paradigm are Matlab/Simulink

(Matlab, 2010), MATRIXX/SystemBuild (Matrixx,

2010), HYBRSIM (Mosterman, 2002) and ACSL

Graphics Modeller (MGA Software 1996). Block

diagram modeling paradigm might be considered as

a heritage of analog simulation (Aström et al. 1998).

On the other hand, object-oriented modeling

languages and compilers supporting the physical

modeling paradigm have become available since the

1990’s decade. This is driven by demands from

users to be able to simulate complex multi-domain

models.

199

Seabra E. and Machado J. (2010).

USING MODELICA MODELLING LANGUAGE FOR PHYSICAL PLANT PARAMETERS EVALUATION AND OPTIMIZATION - A Case Study .

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 199-205

DOI: 10.5220/0003005301990205

Copyright

c

SciTePress

In this paper it is presented a study and shown

how Modelica modeling language can be used to

optimize plant behavior parameters in order to

guarantee the good and desired behavior for the

system, in the shorter time cycle, combined with

other aspects like energy consumption, for example.

To achieve the proposal goal, the section 2 is

devoted to the presentation of Modelica modeling

language and the Dymola Simulation environment;

section 3 presents the case study that is the base for

our study; section 4 discusses the mathematical

modeling of the plant. Further, section 5 presents the

Modelica model of the system (controller model

coupled with plant model); section 6 discusses the

obtained results concerning the defined plant

behavior parameters to study and, finally, section 7,

presents some conclusions and future works, in this

field.

2 MODELICA AND DYMOLA

In the few years of research in modeling and

simulation, the concept of object-oriented modeling

has achieved a big relevance. Several works have

demonstrated how objected oriented concepts can be

successfully employed to support hierarchical

structuring, reuse and evolution of large and

complex models independent from the application

domain and specialized graphical formalism.

To handle complex models, the reuse of standard

model components is a key issue. But in order to

exchange models between different packages an

unified language is needed. Modelica is an object-

oriented, general-purpose modeling language that is

under development in an international effort to

introduce an expressive standardized modeling

language, see (Elmqvist and Mattson, 1997)

(Fritzson and Vadim, 1998). Modelica supports

object-oriented modeling using inheritance concepts

taken from computer languages such as Simula and

C++. It also supports non-causal modeling, meaning

that model’s terminals do not necessarily have to be

assigned an input or output role. In fact, in the last

few years it has been proved in several cases that

non-causal simulation techniques perform much

better than the ordinary object-oriented tools.

Modelica is a powerful programming language

where equations are used for modeling of the

physical phenomena. No particular variable needs to

be solved for manually because the software Dymola

(Dymola software, 2010) has enough information to

decide that automatically. This is an important

property of Dymola to enable handling of large

models having more than hundred thousand

equations. Modelica supports several formalisms:

ordinary differential equations (ODE), differential-

algebraic equations (DAE), bond graphs, finite state

automata, Petri nets, etc.

3 CASE STUDY DESCRIPTION

The case study that is proposed as base for this work

is inspired on the benchmark system proposed by

(Kowalewski et al. 2001).

Figure 2 illustrates an example of an evaporator

system, which consists of two tanks, where an

aqueous solution suffers transformations. In the first

tank that solution should acquire a certain

concentration through the heating of the solution

using an electrical resistance (H1) which provokes

the steam formation.

Associated to the tank1 (figure 2) exist a

condenser (C) responsible for the condensation of

the steam that however it was formed. The cooling,

in that condenser, it is done through the circulation

of a cooling liquid (whose flow is measured by

sensor FIS) that passes through the cooling circuit (if

open the valve V13).

Associate to the tank1 there are a group of

sensors: level sensors (maximum (LIS1) and

minimum (LII1)), temperature sensor (acceptable

maximum (TIS1)); sensor of conductivity (QIS) that

is to indicate the desired concentration; they also

exist several actuators: filling valve of the tank1

(V12), drain valve (V16) and emptying valve (V15),

that it is also the filling valve of the tank2.

Figure 2: Scheme of the entire evaporator system.

In the normal operation mode, the system works

as follows.

The tank1 should be previously filled to its

superior level with an aqueous solution by opening

valve V12. When the tank1 is full, the heating

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

200

system is switch on and also, in simultaneous, the

cooling system of the condenser by opening valve

V13. When it is formed steam, this condenses in the

condenser C. When the concentration desired in the

tank1 is reached, there are switch off the heating

system and the cooling system of the condenser.

Continuously the solution flows from tank1 into

tank2, and it must be guaranteed that the tank2 is

empty. The transfer of the solution to the tank2 is for

a powder-processing operation that is not, here,

described. For that powder-processing operation,

there is necessary to heat the solution to avoid

possible crystallization, and for that there are two

approaches: it can heat until the temperature sensor

of the tank2 indicates that the desired temperature

was reached; or it can heat up for a certain time.

Finally, the tank2 is emptied by the pump P1, if the

valve V18 be opened.

On the other hand, in the possible failure

operation mode, the system works as follows.

A possible failure scenario of the system happens

when the cooling fluid flow in the condenser be to

low (detected by sensor FIS). This implicates the

increase of pressure and temperature in condenser C

and tank1, if the heating system keep switch on

(solution steam). It is necessary to guarantee that the

pressure in the condenser C doesn't exceed a

maximum value to avoid its explosion. For that, it

should be guaranteed that the heating in the tank1 is

switch off before the open of the safety valve (V16).

For this situation of failure operation, it should

switch off the resistance H1 the more quickly

possible, but tends in account that the solution

doesn't crystallize, then that we are before a critical

time. To switch off the resistance H1 they are

considered two possibilities: through a time after

sensor FIS to have detected reduced flow; or through

the sensor of temperature TIS1 (due to the pressure

and temperature are parameters that are directly

related).

There are evidences that should be guaranteed, as

for instance that the tanks should never overflow.

After the failure situation occurs, all of the valves

should be immediately closed.

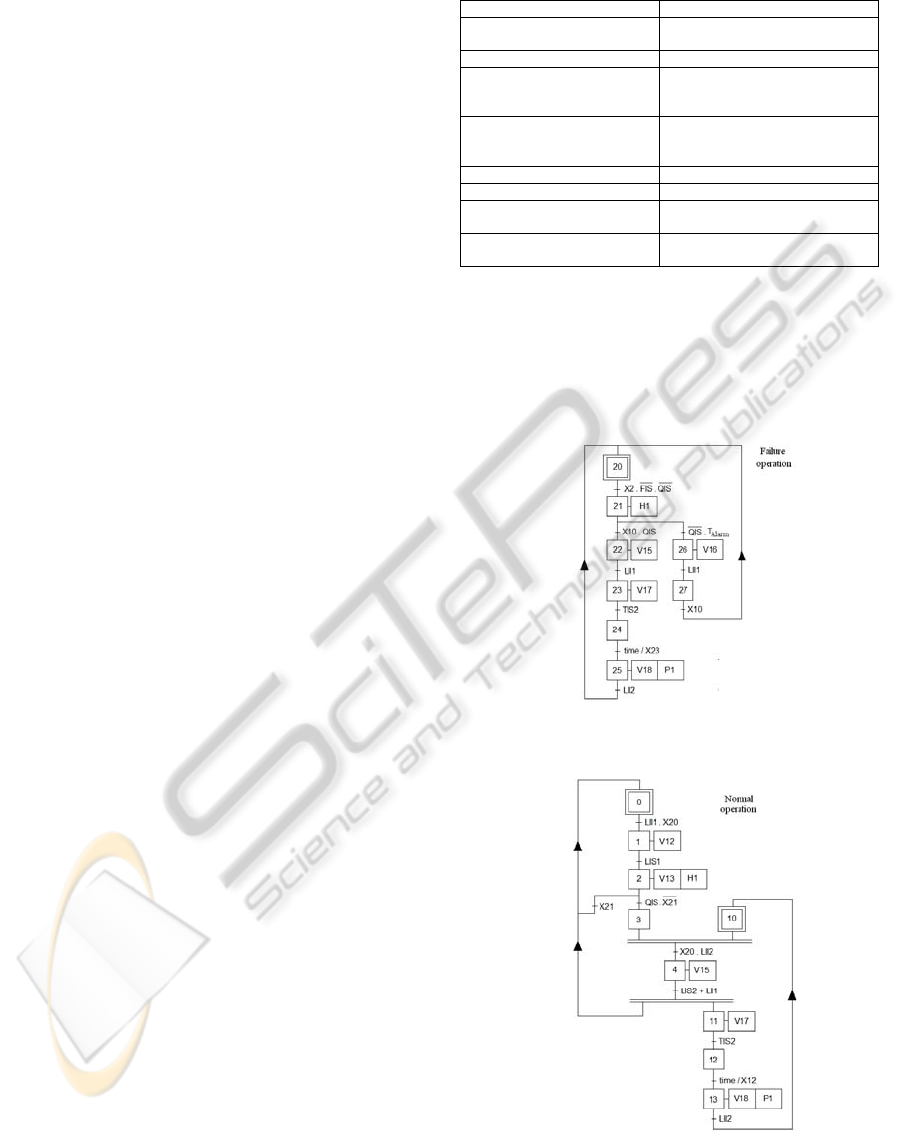

3.1 Controller Specification

In order to guarantee the desired behavior, the

controller specification was developed according to

IEC 60848 SFC specification.

Table 1: Input/Output variables of the controller.

Inputs Outputs

LIS1 – Superior level of the

tank1

V12 – Solution entrance of the tank1

LII1 – Inferior level of the tank1 V13 – Cooling of the condenser

QIS – Electrical conductivity of

the solution in tank1

(concentration)

V15 – Valve of solution passage of

the tank1 for the tank2

TAlarm– Maximum solution

temperature in tank1

(sensor T1S1)

V16 – Drain of the tank1

LIS2 – Superior level of tank2 V17 – Heating of the tank2

LII2 – Inferior level of tank2 V18 – Emptying of the tank2

TIS2 – Solution temperature in

tank2

P1 – Emptying pump of the tank2

FIS – Cooling solution flow of

the condenser C

H1 – Heating Resistance of the tank1

The input and output variables of the controller

which controls the process in closed-loop are

presented and described in table 1.

The SFC specification of the controller behavior

(normal and failure modes) is presented in figures 3

and 4.

Figure 3: SFC specification of the Controller – Normal

Operation Mode.

Figure 4: SFC specification of the Controller – Failure

Operation Mode.

USING MODELICA MODELLING LANGUAGE FOR PHYSICAL PLANT PARAMETERS EVALUATION AND

OPTIMIZATION - A Case Study

201

The controller specification was directly translated

to Modelica modeling language, more specifically to

the library for hierarchical state machines

StateGraph (Otter et al. 2005).

4 PLANT MATHEMATICAL

MODELLING

The next table presents the mathematical equations

that model the system.

The plant modelling has two goals (table 2): first

to assure that the controller specification is adequate

for the intended system behaviour and, second, to

minimize the cycle time for repetitive automation

systems processes. In this paper there are discussed

the two of them: to be sure that the system behaves

as expected – without leading to dangerous

situations - and to maximize the productivity of the

process that it implicates the maximization of the

number of batches.

Due to discrete switching between the two

different continuous systems (T1 and T2), which

happens not only at the stage transitions, by

changing the position of the on/off valves (V15 and

V18), but also in stage 2 for boiling water point, this

developed model is of hybrid nature. The main

required parameters and algebraic equations are

presented in detail in the table 2.

The setting of alarm temperature T

Alarm

is chosen

correctly to accomplish the following two opposed

very important properties: On the one hand it must

be low enough to avoid a dangerous temperature and

pressure values, and on the other hand it has to be

sufficient high so that temperature T does not fall

below a crystallization temperature before liquid

level in tank1 (H

1

) becomes zero.

5 MODELICA MODEL OF THE

SYSTEM

Due to the described potentialities, it was developed

a global model of the evaporator system, already

presented in the previous sections. The plant was

modeled as the controller using the Dymola software

and the object-oriented programming language

Modelica (Fritzson and Vadim, 1998, Elmqvist and

Mattson, 1997). Additionally, to model the

controller, it was used the library for hierarchical

state machines StateGraph (Otter et al. 2005), which

are included in the Dymola software.

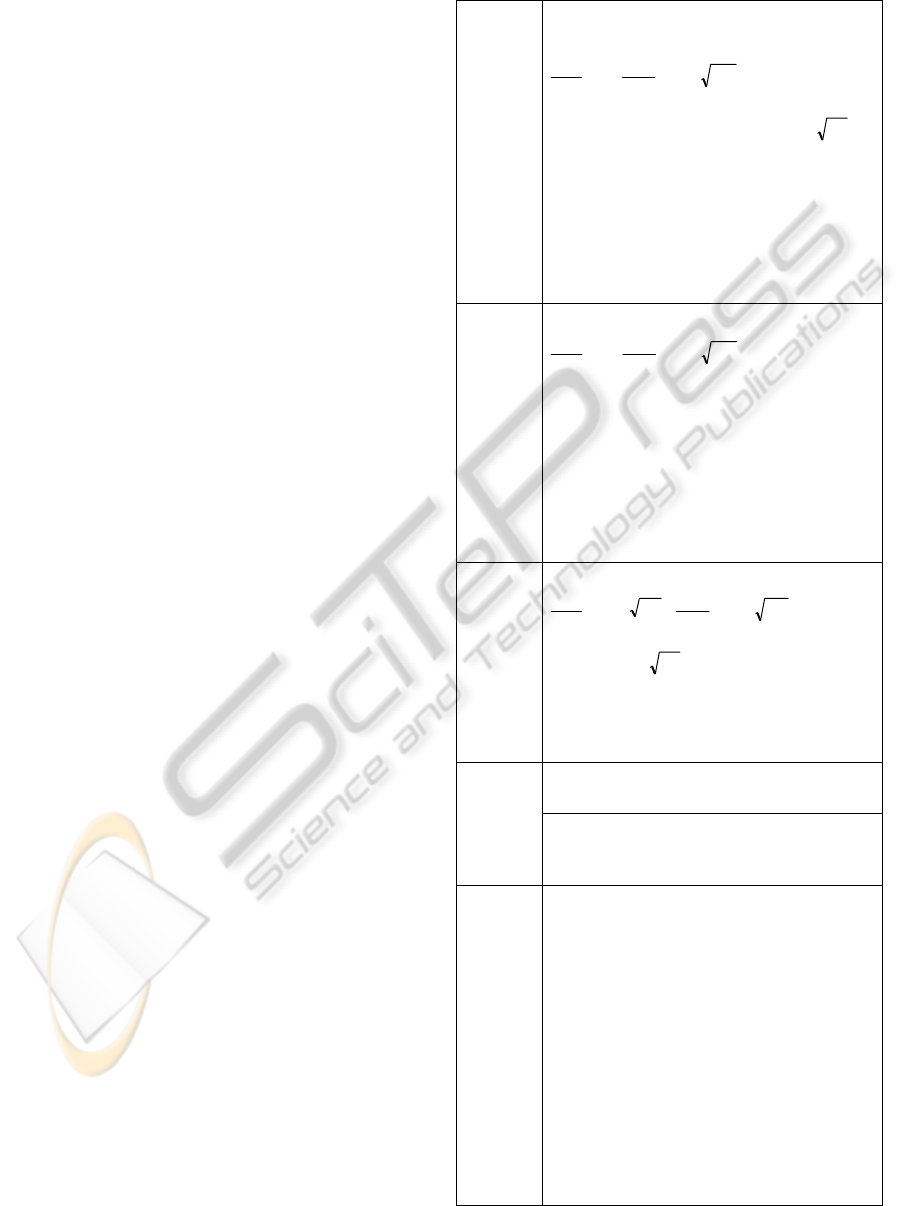

Table 2: System description (differential and algebraic

equations).

Stage 1

Heating

while

T2 is

drained

EvapLossHeat

QQQdtdQ −−=)/(

dtmmcTddtdQ

VLLp

/)).(.()/(

,

+=

0

1

=

dt

dH

;

21

2

HK

dt

dH

−=

)

.(

eLoss

TTkAQ −=

dtdmQ Δ= )./(

evVEvap

h ;

gAAK

R

2)./(

21

=

2

TaTaap ++=

2

1

0

(boiling pressure, dissolve

substance ignored)

TRMmpV

mLVV

)/(=

mmm +=

;

Tbbh

ev 21

+=Δ

VLtotal

QHeat

= 6 kg (total mass of fluid),

(heat supply rate)

3

02.0 mV

V

=

KWkA /24

(vapor volume, assumed to be constant),

=

(heat loss flow per Kelvin)

Stage 2

Cooling

while

T2 is

drained

EvapLoss

QQdtdQ −−=)/(

0

1

=

dt

dH

;

21

2

HK

dt

dH

−=

T < 373K:

dtmcTddtdQ

LLp

/)..()/(

.,

=

0≅

Evap

Q

,373KT >

dtdQ

)/( =

Evap

dmQ = (

WkA 5.22

;

;

:1barp >

cTd

Lp

.(.(

.,

V

hdt Δ)./

K/

dtmm

VL

/))+

ev

.(

Loss

kAQ =

)e

TT −

=

(heat loss flow per Kelvin)

Note: In this stage it will be used the same

algebraic equations and parameters as in stage 1.

Stage 3

Cooling

while

T1 is

drained

Loss

QdtdQ −=)/(

1

2

1

HK

dt

dH

−=

;

11

2

HK

dt

dH

−=

dtmdTcdtdQ

LLp

/)/.()/(

.,

= ;

)

.(

eLoss

TTkAQ −=

gAAK

R

2)./(

12

=

;

;

11

AH

L

m

L

ρ

=

11

.DHAA

π

+=

2

//150 mKWk = (heat loss transfer coefficient),

=0.03m

2

, =0.06m

2

(cross-sectional area T1 and

T2)

1

A

2

A

Variables

state: T (temperature in T1), , (liquid heights,

tanks considered empty when )

1

H

H

2

/

1

2

H

.0≤ m0017

algebraic: (liquid mass), (vapor mass),

L

m

hΔ

V

m

(evaporation enthalpy),

ev

p

(pressure),

A (heat loss area)

Additional

parameters

1

1T

1

a =

a

A

onstants),

kg/K

heat

(diameter of T1), gravity

nt),

=0.03m2, =0.06m

2

(cross-sectional areas of

and ), (pipe cross-sectional

area)

a ,

,

2

A

A

R

3.9 ⋅

4

10⋅

/ mN

2T

0

=

28.5−

4.75

25

10.2 m

−

=

26

/10 mN

22

// KmN

22

/ K ,,aa

2

kgJ /10

6

⋅ ,

(enthalpy constant),

c

p,

= ( pressure c

b 294.3

1

=

L

(liquid

capacity),

mD 2.0=

2

10

a

2

78.2−=b

J /4220

=

3

10⋅ J/

Kkg /

2

/81.9 smg = (

ol (molecular

iquid

nsta

constant),

M

L

314.

KT

e

283=

mkg

L

/018.0= weight of

liquid),

ρ

density),

R

m

8= (molecular gas co

temperature)

3

/970 mkg= (l

molkgJ //

(environment

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

202

Related with the odeled the

fil

plant part, it was m

ling source, the tank1 and tank2, the heater (H1),

the condenser and the valves. For that, it were used

the parameters and algebraic equations presented in

the table 2.

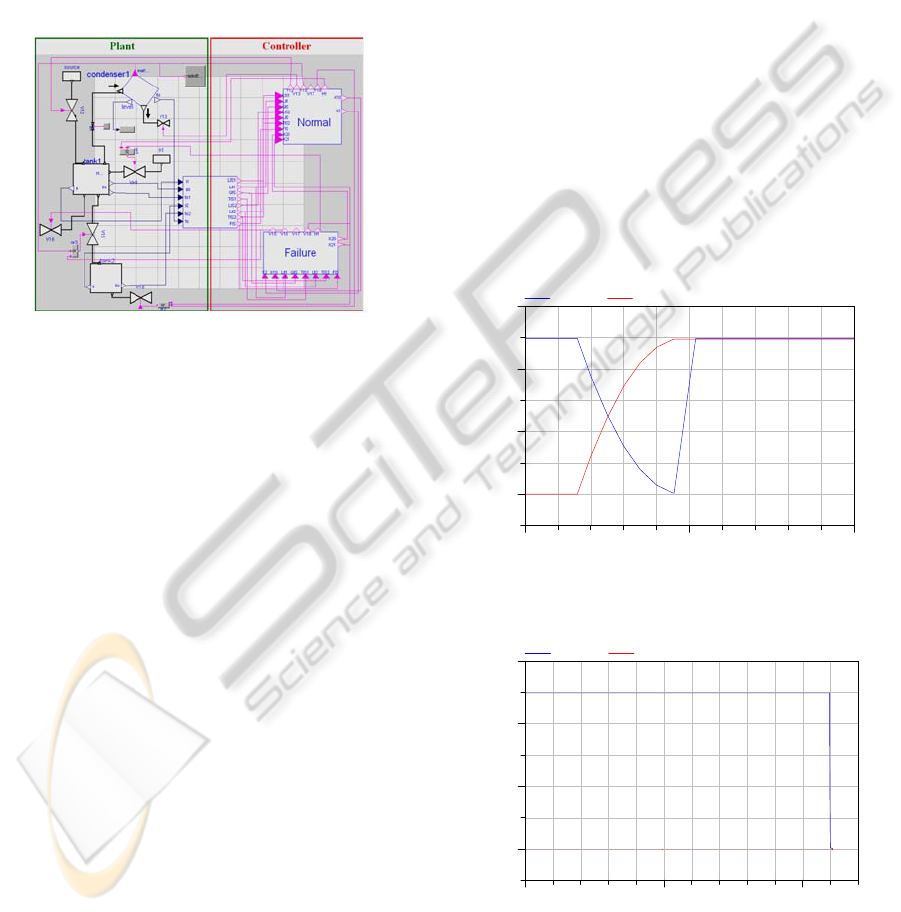

Figure 5 shows the global modelica model of the

system, being highlighted the two main parts, the

physical part (plant) on the left, and the controller on

the right. On the other hand, the controller model

was developed according the SFC specifications (see

figures 3 and 4).

Figure 5: Global modelica model of the evaporator

ue to the reason of it being specified a

di

6 SIMULATION RESULTS

ults of

was necessary to

de

of the controller system (see

fig

ns, respectively, relating to the normal

op

system.

Also, d

screte controller to control the hybrid plant, it was

necessary to implement an appropriate interface, that

translate the analogue outputs signals of the plant

(tanks levels, temperatures, concentration,…) digital

signals, that can be used as inputs of the discrete

controller.

In this section, there are presented res

simulations that were accomplished with the purpose

of studying the dynamical behavior of the hybrid

models described in the previous sections in order to

maximize the productivity of the evaporator process,

in terms, of their energy efficiency and batches

times.

Moreover, these simulations can be seen as a

“system preliminary analysis” to check if the system

behaves in agreement to a given specification for a

particular case, like as, a given a initial state of the

process and a given control program. However, it

must to be enhanced that this is not verification in

the strict sense, since it relies on the appropriate

selection of the considered cases.

In order to perform the hybrid model simulation

with different heating power’s it

fine the parameters, start and stop time of the

simulation, the interval output length or number of

output intervals and the integration algorithm. In the

present work, in all simulations performed, the Dass

algorithm (Basu et al. 2006) with 10000 output

intervals was used.

The first simulations performed was devoted to

verify if the SFC

ures 3 and 4) modeled with Modelica language

with the library for hierarchical state machines

StateGraph simulated correctly the evaporator

system.

Figures 6 and 7 show the results of the first two

simulatio

eration and failure operation modes for the level

tanks. The failure mode it is consequence of the

occurrence of the condenser malfunction during the

production cycle that it originates that the solution

temperature in the tank1 reach the alarm temperature

pre-defined (390K).

2990 3000 301

0

0.0

0.4

0.8

1.2

Fill tank [%]

Time [s]

level_tank1 level_tank2

Figure 6: Level tanks in function of time in normal

operation mode of the evaporator system.

0 1000 2000

0.0

0.4

0.8

1.2

Fill tank [%]

Time [s]

level_tank1 level_tank2

Figure 7: Level tanks in function of time in failure

operation mode of the evaporator system.

USING MODELICA MODELLING LANGUAGE FOR PHYSICAL PLANT PARAMETERS EVALUATION AND

OPTIMIZATION - A Case Study

203

Observing Figure 6 it can be concluded that the

normal operation mode is properly simulated by the

developed program, since the two main properties

that are important to prove are confirmed, for

instance, the drainage of the solution present in the

tank 1 only to happen when the tank2 is empty and

also the filling of the tank1 to happen soon after this

to be empty. On the other hand, observing figure 7,

it can be also concluded that the failure operation

mode is properly simulated, given that is proven that

the tank1 is drained through the safety valve (V16 –

see figure 2) because it is seen that the tank2

remains empty.

After being concluded that the normal and failure

operation behavior is properly simulated by the

proposed program they were performed other

simulations in order to obtain the relationship

between several physical plant parameters that can

obtain the best ratio between the number of batches

and the supply energy costs.

This manner, among of several physical variables

of the process (see table 2) it was chosen the heat

supply rate (Q

Heat

) because it is the most relevant

variable, that determine the rate of the steam

formation (this condenses in the condenser C) and

correspondingly, the time in that the solution present

in the evaporator (tank1) is prepared to be drained

(desired concentration reached).

The solution concentration (C) is obtained by the

following equation:

)

/()(

0 VLL

mmmCC −⋅=

(1)

Where, C

0

is the initial concentration, m

L

is the

liquid mass and m

V

is the vapour mass. In addition,

in all of the performed simulations, it was assumed

concentration values of 0.01000 and 0.01003,

respectively, initial and final.

Figures 8 and 9 illustrate the behavior of the

model given in the table 2 for heat supply rate

(Q

Heat

) of 3000W, respectively for the vapour mass

and concentration.

0 1000 2000 300

0

0.00

0.01

0.02

0.03

Vapour mass [kg]

Time [s]

Vapour_tank1

Figure 8: Vapour mass in function of time with a heat

supply rate of 3000W.

0 1000 2000 300

0

0.00998

0.01000

0.01002

0.01004

Concentration

Time [s]

Concentration_tank1

Figure 9: Concentration in function of time with a heat

supply rate of 3000W.

In a general way, the results presented in the

figures 8 and 9 allow to conclude that the

concentration behavior is properly simulated by the

proposed program.

In particular, analyzing figure 8 it can be stated

that the boiling water point (373K) it is reached after

having elapsed about 800s and after this time the

vapour mass increases continually as it was foreseen

with the increase of the temperature.

On other hand, observing figure 9, it can be

verified that the time in that the solution present in

the tank1 reaches the final concentration (0.01003),

and this way prepared to be drained to tank2, is

about 3000s.

In order to be possible to generalize the batches

optimization, that it implicates the productivity

maximization of the evaporator system, it is

essential to know the optimized relation between the

heat supply rate and the time for the solution reaches

the desired concentration in the tank1 (evaporator).

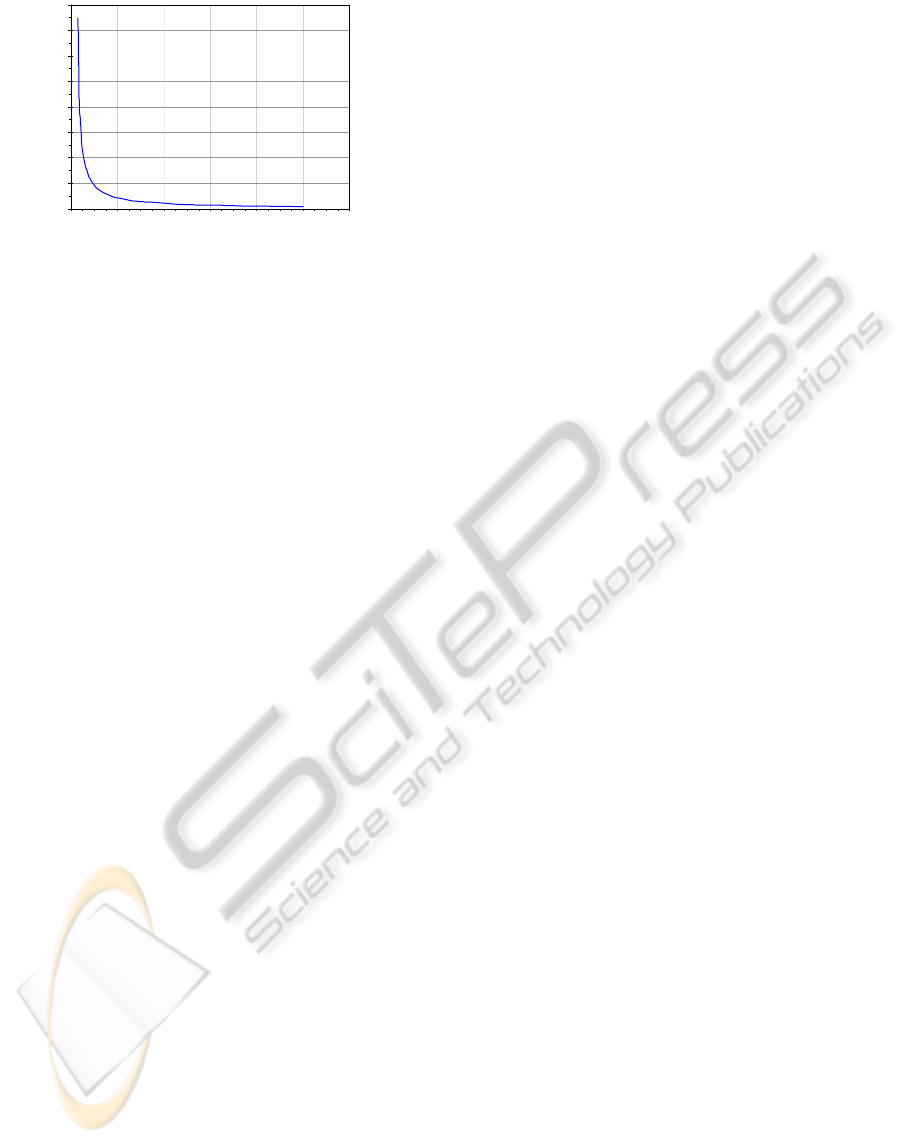

Figure 10 illustrates the time for the solution

reaches the desired final concentration in function of

heat supply rate, as example, from 3000 to

100000W.

Analyzing figure 10, it can be concluded that the

increase of the heat supply rate originates a very

significant decrease on the required time for the

solution reaches the final concentration. It can be

highlighted that the more accentuated time

reductions happens in the interval from 3000 to

20000W.

This manner, in agreement with the simulations

results presented, it can be concluded that the heat

supply rate of 20000W, could be the most

appropriate to obtain the best optimization between

the number of batches and the supply energy costs,

considering the values of the physical variables of

the evaporator system presented in table 2.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

204

0

400

800

1200

1600

2000

2400

2800

3200

0 20000 40000 60000 80000 100000 12000

0

Heat supply rate [W]

Time [

s

Figure 10: Time for the solution present in the tank1

reaches the final concentration in function of heat supply

rate.

7 CONCLUSIONS AND FUTURE

WORK

The simulation used to evaluate the controller and

plant behavior has been developed and proposed in

this paper.

The present research proved to be successful using

the Modelica programming Language to obtain a

plant model and using it, in a closed-loop behavior,

with the controller model.

Some parameters and functional aspects of the

system have been simulated in order to define a set

of values of different variables that make the system

dependable and safe avoiding dangerous situations,

and more efficient, when studied some critical plant

behavior parameters.

The study of critical plant behavior parameters

(like presented in this paper) can be performed using

Modelica in order to obtain simulation models of

complex systems.

As future work the authors believe that, with

auxiliary calculations, it will be possible, using

simulation strategies, to define optimal values for

the different variables, in order to obtain, by one

hand, a safe system behavior and, by other hand, to

optimize the time cycle of Automation repetitive

systems taking into account the critical steps of their

functioning.

ACKNOWLEDGEMENTS

This research project is carried out in the context of

the SCAPS Project supported by FCT, the

Portuguese Foundation for Science and Technology,

and FEDER, the European regional development

fund, under contract POCI/EME/61425/2004 that

deals with safety control of automated production

systems.

REFERENCES

Aström, K. J., Elmqvist, H. & Mattsson, S. E., 1998.

Evolution of continuous time modeling and simulation,

in ‘Proceedings of the 12th European Simulation

Multiconference’, Manchester, UK, pp. 9–18.

Multiconference’, Manchester, UK, pp. 9–18.

Basu S., Pollack R., Roy M., 2006. Algorithms in Real

Algebraic Geometry. In Springer (Eds), Algorithms

and Computation in Mathematics, (10), 2

nd

edition.

Dymola software, 2010. Available in

http://www.3ds.com/products/catia/portfolio/dymola

(consulted in Mar 05th, 2010).

Elmqvist E., Mattson S., 1997. In ESS'97, An Introduction

to the Physical Modelling Language Modelica.

Proceedings of the 9th European Simulation

Symposium. Passau, Germany.

Fritzson, P., Vadim E., 1998. In ECOOP’98: Modelica, a

general object-oriented language for continuous and

discrete event system modeling and simulation. 12th

European Conference on Object-Oriented

Programming. Brussels, Belgium.

Karayanakis, N. M., 1995. Advanced System Modelling

and Simulation with Block Diagram Languages, CRC

Press, Inc.

Kowalewski S., Stursberg O. and Bauer N., 2001. An

Experimental Batch Plant as a Test Case for the

Verication of Hybrid Systems. European Journal of

Control. vol. 7, n_4, pp. 400-415.

Matlab, 2010. Matlab Available in http://

www.Mathworks.com (consulted in March 05

th

, 2010).

MATRIXX, 2010. MATRIXX Available in http://

www.ni.com/matrixx (consulted in March 05

th

, 2010).

MGA Software, 1996. ACSL Graphic Modeller - Version

4.1, MGA Software.

Mosterman P. J., 2002. HYBRSIM - a modeling and

simulation environment for hybrid bond graphs.

Proceedings of the Institution of Mechanical

Engineers, Part I: Journal of Systems and Control

Engineering. Vol. 216, N 1, pp 35-46.

Otter M., Årzén K., Dressler I., 2005. StateGraph - A

Modelica Library for Hierarchical State Machines.

Modelica 2005 Proceedings, 2005.

USING MODELICA MODELLING LANGUAGE FOR PHYSICAL PLANT PARAMETERS EVALUATION AND

OPTIMIZATION - A Case Study

205