A PLANT MATERIAL-BASED AIR PURIFICATION SYSTEM

FOR SWINE ODOUR REDUCTION

Xuezhi Zhou

Department of Physics and Astronomy, University of Manitoba, Winnipeg, R3T 2N2, Manitoba, Canada

Qiang Zhang

Department of Biosystems Engineering, University of Manitoba, R3T 5V6, Winnipeg, Canada

Anhong Huang

Shanghai Shanke Environmental Technologies Ltd. 1288 Yecheng Rd. Jiading District, Shanghai, 201821, China

Keywords: Swine odour, Health symptom, Plant material-based air purification (PMAP), Hydrogen sulphide,

Ammonia, Pig manure, Concentration, Olfactometer.

Abstract: Environmental odour not only serves as a warning of potential health risks, but the odour sensation

themselves can also cause health symptoms , such as headaches, nausea, sore throat, cough, chest tightness,

nasal congestion, shortness of breath, stress, drowsiness, asthma, chronic bronchitis, and alterations in

mood. Swine odour consists of a mixture of volatile organic compounds (VOCs), hydrogen sulphide,

ammonia as well as particulates which adsorbed odourous compounds. A plant material-based air

purification (PMAP) system was evaluated for odour reduction in this study. The PMAP consisted of a

mixture of plant materials which emit volatiles. Measurement was performed in two identical plastic boxes

using pig manure, hydrogen sulphide and ammonia gases as odourous source. The PMAP device was placed

in only one of the boxes. The results showed that PMAP reduced the intensity of swine odour by at least

50%, the concentration of hydrogen sulphide from 20 ppm to 0.2 ppm for a pure hydrogen sulphide source

and from 0.4 to 0.02 ppm for a swine manure source. Similarly, the PMAP reduced ammonia concentration

from 29 to near 0 ppm for a pure ammonia source and from 38 to 10 ppm for the swine manure source.

1 INTRODUCTION

The impact of swine odour on the environment is

one of the major concerns to the general public.

Historically, unpleasant odours have been considered

as warning signals of potential risk to human health,

but not necessarily directly result in health effects

(Phillips, 1992; Gardner, et al., 2000). Recent studies

have demonstrated that odours may not only serve as

a warning signal of potential health risk, but odour

sensations themselves can evoke health symptoms,

including headaches, nausea, sore throat, cough,

chest tightness, nasal congestion, shortness of breath,

stress, drowsiness, asthma, chronic bronchitis, and

alterations in mood, etc. (Wing et al. 2000;

Schiffman et al., 2005;). There are at least three

mechanisms responsible for the health symptoms

caused by the odour. (1) When the concentration of

odorous compounds in the air is above the irritation

threshold, it will directly produce the health

symptoms by irritation. (2) When the concentration

of odorous compounds is below the irritation or

safety threshold but above the odour detection

threshold, many health symptoms can also occur

psychophysically. This psychophysical effect caused

by odour sensation may occur at very low odorant

concentrations. For example, H

2

S gas has a rotten

eggs smell. Its odour detection threshold ranges from

0.5 to 30 ppb while its irritation threshold ranges

from 2.5 to 20 ppm (Schiffman et al., 2005). This

means the average odour threshold of H

2

S is about

three orders of magnitude below its irritation

threshold. (3) Copollutant in an odour mixture is

responsible for some health symptoms (Donham, et

120

Zhou X., Zhang Q. and Huang A..

A PLANT MATERIAL-BASED AIR PURIFICATION SYSTEM FOR SWINE ODOUR REDUCTION.

DOI: 10.5220/0003127101200124

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 120-124

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

al., 1999).

How to reduce and eliminate the swine odour that

evokes health complaints and impairs quality of life

in neighbouring communities has attracted attention

of researchers worldwide. Several techniques have

been developed to reduce the swine odour emission,

such as biofiltration, ozonation, covering the manure

storage, and ultraviolet light (DeBruyn et al., 2001;

Mann et al., 2002; Riley et al., 1989; Vohra et al.,

2006).

The existing technologies have various

drawbacks. For example, it is known that the ozone

itself contributes to air pollution although ozone can

oxidize odour compounds. In other words, the use of

ozone to reduce swine odour may cause secondary

pollution. Ultraviolet light used in the pig barn over

a period of time may be harmful to both the pigs and

operators and it is also expensive. The Biofiltration

have been used to treat exhaust air from pig barns for

odour reduction, but it might cause cross

contamination if used inside the pig barns.

Plant-based aromatic materials have been used as

air fresheners in many different parts of the world

(Heath et al., 1992; Zeng et al., 2003). Recently, a

process has been developed to produce a nano-

crystalline material from extracts of several plants

(or herbs) to air purification (Zhao et al., 2006). All

the constituents in this material are naturally existing

organic materials and environmentally friendly. The

objectives of this study were to design and test a

plant material-based air purification system to verify

the efficiency of this systems in PMAP reducing the

swine odour.

2 MATERIALS AND METHODS

Two identical plastic boxes with dimensions of 64

cm X 45 cm X 40 cm were used to conduct the

experiment. Equal quantities of odour generating

materials (sources) were placed into the two boxes,

respectively. The boxes were then carefully sealed to

prevent any air exchange with the ambient. A hole

of 6 mm diameter was drilled on the center of the

box lids for taking odour measurements from the

boxes. The hole was sealed between the two

measurements. For each test, one box was equipped

with the PMAP. A small device, which includes

about 18 g of PMAP material and a micro electrical

fan to enhance the evaporation of material, was

placed into only one of the boxes. The evaporation

rate of PMAP material is about 1.5 mg per hour. The

other box without PMAP used was the control.

Two sets of tests were performed; one used pig

manure to generate odour and the other used pure

hydrogen sulphide or ammonia as the odour source.

In the first set of tests, about 80 ml of pig manure

from the Animal Research Unit of the Department of

Animal Science, University of Manitoba was

transferred into a glass bottle, and shacked for

homogeneity purposes. Then it was divided equally

into two wide mouthed glass bottles, which were

then placed into the two boxes, respectively as the

swine odour sources. In the second set of tests, the

pure H

2

S was generated by the reaction of Al

2

S

3

and

H

2

O in the wide mouthed glass bottles and the pure

NH

3

from an ammonia water solution.

An AC’ SCENT International Olfactometer (St.

Croix Sensory, Inc., Stillwater, MN, USA) was used

to measure the odour concentration of air in the test

boxes. Five panelists were selected following the EU

Standard EN 13725 (CEN 2003) based on their

specific sensitivity to reference odourant n-butanol.

The odour concentration was determined by the

triangular forces choice method (ASTM E679-04).

Table 1: Concentration of swine odour with and without

PMAP for the 2 sets of the samples.

Sample

Odour

concen.

(OU/m

3

)

Reducing

(%)

S1- with PMAP 1413

S1- without PMAP 2825

50.0

S2- with PMAP 1072

S2- without PMAP 3235

66.9

In the tests with pig manure, two sets of samples

were taken from the two boxes for the olfactometer

analysis. For the first set, the odour samples were

taken from the two boxes after the swine manure

was sealed 18 hours, into two 10-L Tedlar bags

using a vacuum chamber (AC’SCENT Vacuum

chamber, St. Croix Sensory Inc., Stillwater, MN,

USA). When sampling, a bag was placed in the

chamber and the inlet of the bag was connected to a

Teflon probe which was inserted into one of the two

boxes through the hole on the box lid. Each sample

was taken in two steps: (i) fill the bag with 2 L of

odorous air and then evacuated to “coat” the bag,

and (ii) draw odorous air into the bag until the bag

was 75% full. Following the same sampling

procedure, the second set of samples was taken 8

hours after the first set of sample. Each set of sample

has two samples from the two boxes, respectively.

The H

2

S concentration was measured with a

Jerome Meter (JEROME 631-X Hydrogen Sulfide

Analyzer manufactured by Arizona Instruments) in

ppm with an accuracy of 0.001 ppm. After the two

A PLANT MATERIAL-BASED AIR PURIFICATION SYSTEM FOR SWINE ODOUR REDUCTION

121

boxes were sealed and the power of the PMAP

device was turned on, the experimental time was

started to count. Every 15 minutes the data were

taken from both boxes.

The ammonia (NH

3

) concentration was tested with

an ammonia detector tube produced by Gastec Inc.

with range from 0.5 to 50 ppm. A 0.1 ml NH

3

water

solution put in a small glass container as NH

3

source.

After two boxes were sealed and the power of

PMAP device was turned on for 3 hours an open end

of Ammonia detector tube was put into the 6 mm

hole in the lid of the boxes. The concentration data

were taken with a 100 ml pump.

3 RESULTS AND DISCUSSION

3.1 Reduction of Swine Odour

Table 1 shows results of swine ordour concentration

of two sets of the samples with and without PMAP

treatment after 18 and 26 hours for the first (S1) and

second set (S2) of sample. The odour in the control

box without PMAP treatment reached a very high

concentration of 2825 OU/m

3

in 18 h and 3235 in 26

h. These odour levels are much higher than what

normally exists in pig barns. In comparison, the

odour in box treated by PMAP was 1413 and 1072

OU/m

3

at 18 and 26 h, respectively. In other words,

the PMAP reduced the swine odour concentration by

50% at 18 h and 67% at 26 h. It is particularly

interesting to note that odour in the control box

increased from 2825 to 3235 OU/m

3

, or 15%, within

8 h; whereas, the odour in the treated box decreased

from 1413 to 1072 OU/m

3

, or -24% within 8 h. This

trend demonstrates that very high efficiency of

PMAP to reduce the swine odour.

It is also worth to note that the olfactometer

measures the odour concentration, not odour quality

(offensiveness). During the measurement, the

panellists noticed that the sample with the PMAP

treatment had a sweet smell, which was quite

different from the smell of the swine odour. This

means the odour concentration for the samples with

PMAP treatment included the scent of materials in

the PMAP itself. Therefore, the actually rate of

reducing swine odour might be higher than what was

measured by the olfactometer.

3.2 Reduction of H

2

S

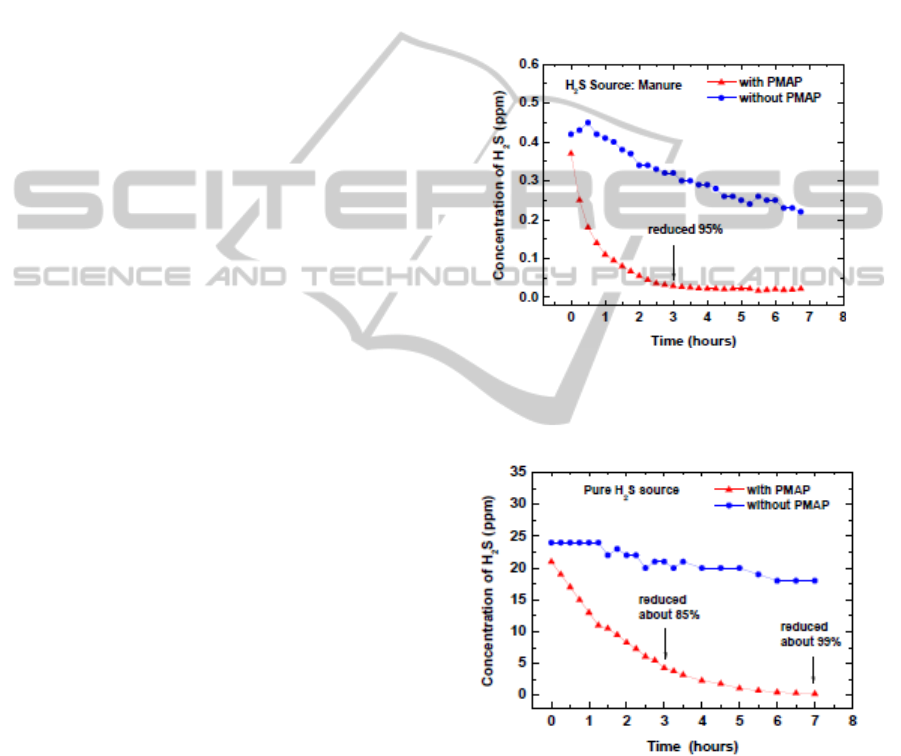

Variations of H

2

S concentration from swine manure

in the two test boxes with time are shown in Figure

1. The concentration of H

2

S in the control box

without the PMAP quickly (30 minutes) reached the

maximum of 0.45 ppm, and then slowly decreased to

0.23 ppm in about 7 hours, while the concentration

of H

2

S in the box with the PMAP decreased sharply

from about 0.4 ppm to 0.02 ppm within 3 hours. The

reduction rate of H

2

S was about 95% within the 3

hours.

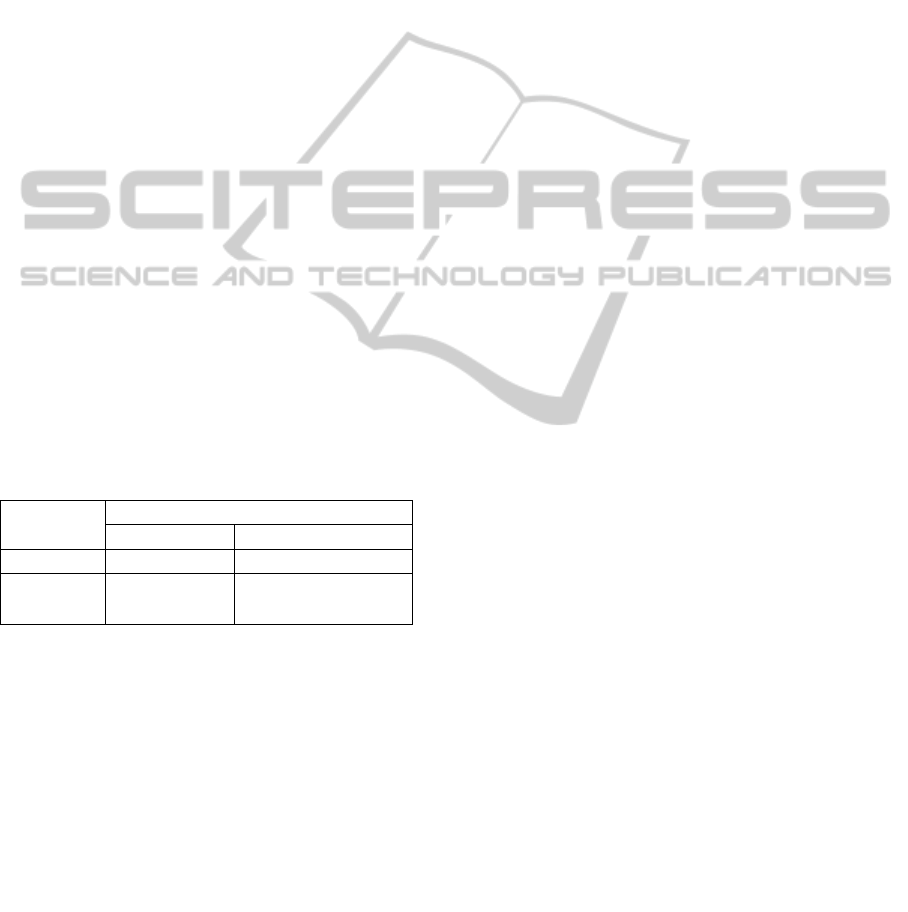

Figure 2 shows variation of H

2

S concentration from

the pure H

2

S source in the two boxes, again with and

without the PMAP, respectively. The H

2

S

concentration in the control box without the PMAP

quickly reaches the maximum, close to 24 ppm, and

Figure 1: Concentration of H2S for the pig manure source

with and without PMAP varies with time. The time starts

to be counted form the source sealed and the power of

PMAP device was turned on.

Figure 2: Concentration of H

2

S for pure H

2

S source with

and without PMAP varies with time. The time starts to be

counted form the source sealed and the power of PMAP

device was turned on.

then slowly decreases to 20 ppm in about 5.5 hours;

the concentration of H

2

S in the box with the PMAP

was sharply reduced and decreases to 3 ppm

(reduced by about 85%) within 3 hours and was

reduced to 0.2 ppm (a reduction of about 98%)

within 5.5 hours. Above two experiments, used pig

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

122

manure and pure H

2

S as odour sources, were more

than 2 replications.

The profiles of the curves in Figure 1 and Figure 2

are similar, which indicates that no matter if H

2

S is

from swine manure or from the chemical reaction,

the PMAP could remove it from the air efficiently.

The H

2

S is one of main gases in the swine odour

and it has been used as an odour indicator of swine

odour (Zhang at. el., 2003). The above result showed

that the H

2

S concentration decreased with time,

suggesting the mechanism of swine odour reduction

by the PMAP was by reducing its components, not

by “masking”.

3.3 PMAP Reduced Concentration of

NH

3

Table 2 listed the results of concentration of NH

3

in

the two boxes after 3 hours. For the pure ammonia

source, the NH

3

concentration in the control box

without the PMAP was 29 ppm (average of two

replications), whereas, the concentration of NH

3

in

the box with PMAP was near 0 ppm (both

replications) (table 2).

When pig manure was placed in the test boxes,

the NH

3

concentration with and without PMAP was

measured to be 38 and 10 ppm, respectively (table 2)

after 3 hours.

Table 2: Concentration of NH

3

measured with a NH

3

detector tube after PMAP power on for 3 hours.

NH

3

Source

Concentration of NH

3

With PMAP Without PMAP

Pure NH

3

29 ppm ~ 0 ppm

Swine

manure

38 ppm 10 ppm

It was noticed that the PMAP could not reduce the

NH

3

concentration to zero for the swine manure as

the NH

3

source. This was because of the swine

manure was continuously emitting NH

3

.

It is known that the high NH

3

levels in pig barns

decrease pig’s health and productivity (

Diekman et al.,

1993)

. Therefore, using the PMAP not only improves

the indoor air quality in pig barns but also has the

potential in improve pig’s health and productivity.

4 CONCLUSIONS

The laboratory experiment shows that the PMAP

consisting of a nano-crystalline plant extracts could

reduce the swine odour by at least 50%. The

measurement results also demonstrated that the

PMAP could reduce the concentrations of hydrogen

sulphide and ammonia

efficiently. This indicates that

the mechanism of PMAP to reduce the swine odour

was not masking. The PMAP provides a promising

approach to reduce the swine odour inside the pig

barns, thus improving the health of workers as well

as pigs.

Based on above results the future research has

first conducted field test to confirm the laboratory

results on PMAP material in pig barn. Secondly, It

will conduct further research to identify the active

components in PMAP to reduce the odour

efficiently. At last, the future research will

investigate the mechanism of the odour reduction by

PMAP.

REFERENCES

ASTM E679-04, 2004. Standard Practice for

Determination of Odor and Test Thresholds By a Forced

Choice Ascending Concentration Series Method of

Limits.

CEN. 2003. Air Quality-Determination of Odour

Concentration by Dynamic Olfactometry, EN 13725,

Technical Committee CEN/TC 264, European

Committee for Standardization.

DeBruyn, J. C. D. D. Mann, and Q. Zhang.

2001.Comparison of odour levels of biofiltered air and

ambient farmyard air. Canadian Biosystems

Engineering 43(6):7-11.

Diekman, M. A., A. B. scheidt, A.L. Sutton, M. L. Green,

J. A. Clapper, D. T. Kelly and W. G. Van Alstine, 1993.

Growth and productive performance, during exposure

to ammomia, of gilts affected with pneumonia and

atrophic rhinitis. Am. J. Vet. Res. 54 (12): 2128-31.

Donham, K., and D. Cumro. 1999. Synergistic health

effects of ammonia and dust exposure. p. 166. In Int.

Symp. on Dust Control in Animal Production Facilities.

Danish Inst. of Agric. Sci., Res. Centre Bygholm,

Horsens, Denmark

Gardner, J. W., H. W. Shin, and E. L. Hines. 2000. An

electronic nose system to diagnose illness. Sens.

Actuators B B70:19–24.

Grinshpun, S. A. A. Adhikari, T Honda, K. Y. Kim, M.

Toivola, K. S. R. Rao and T. Reponen, 2007. Control of

Aerosol Contaminants in indoor Air: Combining the

Particle Concentration Reduction with Microbial

Inactivation, Environ. Sci. Technol. Vol. 41, 606-612.

Heath. R. R. and A. Manukian, 1992. Development and

evaluation of systems to collect volatile semiochemicals

from insects and plants using a charcoal-infused

medium for air purification. J. Chem Ecology,

Vol.18:1209-1226.

A PLANT MATERIAL-BASED AIR PURIFICATION SYSTEM FOR SWINE ODOUR REDUCTION

123

Mann, D. D., J.C. DeBruyn and Q. Zhang. 2002. Design

and evaluation of an open biofilter for treatment of

odour from swine barns during sub-zero ambient

temperatures. Technical Note, Canadian Biosystems

Engineering 44:6.21-6.26 (Technical Note).

Phillips, M. 1992. Breath tests in medicine. Sci. Am. 267

(1): 74–79

Riley, R. L. and E. A. Nardell, 1989. Clearing the air. The

theory and application of ultraviolet air disinfection.

American Journal of Respiratory and Critical Care

Medicine [AM. REV. RESPIR. DIS.]. Vol. 139 : 1286-

1294.

Schiffman S. S. and Williams C. M. 2005. Science of

Odour as a Potential Health Issue, J. Environ. Qual.

Vol. 34, 129-138.

Vohra, A. D. Y. Goswami, D.A. Deshpande and S.S.

Block, 2006. Enhanced Photocatalytic Disinfection of

Indoor Air, Applied Catalysis B: Environmental Vol.

64, 57-65.

Wing. S. and Wolf. S. 2000. Intensive livestock

operations, health, and quality of life among eastern

North Carolina residents, Environ. Health Perspective,

Vol. 108(3) 233-238.

Zeng, H. Y, L. J. Jiang and Y. Q. Zhang. 2003. Chemical

constituents of volatile oil from Houttuynia Cordata

Thunb. J. Plant Resources and Enviroment, 3: 50-52.

Zhang, Q. and X. J. Zhou. 2003. Measurements of odour

and hydrogen sulfide emissions from swine barns.

Canadian Biosystems Engineering 45:6.13-6.18.

Zhao C. X., Y. Z. Liang, and X. N. Li, 2006. Chemical

Composition and Antimicrobail Activity of the Essential

Oil from Clove. Natural Product Research and

Development, 3: 381-385.

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

124