OPTIMIZATION OF ELECTRIC FIELD FREQUENCY ON

DIELECTROPHORETIC IMPEDANCE MEASUREMENT

METHOD FOR ORAL BACTERIA DETECTION

Ryo Hamada

R & D Center, Panasonic Healthcare Co., Ltd., 2131-1, Minanikata, Toon, Ehime, 791-0395, Japan

Department of Electrical and Electronic Systems Engineering, Graduate School of Information Science and Electrical

Engineering, Kyushu University, 744 Motooka, Nishi-ku, Fukuoka 819-0395, Japan

Junya Suehiro

Department of Electrical and Electronic Systems Engineering, Graduate School of Information Science and Electrical

Engineering, Kyushu University, 744 Motooka, Nishi-ku, Fukuoka 819-0395, Japan

Keywords: Dielectrophoresis, Impedance, DEPIM, Bacteria, Oral hygiene, Influenza, Pneumonia.

Abstract: A simple and rapid bacteria detection device for on-site evaluation of oral hygiene in hospitals and clinics

was demonstrated. The developed device utilizes dielectrophoretic impedance measurement (DEPIM)

method. We integrated a micro electrode chip on which bacteria were captured by dielectrophoresis (DEP),

an AC voltage source to induce DEP force, and an impedance measurement circuit to a portable instrument

that enables rapid and automated oral bacterial inspection in hospitals and clinics. Special considerations

have been made on effects of high electrical conductivity of oral samples on DEP force and DEPIM results.

It was shown experimentally and theoretically that using a higher electric field frequency for the DEP

bacteria trap and the impedance measurement could realize DEPIM application to bacteria inspection from

oral samples with higher conductivity. Based on these investigations, we optimized the frequency condition

of the DEPIM suitable for inspecting an oral sample along with the design and development of a portable

DEPIM apparatus for on-site inspection of oral bacteria.

1 INTRODUCTION

Microbiological infectious disease of the oral cavity

is one of the matters for greatest concern since the

relationship between influenza, pneumonia and oral

bacteria, so that accurate evaluation of the amount of

oral bacteria as a level of oral hygiene is required in

order to prevent influenza (Abe et al., 2006a) and

aspiration pneumonia (Abe et al., 2006b). In this

study, a simple and rapid bacteria detection device

for on-site evaluation of oral hygiene in hospitals

and clinics was demonstrated. The developed device

utilizes dielectrophoretic impedance measurement

(DEPIM) method (Suehiro et al., 1999). Bacteria

suspended in a solution is trapped at the gap of

interdigitated microelectrode by positive

dielectrophoresis (DEP), simultaneously, temporal

change of capacitance of the electrode is measured.

Bacteria concentration is calculated based on a

tangent slope of capacitance change. Effect of high

conductivity of oral samples on DEP force and

DEPIM results was experimentally and theoretically

validated.

2 MATERIAL AND METHODS

2.1 Electrodes

Two different electrode configurations were used. A

smooth interdigitated electrode system was

employed in all the DEPIM experiments because

this type of electrode configuration is suitable for

accurate impedance measurement (Suehiro et al.,

1999). The smooth interdigitated electrode arrays of

gold were patterned on a polycarbonate substrate by

125

Hamada R. and Suehiro J..

OPTIMIZATION OF ELECTRIC FIELD FREQUENCY ON DIELECTROPHORETIC IMPEDANCE MEASUREMENT METHOD FOR ORAL BACTERIA

DETECTION.

DOI: 10.5220/0003128901250129

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 125-129

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

a laser ablation technique. Each microelectrode strip

had a 5 μm gap in which cells were trapped and

formed into pearl-chains by positive DEP. On the

other hand, a castellated electrode configuration

(Wang et al., 1993) was employed for the visual

observation of the cell collection process using

positive DEP. The castellated electrode arrays of

chrome were patterned on a glass substrate by

photolithography technique, and the microelectrode

was surrounded by a silicon rubber spacer to form a

chamber in which 22 μl of bacterial suspension

liquid was stored.

2.2 DEP Observation Equipment

The cell suspension liquid was stored in a reservoir

tank and circularly fed to the test chamber using a

peristaltic pump (Suehiro et al., 1999). Sinusoidal

AC voltage was generated by a function generator

(WF 1945, NF Corporation, Japan) and applied to

the electrode system. Visual observation of DEP was

conducted using an inverted microscope (BX-51,

OLYMPUS, Japan) and a CCD digital camera (C-

5060Z, OLYMPUS, Japan). The flow rate of the cell

suspension liquid fed by the peristaltic pump was 2.1

ml/min, and the amplitude of the applied voltage

was 10.0 V peak–peak respectively, which were

found to be appropriate conditions for the

observation of positive DEP in the preliminary tests.

2.3 DEPIM Equipment

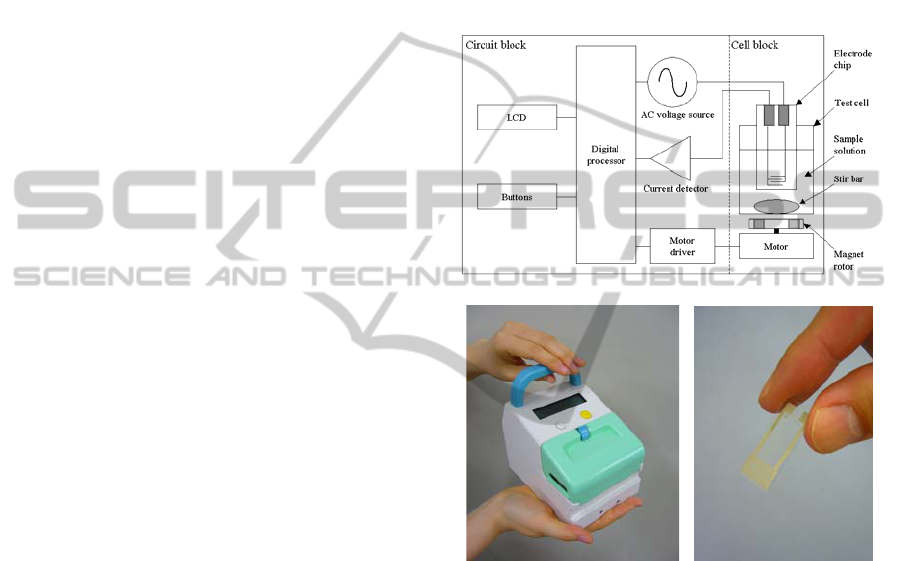

Fig. 1 shows a block diagram and a photographs of

the newly designed and developed DEPIM apparatus

and electrode chip. To enable rapid and automated

bacterial inspection in hospitals and clinics, the

apparatus was designed as a portable instrument to

enable stand-alone measurement without any other

instruments or cables.

The AC voltage source generates AC voltage,

which energizes the interdigitated electrode to

generate positive DEP force. Amplitude of the

applied voltage was 5.0 V peak–peak. AC current

flowing through the electrode is measured by the

current detector. The processor calculates the

electrode capacitance from the amplitudes of the

applied AC voltage and detected current, and the

phase difference between the two components. The

sequential measurement is carried out for 20 s, and

temporal variation of the electrode capacitance is

stored, then a tangent slope of capacitance change is

calculated in order to estimate bacteria

concentration, which has a linear relationship with

the slope.

In the test cell, 5 ml of bacterial suspension is

stored, in which the smooth interdigitated electrode

is immersed. The electrode chip is connected to the

AC voltage source and current detector. A magnetic

stirrer continuously generates a circular flow in the

test cell to enhance the DEP trapping of bacteria.

Impedance values measured by the DEPIM

apparatus were calibrated using a dummy load (a

parallel connection of resistance and capacitance

with known values), as well as a buffer with known

conductivity.

(a)

(b) (c)

Figure 1: The block diagram (a) and photographs of a

newly designed portable DEPIM apparatus (b) and an

electrode chip (c).

2.4 Bacteria Samples

For observation of the DEP trapping process and

optimization of DEPIM conditions, Escherichia coli

(E. coli) strain K-12 (NBRC3301), which have a

high growth rate and have been successfully

employed in previous works (Suehiro et al., 1999),

were employed as a dummy of oral bacteria in order

to improve efficiency of experiments. E. coli were

incubated on agar plates for 24 hours. Before each

measurement, cells were harvested from the agar

and suspended in a 0.1 M mannitol solution. After

several washings by centrifugation, they were finally

resuspended in a 0.1 M mannitol solution (1 μS/cm)

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

126

at various diluted concentrations as determined by a

colony counting method.

Conductivity of the mannitor solution was

adjusted range up to 50 μS/cm by dissolving sodium

chloride to simulate mixing of human saliva. This

value corresponds to be roughly 150 times diluted

human saliva by deionized water (Neyraud et al.,

2009), and bacteria concentration of human saliva

(Abe et al., 2008) at the dilution strength will be

detected by DEPIM method (Suehiro et al., 1999).

3 RESULTS

3.1 Observation of DEP Trapping

Process of Bacteria

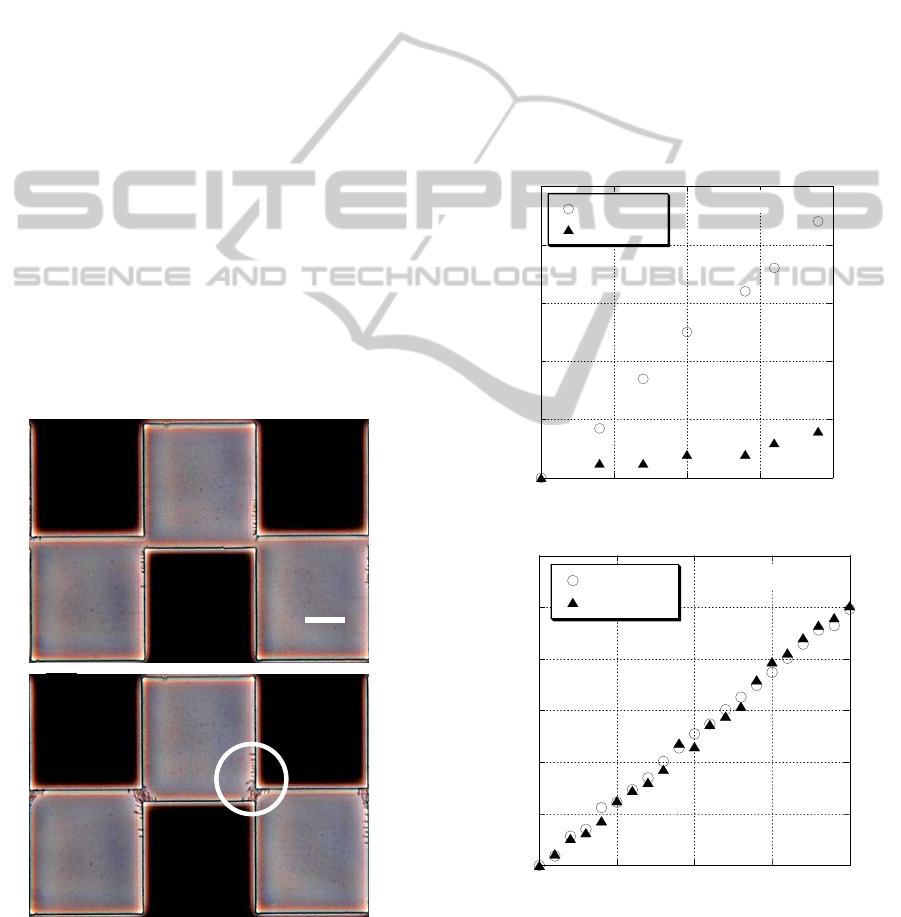

Photographs of the DEP collection of E. coli are

shown in Fig. 2. The DEP collection observations

were made at two different electric field frequencies

of 100 kHz (Fig. 2a) and 800 kHz (Fig. 2b), and

conductivity of the suspending medium of 50 μS/cm.

Bacteria were not trapped at 100 kHz, while some

bacteria were captured at 800 kHz. These

observation results suggest that positive DEP force

exerted on the bacteria becomes weak with increased

conductivity at the 100 kHz frequency.

Figure 2: DEP collection process of E. coli at medium

conductivity of 50 μS/cm and at frequency of 100 kHz (a)

and 800 kHz (b).

3.2 DEPIM Measurement using E. coli

Samples

DEPIM experiments were conducted in this range of

conditions for 1 μS/cm and 50 μS/cm. Fig. 3 shows

temporal variation of the electrode capacitance

increment measured with E. coli at 5x10

6

CFU/ml

(at 100 kHz) and 2x10

7

CFU/ml (at 800 kHz).

Capacitance increase is due to the presence of

bacteria that are trapped and enriched in the

electrode gap. At a frequency of 100 kHz, the

capacitance increase rate in the case of 25 μS/cm

was obviously lowered in comparison with 1 μS/cm

(Fig. 3a). However, at a higher frequency of 800

kHz, the temporal change of capacitance was almost

the same for both the conductivities of 1 μS/cm and

50 μS/cm (Fig. 3b).

0

2

4

6

8

10

0 5 10 15 20

5 μS cm

-1

25 μS cm

-1

Capacitance change, C

T

(pF)

Time, t (sec)

ρ = 5 × 10

6

cm

-3

(a) 100 kHz

0

0.1

0.2

0.3

0.4

0.5

0.6

0 5 10 15 20

5 μS cm

-1

50 μS cm

-1

Capacitance change, C

T

(pF)

Time, t (sec)

ρ = 2 × 10

7

cm

-3

(b) 800 kHz

Figure 3: DEPIM results measured with E. coli. at

frequency of 100 kHz (a), and 800 kHz (b).

(b)

Trapped

E

.coli

(a)

20 μm

OPTIMIZATION OF ELECTRIC FIELD FREQUENCY ON DIELECTROPHORETIC IMPEDANCE MEASUREMENT

METHOD FOR ORAL BACTERIA DETECTION

127

4 DISCUSSION

The DEP force acting on a spherical particle of

radius r suspended in a medium of permittivity s is

given by (Jones, 1995)

23

)](Re[2 EKrF

sDEP

∇=

ωεπ

(1)

where E is the magnitude (RMS) of the applied field

and Re[K(ω)] is the real component of the Clausius–

Mossotti factor given by

**

**

2

)(

sp

sp

K

εε

εε

ω

+

−

=

(2)

where ε

p

*

and ε

s

*

are the complex permittivity of the

particle and surrounding medium, respectively. For a

real dielectric, the complex permittivity is defined as

ω

σ

εε

j−=

*

(3)

where ε is the permittivity and s is the conductivity

of the dielectric and ω is the angular frequency of

the applied field.

An example of a theoretical prediction of the

suspension medium conductivity dependency of

parameter Re[K(ω)] is shown in Fig. 4. One E. coli

cell is modeled as a dielectric sphere covered by

shells. The shells represent the cytoplasmic

membrane and the sphere covered by the shells

represents the cytoplasm (Huang et al., 1992).

Parameter values of E. coli are determined referring

to the referenced literature (Llamas et al., 1998). Fig.

4 indicates that Re[K(ω)] or the DEP force decreases

with increases in the medium conductivity σs at a

lower field frequency. When the medium

conductivity increases from the initial value of 1 to

50 μS/cm, DEP changes from positive-DEP to

negative-DEP at the field frequency of 100 kHz.

This suggests that E.coli cells are not captured at the

electrode gap by DEP under the condition of 50

μS/cm. On the other hand, the DEP force is hardly

dependent on σ

s

at 800 kHz. The theoretical

calculations agree well with the experimental results

shown in Fig. 2 where DEP collection of E.coli is

observed only for low medium conductivity (1

μS/cm) at 100 kHz but no clear differences are

observed with a rise in medium conductivity until 50

μS/cm at 800 kHz.

These results indicate that frequency of 800 kHz

is more appropriate than 100 kHz for DEPIM

measurement of sample with high medium electrical

conductivity, σ

s

.

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

10

3

10

4

10

5

10

6

10

7

10

8

10

9

1 μS cm

-1

20 μS cm

-1

50 μS cm

-1

Re [K]

Frequency (Hz)

Figure 4: Theoretical prediction of the external medium

conductivity σ

s

dependency of Re[K(ω)] spectra.

5 CONCLUSIONS

In this study, we have described the optimization of

AC electric field frequency in the DEPIM method to

enhance the measurable range of conductivity of the

sample solution to adapt the DEPIM method for the

inspection of bacteria obtained from the human oral

cavity. Observation and theoretical calculation of

DEP, and DEPIM measurement was carried out.

From these results, it was shown that higher field

frequency is more suitable condition for bacterial

sample that has higher electrical conductivity of

solution. Consequently, it was demonstrated that the

developed portable DEPIM apparatus is useful in the

on-site evaluation of the bacterial contamination of

clinical samples from the oral cavity for quantitative

evaluation of oral hygiene to prevent influenza and

aspiration pneumonia. In addition, the developed

apparatus will be applied to other fields in which the

investigation of the sample including ionic

substances is necessary, for example, any clinical

samples besides those taken from the oral cavity, as

well aw fields relating to the environment and the

food industry.

REFERENCES

Abe S., Ishihara K., Adachi M., Sasaki H., Tanaka K.,

Okuda K., 2006a. Professional oral care reduces

influenza infection in elderly. Archives of Gerontology

and Geriatrics 43: 157–164.

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

128

Abe S., Ishihara K., Adachi M., Okuda K., 2006b. Oral

hygiene evaluation for effective oral care in preventing

pneumonia in dentate elderly. Archives of Gerontology

and Geriatrics 43: 53-64.

Abe S., Ishihara K., Adachi M., Okuda K., 2008. Tongue-

coating as risk indicator for aspiration pneumonia in

edentate elderly. Archives of Gerontology and

Geriatrics 47 (2): 267-275.

Huang Y., Holzel R., Pethig R., Wang X-B., 1992.

Differences in the AC electrodynamics of viable and

non-viable yeast cells determined through combined

dielectrophoresis and electrorotation studies. Phys.

Med. Biol. 37 (7): 1499-1517.

Jones T. B., 1995. Electromechanics of Particles,

Cambridge University Press. New York, 1

st

edition.

Llamas M., Giner V., Sancho M., 1998. The dynamic

evolution of cell chaining in a biological suspension

induced by an electrical field. J. Phys. D: Appl. Phys.

31 (21): 3160-3167.

Neyraud E., Bult J. H. F., Dransfield E., 2009. Continuous

analysis of parotid saliva during resting and short-

duration simulated chewing. Archives of oral biology

54 (5): 449-456.

Suehiro J., Yatsunami R., Hamada R., Hara M., 1999.

Quantitative estimation of biological cell

concentration suspended in aqueous medium by using

dielectrophoretic impedance measurement method. J.

Phys. D: Appl. Phys. 32: 2814-2820.

Wang X-B., Huang Y., Burt J. P. H., Markx G. H., Pethig

R., 1993. Selective dielectrophoretic confinement of

bioparticles in potential energy wells. J. Phys. D: Appl.

Phys. 26 (8): 1278-1285.

OPTIMIZATION OF ELECTRIC FIELD FREQUENCY ON DIELECTROPHORETIC IMPEDANCE MEASUREMENT

METHOD FOR ORAL BACTERIA DETECTION

129