ANNEALING TEMPERATURE EFFECT ON THE SENSITIVITY

OF SIGE NANOWIRE FOR BIO-SENSOR

Kow-Ming Chang

1,2

, Chu-Feng Chen

1

, Yu-Bin Wang

1

, Chung-Hsien Liu

1

, Jiun-Ming Kuo

1

1

Institute of Electronics, National Chiao-Tung University, No. 1001, University Rd., Hsinchu 300, Taiwan, R.O.C.

2

Department of Electronic Engineering, I-Shou University, No. 1, Sec. 1, Syuecheng Rd., Kaohsiung, 840, Taiwan, R.O.C

Chiung-Hui Lai

Department of Microelectronics Engineering, Chung Hua University

No. 707, Sec.2, WuFu Rd., Hsinchu, 300, Taiwan, R.O.C

Keywords: Silicon nanowire, SiGe, Bio-sensor, 3-amino-propyltrime-thoxy-silane (APTS).

Abstract: Nanowire is widely used in biological sensor because it has the high surface-to-volume ratio. Germanium

(Ge) would be beneficial to enhance the sensitivity of silicon nanowire for bio-sensor. In this study, we have

successfully fabricated the

SiGe on Insulator (SGOI) nanowires with different annealing temperature by

side-wall spacer technique, respectively. The 3-amino-propyltrime-thoxy-silane (APTS) is used to modify

the surface, which can connect the bio-linker. Nanowire is considered as a resistance, and the change of

conductance (ΔG) and sensitivity (S) of different samples corresponding to APTS treatment were

investigated. As annealing temperature was elevated from 800 to 950℃, the SiGe nanowire exhibited

increasing sensitivity in the chemical detection. However, it was noted that degradation of sensitivity was

observed as the annealing temperature increases up to 1000℃. This behavior may be associated with the

reduction of the Ge concentration at the surface of SiGe nanowire due to high-temperature diffusion of Ge

in Si. So, temperature is a key parameter in the annealing process producing two effects: repairs of defects

and Ge diffusion. There would be an optimal annealing temperature between 900 and 1000℃.

1 INTRODUCTION

Silicon nanowire has recently attracted much

attention for its potential applications in the

biological and chemical sensors. Its sensing

mechanism is considered to be the change of its

electrical conductance upon surface as the bio-

molecular stay on it. Due to the large surface-to-

volume ratio and quasi-1D characteristics, the

silicon nanowire sensor provides a high sensitivity in

chemical detection such as PH buffer solution (Cui

et al., 2001), viruses (Patolsky et al., 2004), and

DNA (Li et al., 2004). Silicon nanowires are

particularly appealing for sensing applications, since

the silicon dioxide can effectively passivate surface

dangling bonds, and at the same time can be

chemically modified through the well known silanol

chemistry to provide surface functionalization and

selectivity for particular analytes.

Several studies have been attempted to fabricate

the nanowire by the advance photo-emission such

like Extreme Ultraviolet (EUV) or X-ray (Solak et

al., 1999), or the Atomic Force Microscope (AFM)

lithography (Nemutudi et al., 2001), or nanoimprint

(Yan et al., 2005), or sidewall spacer (Choi et al.,

2002), or vapor state synthesis (Mohanty et al.,

2007), or vapor-liquid-solid (VLS) growth (Li et al.,

2003). The sidewall spacer formation is an easy

process for nanowire fabrication with the advantages

of high-yield and low-cost. The method only using

the combination of the conventional lithography and

process technology was demonstrated without

complex processes such as electron beam

lithography (EBL), scanning probe lithography

(SPL) and VLS, etc.

It is reported that SiGe alloy has higher carrier

mobility than Si and can be thermally oxidized at

relatively low temperature. Moreover, SiGe field

345

Chang K., Chen C., Wang Y., Liu C., Kuo J. and Lai C..

ANNEALING TEMPERATURE EFFECT ON THE SENSITIVITY OF SIGE NANOWIRE FOR BIO-SENSOR.

DOI: 10.5220/0003153503450348

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 345-348

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

effect transistor exhibits the higher current change as

the same gate voltage applied (Yeo et al., 2000). In

the previous works (Change et al., 2008a), it has

already demonstrated IgG antibody sensing

capability of SiGe nanowire sensor. First, the 3-

amino-propyltrime-thoxy-silane (APTS) was used to

modify the surface, which can connect the bio-linker.

APTS is used to modify the surface of native oxide

layer around nanowires. Hydroxyl functional groups

on the surface of native oxide layer were replaced by

the methoxy groups of APTS molecules. After

APTS modification, the surface of nanowire was

terminated by amine groups. In the experimental

environment, amine group is prone to be positively

charged, that is, the surface potential nanowire

increased, and the conductance of p-type nanowire

decreased. Next, bis-sulfo-succinimidyl suberate

(BS3) is used as linker between APTS and IgG

antibody. BS3 treatment resulted in negative charges.

Hence, the conductance of p-type nanowires

increased. After APTS and BS3 modification,

nanowire was capable of capturing IgG antibody.

Instead of the convention silicon nanowire, SiGe

nanowire sensor is expected to have better

sensitivity in the chemical detection for higher

carrier mobility as the same bio-molecular bind on

the surface. It is well known that annealing

temperature did repair the interior defects of SiGe.

The higher concentration of Ge the higher sensitivity

would become. However, excess of Ge will induce

more vacancies of surface, which will degrade the

adhesion between APTS and interface and decrease

sensitivity (Change et al., 2008b).

In this paper, we used the sidewall spacer

technique to fabricate the Si

0.93

Ge

0.07

and Si

0.86

Ge

0.14

nanowires with different annealing temperature for

discussion of the sensitivity, respectively. We focus

on investigating the change of conductance (ΔG) and

sensitivity (S) of different samples corresponding to

APTS treatment.

2 EXPERIMENT

The structure is shown in Figure 1. All test samples

were fabricated on p-type (100)-oriented bare silicon

wafer with 1~10 Ω-cm resistivity. The poly-Si,

Si

0.93

Ge

0.07

and Si

0.86

Ge

0.14

nanowires were

fabricated by the side-wall spacer technique using

the combination of the conventional lithography and

processes technology, respectively. Starting with

standard RCA clean of silicon substrate, wet

oxidation was performed by SVCS Furnace system

at 980℃ for 7 hours to grow the bottom oxide of

about 5500 Å as an insulator oxide. After

lithography patterning of active area, oxide was

etched by Tokyo Electron Limited TE5000 Reactive

Ion Etch (RIE) system to form a 3000 Å oxide step.

Then, standard RCA clean was performed, followed

by a amorphous silicon (α-Si) film of 200 Å

deposition by SVCS Furnace system at 650℃ as

seed layer for SiGe film deposition. Then, a

polycrystalline SiGe film of 600 Å was deposited by

the ultra-high-vacuum chemical vapor deposition

(ANELAVA SiGe UHV-CVD) at 665℃. After

lithography patterning of the Source/Drain (S/D)

contact region, the SiGe film (800 Å, 20% over

etched) was etched by Transformer Coupled Plasma

(TCP) poly etcher. Only the S/D contact region and

the side-wall spacer retained SiGe. The residue SiGe

film is called SiGe nanowire. After lithography

patterning of removal of unwanted sidewall spacer,

the SiGe nanowire were etched and isolated. Finally,

Boron was heavily doped with 5×10

15

atoms/cm

2

at

10 keV to form p-type SiGe nanowire. Next, the

samples were subject to activation annealing in

nitrogen (N

2

) ambient at 800, 900, 950 and 1000 ℃

for 30 minutes. The aluminum was deposited by

thermal coater and patterned to reserve the S/D

region and sintered at 400

o

C for 30 minutes.

The Hewlett Packard HP 4156A was used in this

study to measure the electric characteristics of

nanowire sensor. Drain voltage (V

D

) was varied

from -10 to 10V and 500 mV a step, and back gate

voltage was 0 V. The measurement of electric

characteristics was performed ate every stage of

surface modification, and the average conductance

was then extracted from I

D

-V

D

characteristics with

V

D

= 3~6 V.

Figure 1: Schematic representation of SiGe nanowire

structure by the side-wall spacer technique.

3 RESULTS AND DISCUSSIONS

The sensitivity (S) of a nanowire-based sensor is

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

346

defined as the ratio of the magnitude of conductance

change to the baseline conductance value:

0

00

GG

G

S

GG

−

Δ

==

(1)

, where G

0

is the conductance before molecule

capture, G is the conductance after molecule capture,

and ΔG is the different between G and G

0

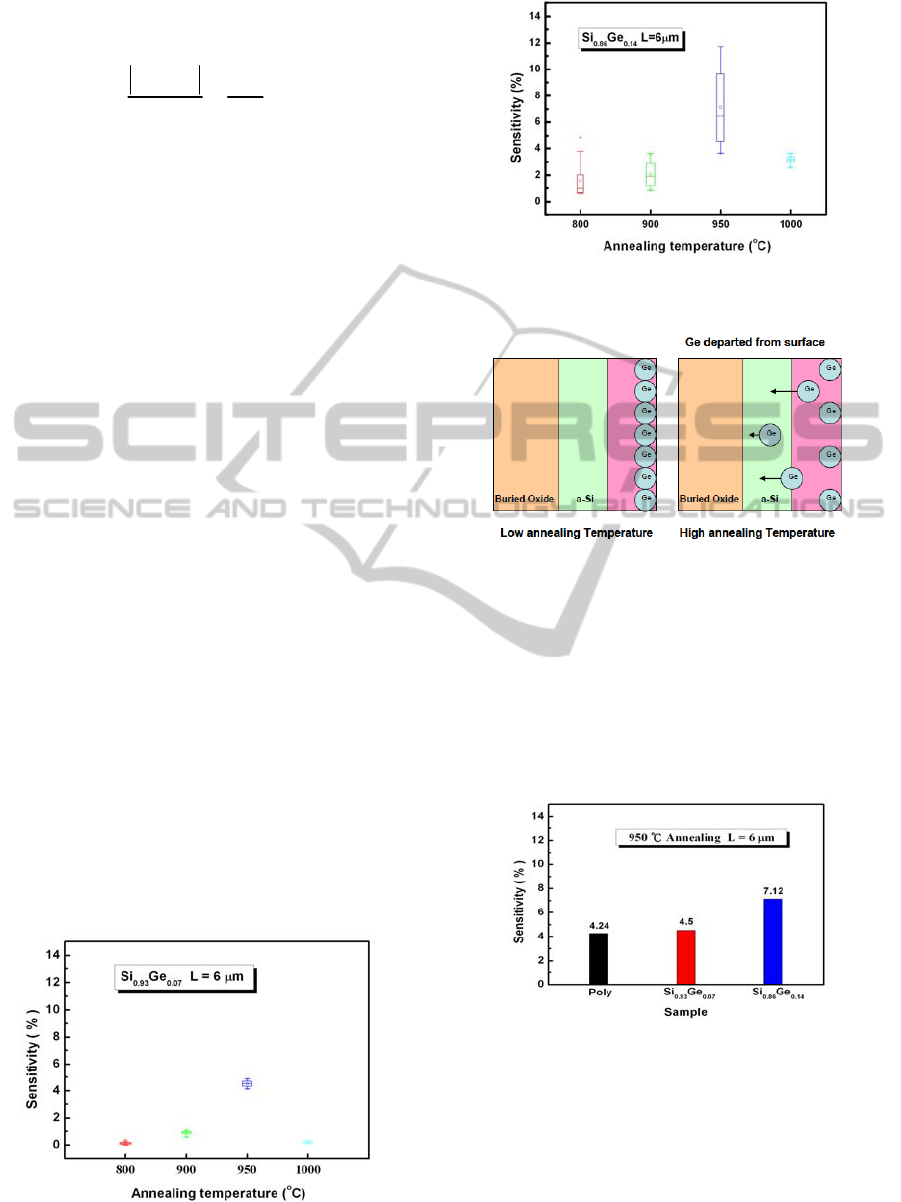

. Figures 2

and 3 show the sensitivity of the Si

0.93

Ge

0.07

and

Si

0.86

Ge

0.14

nanowire with different annealing

temperature after APTS modified, respectively.

Adequate Ge concentration will be more helpful to

enhance the sensitivity of silicon nanowire for bio-

sensor. The sensitivity increased slightly with

increasing annealing temperature from 800 to 900℃.

It is supposed that the annealing energy is

insufficient for repairing the defects. Furthermore, it

is observed that the raise of the sensitivity is more

obvious at temperature of 950℃ due to enough

energy to arrange. The sensitiveity of Si

0.86

Ge

0.14

nanowire could be 11.67% at 950℃ because of

better concentration and quality of Ge. However, it

is noted that a higher annealing temperature of about

1000 ℃ resulted in degraded sensitivity. This

behavior may be associated with reduction of Ge

concentration at the surface of SiGe nanowire

because the velocity of Ge diffusion toward Si

would be increased at higher temperature (Sugiyama

et al., 2004). Figure 4 is a schematic of the Ge

diffusion at low and high temperatures. So,

temperature is a key parameter in the annealing

process producing two effects: repairs of defects and

Ge diffusion. There would be an optimal annealing

temperature between 900 and 1000℃.

Figure 5 shows the sensitivity of poly-Si, Si

0.93

Ge

0.07

and Si

0.86

Ge

0.14

nanowire with annealing temperature

of 950℃ after APTS modified. The higher

concentration of Ge exhibits the higher sensitivity.

Figure 2: Sensitivity of Si

0.93

Ge

0.07

nanowire with different

annealing temperature after APTS modified.

Figure 3: Sensitivity of Si

0.86

Ge

0.14

nanowire with different

annealing temperature after APTS modified.

Figure 4: Schematic illustration of Ge diffusion at low and

high temperatures.

From the above, we conjecture that nanowire

obtains more energy at 950℃ to arrange the lattices

more regularly. Therefore, the lower defects make

the higher sensitivity increase. Hence, there would

be an optimal annealing temperature of about 950℃

in order to obtain better quality and higher

sensitivity.

Figure 5: S Sensitivity of poly-Si, Si

0.93

Ge

0.07

and

Si

0.86

Ge

0.14

nanowire with annealing temperature of

950℃after APTS modified. The higher concentration of

Ge becomes the higher sensitivity.

4 CONCLUSIONS

In this paper, we have investigated the effect of

ANNEALING TEMPERATURE EFFECT ON THE SENSITIVITY OF SIGE NANOWIRE FOR BIO-SENSOR

347

different annealing temperature on the sensitivity of

SiGe nanowire with Ge 7% and 11%. Raising the

annealing temperature can bring large sensitivity due

to repairs of defects, but it will degraded sensitivity

due to Ge diffusion as the annealing temperature

increases up to 1000℃. There would be a reasonable

annealing temperature between 900℃ and 1000℃.

It is concluded from experiments that the optimized

annealing temperature is around 950℃. Adequate

Ge concentration will be more helpful to enhance

the sensitivity of silicon nanowire for bio-sensor.

Si

0.86

Ge

0.14

nanowire with annealing temperature of

about 950℃ can obtain higher sensitivity (~11.67%)

in the APTS detection.

ACKNOWLEDGEMENTS

The authors would like to thank the staff of the

National Nano Device Laboratory for their technical

help. They also acknowledge the financial support of

the National Science Council (NSC) under Contract

Nos. NSC 98-2221-E-009-174-MY3.

REFERENCES

Cui, Y. (2001). Nanowire Nanosensors for Highly

Sensitive and Selective Detection of Biological and

Chemical Species. Science, 293, 1289-1292.

Li, Z. (2004). Sequence-Specific Label-Free DNA Sensors

Based on Silicon Nanowires. Nano Letters, 4(2), 245-

247.

Patolsky, F. (2003). Electrical detection of single viruses.

Proc. Natl. Acad. Sci. U.S.A., 101, 14017- 14022.

Solak, H. H. (1999). Exposure of 38 nm period grating

patterns with extreme ultraviolet interferometric

lithography. Appl. Phys. Lett., 75(15), 2328-2330.

Nemutudi, R. (2001). Modification of a shallow 2DEG by

AFM lithography. Microelectronic Engineering, 57,

967-973.

Yan, X. M. (2005). Fabrication of large number density

platinum nanowire arrays by size reduction

lithography and nanoimprint lithography. Nano Letters,

5(4), 745-748.

Choi, Y. K. (2002). A Spacer Patterning Technology for

Nanoscale CMOS. IEET Transactions on Electron

Devices, 49(3), 436-441.

Mohanty, P. (2007). Simple vapor-phase synthesis of

single-crystalline Ag nanowires and single-nanowire

surface-enhanced Raman scattering. J. AM. CHEM.

SOC., 129, 9576-9577.

Li, C. (2003). Diameter-controlled growth of single-

crystalline In

2

O

3

nanowires and their electronic

properties. Adv. Mater., 15(2), 143-146.

Yeo, Y.-C. (2000). Enhance Performance in Sub-100 nm

CMOSFETs using Strained Epitaxial Silicon-

Germanium. IEDM, 00-753.

Change, K.-M. (2008a). The Ge enhance the sensitivity for

bio-sensor. 2

nd

IEEE International Nanoelectronics

Conference, 811- 814.

Chang, K.-M. (2008b). Higher drive current for SiGe

nanowires. 2

nd

IEEE International Nanoelectronics

Conference, 315-319.

Sugiyama, N. (2004). Temperature effects on Ge

condensation by thermal oxidation of SiGe-on-

insulator structures. Journal of Applied Physics, 95(2),

4007-4011.

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

348