DEVELOPMENT OF VERTEBRAL METRICS

An Instrument to Study the Vertebral Column

António Jordão

Departamento de Física, Faculdade de Ciências e Tecnologia, Universidade Nova de Lisboa

Quinta da Torre P-2829-516, Caparica, Portugal

Instituto de Biofísica e Eng. Biomédica, Faculdade de Ciências da Universidade de Lisboa

Campo Grande, P-1749-016, Lisboa, Portugal

Pedro Duque

Departamento de Física, Faculdade de Ciências e Tecnologia, Universidade Nova de Lisboa

Quinta da Torre, P-2829-516, Caparica, Portugal

Claudia Quaresma

CEFITEC, Departamento de Física, Faculdade de Ciências e Tecnologia, Universidade Nova de Lisboa

Quinta da Torre, P-2829-516, Caparica, Portugal

Pedro Vieira

Departamento de Física, Faculdade de Ciências e Tecnologia, Universidade Nova de Lisboa

Quinta da Torre P-2829-516, Caparica, Portugal

Instituto de Biofísica e Eng. Biomédica, Faculdade de Ciências da Universidade de Lisboa

Campo Grande, P-1749-016, Lisboa, Portugal

Keywords: Non-invasive instrument, Spine, Biomechanical, Image processing, Evaluation, Standing position.

Abstract: The purpose of this article is to present a new instrument to study the vertebral column. This device is an

evolution from Vertebral Metrics (Quaresma, 2010). In this new device, the detection of the spinous process

is semi-automatic, non-invasive and it is prepared to analyse the entire population. The data acquired from

the instrument will allow three dimensional analysis of the vertebral column in standing position. With this

instrument, hospital staff will be able to study biomechanical changes in the vertebral column due to

incorrect exercise, injury, congenital malformations, obesity, pregnancies, etc. The device uses a system of

movement in two axes that is controlled by software. The software uses a video camera and image

processing algorithm to detect points that were previously marked in the spinous process of the individual

under study. The software gives orders to the mechanic part to move the equipment to position the mark

made by laser upon the spinous process. In these conditions, the spatial coordinates of the spinous process

are stored and the process is repeated for the others spinous processes. A complete examination takes

approximately 2 minutes and 25 seconds after manual tracing of the spine and improving is being made to

the software to reach the 30 seconds mark. This instrument has the possibility of performing consecutive

sweeps, for dynamic accommodation studies.

1 INTRODUCTION

The spinal column supports and protects the spinal

cord and roots, as well as offer flexibility that is vital

to the movement of the trunk.

Diseases of the spinal column have been

increasing worldwide, due to several factors, in

particularly congenital malformations, sedentary

lifestyle, incorrect eating habits, posture and

224

Jordão A., Duque P., Quaresma C. and Vieira P..

DEVELOPMENT OF VERTEBRAL METRICS - An Instrument to Study the Vertebral Column.

DOI: 10.5220/0003164802240229

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 224-229

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

exercise. In many of these factors, the study of the

spinal curvature will be an important tool to detect

and try to solve them.

The radiological studies are the most widely

used methods for assessing the spinal column

curvatures; however these are invasive, since the

patient is subjected to ionizing radiation. (Quaresma,

2009a)

There are other non-invasive alternatives for

measuring the curvature of the spinal column, yet

most of them only allow the study of one plane and

those that analyse the spinal column in three

dimensions normally use infrared cameras (Vismara,

2010) making the equipment very expensive.

Figure 1: Image of Vertebral Metrics.

Vertebral Metrics (Figure 1) is a non-invasive

mechanical apparatus that was built to identify the

X, Y and Z positions of each vertebra, from the first

cervical vertebra to the first sacral vertebra (Secca,

2008). In a global way Vertebral Metrics evaluates

the curvatures and lateral deviations of the spinal

column in the standing position. (Quaresma, 2009a,

2009b, 2009c)

In the Vertebral Metrics the examiner, starts by

marking on the skin of the person under study the

spinous processes, from the first cervical vertebra to

the first sacral vertebra, using a washable pen. The

evaluation starts by placing the first horizontal piece

in the occipital region. Then it is necessary to move

each piece and place it in line with each mark. In

this device the data collection takes about seven

minutes after the manual marking. (Quaresma,

2009b, 2010)

The aim of this study is to improve the Vertebral

Metrics and take a step forward, performing an

automated measurement of the spine column. With

this new equipment the tests will be faster, simpler

and with a better resolution.

In this new device the same method of tagging

the spinal processes is going to be used, but instead

of a manual measuring, the device will perform it

automatically.

For a better understanding of how the instrument

works, the axis system used will be defined as

following: the transversal distance as our X

coordinate, the antero-posterior distance as the Y

coordinate and the height as Z coordinate.

Figure 2: Aspect of the instrument.

To measure the distance between the device and

the spinal process (Y), a CCD camera, a laser diode

and a lighting system were used. To get an accurate

measurement of the Y distance it is necessary that

the laser spot and the skin mark be coincident. So

this apparatus was assembled over a high precision

X, Z positioner (Figure 2). In order to control the X,

Z movement an image processing software was

develop to find the spinal processes marks and laser

spot, so we can calculate the necessary movements

of the system. When laser spot and spinal process

marks are coincident the system stores the X, Y, Z

coordinates.

When the acquisition is done all the data is

collected by the software and stored it in a single

file, for further offline processing.

2 MECHANICAL SYSTEM – X/Z

POSITIONER

There were two main goals for the mechanical

structure: resolution and speed. The instrument was

constructed based on the following pre-requisites:

- The mechanical system should move all the

hardware necessary for the image acquisition in

two directions, up and down (Z direction), left

and right (X direction).

- Must move 2000 mm in Z and 300 mm in X.

- Resolution must be better than 0.5 mm.

DEVELOPMENT OF VERTEBRAL METRICS - An Instrument to Study the Vertebral Column

225

- Travel speed, must move 1000 mm in Z direction

in 30s (33.3 mm/s).

- Must move in X direction fast enough to position

the camera and laser before the system arrives at

the corresponding Z position.

- Must have a communications protocol controlled

by software.

For the Z positioner a 2 meters DryLin ZLW belt

drive from Igus™ was used. It travels 66 mm per

revolution, and supports speeds up to 5 m/s. The X

positioner is a linear slide table DryLin SHTS Fast.

It has a high helix pitch leadscrew providing high

speed positioner, 50 mm per revolution.

The motors are step by step motor type, for

precision positioning, each step rotates the motor

shaft 0.9

o

, so a full rotation or revolution is 400 steps

(360

o

/ 0.9

o

= 400). For increased torque, motor Z

has a gear box that reduces 7 revolutions to 1 (7:1).

Knowing this we can define the resolution for

the positioners:

Table 1: Resolution of the positioners.

Axe [Step/rev] [mm/rev]

Resolution

[mm/step]

X 400 50 0.125

Z 400*7 = 2800 66 0.024

The selected motors are both from Lin

Engineering™. In terms of Z direction a high torque

bipolar motor, model 5709L-01P with 1 Nm of

maximum torque and 6.25 rev/s maximum speed.

The X motor, is a high torque bipolar motor, model

4209L-01P with 0.35 Nm of maximum torque and

18.75 rev/s maximum speed. Both motors have

independent drivers from Lin Engineering™, model

R325. These drivers provide smooth motor rotation

and micro stepping configuration, also includes Pole

Damping Technology™ (PDT) that enhances step

motor performance by dampening each full step in

order to create a more accurate and smooth motion

profile.

The motion and control of the motors will be

performed by a microcontroller PIC16F877 from

Microchip™. This microprocessor will work with a

16MHz clock and independently generate the two

pulse clocks for step by step motion of the motors. It

will also monitor limit switches, control serial

RS232 communications and control laser and lights

relays.

In terms of RS232 communication a protocol

was developed based on instructions and replies, the

microprocessor will be a slave system, i.e., will only

answer and execute commands from the PC.

Figure 3: Scheme of the communication system.

3 CALCULATION OF DISTANCE

USING THE LASER DIODE

MARK

The laser diode is situated on top of the camera in a

fixed height and angle. Through trigonometric

equations the distance between the equipment and

the individual that is under study can be calculated.

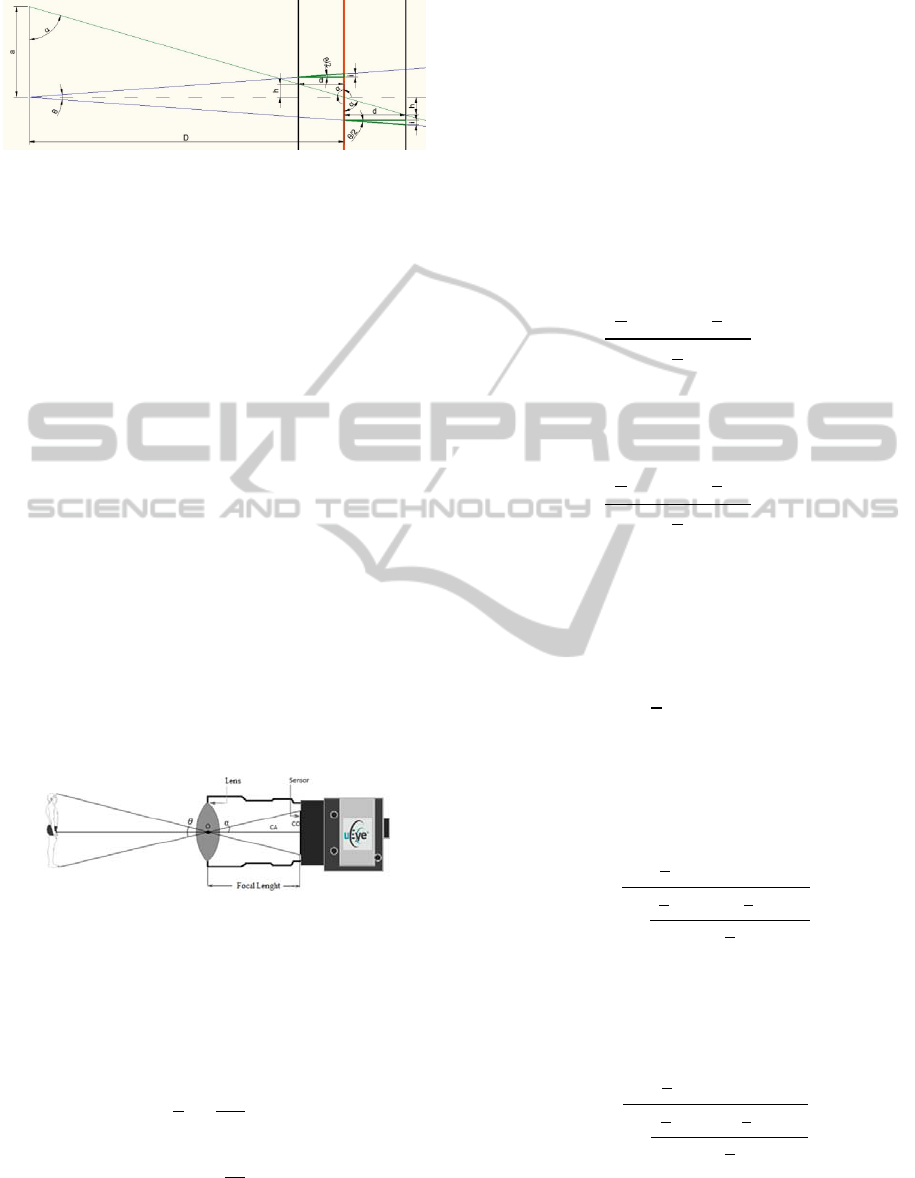

Figure 4: Representation of the measurement of the

antero-posterior distance.

In the Figure 4 the blue lines represent the

viewing angle of the camera and the green line

represents the laser beam.

Knowing the angle of the laser diode, angles of

the camera, the real dimensions of each pixel in the

reference plane (orange plane), as well as the

distance between the reference plane and the focal

centre of the camera, the distance between the laser

diode mark and the focal plane of the camera can be

obtained.

Microprocessor

PIC16F877

Limit switc

h

senso

r

s

Motor Drivers

Relays

RS

232

Motor

Z

Motor

X

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

226

Figure 5: Scheme to demonstrate the calculation of the

Antero-posterior distance.

Distance=D − d

(1)

Distance – Distance between the camera and the

measuring point

D - Distance between the camera focal plane and the

orange plane (reference plane)

d - Variation of distance between the person under

study and the reference plane

The variable d is positive when the plane under

study is on the left of the reference plane otherwise

is negative. The variable d is calculated using

following formula:

d=h×tan(α)

(2)

θ – Vertical viewing angle of the camera

h – Real height of the mark of the laser diode

The viewing angle of a camera is the maximum

angle at which two light beams can intersect at the

secondary focal point (O, Figure 6). In other words,

the viewing angle is the maximum angle of vision of

the camera. The viewing angle depends on the focal

length as well as the dimensions of the sensor. The

viewing angle is higher when the sensor is larger and

when the focal length is lower. (Hecht, 2002)

Figure 6: Representation of the viewing angle of the

camera.

From the observation of Figure 6 the value of the

viewing angle of the camera is obtained through the

following equations:

=2

(3)

tan

2

=

/2

(4)

where:

=2

(

2

) (5)

θ – Viewing angle of the camera

S – Sensor dimension

f – Focal Length

With the viewing angle of the camera and the

distance that the individual under study is from the

reference plane (d), is possible to know the real

dimension of the viewing window of the camera as

well as the real value of each pixel in the plane

under study. The real value of each pixel can be used

to indicate the precise location, to which the

mechanical instrument has to move in order to put

the laser mark on top of the blue points.

To calculate the real value of each pixel for a

specific distance of the subject under study, the

following formula was applied:

P=

R

2

m − tan

2

R

2

(6)

If the pixel coordinate of the laser mark is less than

half of the camera resolution in the vertical axis.

Otherwise P is given by:

P=

R

2

m + tan

2

R

2

(7)

m – Real dimension of the pixel in the reference plane

R – Sensor Resolution

P – Real value of the pixel in the plane under study

Knowing the real pixel dimension is possible to

calculate h.

h=(

R

2

−p)P

(8)

p – Vertical pixel coordinate of the laser

Solving equation 2 in order to d and replace the

result in equation 1, it was found that the distance is

given by:

Distance= D −

R

2

−p m tan

(

α

)

1+

R

2

−ptan

2

tan

(

α

)

R

2

(9)

If the pixel coordinate of the laser mark is less than

half of the camera resolution in the vertical axis.

Otherwise:

Distance=D −

R

2

− p m tan

(

α

)

1−

R

2

−ptan

2

tan

(

α

)

R

2

(10)

If the person under study is at 33 cm from the

equipment, and using a Eye camera model 1440

(resolution 1024x1280) the resolution given by the

DEVELOPMENT OF VERTEBRAL METRICS - An Instrument to Study the Vertebral Column

227

software on the vertical plane is expected to vary

from 0,04 to 0,07 mm, and on the horizontal plane

0,05 to 0,1 mm (value of the pixel).

4 DETECTION OF THE SPINOUS

PROCESSES

To develop the software for detecting spinous

process we used Matlab (MATrix LABoratory, a

numeric computer environment for programming),

where respectively, the processing code and image

analysis, as well as functions for communication

with the mechanical equipment were created.

The first step in the development of the software

to detect the spinous process consisted of choosing

the marker to sign the spinous process in the skin.

For this purpose, several tests were made to find the

best marker, this tests were made to see how the

markers behaved in the skin. It was observed that if

the ink of the marker spread in contact with the skin

the marker could not be used, because the detection

of the point would became harder or could even fail.

The tests showed that skin has mainly the red and

green components in a RBG camera, so the blue will

be the best bet for the marker.

As the processing and image analysis is based on

logical operators, it was necessary to binarize the

image. However, since the processing of the image

in terms of the detection of the points and the laser

mark had to be done in real time and as swiftly as

possible, complex binarization algorithms could not

be used. Therefore, it was decided to make a

binarization by comparing the green and blue

components of the image to detect the blue marks.

This binarization option is the result of tests

performed with the markers. It was observed that

only the area of the blue mark had the blue image

component higher than the green. In other areas of

the skin, the red component of the image dominated,

followed by the green and finally blue. More tests

must be performed to see if this is compatible with

all skin types (Caucasian restricted at this point), but

for now this feature was taken in advantage to make

the image binarization.

An opening operation was applied to the image

in order to reduce the artefacts caused by

binarization. This operation is the result of an

erosion followed by dilatation of the image with the

same mask. This image processing operation keeps

only the structures that are similar to the mask, and

also the ones that are contained within the area of

those same structures.

After this treatment, an algorithm of connected

components (Gonzalez, 2002, 2004) was applied to

the image. This algorithm allows the detection of

objects in binarized images.

Following the detection of objects and using

image analyses the dimensions and centroids of the

objects were calculated. Subsequently, some

comparisons were made to test whether the object

being analyzed is actually the point made by the

marker or not. If the object detected is really a mark,

its coordinates are stored.

The detection of the laser mark is made in a

similar manner to that used in the detection of the

points, yet its binarization is different.

To find the mark position of the laser diode the

red component of the image is compared with the

green component. When the green component has a

higher level than the red component this means that

it is in the area of the laser mark.

Figure 7: Aspect of the blue and green laser mark on the

skin (a); Binarization plus opening operation of the blue

mark (b); Binarization of the laser mark (c).

In order to move the mechanical equipment to

put the mark of the laser diode on top of the blue

dots it is necessary to calculate the distance from the

laser point to the blue point in pixels and convert it

into real values. For this conversion a reference in

the image is needed, the reference used was the

mark of the laser diode. The mark of the laser diode

was also used to calculate distances allowing us to

calculate the third spatial coordinate of the blue

mark (Muljowidodo K, 2009

).

When the equipment is on the right spot, the

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

228

software will store the Y coordinate of the spinal

process and will indicate to the hardware

(mechanical system) the exact moment when it must

save the X and Z coordinates.

5 CONCLUSIONS

This project is still in the test stage, but it already

managed to detect each spinal process in 95 ms and

a complete examination after manual tracing of the

spinal process is taking 2 minutes and 25 seconds.

This time can be improved if the software code is

change for a C language format, most of this time is

being expended in the communication, our goal is to

reach the 30 second mark. The initial intend is to

analyze 25 spinal processes from the first cervical

vertebra to the first sacral vertebra in the standing

position, in the same exam. This option can be

explained by the method used for the manual

marking by palpation and also due to the difficulty

in visualizing the spinal processes that are near the

hair line. In the measurements made with the

equipment it was obtained a maximum error of 1.3

mm in Y, 0.6 mm in X and 0.4 mm in the Z

coordinate, taking into account that the markers have

2 mm in diameter this result is acceptable. However

further tests must be made to improve the detection

of the markers as well as a comparison test to

validate the instrument. At this moment tests are

being made with florescent markers, confident that

this will work for all skin types.

This equipment will allow the possibility of

consecutive sweeps allowing the analysis of the

dynamic postural adjustments of the spine. The

results obtained with this apparatus will allow a

posterior spinal reconstruction in three dimensions

and the calculus of the intervertebral forces. This

instrument will contribute for a detailed study of the

dysfunctions and / or pathologies of the spinal

column.

This device will promote a more efficient and

accurate data acquisition, and it will allow a faster

and simpler mode to study the curvatures and lateral

deviations of the column. The data acquired from the

device can be used in the future to study the

vertebral discs stress and will take a key role in the

biomechanical study of the spinal column.

REFERENCES

Gonzalez, R; Woods, R.; (2002); Digital Image

Processing; (2th ed.) Prentice Hall.

Gonzalez, R.; Woods, R.; Eddins, S.; (2004); Digital

Image Processing using Matlab; Prentice-Hall.

Hecht, E.; (2002); Óptica; (2th ed.) Fundação Calouste

Gulbenkian

Muljowidodo K.; Mochammad A. Rasyid; SaptoAdi N &

Agus Budiyono; (2009); Vision based distance

measurement system using laser pointer design for

underwater vehicle; Indian Journal of Marine Sciences

Vol. 38(3), pp. 324-331

Quaresma, C.; Secca M.; O’Neill J.; Branco J.; (2010);

Vertebral Metrics: Aplication of a Mechanical

Instrument to Evaluate the Spinal Column in Pregnant

Women; International Conference: Biodevice

Quaresma, C.; Secca M.; O’Neill J.; Branco J.; (2009a);

Development of a Mechanical Instrument to Evaluate

Biomechanically the Spinal Column in Pregnant

Women; International Conference: Biodevice, 310-

113.

Quaresma, C.; João, F.; Fonseca, M.; Secca, M.; Veloso,

A.; O’Neill, J.; Branco, J.; (2009b); Validation of

Vertebral Metrics: a mechanical instrument to

evaluate posture of the spinal column; O. Dössel and

W.C. Schlegel (Eds): WC IFMBE Proceedings

25/VII, 711–713.

Quaresma, C.; Secca, M.; O’Neill, J.; Branco, J.; (2009c);

Métrica Vertebral: Instrumento de Avaliação

Biomecânica da Coluna Vertebral; III Congresso

Nacional de Biomecânica.

Secca, M.; Quaresma, C; Santos, F.; (2008); A Mechanical

Instrument to Evaluate Posture of the Spinal Column

in Pregnant Women. In IFMBE Proceedings 4th

European Conference of the International Federation

for Medical and Biological Engineering. 23-27

Vismara L.; Menegoni F.; Zaina F.; Galli M.; Negrini;

Capodaglio S.; (2010); Effect of obesity and low back

pain on spinal mobility: a cross sectional study in

women; Vismera et al. Journal of NeuroEngineering

and Rehabilitation 7:3.

DEVELOPMENT OF VERTEBRAL METRICS - An Instrument to Study the Vertebral Column

229