SELECTIVELY BONDED POLYMERIC CHECK VALVE FOR

THE RELIABLE REGULATION OF INTRAOCULAR PRESSURE

Seongmin Im, Byungphil Mun, Jaeyong An, Jongchan Choi

School of Mechatronics, Gwangju Institute of Science and Technology, Gwangju, Korea

Sung Yang

1,2,3

, Jonghyun Lee

1,2,3

1

School of Mechatronics,

2

Graduate Program of Medical System Engineering

3

Department of Nanobio Materials and Electronics, Gwangju Institute of Science and Technology, Gwangju, Korea

Keywords: Glaucoma drainage device, Polymer, Check Valve, Selectively bonding, Intraocular Pressure, FEA, MEMS.

Abstract: A glaucoma drainage device for the regulation of intraocular pressure is presented. The device consists of

three biocompatible polymer layers: the cover (top layer), the diaphragm (intermediate layer), and the

baseplate with a cannular (bottom layer). Finite element analyses (FEA) were performed to find optimal

design parameters for the targeted cracking pressure: the diameter of orifice, the thickness of intermediate

layer, the width of the channel, and the overlapped length of the orifice over valve seat. Top and bottom

layers were made by polydimethylsiloxane (PDMS) replica molding process, and an intermediate thin layer

with through-holes was fabricated by PDMS fill-in molding method and hydrophobic treatment. The

overlapped area of the bottom layer was coated with Cr and Au by using PDMS as a shadow mask. Metal

layers are not to be bonded between the bottom and the intermediate layers so that the device showed the

enhanced reliability in operation and the higher yield in production. Oxygen plasma treatment was

performed for irreversible bonds between separate three PDMS layers. The experimental cracking pressure

of the fabricated valve was 2.50 kPa, which is very close to the target value (2.67 kPa). The experiments

showed that the proposed polymer check valve can regulate the pressure of the aqueous humour, fluid in an

anterior chamber, within the normal intraocular pressure range (15~20mmHg) with a high repeatability.

1 INTRODUCTION

In microfluidic systems, valves are one of the most

important components to control the flow of the

systems. One of the most important characteristics

of microvalves is reliability, and high reliability

makes microfluidic systems successful. Check

valves are passive microvalves which allow

unidirectional flow. In micro check valve, reliability

can be defined as the consistency of cracking

pressure, flow rate, and diode-like characteristic.

Check valves can be used for flow regulation, on/off

switch, and sealing of liquid/gas/vacuum (Kwang W

Oh et al., 2006). Glaucoma drainage devices and

drug delivery are representative applications of

micro check valve for bionics. Currently, the reliable

fabrication and operation are the key issues in the

micro check valve (Ronalee Lo et al., 2009).

Though prior micro check valves have several

advantages: simple fabrication, polymer and cheap,

there is a stiction problem in the bonding process of

polymer layers (Nooli Jeon et al.,2002). To detach

the overlapped area between valve seat and valve

orifice, air or water should be introduced quickly

during bonding process before polymer layers are

irreversibly bonded. If the overlapped area is not

completely detached, cracking pressure and flow

rate of the fabricated device will vary seriously

during operation as shown in Fig. 1.

Glaucoma is the second leading cause of

blindness in the world, and it is estimated that 66.8

million people are suffering from glaucoma

(Quigley HA., 1996). Glaucoma is theoretically

defined as a progressive optic neuropathy as a result

of elevation of intraocular pressure (IOP) above the

physiological level of individuals (Shiose Y.,1990).

Glaucoma drainage devices (GDDs) have the

potential to regulate flow reliably and to maintain

IOP below 20mmHg.

234

Im S., An J., Choi J., Mun B., Yang S. and Lee J..

SELECTIVELY BONDED POLYMERIC CHECK VALVE FOR THE RELIABLE REGULATION OF INTRAOCULAR PRESSURE.

DOI: 10.5220/0003167302340237

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 234-237

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

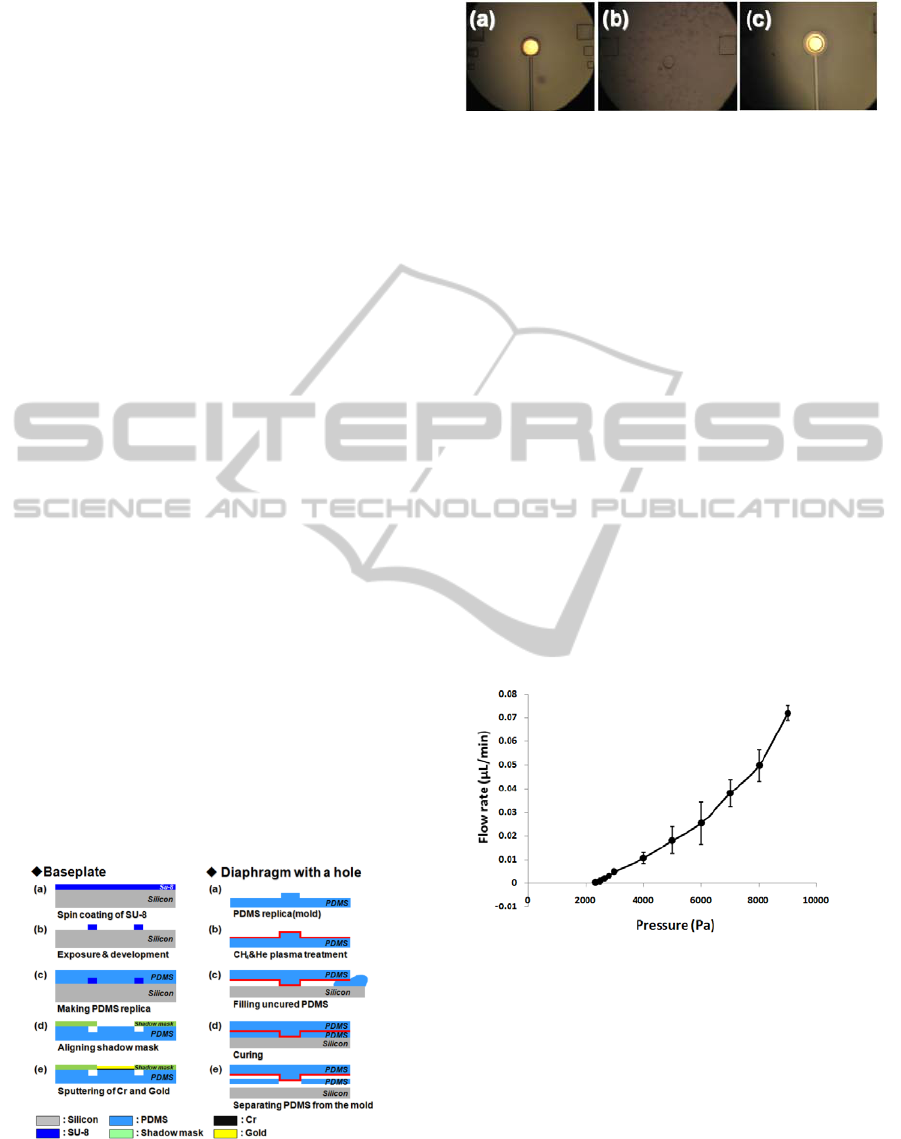

Figure 1: A PDMS diaphragm valve and stiction problem; (a) Schematic drawing of a PDMS check valve, (b) Illustration of

a normal valve under forward pressure, and (c) Illustration of a valve with stiction problem.

This paper describes the advancements of the

existing micro check valve through the selective

bonding of PDMS layers: the high consistency of

cracking pressure, flow rate, and diode-like

characteristic (Seongmin Im et al., 2010). Also, it

will be confirmed that the proposed micro check

valve has a great potential as a component of a

glaucoma drainage device.

2 DESIGN AND OPERATION

2.1 Design

Fig. 2 shows the micro check valve with two layers,

and each layer is made of PDMS. There are four

design parameters for the targeted cracking pressure:

the diameter of hole, the thickness of membrane, the

width of the channel, and the overlapped length of

the hole over valve seat. The thickness of membrane

is the most critical factor for the cracking pressure.

The top layer is thin membrane which has a hole

(valve orifice) in it. The thickness of the membrane

is 122um, and the diameter of the hole is 350um.

The bottom layer is micro channel, and defines the

fluidic channel and valve seat. The dimensions of

the channel are 100um width and 100um height, and

the diameter of the cylindrical post is 450um. Cr and

Au are deposited on the valve seat with 20nm

respectively. These thin Cr/Au layers are introduced

to prevent the stiction problem between the valve

orifice and the valve seat during bonding process.

A glaucoma drainage device integrates the cover

(top layer), the diaphragm (intermediate layer), and

baseplate with a cannular (bottom layer) as shown in

Fig. 3. The base plate is a square, 5mm each side.

The cannula dimensions are 15mm length, 1mm

width, and 900um height, and internal microchannel

is 100um width and 100um height. The square-

shaped valve cover is equipped with the cylindrical

post array (450um in diameter and the 80um in

height). The valve cover is bonded on the

Figure 2: Illustration of a PDMS diaphragm valve with

Cr/Au layer on the valve seat for selective bonding of

PDMS layers.

intermediate layer after flipping down to prevent

conjunctiva from directly contacting with valve

orifice so that the stable valve operation of the micro

check valve will be secured in terms of cracking

pressure and flow rate after the implantation.

Figure 3: Illustration of a glaucoma drainage device. The

device consists of the cover (top layer), the diaphragm

(intermediate layer), and the baseplate with a cannular

(bottom layer). The cover is bonded on the diaphragm

after flipping down.

2.2 Operation Principle

The proposed micro check valve is normally-closed

allowing one directional flow. When the internal

pressure is higher than external pressure, the valve

opens, and the valve remains closed when the

external pressure is higher than internal pressure.

After the implantation of a GDD, the end of the

SELECTIVELY BONDED POLYMERIC CHECK VALVE FOR THE RELIABLE REGULATION OF INTRAOCULAR

PRESSURE

235

cannula is located in the anterior chamber of the eye

ball. When the IOP is higher than the cracking

pressure of a GDD, the valve drains the surplus

aqueous humour to regulate the pressure of the

anterior chamber.

3 FABRICATION

The fabrication of the bottom layer started with spin

coating of SU-8 on the silicon wafer. The SU-8 in

100um height on the silicon wafer was patterned,

and it served as a mold. PDMS was poured on the

mold, and was cured at 90

℃ for 1h. The PDMS

replica was separated from the SU-8 mold, and the

shadow mask was aligned on the PDMS replica. Cr

and Au are deposited on the valve seat for the

selective bonding between the cover and the

diaphragm.

The fabrication of the diaphragm (intermediate

layer) with a through-hole started with making a

PDMS replica. The PDMS replica has a post 350um

in diameter and 122um in height. The hydrophobic

treatment using CH4 and He was performed on the

surface of the PDMS replica. The PDMS replica was

put on a silicon wafer, and uncured PDMS was filled

in the space between the PDMS replica and silicon

wafer. The uncured PDMS layer was cured at 90℃

for 1h, and the diaphragm was separated from the

molds (Jongchan Choi et al., 2010). The cover of the

device was simply made using soft-lithography.

Oxygen plasma treatment enables the surface

modification of PDMS layers and irreversible bonds

each layer. An aligner was used to assemble three

layers, and the valve orifice and the valve seat were

selectively bonded.

Figure 4: Fabrication sequence; A CH

4

/He plasma surface

treatment of a PDMS mold was performed to make a

diaphragm with a through-hole. Soft-lithography process

was used to fabricate the bottom layer.

Figure 5: Micrographs of the check valve (Top view); (a)

the bottom layer after sputtering of Cr and Au, (b) a

diaphragm with a through-hole, and (c) a micro check

valve after bonding the diaphragm and the bottom layer.

4 EXPERIMENT AND RESULTS

The performance of the fabricated check valve was

tested by using a hydrostatic pressure and analytical

balance. After connecting the micro check valve

with a pressurized water source, the valve was

placed on the analytical balance. In order to

experimentally find the cracking pressure of the

valve, the flow rates of three devices were recorded

with respect to the input pressure. The data were

attained for 3 min at high pressure (≥ 3000 Pa) and

for 10 min at low pressure (< 3000 Pa). From the Fig

6, the mean value and standard deviation of the

cracking pressure was found to be 2444 ± 87.76 Pa

and, which is very close to the target value (2666 Pa)

for the glaucoma drainage device. When reverse

pressures over 10 kPa was applied, the leakage was

not occurred.

Figure 6: Outlet flow rate versus input pressure. The

cracking pressure is 2444 ± 87.76 Pa (n=3). The steady

state outlet flow rates were 0.025 ± 0.009 μL/min (n=3, at

6000 Pa). When the reverse pressure over 10 kPa was

applied, the leakage was not observed.

Fig. 7 shows the experimental result of the

repeatability test. The flow rates in the steady state

were nearly 0 μL/min at 2350 Pa (slightly lower than

cracking pressure) and 0.0081 μL/min ± 2% at 4000

Pa (sufficiently higher than desirable intraocular

pressure). The negligible variance in the

repeatability test indicates that the reliability of the

valve is considerably enhanced, and the selectively

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

236

bonded diaphragm valve has great potential as a

component of a glaucoma drainage device.

For the future work, the fabricated glaucoma

drainage device will be implanted in a rabbit’s eye to

find the in-vivo cracking pressure and to monitor the

postoperative fibrosis. Furthermore, the

biocompatibility of the device will be examined

through in-vivo experiments. Even though the body

of the device is made of an approved biocompatible

material, Cr/Au layers of the device should be

checked of biocompatibility.

Figure 7: Repeatability of the outlet flow rate. The steady

state flow rates were 0 μL/min (n=7, at 2350 Pa) and

0.0081 μL/min±2% (n=7, at 4000 Pa).

ACKNOWLEDGEMENTS

This work was partially supported by the World

Class University (WCU) program at GIST through a

grant provided by the Ministry of Education,

Science and Technology (MEST) of Korea (Project

No. R31-2008-000-10026-0)

REFERENCES

Kwang W. Oh, Chong H. Ahn, 2006, “A Review of

Microvalves”, J. Micromech. Microeng, Vol. 16, pp.

13-39

Ronalee Lo, Po-Ying Li, Saloomeh Saati, Rajat N.

Agrawal, Mark S. Humayun, Ellis Meng, 2009, “A

Passive MEMS Drug Delivery Pump for Treatment of

Ocular Diseases”, Biomedical Microdevices, DOI

10.1007/s10544-009-9313-9

Noo Li Jeon, Daniel T. Chiu, Christopher J. Wargo,

Hongkai Wu, Insung S. Choi, Janelle R. Anderson,

George M. Whitesides, 2002 "Design and Fabrication

of Integrated Passive Valves and Pumps for Flexible

Polymer 3-Dimensional Microfluidic Systems",

Biomedical Microdevices, 4:2,117-121

Quigley H. A., 1996, Number of people with glaucoma

worldwide., Br J Ophthalmol; 80:389

–

393

Shiose Y., 1990, Intraocular pressure: new perspectives.,

Surv Ophthalmol;34:413

–

435

Seongmin Im, Byungphil Mun, Jaeyong An, Jongchan

Choi, Sung Yang, and Jong-Hyun Lee, 2010,

“Selectively bonded polymeric Check Valve for the

Regulation of Intraocular Pressure”, KSME

Conference on Dynamics and Control, Gwangju,

pp.286

Jong Chan Choi, Sang Youl Yoon, Sung Yang, 2010,

“Simple PDMS double molding method for PDMS

membrane with micro through-hole via CH4/He

plasma surface treatment”, The12th Korea MEMS

Conference, Busan, pp. 373

SELECTIVELY BONDED POLYMERIC CHECK VALVE FOR THE RELIABLE REGULATION OF INTRAOCULAR

PRESSURE

237