DEVELOPMENT AND VALIDATION OF A PRESSURE

TRANSDUCER AND ITS ELECTRONICS FOR ESOPHAGEAL

MANOMETRY

D. S. Ferreira, L. M. Gonçalves, J. H. Correia and G. Minas

Algoritmi Centre, Universidade do Minho, Campus Azurém, 4800-058 Guimarães, Portugal

Keywords: Manometry, Esophageal motility disorders, Solid-state strain gauge.

Abstract: This paper reports the development and validation of strain gauge transducers and its readout electronics

with the ultimate goal of integration in a commercial endoscopic capsule (EC). The deposition process of

strain gauge transducers on a capsule surface, using microfabrication techniques, is described. An electronic

circuit is designed, implemented and tested for the amplification of the transducer output signal.

Electromechanical tests are performed on a cylindrical tube, which simulates the capsule weight and

dimensions, and the obtained results allowed establishing a correlation between the output signal and the

stress applied on an EC. These results represent an important step for the implementation of a more

advanced capsule manometry system.

1 INTRODUCTION

The gold standard for the assessment of esophageal

motor functions is manometry. With this technique it

is possible to measure pressure changes that reflect

the strength and timing of muscles contraction and

relaxation. The major indications for esophageal

manometry are the evaluation of dysphagia and non-

cardiac chest pain. Esophageal manometry is, as

well, the standard method to establish the diagnosis

of: achalasia - low repetitive amplitude contractions

(10-40 mmHg); diffuse esophageal spasm -

uncoordinated contractions (>30 mmHg); and

Nutcracker esophagus - high-amplitude peristaltic

pressure waves (>180 mmHg) (Murray, 2003;

Holloway, 2006; Bodger, 2006; Pandolfino, 2009).

Manometry equipment is composed by two

major components: a pressure transducer and a

recording system. The transducer element can be a

water-perfused catheter connected to external

transducers, or intraluminal solid-state strain gauge

transducers. These are used to determine pressure

profiles in the esophageal sphincters and body, and

to convert it into an electrical signal. Although being

more expensive, solid-state manometry devices

present some important advantages: they have much

higher frequency response characteristics, and they

require less technical expertise to use (Murray,

2003; Holloway, 2006; Bodger, 2006).

Solid-state strain gauges are based on the

piezoresistive effect, i.e. there is a change of

electrical resistance upon mechanical deformation of

the surface where they are attached to. These are

usually placed in a Wheatstone bridge configuration,

with all resistors attached to the mechanical surface

to minimize the effect of temperature.

(Wolffenbuttel, 1994). The output signals of the

bridge, which provide a direct measure of

intraluminal pressure, are amplified before being

recorded on a computer for further data processing

and analysis (Murray, 2003; Bodger, 2006).

More recently, the basic format of manometric

studies has been replaced by intraluminal pressure

topography plots. This novel technique is known as

high-resolution manometry and its concept consists

in miniaturizing and increasing the number of

transducers on the manometric instrument, so that it

is possible to define the pressure profile as a spatial

continuum (Bodger, 2006; Pandolfino, 2009).

The long term of this project is to integrate

manometry functions within a commercial

endoscopic capsule (EC), using solid-state strain

gauge transducers. Some capsules, such as the pH

and pressure capsule, have incorporated a single

solid-state transducer to record mechanical events.

397

Ferreira D., Gonçalves L., Correia J. and Minas G..

DEVELOPMENT AND VALIDATION OF A PRESSURE TRANSDUCER AND ITS ELECTRONICS FOR ESOPHAGEAL MANOMETRY.

DOI: 10.5220/0003169303970400

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 397-400

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

However they are not yet able to record images from

the gastrointestinal tract (Camilleri, 2008). With the

very promising developments on the capsule

locomotion and stopping mechanisms, the addition

of manometry functions as a complement to existent

EC imaging functions will be of great clinical utility.

Using microtechnologies it is possible to build

small transducers on the capsule surface. These

technologies enable implementation of many

transducers that can record pressure values all

around the capsule area. As a first step, the

deposition process of strain gauge transducers is

studied and described. Also, an electronic circuit for

the readout of the transducer output signal is

designed and implemented. The proper functioning

of the circuit will be first tested using a commercial

strain gauge transducer. The results of the system

performance and amplification circuit are described.

2 EXPERIMENTAL

2.1 Fabrication of Transducer Element

The transducer element can be fabricated with thin-

film deposition and patterning processes. However,

some constrains were already studied and must be

considered during the fabrication process: the

polymer of current available EC cannot support

temperatures above 120 ºC and is incompatible with

chemicals (solvents) used in some photo-

lithographic processes; and the curved surface of EC

limits the use of rigid lithographic masks.

The fabrication of the sensing element starts with

a polyimide film (5 mm in length and width, and a

thickness of 25 µm). Next, a chromium layer is

deposited in the polyimide film by e-beam. A

photoresist mask is created by lithography processes

to be used in the wet-etching of the chromium film.

The polyimide film is then etched, using the

chromium pattern film as mask. This patterned

polyimide film is after used as shadow mask in the

deposition of metal in the EC. A shadow mask

process allows the fabrication of the transducer

element, despite the constraints previously

considered. The mask is glued to the EC surface

before the deposition of a thin metal layer. Since

there is only a single mask, there are no concerns

regarding its alignment. The metal deposition occurs

through the etched region of the polyimide mask,

creating regions were metal will be deposited, and

regions without metal, forming the transducer

element in the EC. After the deposition, the mask is

removed, exposing the transducer that should be

encapsulated with a biocompatible polymer. Due to

the mentioned fabrication constraints, the deposition

process is being optimized for the capsule surface

polymer, and is currently in progress.

2.2 Circuit Design

For the circuit design and test, one commercial

solid-state strain gauge transducer was connected in

a quarter Wheatstone bridge configuration (Figures

1 and 2). The transducer length and width is equal to

5 and 1.8 mm, respectively, and it has a resistance of

120 ± 5%. Since our surface is not planar we will

not use two gauges because it cannot be assured the

same proportion of compressive and tensile stress in

both transducers. Also, an in vivo study of Cowles et

al. (1978) found that mechanical events recordings

obtained from a one quarter Wheatstone bridge

transducer were of the same quality as those

produced by a one half bridge configuration, in

terms of accuracy, sensitivity and stability.

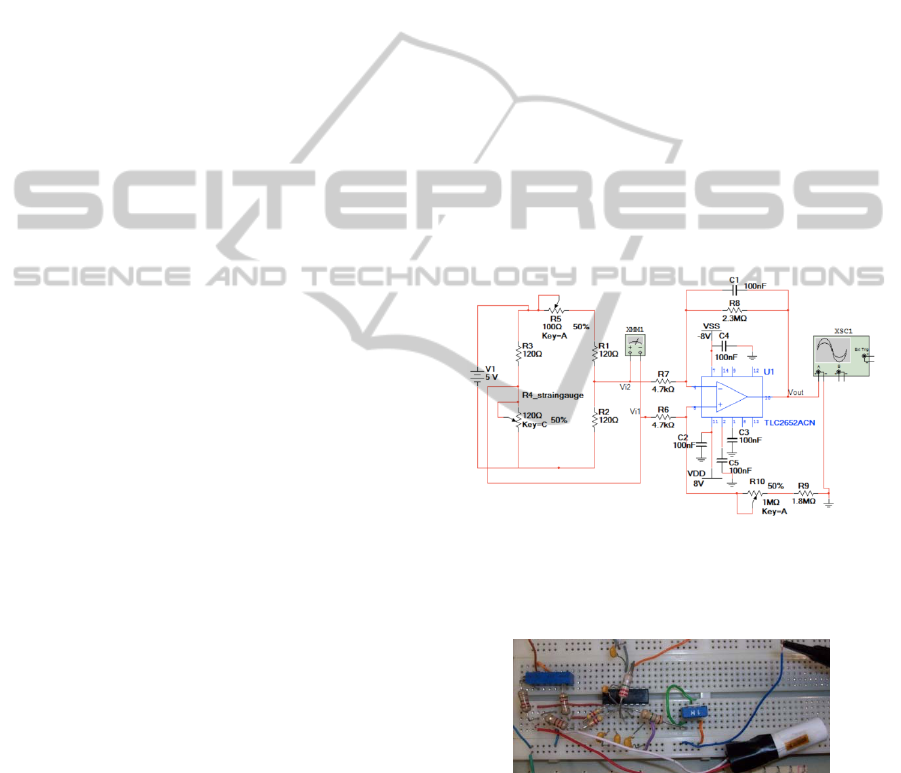

Figure 1: Layout of the system circuit with a differential

amplifier, TLC2652CN, to increase the amplitude of the

bridge output signal. The TLC2652CN features low offset

voltage 1PV with -0.003 V/°C, and a CMRR of 120 dB.

Figure 2: Implementation of the circuit on a breadboard.

The strain gauge was glued to a cylindrical tube

using cyanoacrylate glue. The gauge lead out wires

were then soldered to electrical wires and mounted

on a breadboard, in a bridge circuit, together with

three resistors - R1, R2 and R3 - of the same value

(120 ). The multi-turn potentiometer (R5) is used

to compensate the resistance tolerance of the bridge

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

398

resistors. Several capacitors are used to minimize the

noise introduced by the power supply.

The Wheatstone bridge output (V

out2

) is

calculated using Equation 1 (Buchla, 1992), where R

is equal to 120 , R corresponds to the strain

gauge resistance variation (directly correlated with

the applied stress), and V

ref

is equal to 5 V.

=

−

=

.

∆

(1)

The transducer output is transmitted to an

amplifier with a gain of 500. The output signal (V

out

)

from the amplifier is expressed as:

=

.

−

(2)

For the circuit to work as a differential amplifier:

=

(3)

Due to the mismatched of the resistors tolerance,

which in our circuit is amplified by a factor of 4, the

errors that can be introduced are in the order of 20%:

≈

4

1

00

=0.2

(4)

where p is the resistors tolerance and H is the

fractional difference between the two ratios. To

solve this mismatch we can use high precision

resistors, but a more cost-effective solution for a

printed circuit board is the addition of a

potentiometer (R10) in series with R9, to adjust

Equation 3 and balance the circuit. Therefore, we

will have a fixed and a variable resistor:

=

−

4

100

.

= 1.84

(5)

=2.

4

100

.

= 0.92

(6)

2.3 Electromechanical

Characterization

The effects of applied displacement in the

piezoresistive gauge, attached to a cylindrical

surface, were investigated under a three point

bending test. There are many techniques to assess

the gauge mechanical behavior, but three point

bending test has the advantage of being simple and

reproducible (Schriefer, 2005). The test was

performed in an AG-IS Shimadzu testing machine

with a load cell of 1 KN. The cylindrical tube was

positioned for transversal loading with a distance

between the lower supports (L) of 10 mm.

The ultimate stress (

V

, in MPa) was calculated

using the force (F, in N) versus displacement curves

(obtained directly from the testing machine), and the

following equation:

=

4

(7)

where I is the second moment of area (in mm

4

). For

a circular cross section I is calculated as follows:

=

4

(8)

in which R is the tube radius (equal to an available

EC radius, 5.5mm) (Schriefer, 2005).

3 RESULTS AND DISCUSSION

In order to test the reliability and calibrate the

electronic circuit with applied stress, the transducer

was glued on a cylindrical tube, and a three point

bending test was performed. The test was carried out

to simulate the mechanical functions of the

esophageal sphincters.

With the testing machine four cycles of

displacement were applied with a maximum

displacement of 0.02 mm. A constant speed of

0.1 mm/min was used, and the force-displacement

data was collected every second (Figure 3).

Figure 3: Representative force-displacement graph.

From the above data, the values of force at each

displacement could be determined. The strain gauge

transducer’s resistance variation was also measured

during the four cycles of displacement (Figure 4). As

would be expected, the transducer’s electrical

resistance variation is proportional to the mechanical

deformation: it reaches its maximum variation

(119.518 ), compared to its initial value at 0 mm,

when the displacement is equal to 0.02 mm.

Simultaneously, output voltages (V

out

) were

recorded using a data acquisition platform (Arduino

Uno) and a LabView interface. This software

platform makes it possible to process and display

0.000

0.005

0.010

0.015

0.020

0.025

0.00 0.50 1.00 1.50

Displacement (mm)

Force (N)

DEVELOPMENT AND VALIDATION OF A PRESSURE TRANSDUCER AND ITS ELECTRONICS FOR

ESOPHAGEAL MANOMETRY

399

Figure 4: Transducer’s resistance variation with applied

displacement, for all the four cycles.

pressure-voltage data in real-time. The stress was

then calculated using Equations 7 and 8, and the

stress-output voltage curve was traced (Figure 5).

In Figure 5 one of the cycles is represented, and

it can be concluded that the bridge output voltage is

nearly proportional to the mechanical stress applied

on the tube. With this result it will be possible to

establish a correlation between the measured voltage

and the stress induced on a capsule while travelling

in the esophagus.

Figure 5: Representative stress-ouput voltage graph.

The main goal of the experiment was to verify

this stress-voltage relation which was achieved for

circuit calibration and for a further implementation

in a microelectronics process, like CMOS.

4 CONCLUSIONS

There is a great interest in developing

gastrointestinal manometry systems using solid-state

strain gauge transducers. Manometry techniques,

using long catheters have the potential to be replaced

by more comfortable and simple procedures using

endoscopic capsules. We report the design and

performance of a strain gauge transducer and its

readout circuit, calibrated for the measurement of

the induced stress on endoscopic capsules. The

initial results obtained make it possible to go a few

steps further in system miniaturization and

integration and represent a very important step for

the development of a more advanced capsule

manometry system. In the future, we aim to improve

and integrate all the readout circuit within a CMOS

chip. Moreover, we want to optimize the transducer

deposition process, overcoming the constraints

related with the capsule polymeric material.

ACKNOWLEDGEMENTS

This research was supported by the Portuguese

Foundation of Science and Technology and the

MIT|Portugal Program (SFRH / BD / 38978 / 2007).

The author acknowledges Vitor Sencadas, Hélder

Covas and Leandro Cruz, for all their supportive

assistance during mechanical and electronic tests.

REFERENCES

Bodger, K., Trudgill, N., 2006. Guidelines for oesophageal

manometry and pH monitoring. BSG Guidelines in

Gastroenterology, 1-12.

Buchla, D., 1992. Applied Electronic Instrumentation and

Measurement, Merrill, New York.

Camilleri, M. et al., 2008. American

Neurogastroenterology and Motility Society consensus

statement on intraluminal measurement of

gastrointestinal and colonic motility in clinical

practice. J Neurogastroenterol Motil., 20, 1269-1282.

Cowles, V. E. et al., 1978. A Quarter Wheatstone Bridge

Strain Gage Force Transducer for Recording Gut

Motility. Digestive Diseases, 23, 936-939.

Holloway R. H., 2006. Esophageal Manometry. GI

Motility online.

Murray, J. A., Clouse, R. E., Conklin, J. L., 2003.

Components of the standard oesophageal manometry.

Neurogastroenterology And Motility, 15, 591-606.

Pandolfino, J. E., Fox, M. R., Bredenoord, A. J., Kahrilas,

P. J., 2009. High-resolution manometry in clinical

practice: utilizing pressure topography to classify

oesophageal motility abnormalities.

Neurogastroenterology And Motility, 1-11.

Schriefer, J. L. et al., 2005. A comparison of mechanical

properties derived from multiple skeletal sites in mice.

Journal of Biomechanics, 38, 467-475.

Wolffenbuttel, R. F., Schekkerman, A. R., 1994.

Integrated Instrumentation Amplifier for the Phase

Readout of Piezoresistive Strain Gauges. IEEE

Transactions on Instrumentation and Measurement,

43, 906-911.

119.516

119.518

119.520

119.522

119.524

119.526

119.528

119.530

0.000

0.005

0.010

0.015

0.020

0.025

0 20406080100

Resistance ()

Displacement (mm)

Time (sec)

Displacement

Resistance

-90

-75

-60

-45

-30

-15

0

0 50 100 150 200

Output Voltage, V

out

(V)

Stress (mmHg)

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

400