DATA MINING ON THE INSTALLED BASE INFORMATION

Possibilities and Implementations

Rashid Bakirov

Center for Sensor Systems (ZESS), University of Siegen, Siegen, Germany

Christian Stich

ABB Corporate Research Germany, Ladenburg, Germany

Keywords:

Data mining, Installed base, Proposals to customers, Failure prediction.

Abstract:

Managing the installed base at customer sites is a key for customer satisfaction. Hereby installed base com-

prises installed systems and products at customer sites which are currently being serviced by the producer

company. The purpose of the present study is developing use cases for data mining on the installed base infor-

mation of a large manufacturing company and specifically ABB, and constructing data mining models for their

implementation. The aim is to use the available information to enhance customer-tailored sales and proactive

service. This includes recommendations to customers and failure prediction. The developed models employ

association rules mining, classification and regression, realized with the help of data mining tools Oracle Data

Mining and Weka. Results have been evaluated using statistical means, as well as discussed with the experts

at the company. These results suggest that with the reasonable amount of data, installed base information is a

potential source for data mining models useful for business intelligence.

1 INTRODUCTION

At the present time, with the improvement in data

storage software and hardware systems, the amount

of available data about each individual or organization

is rapidly increasing. Today’s intense global competi-

tion, cost pressure, unstable markets and empowered

customers are the reasons why industrial enterprises

have to fully utilize this knowledge. An important as-

pect of knowledge discovery for customer-specific of-

fering and services is using historical data to find hid-

den relations using advanced data analysis techniques

known as “data mining”.

To enable customer tailored services, it is impor-

tant for companies to keep track of their installed

base, in other words, the products they produce and

need to maintain. An installed base system could be

used as a basis for data mining, identifying possible

relations between products, discovering patterns of

service jobs, predicting interest of customers to prod-

ucts and in many other various applications. Results

will lead to improved customer sensitive offerings and

service which would ultimately increase the sales of

products, lower costs for the customers and predict

service needs for the providing company.

In this work theoretical applications of data min-

ing on the installed base are analyzed, and implemen-

tations are shown. They are implemented on an inter-

nal data ware house of ABB, which is called ServIS,

the Service Information System. ABB is a multina-

tional corporation headquartered in Zurich, Switzer-

land. ABB’s core businesses are power and automa-

tion technologies and it holds market-leading posi-

tions in most key product areas. ABB employs more

than 116,000 people and operates in approximately

100 countries (ABB Group, 2010). ServIS is a com-

prehensive information system, that encompasses all

of the products and systems, customers’ services and

a range of additional data from all five divisions of

ABB. It was developed by ABB Corporate Research

Center Germany and provides a tool for outlining

and maintaining ABB’s installed base information.

Goal of ServIS is to operatively provide ABB’s field

service and technicians with information about cus-

tomers’ sites and equipment installed there.

The purpose of this paper is to present use cases

for data mining which target real business problems,

and show their realization using available technolo-

649

Bakirov R. and Stich C..

DATA MINING ON THE INSTALLED BASE INFORMATION - Possibilities and Implementations.

DOI: 10.5220/0003186506490654

In Proceedings of the 3rd International Conference on Agents and Artificial Intelligence (ICAART-2011), pages 649-654

ISBN: 978-989-8425-40-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

gies. The first part of the work gives information

about similar research and demonstrates possible us-

ages of data mining on a large production company’s

installed base data. The second part describes the ap-

plication the aforementioned use cases to the real data

warehouse of ABB, evaluates the results and identi-

fies possible shortcomings of these approaches. The

final part concludes the paper, giving a summary of

the conducted work and outlines perspectives for the

future works this area. Paper provides references for

used algorithms.

2 DATA MINING ON THE

INSTALLED BASE

INFORMATION

2.1 Review of Similar Works

Data mining on installed base presents many different

interesting opportunities for companies but not much

research work has been done in this field. Most of

related work deals only with subsets of installed base.

DaimlerChrysler, now Daimler, has successfully

employed data mining on their installed base. In the

paper “Forecasting the Fault Rate Behavior for Cars”

(Lindner and Studer, 1999), authors forecast the num-

ber of complaints for separate details of the cars that

will be produced in the future using neural networks

and decision trees. The implementation of the sys-

tem proposed by the authors was successfully tested

and has been transferred to the product controlling de-

partment.

In whitepaper “Data Mining in Equipment Main-

tenance and Repair: Augmenting PM with AM” (Ex-

clusive Ore Inc., 2003), the possibility of anticipatory

maintenance based on previous services data is dis-

cussed. A database of a large locomotive manufac-

turer was examined as a case study. Authors con-

cluded that, data mining of equipment maintenance

and repair data can help discover anticipatory main-

tenance (AM) procedures, improper repairs or other

maintenance, ways to improve repairs, undocumented

repair methods, as well as warn about likely failures

in advance. This all would result in less future fail-

ures, and lower downtime by failures.(Exclusive Ore

Inc., 2003).

Data mining was also used by Xerox to analyze

the service need of their installed base including ser-

vice of customer replaceable units (CRU). Aim of the

project was “measurable cost reduction in services de-

livery, including field service and consumable sup-

plies replenishment” (Minhas, 2003). Xerox used Or-

acle database for storing the information and Oracle

Data Mining (ODM) to for clustering of customer us-

age based on various attributes. (Minhas, 2003)

2.2 Use Cases of Data Mining in

Installed Base

The usage of data mining in the specific installed

base database will naturally depend on the data, data

model, structure and quality of data. This section de-

scribes its use cases. It is assumed that the database

has full information about products, customers and

services, as well as any necessary additional data.

Databases like that need to be constructed from vari-

ous datasets, tables and databases acquired from dif-

ferent divisions of company.

One use of data mining is cross-selling and mak-

ing recommendations to customers. Cross-selling in-

volves selling additional products to the same cus-

tomer, or bundling products in packets and selling

them together. Using data mining methods would

help to identify which products would interest spe-

cific customers. It is possible not only to create bun-

dles of products, but also to recommend interesting

products to the customers. Two approaches to make

a recommendation are possible. One is to show what

did other customers, who bought a particular product,

also purchase, as seen on Amazon Internet store (Lin-

den et al., 2003). This requires relatively few informa-

tion - only transaction ID, and ID’s of products which

appear on this transaction. Second approach is to rec-

ommend the products which are purchased by simi-

lar customers. The similarity criteria could be com-

bined from different inputs, for example company lo-

cation, size, industry type etc. These two described

approaches can be used together. They can be applied

to to identify suitable target audiences of marketing

campaigns, directed both to attract new customers and

make offers to the existing ones. Here, it is attempted

to discover customers, who will be interested in of-

fer, rather than offers, which might interest the cus-

tomer. The customers could then be assigned with

response scores for the particular campaign. An ex-

ample of this use case can be the following. Suppose

that two products, A and B are frequently bought to-

gether. Then, a company can offer a product B to the

customer that purchases A. In the second approach,

company can search for the customers, who have only

A, to use them as marketing targets for B.

A potential area of data mining’s application is

failure prediction. It should be possible to use the re-

pair history of the product, or of the other products

on the same site to make predictions about future fail-

ures. This method is less expensive than real time

ICAART 2011 - 3rd International Conference on Agents and Artificial Intelligence

650

condition monitoring using sensors and probes. Dis-

covery of common repair sequences would also assist

in improving the repair process itself. (Exclusive Ore

Inc., 2003). Suppose that product B regularly fails af-

ter failure of product A. Then the servicing company

can check the status of B each time after A fails. Also,

if it is concluded that the reason of B’s failure is the

failure of A, while repairing B, the parts of it which

has connection with A could have higher probability

of malfunction and can be checked first.

Another usage of data mining, is prediction of cus-

tomer leaving. There are two different models regard-

ing this topic. One is to predict if the customer will

leave in certain amount of time and another is to pre-

dict, for how long will customer stay with the com-

pany. Data mining can also be applied to estimate

customers’ prospective value, a revenue that customer

will bring during his remaining lifetime. This can

be used in identifying “good” and “bad” customers

(Berry and Linoff, 2004). Both models of attrition

prediction and other applications of data mining can

assist in corporate planning. Predicting amount of

failures for automobiles has successfully been applied

at DaimlerChrysler (see section 2.1). Same methods

could be applied on general installed base data, to pre-

dict failure rates of various products for financial, lo-

gistical and other planning.

Data quality control is another important task, par-

ticularly when managing a large installed base data

warehouse with many various information sources.

With the help of data mining, it is possible to improve

automation of this task. Two possible approaches in

this case are discovery of numerical outliers and iden-

tification of cases that do not fall into general patterns

identified by other data mining techniques. Identifi-

cation of cases that do not fall into general patterns

can also lead to discovery of holes in data. Discover-

ing and treating outliers is an important preprocessing

task before applying other data mining algorithms.

3 DATA MINING ON ABB’S

INSTALLED BASE

ABB’s ServIS is based on a data warehouse which

stores data in Oracle relational database. This

database consists of more than 200 tables with in-

stalled base and administrative data. Information on

the ABB products, materials, customers, services etc.

which is included in the system, can be used as a ba-

sis for data mining. Amount of available data was

quite large, encompassing about 30,000 products or

700,000 equipment units. Nevertheless, its quality

was not always on desired level for the data mining

purposes. These are missing data such as NULLs,

“other” or “unknown” entries, as well as scarcity of

historical data and lack of information that could be

useful for data mining purposes.

As the ServIS is based on Oracle 10g database,

the first choice of software for data mining was Ora-

cle Data Mining (ODM) (Oracle Corporation, 2010),

which is an built-in option of the database, with Ora-

cle Data Miner GUI. Additionally free Weka (Witten

and Frank, 1999) software was chosen as an alterna-

tive, to estimate results from ODM. Following sec-

tions present information on tested data mining mod-

els on ABB’s installed base information.

3.1 Association Rules on ABB Products

This model aims to discover ABB products that tend

to be on the same site - plant, factory, etc. An imple-

mentation of association rules discovery is done using

Apriori algorithm (Agrawal and Srikant, 1994). Simi-

lar method is also used by Amazon to find suggestions

for the customers (Linden et al., 2003) This algorithm

is available in most data mining packages including

ODM.

After constructing a data table, algorithm was ex-

ecuted with different generalization levels of prod-

ucts. To find optimal level, as suggested by Berry

and Linoff (Berry and Linoff, 2004), we used a dy-

namic approach, considering the item of the most spe-

cific generalization level and comparing amount of

item’s occurrences to heuristically identified thresh-

old value. If this amount is less than threshold, we

considered the next less specific generalization level,

continuing the process until the generalization level

which satisfies the threshold condition is found. Ex-

perimental threshold values of 50, 100, 200, 400 were

used, based on the number of occurrences in the mid-

dle generalization level, with the maximum of 506

and average of 23. 10% confidence and 1% support

thresholds were used for models.

We got at most 14 rules as a result of a single

model. This was dynamic generalization model with

200 occurrences threshold. This performance can be

explained by a specific nature of ABB. Even while

the number of products is quite large, 22,000 com-

pared with an average of 50,000 products in large su-

permarket (Nestle, 2002), ABB has lesser diversity of

products and fewer amount of customers when com-

pared to a supermarket. Customers of ABB that come

from the same industries tend to purchase similar mix

of products. Combining results from all models, we

get 9 rules with confidence levels higher than 75%

with various support levels ranging from 1% to 3%.

This method is easily reproducible and reusable.

DATA MINING ON THE INSTALLED BASE INFORMATION - Possibilities and Implementations

651

It can be used in combination with other data min-

ing or statistical methods, such as prediction of cus-

tomer interest described in the next section, for better

final outcome. Association rules on products can be

applied to provide aid in cross-selling and make rec-

ommendations to customers. It is possible to realize

automatic recommendation system on company’s In-

ternet portal, where customers reviewing a particular

product are notified of products, that were purchased

together with this one.

3.2 Prediction of Customer Interest

This model tries to determine customers with possible

interest in a given product. The idea is to use all the

data about customers that might be relevant in deci-

sion making and a binary attribute, showing whether

customer bought particular product. The approach is

first to build a classification model, predicting that bi-

nary variable on sample data, then apply the result

model to all available data and make predictions about

each single case. The used data included informa-

tion about technical site (location, industry, number of

products and materials on the site), information about

the company which owns the site (location, number of

sites the company owns, relation to ABB). Addition-

ally, binary variables that show whether the popular

products in the database exist on the given site were

included. This greatly improved the accuracy of mod-

els.

Models were built to predict the existence of some

of ABB’s more widespread products on the site. The

chosen decision trees classification technique pro-

duces a whitebox model - in other words, the pos-

sibility to see resulting rules and determine on which

attributes does the final result depend the most. ODM

implements a variation of CART decision tree algo-

rithm (Breiman et al., 1984). As there were not any

missing values in input table and decision tree is resis-

tant to outliers and does not require normalization, no

other pre-processing methods except from gathering

data from different tables were used. To build mod-

els, we used stratified sample, which keeps original

distribution of data, of around 10,000 cases for each

model. 60% of sample were used in tree building and

40% in its testing. An example of sample build data

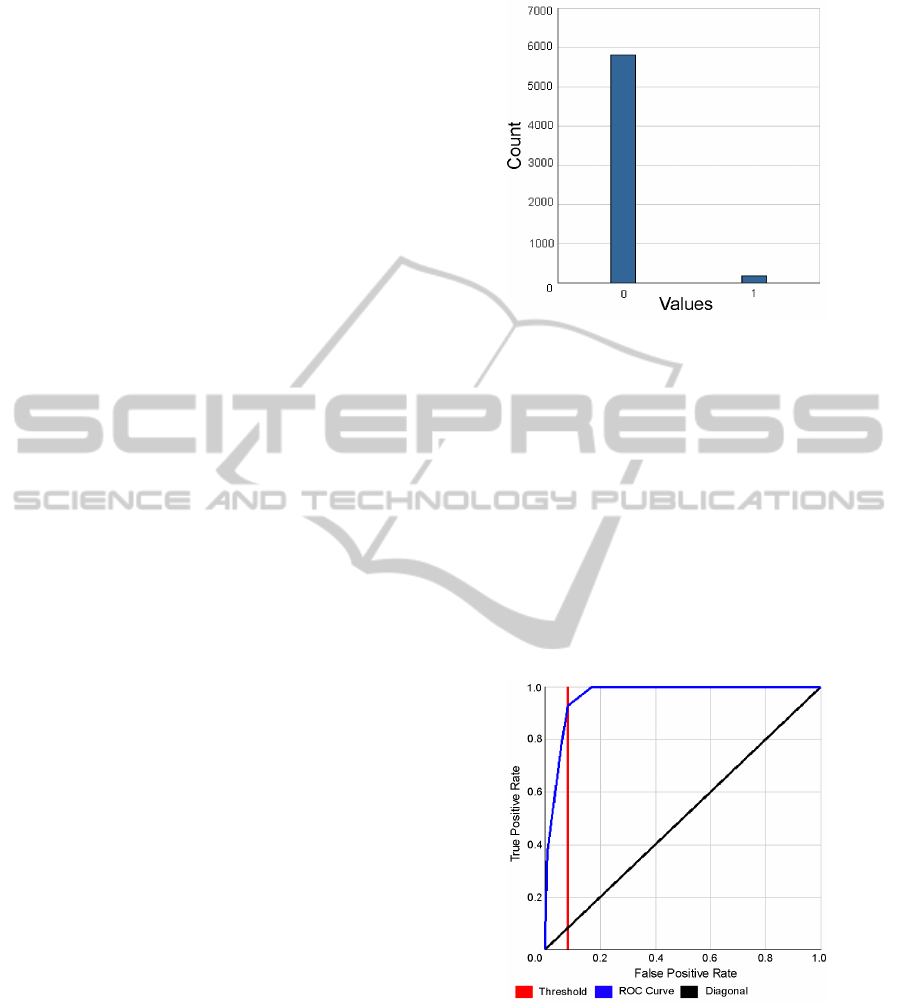

for prediction for product A with distribution of class

(goal) attribute can be seen in figure 1.

Models were built and tested for several most fre-

quent products in ABB’s installed base to make state-

ment more significant. We will review results on an

example of A’s prediction. After the decision tree is

built, it is applied to test data. With the default proba-

bility threshold value of 0.5, model correctly predicts

Figure 1: Sample build data for product A prediction.

99.19% of negative and 36.73% of positive cases. In

some cases a user might want to bias the prediction in

the direction of making more correctly identified pos-

itive cases at the cost of less correctly identified neg-

atives, or in the reverse direction. This can be imple-

mented by altering the threshold value. Optimal value

for thresholds - the one which maximizes true pos-

itive rate and minimizes the false positive rate, may

be found using ODM ROC-chart (Receiver Operator

Characteristic) (figure 2). In our case it’s 0.11. If we

use this threshold, model correctly predicts 91.71% of

negative and 92.86% of positive cases.

Figure 2: Prediction ROC of A. Area under curve is 0,96.

When we test the model with all of the available

data, which also includes training data, with the same

threshold, we get similar results - 91.88% (35,703 of

38,859) true negatives and 90% (909 of 1009) true

positives. Ideally, training data has to be excluded

from test set. In our case, since training data is only

roughly 16% of all the available data and the results

are similar with results of the model bulidng test, this

ICAART 2011 - 3rd International Conference on Agents and Artificial Intelligence

652

slight error in evaluation is neglected.

Achieved results show that the models perform

well when predicting product type that appear fairly

often in installed base, as well as on those which ap-

pear less often. In our case, and the most of related

cases true positive predictions is more important than

true negatives. We achieve more true positives by al-

tering prediction threshold. Of course, more frequent

does product appear in dataset; more significant are

model’s results. With products that rarely appear, a

very heavy cost matrix biasing has to be used for a

model to make positive predictions. This greatly de-

creases true negatives accuracy rate. Industry branch

of the site was identified as the most significant at-

tribute, being the first splitting criterion in 3 out of

4 models for different products. Other significant at-

tributes were location of the site and amount of prod-

uct types on the site.

A drawback of this approach is that a separate

model has to be constructed for every product, on

which predictions are made. This approach can be

combined with the association rules mining to achieve

even more accurate predictions. Results of customer

interest prediction models can be used for recommen-

dations to customers for marketing purposes, as well

as data quality control.

3.3 Prediction of Future Repair Jobs

This model attempts to determine amount of repair

jobs for various materials in installed base. It also

aims to identify attributes that have the largest ef-

fect on amount of repairs. Different variations of

this model were tested; regression - predicting exact

amount of repair jobs and classification, splitting goal

value into none/low/high categories (ternary classifi-

cation) or making binary “yes”/“no” categories (bi-

nary classification) predictions. This approach is sim-

ilar to the method of Lindner and Studer (section 2.1).

Both approaches use amount of repairs that happened

before to forecast repairs that will happen in the fu-

ture. The difference is the lack of available historical

data for us to use. Instead, we use additional infor-

mation about site and material which can be found

in ServIS. General information about site of location

(see previous section) as well as information about

material (type, age) and repairs history from previous

years were used as predictors for the model. Because

of data quality problems, dataset used for models in

this section consisted of only 778 cases. This results

in lower significance of achieved results.

Considering that they are based on a very limited

dataset, models in this section have fairly high accu-

racy rates. For instance, ODM regression model that

Figure 3: Ternary classification results.

Figure 4: Binary classification results.

is based on Support Vector Machines (Vapnik, 1995)

has 27.48% predictive confidence. Predictive confi-

dence shows how much better given model is than a

“naive” model, a model that predicts average value

for the dataset. Predictive confidence is the percent-

age increase in accuracy of prediction gained by the

tested model over a naive model. Binary and ternary

classification results can be seen on the figures 3 and

4. We can see that in both cases, Weka J48 (imple-

mentation of C4.5 decision tree algorithm) provides

better results. The most important predictor for deci-

sion tree models was average of repair jobs on mate-

rial in previous years. Other significant attributes for

both classification algorithms were type of material,

amount of materials, industry branch as important.

Models described in this section can help in finan-

cial and logistical planning. For example, the budget

of company can be adjusted to include repair costs

and the spare parts could be prepared beforehand.

This knowledge can also be a factor for choosing prof-

itable service contract terms. Another usage of the

models is optimization of proactive service (section

DATA MINING ON THE INSTALLED BASE INFORMATION - Possibilities and Implementations

653

2.2). Choice of a particular model will depend on a

use case, for example when assessing the behavior of

a product, ternary classification could be enough, but

planning service budget or preparing spare parts for

product is better done with numerical values. Other

factors in choosing model are its accuracy and impor-

tance of obtaining rules, as for example ODM regres-

sion does not provide any. Another interesting data

mining approach to service jobs history is discovering

common sequences of failures on the site and using

these results to make prognoses about future repairs.

This was not implemented in our work due to scarce

data.

4 CONCLUSIONS

In this paper we have analyzed the possibilities of ap-

plication of data mining techniques on the installed

base in form of use cases. Data mining helps to dis-

cover relationships between products, customers, ser-

vice jobs etc. This information can be helpful in many

areas, among them cross-selling, marketing, proactive

service, contracts management, data quality control,

corporate planning. We implemented the use cases

using both mining tools. After tests and assessment

we have reached a conclusion that results of prelim-

inary tests were good and that it was worth continu-

ing research in this direction. Prediction of customer

interest in products have provided the best results.

These results have proven that data mining methods

could be successfully implemented on installed base

data.

With the increased amount of data and improve-

ment of its quality, more data mining models de-

scribed in section can be applied to ABB’s installed

base system. Then the obtained results are expected

to be more accurate and significant. Some refinement

and restructuring of data is necessary in order to ap-

ply certain models. After development and tests of

various models, the ones that provide useful results

for the outlined use cases can be implemented in real

business applications. Model training and applica-

tion processes can be extracted from ODM in form

of PL/SQL packages, that may be used in respective

software or web-interfaces to show data mining re-

sults. For instance, results of association rules mining

can be used to make automated suggestions to cus-

tomers in company’s web portal. PL/SQL packages

can be scheduled to run automatically to keep models

and results up to date with new data.

Successful business applications based on data

mining on the installed base information would cre-

ate a win-win situation both for a business and a

customer, offering appropriate products and systems,

identifying cross-selling opportunities and predicting

the maintenance needs. This would result in easier

product selection and decrease of downtime costs for

the customer and increased profits for the business.

REFERENCES

ABB Group (2010). ABB Group Annual Report 2009.

Agrawal, R. and Srikant, R. (1994). Fast Algorithms for

Mining Association Rules in Large Databases. In

VLDB ’94: Proceedings of the 20th International

Conference on Very Large Data Bases, pages 487–

499. Morgan Kaufmann Publishers Inc.

Berry, M. J. A. and Linoff, G. S. (2004). Data mining tech-

niques: For marketing, sales, and customer relation-

ship management. Wiley, Indianapolis, Ind., 2. edi-

tion.

Breiman, L., Friedman, J. H., Olshen, R. A., and Stone,

C. J. (1984). Classification and regression trees. The

Wadsworth statistics/probability series. Wadsworth

International Group, Belmont Calif.

Exclusive Ore Inc. (2003). Data Mining in Equipment

Maintenance and Repair: Augmenting PM with AM.

Linden, G., Smith, B., and York, J. (2003). Amazon.com

recommendations item-to-item collaborative filtering.

In Internet Computing, IEEE. IEEE Computer Soci-

ety.

Lindner, G. and Studer, R. (1999). Forecasting the Fault

Rate Behavior for Cars. In Proceedings of Workshop

”From Machine Learning to Knowledge Discovery in

Databases” at the ICML 1999, Bled, Slowenia, June,

26-31, 1999.

Minhas, R. (2003). Towards Intelligent Machines: A Xerox

Initiative for Customer Assisted Self Help.

Nestle, M. (2002). The soft sell: how the food industry

shapes our diets.

Oracle Corporation (2010).

Vapnik, V. (1995). The nature of statistical learning theory.

Springer, New York.

Witten, I. H. and Frank, E. (1999). Data mining: Practical

machine learning tools and techniques with Java im-

plementations. The Morgan Kaufmann series in data

management systems. Morgan Kaufmann, San Fran-

cisco, Calif.

ICAART 2011 - 3rd International Conference on Agents and Artificial Intelligence

654