DESIGN APPROACH OF DISTRIBUTED SYSTEMS FOR THE

CONTROL OF INDUSTRIAL PROCESS

D. Boudebous, J. Boukachour, S. Benmansour and N. Smata

Laboratory CERENE, ISEL quai Frissard BP 1137 76603, Le Havre cedex, France

Keywords: Control system, Industrial processes, Physical processes, Temporal dependence, Petri nets.

Abstract: This article describes a methodological approach to the design of distributed systems for the control of

industrial process. The designer tackles the problem by specifying the behaviour of the process rather than

by specifying a solution. In this way he defines the “what to control”. This specification can then be

converted not only into a Petri net to allow the checking of certain properties of the described behaviour, but

also into a logical network of communicating modules which defines the logical structure of the process

control system. In both cases, the rules of conversion are direct and simple.

1 INTRODUCTION

In various fields of application, the constraints that

computer systems have to take into account

increasingly force their design as distributed

systems. Also, at various stages of design, the need

to take into account the expression of the

distribution (Chen and Yeh, 1983), (Krause and all,

2009), (Lamport, 1983), as well as the expression of

parallelism, soon makes itself felt. However, in the

face of the complexity of the problems to be

resolved, the effective utility of such linguistic tools

remains largely dependent on methodological

analysis and design guides, which allow us to move

from the wording of the problem to a choice of

solutions.

In this article we present a methodological

approach to the design of distributed systems for the

control of production systems, which can guide the

designer from the initial specification of a problem

right up to the implementation of his solution on an

execution structure. In this approach we identify

three stages:

• the logical construction of the control system in

terms of communicating modules;

• the detailed design of the modules and their

programming;

• the definition of a system execution structure.

These three stages allow the gradual construction, by

levels of abstraction, of a solution which is, as far as

possible, independent of the physical network of the

sites. In this article we tackle the first stage by

presenting an approach which uses a coherent

combination of guides and tools, to facilitate the

construction, specification and correction of the

logical structure of industrial process design systems

in terms of communicating modules (Kramer and

all, 1989), (Kramer and all, 1983). This approach is

based essentially on a problem-oriented approach. In

comparison with other methods, the designer does

not approach the logical structuring of his control

system by asking himself at the outset “how to

control” his industrial process. Instead he

approaches the problem by first asking himself

“what to control”. Rather than specify the control

system, he specifies the behaviour of the industrial

process by identifying the existing physical

processes and their temporal dependences. It is this

specification which constitutes the terms of the

problem to be resolved and which is then used to

deduce the logical structuring of his control system.

He considers for this that the modular entities of his

control system are merely abstract views of the

physical processes of his industrial process and that

the temporal relationships which interlink these

physical processes specify the inter-modular

behaviour of the control system. It is during this

phase dedicated to the analysis of “what to control”

rather than “how to control” that the designer is best

placed to make good choices which guarantee the

quality of the functional breakdown (clarity,

efficacy, robustness, maintainability and reusability)

and which take into account the constraints of the

157

Boudebous D., Boukachour J., Benmansour S. and Smata N..

DESIGN APPROACH OF DISTRIBUTED SYSTEMS FOR THE CONTROL OF INDUSTRIAL PROCESS.

DOI: 10.5220/0003438801570164

In Proceedings of the 13th International Conference on Enterprise Information Systems (ICEIS-2011), pages 157-164

ISBN: 978-989-8425-55-3

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

problem posed (flexibility in the distribution of the

control system in different sites, parallelism and

safety). It is also the optimum moment to discuss

his choices with the user.

In this article we deal with the modelling of the

behaviour of the processes. We present the

formalisms (textual and graphic) which enable the

specification of this behaviour by following a

top-down or a bottom-up approach. This

specification can then be directly converted into a

Petri net (Brams, 1983) (Cao and all, 2003)

(Drzymalski and Odrey, 2008) so that the

behavioural properties of the modelled process can

be checked. We will then demonstrate that it is

equally possible, through direct and simple

conversion, to pass from this specification of the

system behaviour to the logical construction of the

control system in terms of communicating modules.

Finally we will illustrate our argument with an

example.

2 THE INDUSTRIAL PROCESS

DESCRIPTION MODEL

An industrial system is defined by a set of entities

(trucks, robots, atmospheric environment, …) whose

attributes are likely to evolve with time, and also by

a set of physical processes. At any given moment

the physical state of the process is determined by the

attributes of its entities. This physical state could

correspond to a state of normal functioning or to a

state of breakdown. The role of the individual

physical processes is to enable the industrial system

to evolve from one state to another, by carrying out a

particular physical activity in a determined time.

The process model is represented by <P, Q, C>

where:

• P represents the set of physical processes p

i

,

• Q the set of its physical states q

i

,

• and C its behaviour.

If a

ij

is the jth activity carried out by the physical

process p

i

, then t(a

ij

) denotes the start date of this

activity and t’(a

ij

) its finish date.

The history of a physical process p

i

at any given

moment is defined by the chronological order of the

activities carried out since the start of the system.

This order is expressed as h

i

= (a

i0

, a

i1

, ....., a

in

)

where t’(a

ij

)≤ t(a

ij+1

). The behaviour of a process

defines a partial order among the elements of the

orders h

i

of the set of the physical processes p

i

. This

ordering is determined by four types of temporal

dependence which interlink the physical processes.

These are: causal precedence, coupling, temporal

precedence and independence which are defined in

Sections 2.1, 2.2, 2.3 and 2.4.

To specify the behaviour of a process we present

two formalisms. The first allows us to specify

independently for each physical process p

i

of the

process, all its direct temporal dependences, with the

help of temporal relationship operators (

″→″

for

causal precedence,

″⇒″

for coupling, and

″

-->

″

for

temporal precedence) and physical process

composition operators

″

*

″

(and),

″

+

″

(or) and

″⊕″

(xor).

The second formalism permits the specification

of the temporal dependences of the physical

processes in a graphical form close to that of Petri

nets (Dong and all, 2001) (Kara and all, 2009). In

this formalism the places are labelled and retain their

habitual representation and meaning. We call E the

set of labels e

i

associated with these places. We can

associate each of these labels with a specific

physical state defined in Q. We call R: E*Q the

relationship which joins a physical state q

j

to each

place e

i

. The transitions represented by rectangles

correspond to the physical processes p

i

of the

system. These transitions are not necessarily atomic:

new rules, according to the temporal dependences of

the process concerned, define the conditions of

activation and the effect of an activation on the input

and output places of a transition. The type of

dependence is determined by the type of arcs which

link the places and the transitions between them

(″→″ for causal precedence, ″•⇒″ and ″⇒•″ for

coupling, and ″-->″ for temporal precedence).

A marking M: is a function from P*E → Ν (where

Ν is the set of positive integers).

M(p

i

,e

j

) denotes the number of tokens in the place e

j

before activation of the physical process p

i

, and

M’(p

i

,e

j

) denotes the number of tokens in the place e

j

after activation of the physical process p

i

M(-,e

j

) denotes the initial state of the place e

j

.

The two formalisms used are equivalent. In

comparison with Petri nets, this type of formalism

permits a more concise expression which is thus

easier to read and to write. It can be converted into a

Petri net to enable the formal checking of the

properties of the described behaviour. In the

following paragraphs we will deal more precisely

with the definition of the different temporal

dependences and their specification in the two

formalisms, before addressing, in Sections 3 and 4,

the approach to modelling and to checking the

behavioural properties of a process.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

158

2.1 Causal Precedence

Given two physical processes p

1

and p

2

of an

industrial system, if h

1

= (a

10

, a

11

, ...., a

1n

, ...) and

h

2

= (a

20

, a

21

, ...., a

2n

, ...) respectively represent their

histories, we will say that p

1

precedes p

2

and we

write p

1

Ù p

2

if at any given moment for each

couple (a

1k

, a

2k

) we have t’(a

1k

) ≤ t’(a

2k

), if this

condition is not met we write ⎤( p

1

Ù p

2

).

p

1

→ p

2

if and only if

(1) p

1

Ù p

2

(2) there exists no p

i

such that p

1

Ù p

i

et p

i

Ù p

2

(3) there exists no p

i

≠ p

1

such that p

i

Ùp

2

et

⎤( p

i

Ù p

1

)

(4) there exists no p

j

≠ p

2

such that p

1

Ù p

j

et

⎤( p

2

Ù p

j

)

We will say that p

1

is the immediate predecessor

of p

2

and that p

2

is the immediate successor of p

1

.

We can deduce from this on the one hand that p

2

can

only start an activity if and only if p

1

finishes an

activity and on the other hand that each completion

of activity p

1

can lead only to the start of an activity

by p

2

. These definitions relate to the definitions of

precedence and causal precedence presented for the

events in (Baker and Hewitt, 1997). In a relationship

of causal precedence we can describe a physical

process as having several immediate successors or

several immediate predecessors. For this we use the

physical process composition operators ″*″ , ″+″

and ″⊕″. The basic notation of such temporal

relationships is defined in Table 1. These basic

relationships can be combined to express more

complex temporal relationships, in which the usual

rules of parenthesis allow the definition of priorities

among the composition operators.

2.2 Coupling

Given two physical processes p

1

and p

2

of an

industrial system, if h

1

= (a

10

, a

11

, ...., a

1n

, ...) and

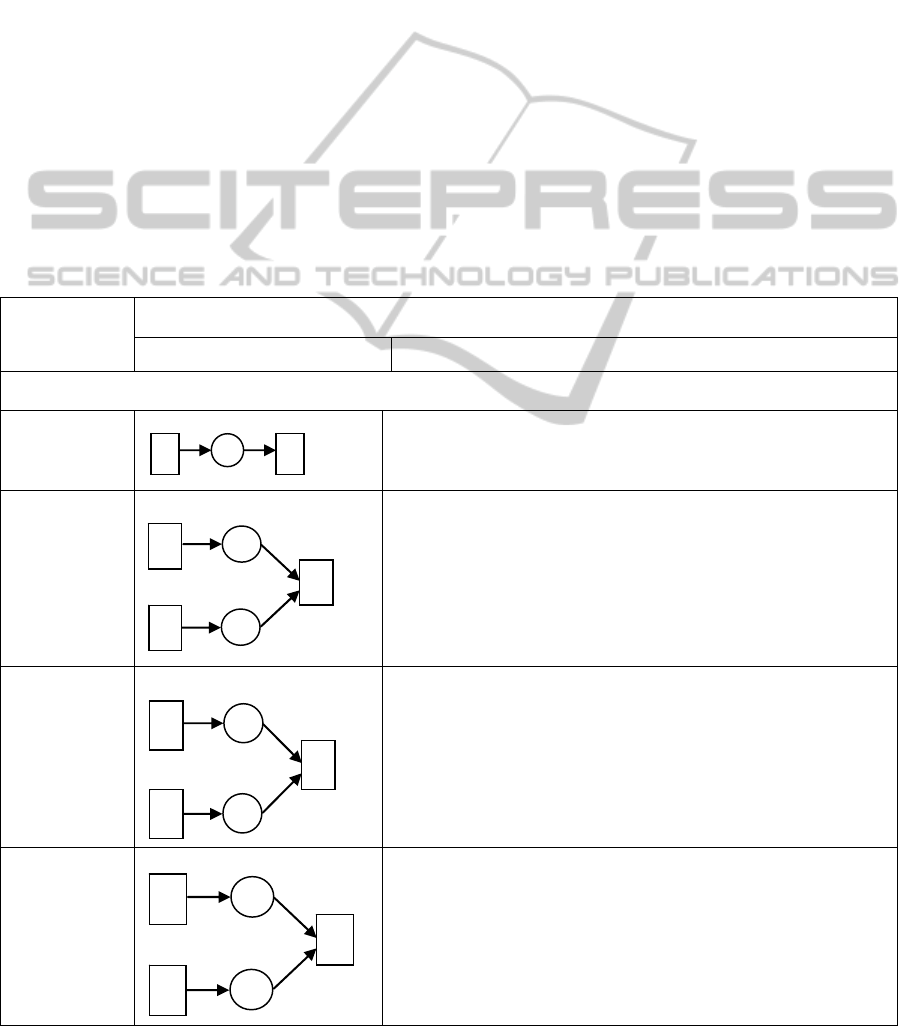

Table 1: Basic notation of causal precedence relationships.

Textual Form Graphical Form

Representation Rules of progress of the token

Designation of immediate predecessors

p

1

→ p

2

Before activation of p

2

: M(p

2

,e

1

)>0

After activation of p

2

: M’(p

2

,e

1

)=M(p

2

,e

1

)-1

p

1

+ p

2

→ p

3

Before activation of p

3

: M(p

3

,e

1

)>0 or M(p

3

,e

2

)>0

After activation of p

3

: M’(p

3

,e

1

)=if M(p

3

,e

1

)>0 then

M(p

3

,e

1

)-1 or M(p

3

,e

1

) else M(p

3

,e

1

) and

M’(p

3

,e

2

)= if M(p

3

,e

2

) > 0 then M(p

3

,e

2

)-1 or M(p

3

,e

2

)

else

M(p

3

,e

2

) and M’(p

3

,e

1

) + M’(p

3

,e

2

)= M(p

3

,e

1

)+ M(p

3

,e

2

) – 1

p

1

* p

2

→ p

3

Before activation of p

3

: M(p

3

,e

1

)>0 and M(p

3

,e

2

)>0

After activation of p

3

: M’(p

3

,e

1

) = M(p

3

,e

1

) - 1 and

M’(p

3

,e

2

) = M(p

3

,e

2

) - 1

p

1

⊕p

2

→ p

3

Before activation of p

3

: M(p

3

,e

1

)>0 and M(p

3

,e

2

)=0 or

M(p

3

,e

1

)=0 and M(p

3

,e

2

)>0

After activation of p

3

: M’(p

3

,e

1

) = if M(p

3

,e

1

)>0 then

M(p

3

,e

1

)-1 else M(p

3

,e

1

) and

M’(p

3

,e

2

) = if M(p

3

,e

2

)>0 then M(p

3

,e

2

) -1 else M(p

3

,e

2

)

e

1

p

1

p

2

e

1

p

2

p

1

p

3

*

e

2

⊕

p

2

p

1

p

3

e

2

e

1

e

1

p

2

p

1

p

3

+

e

2

DESIGN APPROACH OF DISTRIBUTED SYSTEMS FOR THE CONTROL OF INDUSTRIAL PROCESS

159

h

2

= (a

20

, a

21

, …., a

2n

, ...) represent their respective

histories, we will say that p

2

is coupled to p

1

for its

start if at any given moment, whatever a

21

denotes,

there exists an a

1k

such that t(a

1k

)≤t(a

21

) ≤ t’(a

1k

).We

will write p

1

⇒p

2

. From this relationship we can

deduce on the one hand that p

2

can only start an

activity if and only if p

1

has an activity in progress,

and on the other hand that if p

1

has an activity in

progress, this activity can only start an activity in p

2

.

Moreover, we will say that p

2

is coupled with p

1

for

stopping if at any moment, whatever a

21

denotes,

there exists an a

1k

such t(a

1k

)≤t’(a

21

) ≤ t’(a

1k

). To

designate the predecessors of p

2

we will note p

1

⇒p

2

,

and we can deduce from this that p

2

can only finish

an activity if and only if p

1

has an activity in

progress. In the same way, to designate the

successors of p

1

we note p

1

⇒p

2

and it can be

deduced that if p

1

has an activity in progress this

activity can only provoke the end of a p

2

activity.

As well as the operators ″*″, ″+″ and ″⊕″ we use the

composition operator ″;″ to link several physical

processes into a coupling relationship. This operator

allows us to define an order for the starting or

stopping of coupled physical processes. The

coupling relationships can also be represented

graphically. The implied transitions are not

considered to be atomic.

2.3 Temporal Precedence

Physical processes p

1

, p

2

, ......, p

n

which are not

interlinked by a relationship of causal precedence or

coupling, are linked by the relationship of temporal

precedence, if at any given moment just one of these

n processes could be active. In other words, it must

be possible at any given moment to describe the

history of these n processes in a chronological order

of activity h

x

= (a

x0

, a

x1

, ...a

xi

, ...) where each activity

a

xi

designates an activity carried out by any one of n

physical processes, such that whatever the value of i,

t(a

xi

) ≤ t(a

xi+1

) and t’(a

xi

) ≤ t’(a

xi+1

).

This type of temporal dependence which was

also introduced in for events, supposes the existence

of a sequencer whose job is to put into an arbitrary

order the physical processes ready to start an

activity. Let us suppose this order is created by a

priority circulating on a unidirectional virtual ring,

on which are placed the n physical processes. A

process can only start an activity if it receives the

priority, which it retains until the end of this activity.

A process which receives the priority must transmit

it to its successor if it cannot start an activity

immediately. The specification of a temporal

precedence relationship under these conditions

comes down to specifying the order of the physical

processes on the virtual ring. Given two physical

processes p

1

and p

2

,

we note p

1

--> p

2

to state that p

2

is the immediate

successor of p

1

or that p

1

is the immediate

predecessor of p

2

on the virtual ring. In a temporal

precedence relationship we can use the process

composition operator, ″⊕″, to stipulate that a

physical process at any given instant is part of a

virtual ring chosen among several.

2.4 Independence

When two physical processes p

1

and p

2

are not

linked by any one of the three temporal dependences

we have just described, we will say they are

independent. Under these conditions, activities p

1

and p

2

can take place at the same time or in any

order. In the two formalisms that we are using, the

relationship of independence is not explicitly

expressed.

3 THE APPROACH TO

MODELLING THE

INDUSTRIAL PROCESS

This relies on finding a good level of abstraction in

the description of the behaviour of the industrial

process allowing reflection on its organisation and

also allowing good functional breakdown.

It could be top-down: in this case one would

proceed by successive refining of physical processes

to more elementary physical processes. It could also

be bottom-up: in order to understand the behaviour

of the industrial process one would proceed first

with the identification of elementary physical

processes. In this phase one could proceed either by

successive refinements or directly by intuition. In a

second phase these physical processes are

regrouped. This is the approach adopted in (Yau and

Caglayan, 1983). It allows the integration of a

bottom-up approach within a globally top-down

approach. In the case of a top-down approach, there

exists a well-defined criterion of latest stopping

point: the designer must stop when he obtains

physical processes which cannot be further broken

down into more elementary processes assuring

activities of a different nature. The other criteria are

based on the designer’s competence and his

knowledge of the problem he is tackling. In a

top-down approach it is about the criteria of the

latest stopping point, and in a bottom-up approach

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

160

the criteria of the earliest stopping point. Whatever

the case, in order to manage more easily the

complexity of the analysis of the behaviour of his

process, the designer can first identify only the

independent physical processes or those interlinked

by causal precedence and temporal precedence

relationships, and only then can he proceed in a

more local way to a breakdown into coupled

physical processes. In the first instance the

relationships of causal and temporal precedence are

defined, and only after that the coupling

relationships. The textual formalism that we are

using allows us to key in and carry out automatically

the usual syntactic checks on the specification of the

behaviour of a process. It is then possible to convert

this specification automatically into a Petri net using

the conversion rules defined in Table 1 and in (Yan

and Caglayan, 1983). The existing tools surrounding

Petri nets thus allow us to assure that the described

behaviour respects certain properties of good

functioning: mutual exclusion, deadlock, liveness

and termination (Kara and all, 2009). Moreover, as

the places in our graphical model are associated with

physical states of the process, we can deduce

automatically all the accessible global states of the

process by constructing a graph of markings. These

global states must describe coherent situations.

4 LOGICAL STRUCTURE

CONSTRUCTION RULES

To describe the logical structure of a control system

we use the concept of communicating modules.

These are modular, multi-task entities which do not

communicate by variables, but communicate with

one another (for coordination purposes) via internal

ports and with the process (which they control) via

external ports. The inter-modular links defined

between the ports can be of different types:

1 towards 1, 1 towards n, n towards 1 or n towards

m. They allow us to describe the logical structure of

the system as a logical network of autonomous

communicating modules, in which checking is

decentralised, and where the following circulate:

- events reporting on the evolution of the process,

- controls, requests and reports,

- or again the data or the results of the data-

processing.

In this description, the modules are represented

graphically by rectangles, the input ports by the

symbol and the output ports by the symbol

The logical structure of a control system in terms

of communicating modules is largely directly

deduced by the graphical representation of the

process behaviour described in Section 2:

(1) Each transition is replaced by a communicating

module which abstracts the corresponding physical

process p

i

.

(2) The arcs which interlink the transitions thus

become inter-modular links via which control

transfer messages will circulate.

(3) Analysis of the control algorithms of each

physical process allows us to determine, for the

corresponding modules, the other ports where will

circulate external messages exchanged with the

process, as well as potential data shared between

these modules.

5 ILLUSTRATION OF THE

APPROACH

To illustrate our approach, we use as our example a

mixer, a test example, which has the feature of

bringing into play various physical processes.

This is a process which manufactures a product x by

mixing a given quantity of two liquid products a and

b, and a given quantity of soluble product y that we

call rolls. The liquid products are contained in two

vats A and B which feed vat C via controllable

valves Va and Vb. Vat C is equipped with a level

sensor, which allows it to measure the required

quantity of the two products, and a controllable

valve Vc which allows it to empty its contents into

the mixer. Moreover, the rolls are transported into

the mixer via a controllable, motorised conveyor

belt. There is also a device which detects the

passage of each roll. Finally, the mixer has a

controllable motor which operates both the mixing

process of its contents and also the emptying

process. For this last operation there is a sensor

which can detect the high and low positions of the

mixer.

Table 2 identifies the entities which constitute

the process and whose attributes are likely to evolve

with time. We have also defined in Table 2 the level

of observation of this evolution, by specifying for

each entity the attributes which describe it, and for

each attribute its domain of definition.

Four physical processes lead from one physical

state to another. These are: the emptying of vat C,

the filling of vat C, the transport of the rolls, and the

mixing-emptying of the mixer. The temporal

dependences which interlink these physical

processes define the behaviour of the process.

DESIGN APPROACH OF DISTRIBUTED SYSTEMS FOR THE CONTROL OF INDUSTRIAL PROCESS

161

Table 2: List of constituent entities of the industrial process.

Entities Attributes Domain of definition of the attributes

Vat A and Vat B

Vat C

Conveyor belt

Mixer

State of valves Va and Vb

State of content

State of valve Vc

State of operation

Position

State of content

State of operation

(closed, open)

(full, empty)

(closed, open)

(stopped, moving)

(high, low)

([empty], [liquids a and b], [rolls], [liquids a and b, rolls])

(off, mixing, emptying)

Figure 1: Graphical representation of the behaviour of the process superimposed on the graphical representation of the

logical structure of its control system.

We specify these dependences in the following

way, by indicating in each case for each physical

process, first of all its immediate predecessors and

then its immediate successors:

For the filling of vat C:

Emptying-vat-C

→

Filling-vat-C

Filling-vat-C

→

Emptying-vat-C

For the emptying of vat C:

Filling-vat-C*mixing-emptying-mixer

→

Emptying-vat-C

Emptying-vat-C

→

Filling-vat-C*Mixing-emptying-mixer

For the transport of the rolls:

Mixing-emptying-mixer

→

Transport-rolls

Transport-rolls

→

Mixing-emptying-mixer

For the mixing-emptying of the mixer:

Emptying-vat-C * Transport-rolls

→

Mixing-emptying-mixer

Mixing-emptying-mixer

→

Emptying-vat-C*

Transport-rolls

Figure 1 shows the graphical representation of

the behaviour of the process superimposed on the

graphical representation of the logical structure of its

control system in terms of communicating modules.

In Table 3 we show for each place in the diagram the

corresponding physical state of the process.

6 CONCLUSIONS

This article has essentially been concerned with the

functions of control and supervision of the process,

which we approached from a perspective of

synchronisation, in view of the nature of the

problems which arise in industrial processes and

more particularly in flexible manufacturing systems.

In

the first stage of our approach, the designer starts

*

*

*

*

e

5

e

4

e

3

e

6

e

1

e

2

rolls passage

senso

r

conveyor belt

controls

level sensor

of vat C

Va and Vb

controls

Vc controls

level sensor

of vat C

mixer position

sensor

Mixer

controls

emptying vat C

filling vat C

transport rolls

mixing-emptying

mixer

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

162

Table 3: Correspondence of the places and physical states of the process.

Places Physical states Places Physical states

e1

e2

e3

State of valves

Va and Vb=closed

State of valve Vc=closed

State of content of

vat C=empty

State of valves

Va and Vb=closed

State of valve Vc = closed

State of content of vat C=full

State of operation of

conveyor belt = stopped

Position of mixer=high

No [rolls] in state of content of mixer

State of operation of mixer=off

e4

e5

e6

State of operation of

conveyor belt= stopped

Position of mixer=high

[rolls] in state of content of mixer

State of operation of mixer=off

State of valve Vc=closed

Position of mixer=high

[Liquids a and b] in state of content of mixer

State of operation of mixer=off

State of valve Vc=closed

Position of mixer=high

No [liquid a and b] in state of content of mixer

State of operation of mixer=off

with the analysis of “what to control” in order to

break the control system down into communicating

modules, and to specify the inter-modular behaviour

of this system. At this stage of the design, his aim

must be to reveal the possibilities of distributing the

control system in different sites, by carrying out a

functional breakdown where he introduces no

artificial constraints on the distribution: so he should

ignore the distribution of the modules in different

geographical sites. Moreover, by describing the

temporal dependences of the physical processes, the

designer merely uses time as a means of sequencing:

thus he also avoids the constraints of “real time”. It

is during the course of the second stage, dedicated to

the analysis of “how to control” that the designer

will need to move on to a more precise definition of

the constraints of “real time” at the same time as the

behaviour of the modules (communication policies

on the ports and relationships between the input and

output of a module).

The third stage is devoted to finding the

execution structure which responds best to the

constraints of ‘real time”, distribution and operating

reliability. We are currently working on the second

stage of the approach, but also on the production of a

prototype JAVA programming environment based

on these ideas in order to facilitate the

methodological construction of industrial process

control systems.

REFERENCES

Baker, H., Hewitt, C., 1997. Laws for communicating

parallel processes. Information processing. B.Gilchrist

Editor IFIP.

Brams, G. W., 1983. Réseaux de Petri : théorie et

pratique. Édition Masson.

Cao, J., Chan, A., Sun, Y., & Zhang, K., 2003. Dynamic

configuration management in a graph-oriented

Distributed Programming Environment. Science of

computer programming, volume 48, issue 1, July

2003, pages 43-65.

Chen, B. S., Yeh, R.T., 1983. Formal specification and

verification of distributed systems. IEEE Trans. on

soft. eng. Vol SE-9, n° 6, pp. 710-722.

Dong, M., Chen, F., 2001. Process modeling and analysis

of manufacturing supply chain networks using object

oriented Petri nets. Robotic and Computer Integrated

Manufacturing, 17, pages 121-129.

Dotoli, M., Fanti, M.P., Giua, A., Seatzu, C., 2006. First

order hybrid Petri nets. An application to distributed

manufacturing systems. Nonlinear Analysis: Hybrid

Systems, 20 May 2006 pages 408-430.

Drzymalski, J., Odrey, N.G, 2008. Supervisory control of

a multi-echelon supply chain: A modular Petri net

approach for inter-organizational control. Robotics and

Computer-Integrated Manufacturing, 24, 2008, pages

728-734.

Ezzedine, H., Trabelsi, A., Kolski, C., 2006. Modelling of

an interactive system with an agent-based architecture

using Petri nets, application of the method of the

supervision of a transport system. Mathematics and

Computers in Simulation, 10 January 2006 pages 358-

376.

DESIGN APPROACH OF DISTRIBUTED SYSTEMS FOR THE CONTROL OF INDUSTRIAL PROCESS

163

Gabrielian, A., Franklin, M.K., 1990. Multi-level

specification and verification of real time software.

12th inter. conf. on soft. eng. March 26-30, 1990.

Kara, R., Ahmane, M., Loiseau, J. J, Djennonne, S., 2009.

State space analysis of Petri nets with relation

algebraic methods. Nonlinear analysis: hybrid

systems, volume 3, issue 4, pages 738-748.

Kramer, J., Magee, J., Sloman, M., 1989. Constructing

distributed systems in CONIC. IEEE transactions on

software engineering, volume 15, issue 6, June 1989,

pages 663-675.

Kramer, J., Magee, J., Sloman, M., Lister, A., 1983.

CONIC: An integrated approach to distributed

computer control system. IEEE Proc. Vol 130, 1,1983.

Krause, C., Maraikar, Z., Lazovik, A., Arbab, F., 2009.

Modeling dynamic reconfigurations in Reo using

high-level replacement systems. Science of computer

programming, 2009, pages 1-14.

Lamport, L., 1983. Specifying concurrent program

modules. ACM trans. on prog. lang. and syst. Vol 5,

n° 2, 1983, pp. 190-222.

Philippi, S., 2006. Automatic code generation from high

level Petri-Nets for model driven systems engineering.

Journal of systems and software 79, 2006,

pages 1444-1455.

Vasenin, V. A., Vodomerov, A.N., 2007. A formal model

of a system for automated program parallelization.

Source Programming and Computing Software,

volume 33, Issue 4, pages 181–194.

Yau, S. S., Caglayan, M. U., 1983. Distributed software

system design representation using modified Petri

nets. IEEE Trans. on soft. eng. Vol SE-9, n° 6.

Yu, H., Reyes, A., Cang, S., Lloyd, S., 2003. Combined

Petri nets modelling and AI based heuristic hybrid

search for flexible manufacturing systems -part 1. Petri

net modelling and heuristic search. Computer &

Industrial Engineering 44, pages 527-543.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

164