PRINCIPAL COMPONENTS ANALYSIS METHOD

APPLICATION IN ELECTRICAL MACHINES DIAGNOSIS

J. F. Ramahaleomiarantsoa, N. Heraud

Université de Corse, U.M.R. CNRS 6134 SPE, BP 52, 20250 Corte, France

E. J. R. Sambatra

Institut Supérieur de Technologie, BP 509, 201 Antsiranana, Madagascar

J. M. Razafimahenina

Ecole Supérieure Polytechnique, BP O, 201 Antsiranana, Madagascar

Keywords: Diagnosis, Principal components analysis, Residues, Wound rotor induction machine, Modeling.

Abstract: Electrical machines are found in many applications, especially in wind energy conversion chain (WECC).

However, these machines still remain the most potential of failures. Many researches and improvements

have been carried out but in the aim of optimal operation systems, monitoring and diagnosis techniques are

among the interests of existing laboratories and research teams. This paper deals with the principal

components analysis (PCA) method application in electrical machines, especially a wound rotor induction

machine (WRIM), diagnosis. The used PCA approach is based on residues analysis. To perform the matrix

data needed for PCA method data input, an accurate analytical method of the WRIM is proposed. WRIM

and PCA models are implemented in Matlab software. The simulation results show the potential necessity

of the considered PCA method on the WRIM faults detection compared to some other signal analysis

method.

1 INTRODUCTION

Since many years, faults detection in electrical

machines has been object of both industrial and

teaching laboratories. Previously, DC and

synchronous machines were the most used on

industry applications, and reliability researches were

focused on these types of machines. With

technological developments, power electronic

progress and the economic issue, the squirrel cage

and the wound rotor induction machines have taken

their place in several applications domain like

transportation, energy production and electrical

drives through their robustness, reliability and lower

costs. Although researches and improvements have

been carried out, these machines still remain the

most potential of the stator and the rotor failures.

In fact, this article shows one of several

methodology for monitoring and doing diagnostics

related to the faults on a wound rotor induction

machine (WRIM) based WECC by the residues

analysis of its state variables. The approach is based

on the principal components analysis (PCA) method.

The first part of this paper deals with the WRIM

modeling followed by some reminders of the

different types of stator and rotor WRIM faults. The

second part is devoted at the PCA principle. The

PCA model construction method and the choice

criterion of the number of components to be retained

is discussed, followed by the PCA residues

generation technical for the faults detection and the

localization. The third part talks about the method

validations using Matlab/Simulink software. The

simulation results of several variables (stator and

rotor currents, shaft rotational speed, electrical

power, electromagnetic torque and other variables

issued from mathematical transformations) of

healthy and faulted WRIM are analyzed.

167

F. Ramahaleomiarantsoa J., Heraud N., J. R. Sambatra E. and M. Razafimahenina J..

PRINCIPAL COMPONENTS ANALYSIS METHOD APPLICATION IN ELECTRICAL MACHINES DIAGNOSIS.

DOI: 10.5220/0003542501670175

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 167-175

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

Special attention has been reserved to the PCA

residues representations. The last part is reserved to

the analyze and discussion of simulation results.

2 WRIM MODELLING

In the process of faults survey and diagnosis, an

accurate modeling of the machine is necessary. In

this paper, three phases model based on

magnetically coupled electrical circuits was chosen.

The aim of the modeling is to highlight the

electrical faults influences on the different state

variables of the WRIM. For that, some modeling

assumptions given in the following section are

necessary.

2.1 Modeling Assumptions

In the proposed approach, we assumed that:

• the magnetic circuit is linear, and the relative

permeability of iron is very large compared to the

vacuum.

• the skin effect is neglected,

• hysteresis and eddy currents are neglected,

• the airgap thickness is uniform,

• magnetomotive force created by the stator and the

rotor windings is sinusoidal distribution along the

airgap,

• the stator and the rotor have the same number of

turns in series per phase,

• the coils have the same properties,

• the WRIM stator and rotor coils are coupled in star

configuration and connected to the considered

balanced state grid.

2.2 Differential Equation System of the

WRIM

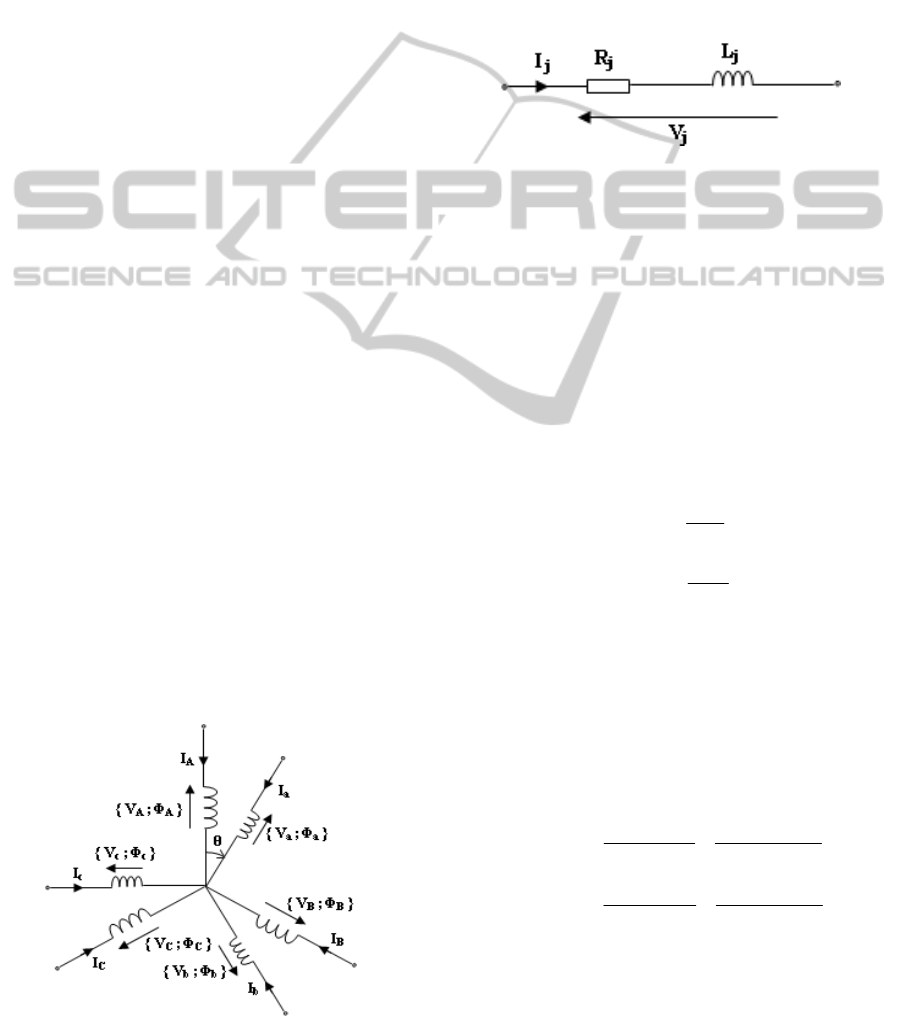

Figure 1: Equivalent electrical circuit of the WRIM.

V

j

, I

j

and Φ

j

(j : A, B, C for the stator phases et a, b,

c, for the rotor phases) are respectively the voltages,

the electrical currents and the magnetic flux of the

stator and the rotor phases, θ is the angular position

of the rotor relative to the stator.

The figure 1 shows the equivalent electrical

circuit of the WRIM. Each coil, for both the stator

and the rotor, is modelised with a resistance and an

inductance connected in series configuration (Fig.

2).

Figure 2: Equivalent electrical circuit of the WRIM coils.

We note the voltages vector ([V

S

], [V

R

]), the

currents vector ([I

S

], [I

R

]) and the flux vector ([Φ

S

],

[Φ

R

]) of respectively the stator and the rotor:

[]

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

C

B

A

S

V

V

V

V

;

[]

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

C

B

A

S

I

I

I

I

;

[]

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

C

B

A

S

φ

φ

φ

φ

[]

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

c

b

a

R

V

V

V

V

;

[]

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

c

b

a

R

I

I

I

I

;

[]

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

c

b

a

R

φ

φ

φ

φ

[][][]

[]

dt

d

IRV

S

SSS

φ

+=

(1)

[][][]

[]

dt

d

IRV

R

RRR

φ

+=

(2)

[

]

[

]

[

]

[

][ ]

RSRSSS

IMIL

+

=

φ

(3)

[

]

[

]

[

]

[

][ ]

SRSRRR

IMIL

+

=

φ

(4)

[R

S

] and [R

R

] are the resistances matrix, [L

S

] and [L

R

]

the own inductances matrix, and [M

SR

] and [M

RS

] the

mutual inductances matrix between the stator and

the rotor coils.

With (3) and (4), (1) and (2) become:

[][][]

[

]

[

]

{

}

[][]

{}

dt

IMd

dt

ILd

IRV

RSRSS

SSS

++=

(5)

[][][]

[

]

[

]

{

}

[][]

{}

dt

IMd

dt

ILd

IRV

SRS

RR

RRR

++=

(6)

By applying the fundamental principle of dynamics

to the rotor, the mechanical motion equation is

(Wieczorek and Rosołowski, 2010):

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

168

remvt

CCf

dt

d

J −=Ω+

Ω

(7)

dt

d

θ

=Ω

(8)

with:

[]

[

]

(

)

[]

I

d

Ld

IC

t

em

*

*

2

1

θ

=

(9)

t

J is the total inertia brought to the rotor shaft,

Ω

the shaft rotational speed, [I]=[I

A

I

B

I

C

I

a

I

b

I

c

]

t

the

currents vector,

v

f the viscous friction torque,

em

C

the electromagnetic torque,

r

C the load torque,

θ

the angular position of the rotor relative to the stator

and [L] the inductances matrix of the machine.

Introducing the cyclic inductances of the stator

and the rotor

SSC

LL

2

3

=

and

RRC

LL

2

3

=

(L

S

is the

own inductance of the each phase of the stator and

L

R

is the own inductance of the each phase of the

rotor), the mutual inductances between the stator and

the rotor coils M

SR

and pole pair number p, the

inductance matrix of the WRIM car be written as

follow:

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎣

⎡

=

RCSRSRSR

RCSRSRSR

RCSRSRSR

SRSRSRSC

SRSRSRSC

SRSRSRSC

LfMfMfM

LfMfMfM

LfMfMfM

fMfMfML

fMfMfML

fMfMfML

L

00

00

00

00

00

00

][

123

312

231

132

213

321

(10)

1

cos( )

f

p

θ

=

(11)

2

2

cos( )

3

fp

π

θ

=+

(12)

3

2

cos( )

3

fp

π

θ

=−

(13)

In choosing the stator and rotor currents, the shaft

rotational speed and the angular position of the rotor

relative to the stator as state variables, the

differential equations system modeling the WRIM is

given by:

])][[]([][][

1

XBUAX −=

−

&

(14)

with:

t

cbaCBA

IIIIIIX ] [][

θ

Ω=

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

100

00

00][

][

t

J

L

A

;

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

−=

0

][

][

r

C

V

U

;

t

cbaCBA

VVVVVVV ] [][ =

;

⎥

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎢

⎣

⎡

−

−

Ω+

=

010

0

][

][

2

1

00

][

][

][

v

t

f

d

Ld

I

d

Ld

R

B

θ

θ

This model of the WRIM will be used to simulate

both the healthy and the faulted operation case of the

stator and the rotor.

2.3 WRIM Faults

The necessity for having reliable electric machines is

more important than ever and the trend continues to

increase. Lighter machine having a considerable

lifetime is now possible due to advances in

engineering and materials sciences domain.

Although the constant improvements on design

technical of reliable machine, different type of faults

still exist. The faults can be resulted by normal wear,

poor design, poor assembly (misalignment),

improper use or combination of these different

causes.

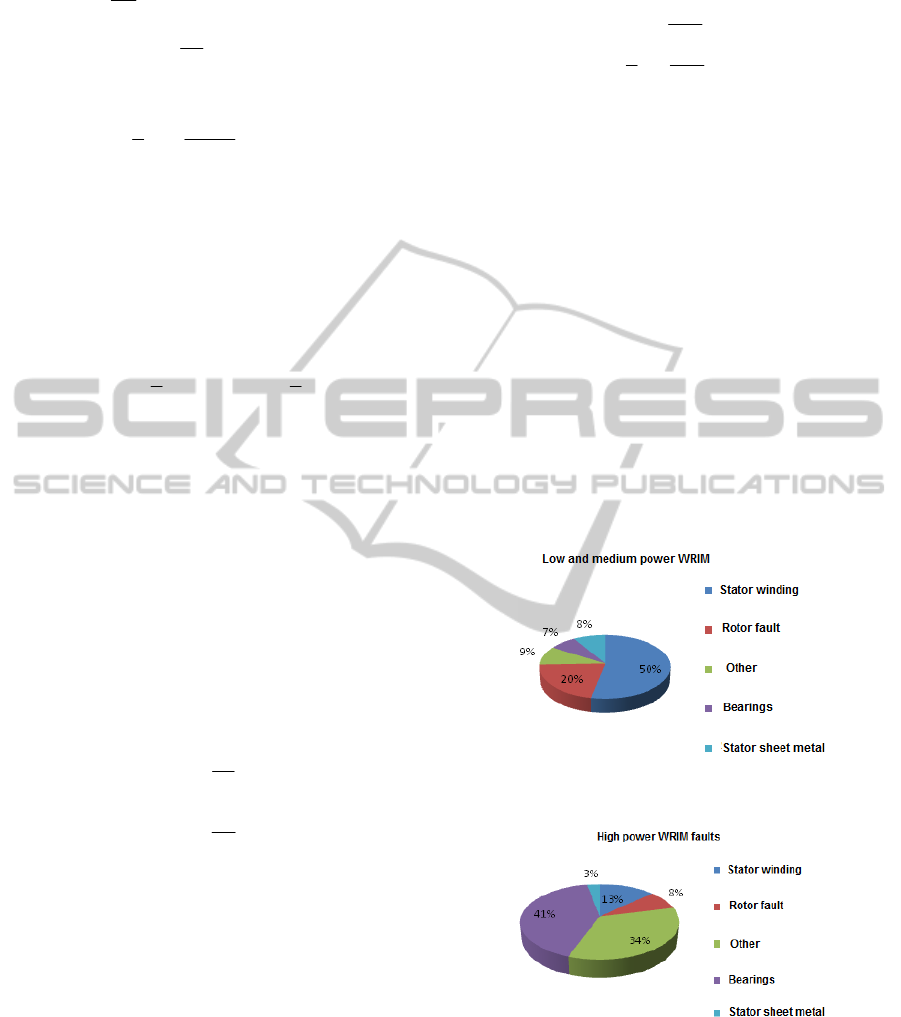

Figure 3: Low and medium power induction machines

faults (Razik, 2002; Chia-Chou et al., 2008).

Figure 4: High power induction machines faults (Razik,

2002; Chia-Chou et al, 2008).

Figure 3 and figure 4 present the faults

distribution carried out by a German company on

industrial system. The figure 3 show the faults of the

low and medium power machines (50 KW à 200

KW), and the figure 2 those of the high power

PRINCIPAL COMPONENTS ANALYSIS METHOD APPLICATION IN ELECTRICAL MACHINES DIAGNOSIS

169

machines (from 200 KW)

(Razik, 2002; Chia-Chou et

al., 2008)

.

Figure 3 shows that the most encountered faults

of the low and medium power on the induction

machines are the stator faults and the figure 4 shows

that the faults due to mechanical defects give the

highest percentages. The induction machines faults

can be classified into four categories (

Chia-Chou et

al., 2008

):

The stator faults can be found on the coils or the

breech. In most cases, the winding failure is caused

by the inter-turns faults. These last grow and cause

different faults between coils, between several

phases or between phase and earth point before the

deterioration of the machine (Sin et al., 2003). The

breech of electrical machines is built with insulated

thin steel sheets in order to minimize the eddy

currents for a greater operational efficiency. In the

case of the medium and great power machines, the

core is compressed before the steel sheets

emplacement to minimize the rolling sheets

vibrations and to maximize the thermal conduction.

The core problems are very little, only 1% compared

to winding problems (Negrea, 2006).

The rotor faults can be bar breaks, coils faults or

rotor eccentricities.

The bearings faults can be caused by a poor choice

of materials during the manufacturing steps, the

problems of rotation within the breech caused by

damaged, chipped or cracked bearing and can create

disturbance within the machines.

The other faults can be caused by the flange or the

shaft faults. The faults created by the machine flange

are generally caused during the manufacturing step.

Although the induction machines are robust, they

can be seats of different types of faults that can be

classified into two categories (Kliman et al., 1996):

• The hard and brutal faults modelised by an abrupt

inputs change or system parameters.

• The soft and arising faults due to gradual changes

of system parameters compared to their normal

values.

As previously mentioned, for the state survey of the

electrical machines, the PCA method was adopted.

3 PCA METHOD APPROACH

The PCA principle is based on simple linear algebra.

It can be used as exploring tool, analyzing data and

models design. The PCA method is based on a

transformation of the space representation of the

simulation data. The new space dimension is smaller

than that the original space dimension. It is classified

as without models method categories (Liu, 2006). It

can be considered as a full identification method of

physical systems (Marx et al., 2007; Ku et al., 1995;

Huang, 2001). The PCA allow to provide directly

the redundancy relations between the variables

without identifying the state representation matrix of

the system. This task is often difficult to achieve.

3.1 PCA Method Formulation

We note by x

i

(j) = [x

1

x

2

x

3

…x

m

] the measurements

vector « i » represents the measurement variables

that must be monitored and ranging from 1 to m and

« j » the number of the performed measurements for

each variable « m », ranging from 1 to N.

The measurements data matrix (X

d

€ R

N*m

) can

be written:

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎝

⎛

=

)(...)(

.........

)1(...)1(

1

1

NxNx

xx

X

m

m

d

(15)

This data matrix can be described with a possible

smallest set of new synthetic matrix, that is a

orthogonal linear projection of a subspace of m

dimension in a less dimension subspace l (l<m). The

method consists in identifying the PCA model and is

based on two steps (Li and Qin, 2001):

• Determination on the eigenvalues and the

eigenvectors of the covariance matrix R.

• Determination of the structure of the model, which

consists to calculate the components number « l » to

be retained in the PCA model.

3.2 Eigenvalues and Eigenvectors

Determination

Variables must be centered and reduced to make

data matrix independent of variables physical units.

Then, the new obtained normalized measures

matrix is:

]...[

1 m

XXX

=

(16)

And the covariance matrix R is given by:

T

XX

N

R

1

1

−

=

(17)

In decomposing R, (16) can be expressed as:

T

P

P

R

Λ

=

(18)

With

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

170

m

TT

IPPPP ==

(19)

Λ

is diagonal matrix of the eigenvectors of R and

their eigenvalues are ordered in descending order

with respect to magnitude values (

)...

21 m

λ

λ

λ

≥≥≥ .

The eigenvectors matrix P is expressed as:

],...,,[

21 m

pppP =

(20)

i

p is the orthogonal eigenvectors corresponding to

i

λ

. Then, the principal components matrix is:

XP

T =

(21)

mN

T

*

ℜ∈

3.3 PCA Model Construction

To obtain PCA model, the components number “l”

to be retained must be determined. This step is very

important for PCA construction. For that, many rules

have been proposed by (Li and Qin, 2001). Most are

from sometimes subjective heuristics method or

criteria used in system identification in privileging

the data matrix approximation of the data matrix. In

this paper, "average eigenvalues" criterion is used.

The principle is based on the determination of the

variances of each component with the centered and

reduced variables. The number of variables l to be

retained to construct the PCA model is equal to the

number of components whose variance is greater

than unity.

By taking into account the number of

components to be retained and by partitioning the

principal components matrix T, the eigenvectors

matrix P and the eigenvalues matrix

Λ

(Valle et al.,

1999; Benaicha et al., 2010), the constructed PCA

model is given by:

[

]

)(** lmN

r

lN

p

TTT

−

=

(22)

[

]

)(** lmN

r

lN

p

PPP

−

=

(23)

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

Λ

Λ

=Λ

−− ))((

*

0

0

lmlm

ll

L

MOM

L

(24)

p

T

and

r

T is respectively the principal and residual

parts of T,

p

P

and

r

P is respectively the principal

and residual parts of P.

With this PCA model, the centered and reduced

matrix X can be written as:

T

rr

T

pp

TPTPX +=

(25)

In considering:

∑

=

==

l

i

T

ii

T

ppp

TPTPX

1

(26)

∑

+=

==

m

li

T

ii

T

rr

TPTPE

1

(27)

The centered and reduced matrix data is given by:

p

X

XE

=

+

(28)

p

X

is the principal estimated matrix and E the

residues matrix which represent information losses

due to the data matrix

X reduction. It represents the

difference between the exact and the approached

representations of

X. This matrix is associated with

the lowest eigenvalues

1

,...,

lm

λ

λ

+

. Therefore, in this

case, data compression preserves all the best the

information that it conveys. Under the application of

PCA at diagnosis, the number of components has a

significant impact on each step of faults detection

and localization procedure.

Nine state variables (m=9) have been chosen to

be monitored and 10000 measures (N=10000)

during 4s are considered. The WRIM faults are

introduced from the initial time (t=0s) to the final

time (t=4s) of the different simulations. The machine

is coupled to a mechanical load torque (10Nm) at

t=2s. The considered faults are respectively,

increases from 10% to 40% of the resistance value

of both the stator and rotor coils.

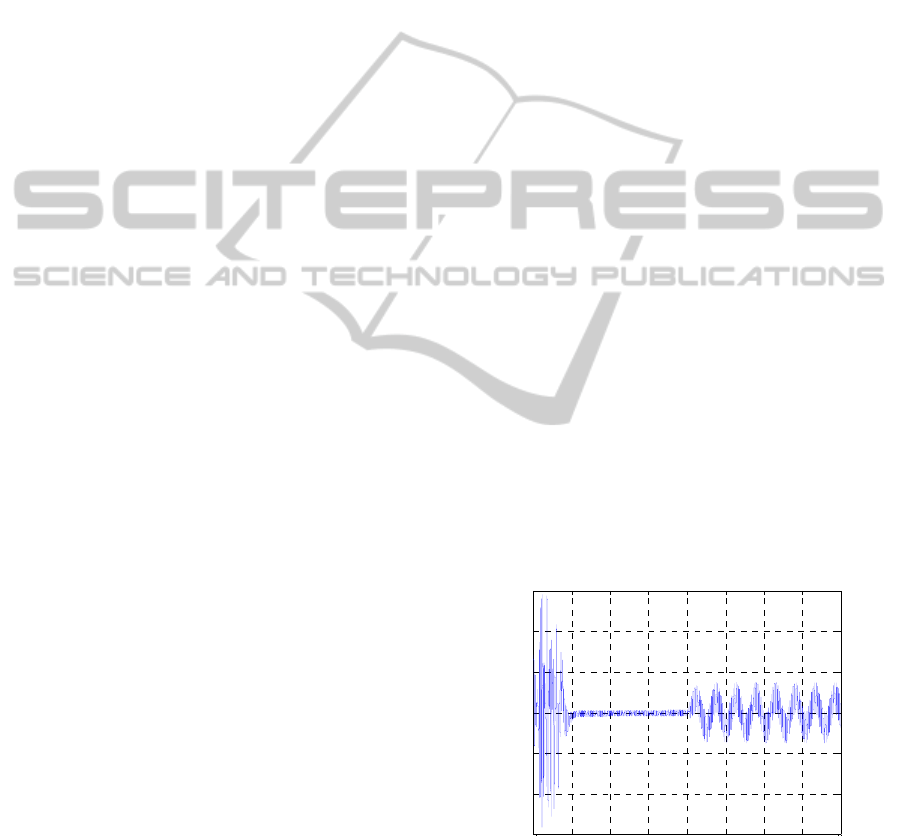

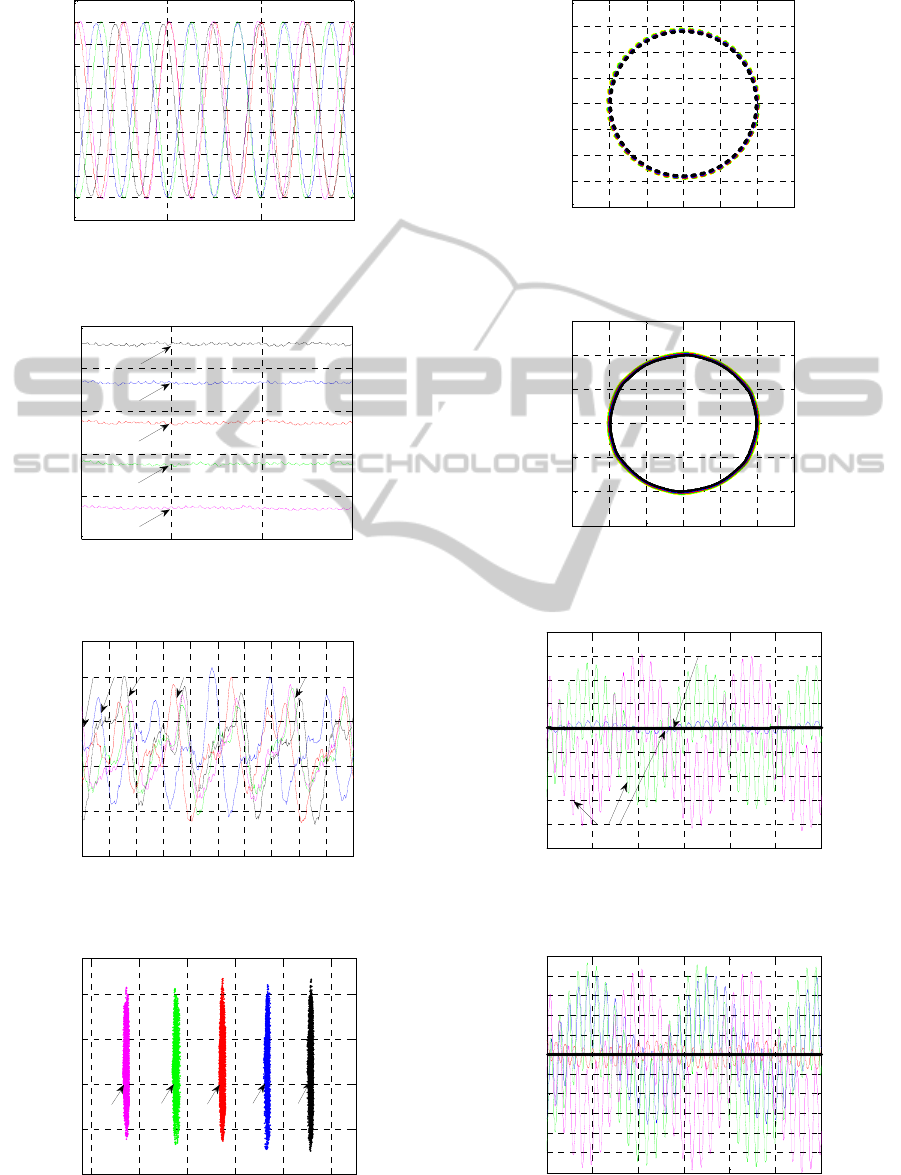

The following figures (Fig. 5 and Fig. 6)

represent the residues variation of the WRIM stator

current versus time and show the number

l impact in

the diagnosis approach:

Figure 5: Stator current residue for l = 5.

Figure 6 show that the chosen number of

components is too high then the residual space

dimension is reduced. Some faults are projected in

0 0.5 1 1.5 2 2.5 3 3.5 4

-1.5

-1

-0.5

0

0.5

1

1.5

Phase "A" stator current

Time [s]

PRINCIPAL COMPONENTS ANALYSIS METHOD APPLICATION IN ELECTRICAL MACHINES DIAGNOSIS

171

the principal space and the stator current residues

can not be detectable.

Figure 6: Stator current residue for l = 6.

However, with the figure 5, the number of

components is well chosen. Faults can be detected

and localized and the PCA model is well

reconstructed.

Generally, the detection approach in the case of

diagnosis based on analytical model is linked with

the residues generation step. From these residues

analysis, the decision making step must indicate if

faults exist are not. The residues generation

approach can be the state estimation approach or the

parameter estimation approach.

The residue indicates the information losses

given by the matrix dimension reduction of the state

variables matrix data to be monitored. Indeed, a

small residue means that the estimated value tends to

the exact value in healthy operation case.

In our case, the eigenvalues corresponding to the

number of the retained principal components

represent 93% of the total sum of eigenvalues. 0nly

7% of the total represent the residues subspace. One

can conclude that the PCA model has been well

constructed.

4 PCA METHOD APPLICATION

ON WRIM

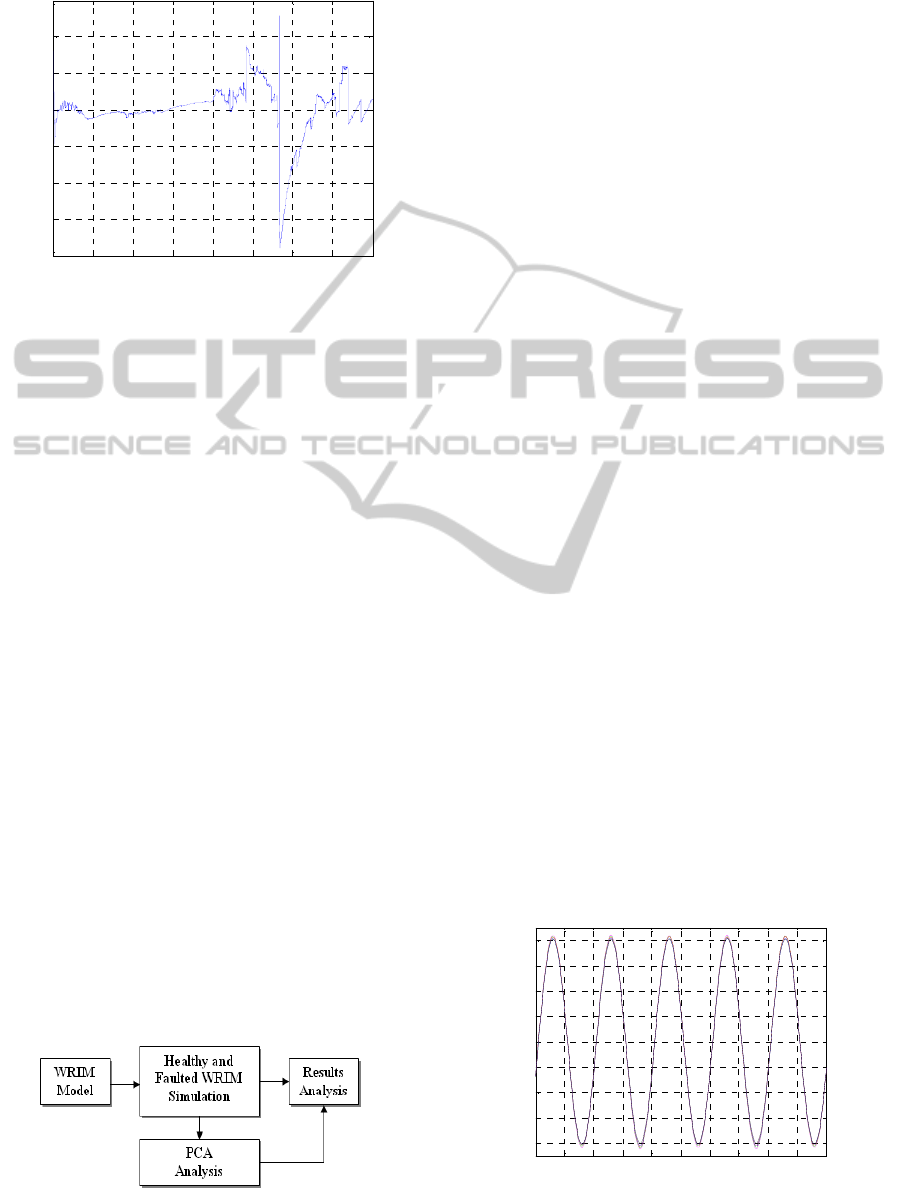

The WRIM data simulation approaches with the

PCA method are given by the following figure:

Figure 7: Synoptic diagram of the different steps of the

data treatment.

The simulation approach is divided in four blocs:

• WRIM modeling: mathematical equations

calculation and simulation.

• Simulations results: graph showing the output

states of the system (healthy and faulted operation)

• Simulations data: simulation results acquisition as

matrix form.

• PCA: data treatment and system diagnosis.

4.1 Considered Faults

In normal operation, a resistance value variation

compared to its nominal value (in ambient

temperature, 25°C) is considered as faulted machine

due to machine overload or coils fault (Razik, 2002).

The resistance versus the temperature is

expressed as:

)1(

0

TRR

Δ

+

=

α

(29)

0

R is the resistance value at T

0

= 25°C,

α

the

temperature coefficient of the resistance and

T

Δ

the

temperature variation.

4.2 Simulation Results

The different simulation results have been

performed with respect to the simulation conditions

mentioned earlier.

Figure 8 to figure 17 represent the real variations

without PCA method (Fig. 8 to Fig. 14) and the

residue variations with PCA application (Fig. 15 to

Fig. 17) of the faulted WRIM state variables in

considering stator faults.

With the WRIM state variables, other quantities

issued to their transformations have been calculated:

• quadrature axis and direct axis currents with Park

transformation,

•

α

axis and

β

axis currents with Concordia

transformation.

0 0.5 1 1.5 2 2.5 3 3.5 4

-8

-6

-4

-2

0

2

4

6

x 10

-7

Phase "A" stator current

Time [s ]

3.2 3.21 3.22 3.23 3.24 3.25 3.26 3.27 3.28 3.29 3.3

-8

-6

-4

-2

0

2

4

6

8

Stator phase "A" current [A]

Time [s ]

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

172

Figure 8: Real variations versus time of the stator current

of the healthy and faulted WRIM.

Figure 9: Real variations versus time of the rotor current

of the healthy and faulted WRIM.

Figure 10: Real variations versus time of the shaft

rotational speed of the healthy and faulted WRIM.

Figure 11: Real variations versus time of the

electromagnetic torque of the healthy and faulted WRIM.

Figure 12: Real variations of electromagnetic torque

versus the shaft rotational speed of the WRIM.

Figure 13: Real variations of

β

axis current versus the

phase

α

axis current of the stator phase.

Figure 14: Real variations of the quadrature axis current

versus the phase direct axis current of the stator phase.

Figure 15: Variations of the stator phase “A” current

residues versus time of the healthy and faulted WRIM.

2.5 3 3.5 4

-10

-8

-6

-4

-2

0

2

4

6

8

10

Rotor phase "a" current [A]

Time [s ]

2.5 3 3.5 4

287.5

288

288.5

289

289.5

290

Shaft rotational speed [rad/s]

Tim e [s ]

Healthy

10%

20%

30%

40%

2.8 2.82 2.84 2.86 2.88 2.9 2.92 2.94 2.96 2.98 3

10.3

10.35

10.4

10.45

10.5

Electromagnetic torque [Nm]

Tim e [s ]

40%

10%

20% 30%

Healthy

287.5 288 288.5 289 289.5 290

10.3

10.35

10.4

10.45

10.5

Electromagnetic torque [Nm]

Shaft rotational speed [rad/s]

40%

30%

20%

10%

Healthy

-15 -10 -5 0 5 10 15

-20

-15

-10

-5

0

5

10

15

20

Beta axis current [A]

Alpha axis current [A]

-15 -10 -5 0 5 10 15

-15

-10

-5

0

5

10

15

Quadrature axis current [A]

Direct axis current [A]

2.8 2.9 3 3.1 3.2 3.3 3.4

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

Phase "A" stator current

Time [s ]

Healthy

Faulted

2.8 2.9 3 3.1 3.2 3.3 3.4

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

Phase "a" rotor current

Time [s ]

PRINCIPAL COMPONENTS ANALYSIS METHOD APPLICATION IN ELECTRICAL MACHINES DIAGNOSIS

173

Figure 16: Variations of the rotor phase “a” current

residues versus time of the healthy and faulted WRIM.

Figure 17: Variations of electromagnetic torque residues

versus the shaft rotational speed residues of the WRIM.

4.3 Discussion

Several types of representations are used in the

signals processing domain, in particular for electrical

machines diagnosis. We can mention the temporal

representation (Fig. 8 to Fig.11, Fig. 15 and Fig. 17)

and the signal frequency analysis. Although they

have demonstrated their effectiveness, the state

variables representations between them also show

their advantages. They can be performed without

mathematical transformation (Fig. 12) and with

mathematical transformation (Fig. 13 and Fig. 14).

The latter representation type and the temporal

representation are confronted with the PCA method

application results (Fig. 15 to Fig. 17). Only the

simulation results with stator faults are presented

because the global behavior of the state variables in

both rotor and stator faults are almost similar.

For the temporal variations case, the rotor

currents (Fig. 9) and the shaft rotational speed (Fig.

10) are the variables which produce the most

information in presence of faults. The faults occur

on the rotor current frequency and the shaft

rotational speed magnitude.

Also, the electromagnetic torque variations

versus the shaft rotational speed clearly show the

WRIM operation zone in the presence of faults (Fig.

12). Contrary to this, the representations with

mathematical transformations (Fig. 13 and Fig. 14)

do not provide significant information due to the fact

that the stator currents remain almost unchanged in

the presence of faults (Fig. 8).

With PCA method application, all representation

types well show the differences between healthy and

faulted WRIM (Fig. 15 to Fig. 17). In the healthy

case, residues are zero. When faults appear, the

residue representations have an effective value with

an absolute value greater than zero.

In the figure 17, the healthy case is represented

by a point placed on the coordinate origins. Also,

one can show several right lines corresponding to

the faulted cases. This behavior is due to the

proportional characteristic of the considered faults.

PCA method proved so effective in electrical

machines faults detection. This requires a good

choice of the number of the principal components to

be retained so that information contained in residues

is relevant.

5 CONCLUSIONS

PCA method based on residues analysis has been

established and applied on WRIM diagnosis.

An accurate analytical model of the machine has

been proposed and simulated to performed the

healthy and faulted data for PCA approach need.

Several representations of nine state variables of

the machine have been analyzed. In the case of

temporal variation and without PCA, the rotor

current and the shaft rotational speed are the more

affected by the considered fault type. The

representations of the electromagnetic torque versus

the shaft rotational speed in both with and without

PCA approach show clearly the presence of faults.

Indeed, PCA method is interesting for all type of

representation compared to some other signal

processing types.

ACKNOWLEDGEMENTS

This research was supported by MADES/SCAC

Madagascar project. We are grateful for technical

and financial support.

REFERENCES

Wieczorek, M., Rosołowski, E., 2010. Modelling of

induction motor for simulation of internal faults,

Modern Electric Power Systems 2010, Wroclaw,

Poland MEPS'10 - paper P29.

Razik, H., 2002. Le contenu spectral du courant absorbé

par la machine asynchrone en cas de défaillance, un

état de l’art, La revue 3EI, n°29, pp. 48 - 52.

Chia-Chou, Y. & al., 2008. A Reconfigurable Motor for

Experimental Emulation of Stator Winding Interturn

and Broken Bar Faults in Polyphase Induction

Machines, IEEE transactions on energy conversion,

vol.23, n°4, pp. 1005-1014.

-0.4 -0.3 -0.2 -0.1 0 0.1 0.2 0.3 0.4 0.5 0.6

-0.4

-0.2

0

0.2

0.4

0.6

Electromagnetic torque

Shaft rotational speed

Healthy

40%10%20% 30%

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

174

Sin, M. L., Soong, W. L., Ertugrul, N., 2003. Induction

machine on-line condition monitoring and fault

diagnosis – a survey, University of Adelaide.

Negrea, M. D., 2006. Electromagnetic flux monitoring for

detecting faults in electrical machines, PhD, Helsinki

University of Technology, Department of Electrical

and Communications Engineering, Laboratory of

Electromechanics, TKK Dissertations 51, Espoo

Finland.

Kliman, G. B., Premerlani, W. J., Koegl, R. A., Hoeweler

D., 1996. A new approach to on –line fault detection

in AC motors, San Diego, in Proc. IEEE Industry

Applications Society Annual Meeting Conference, CA,

pp. 687-693.

Liu, L., 2006. Robust fault detection and diagnosis for

permanent magnet synchronous motors, PhD

dissertation, College of Engineering, The Florida

State University, USA.

Marx, B., Mourot, G., Maquin, D., Ragot, J., 2007.

Validation et réconciliation de données. Approche

conventionnelle, difficultés et développements,

Workshop Interdisciplinaire sur la Sécurité Globale,

WISG’07, Troyes, France.

Ku, W., Storer, R. H., Georgakis, C., 1995. Disturbance

detection and isolation by dynamic principal

component analysis. Chemometrics and Intelligent

Laboratory Systems, 30, pp. 179–196.

Huang, B., 2001. Process identification based on last

principal component analysis, Journal of Process

Control, 11, pp.19–33.

Li, W., Qin, S. J., 2001. Consistent dynamic pca based on

errors-in-variables Subspace identification, Journal of

Process Control, 11(6), pp. 661–678.

Benaicha, A., Mourot, G., Guerfel, M., Benothman, K.,

Ragot, J., 2010. A new method for determining PCA

models for system diagnosis, 18th Mediterranean

Conference on Control & Automation Congress

Palace Hotel, Marrakech, Morocco June 23-25, pp.

862-867.

Valle, S., Weihua, L., Qin, S. J., 1999. Selection of the

number of principal components: The variance of the

reconstruction error criterion with a comparison to

other methods, Industrial and Engineering Chemistry

Research, vol. 38, pp. 4389-4401.

Harkat, M. F., Mourot, G., Ragot, J., 2005. An improved

PCA scheme for sensor FDI: Application to an air

quality monitoring network, Preprint submitted to

Elsevier Science.

PRINCIPAL COMPONENTS ANALYSIS METHOD APPLICATION IN ELECTRICAL MACHINES DIAGNOSIS

175