CROSSLINKING BY PEROXIDE AND SULPHUR

VULCANIZATION: CHEMICAL MECHANISMS

AND REACTION KINETIC DETERMINATION

A Comprehensive Numerical Model

Gabriele Milani

Technical University of Milan, Piazza Leonardo da Vinci 32, 20133, Milan, Italy

Federico Milani

CHEMCO Consultant, Via J. F. Kennedy 2, 45030, Occhiobello, Rovigo, Italy

Keywords: Vulcanization, Kinetic model, Peroxides, Accelerated sulphur, Crosslinking, Mathematical model.

Abstract: The work presents a comprehensive numerical model to optimize mechanical properties of thick rubber

vulcanized items, comprising medium and high voltage electric cables and 3D devices. Several

vulcanization systems are considered, including peroxides and accelerated sulphur. In the case of peroxides,

both a genetic algorithm (GA) with zooming and elitist strategy and an alternating tangent (AT) approach

are adopted to determine the optimal final mechanical properties (tensile strength) of 2D and 3D rubber

items. The use of a mixture of peroxides is also taken into account, demonstrating that it helps in reducing

the curing time and/or in increasing the optimal tensile strength in both core and skin of thick devices. For

sulphur vulcanization, a mathematical kinetic model is presented to accurately predict the crosslinking

density of vulcanized rubber. It bases on the actual reactions occurring in practice and allows to estimate the

overall degree of vulcanization of real manufactured items.

1 INTRODUCTION

The matter of vulcanizing adequately thick rubber

items has been in the recent past largely under-

investigated, since the utilization was limited to

items with thicknesses not exceeding 5 mm. The

need of producing rubber insulators for medium and

high voltage electric cables have made critical the

problem of obtaining a sufficient vulcanization level

for thick items. As a matter of fact, for thick objects,

the skin results usually over-vulcanized whereas the

core remains essentially under-vulcanized.

Considering that the final mechanical properties

(elastic and inelastic) of the items are strongly

dependent on the degree of vulcanization, it can be

argued that the optimization of the vulcanization

production parameters (temperature and exposition

time) is critical. In particular, it has been widely

shown that final vulcanized rubber mechanical

properties (elastic modulus, tension set, tensile

strength, tear resistance, etc.) depend on the degree

of vulcanization.

In this framework, this paper presents a

comprehensive numerical model to optimize

mechanical properties of thick rubber vulcanized

items, comprising medium and high voltage electric

cables and 3D devices. Both peroxides and

accelerated sulphur vulcanization systems are

considered. In the case of peroxides, both a genetic

algorithm (GA) with zooming and elitist strategy

and an alternating tangent (AT) approach are

adopted to determine the optimal final mechanical

properties (tensile strength) of 2D and 3D rubber

items. The use of a mixture of peroxides is also

taken into account, demonstrating that it helps in

reducing the curing time and/or in increasing the

optimal tensile strength in both core and skin thick

items. While for peroxides the decomposition kinetic

is known, and hence the reticulation level is directly

dependent on the quantity of decomposed peroxide,

for accelerated sulphur a comprehensive kinetic

87

Milani G. and Milani F..

CROSSLINKING BY PEROXIDE AND SULPHUR VULCANIZATION: CHEMICAL MECHANISMS AND REACTION KINETIC DETERMINATION - A

Comprehensive Numerical Model.

DOI: 10.5220/0003543000870092

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2011), pages

87-92

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

model is still missing, Kresja & Koenig (1993). At

this aim, for sulphur vulcanization, a mathematical

kinetic model is presented to accurately predict the

crosslinking density of vulcanized rubber. Unknown

parameters of the model are numerically fitted

through experimental cure curves provided by the

rotor-less cure-meter RPM 2000 (ASTM D 5289)

and/or rotor cure-meter (ASTM D 2084-81).

2 HEAT EXCHANGE MODEL:

GOVERNING PARTIAL

DIFFERENTIAL EQUATIONS

Temperature profiles for each point of a generic item

can be obtained solving numerically a differential

equation field problem representing Fourier’s heat

equation law, which, in its general form, may be

written as:

0

2

rpp

p

pp

HrT

t

T

c

(1)

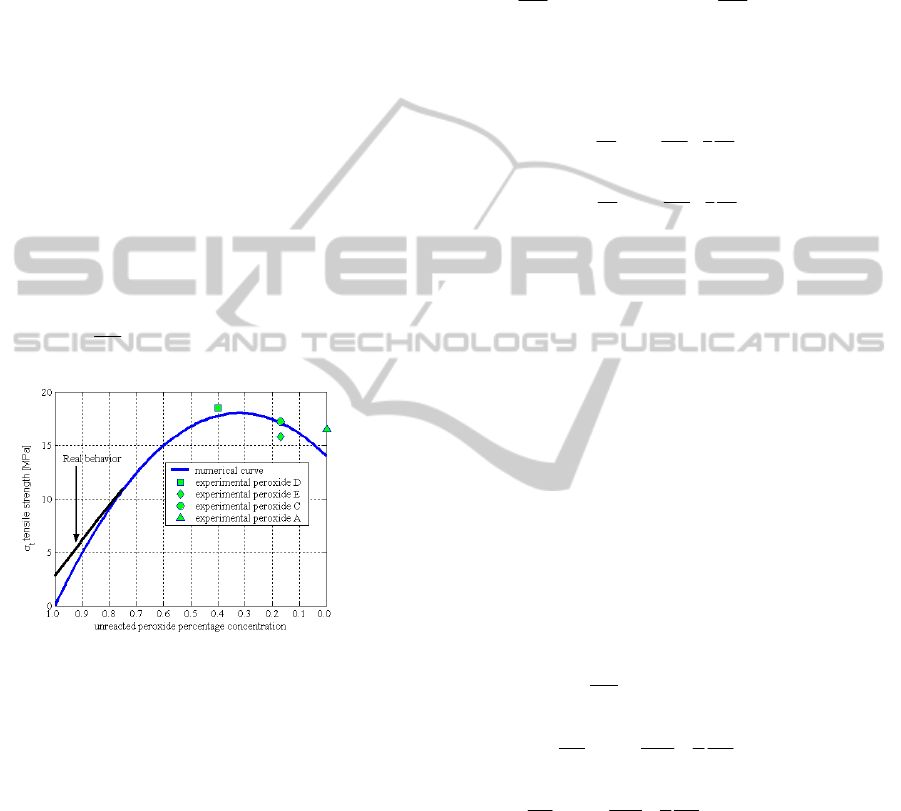

Figure 1: Non-linear behaviour of final tensile strength of

an item with respect to unreacted peroxide concentration.

Where

p

is the coefficient of thermal

conductivity,

p

p

c

is the specific heat,

p

is rubber

density,

r

H

is rubber specific heat (enthalpy) of

reaction,

p

r

is the rate of cross-linking. The term

rp

Hr

in equation (1) is the heat required by the

decomposition of the peroxide during peroxidic

crosslinking.

r

H

usually ranges from 120 to 180

kJ/mo

. From a technical point of view, the final

tensile strength of a vulcanized item does not

increase linearly with the curing time, but it passes

from a maximum as shown in Figure 1.

Optimal

T

ˆ

curves (expressed as implicit

functions in cure temperature

c

T

and

t

) can be

deter-

mined solving point by point the following

optimization problem:

max

max

11

0

0

tosubject

,

1

maxor,

1

max

tt

TT

tTF

N

tT

N

i

c

i

c

N

k

ii

c

k

t

L

N

k

ii

c

k

t

L

LL

conditionsinitialandboundary

0

1

0

1

systemPDEs

2

2

2

2

rpp

p

pp

j

p

jj

Hr

r

T

r

r

T

t

T

c

r

T

r

r

T

t

T

c

(2)

Where

L

N

is the number of layers in which the

insulator thickness is subdivided,

k

is the

k

-th

layer and

max

c

T

(

max

t

) is an upper bound limitation

for cure temperature (exposition time).

Two dedicated distinct models have been

developed and tested by the authors to solve (2), see

Milani & Milani (2008, 2009, 2010a) for algorithm

details. The first one is a non-standard genetic

algorithm (GA), whereas the second is an alternating

tangent approach (AT), described in detail hereafter.

When an expensive grid procedure is used, for

each point

ji

c

ji

tTP ,

,

of the grid, a mixed

algebraic-PDEs system is numerically solved by

means of the finite element method:

L

N

k

ji

c

k

t

L

t

tT

N

1

,

1

0

1

2

2

r

T

rr

T

t

T

c

j

p

jj

0

1

2

2

rpp

p

pp

Hr

r

T

r

r

T

t

T

c

+ initial and boundary conditions

(3)

2.1 Peroxidic Vulcanization

For EPM/EPDM the following peroxides are

ordinarily used (commercial names by Akzo):

Trigonox 101 (t

1/2

=0,1h at 171°C)(E), Perkadox BC

(t

1/2

=0,1h at 162°C)(C), Trigonox 29 (t

1/2

=0,1h at

138°C)(A) and Perkadox 14 (t

1/2

=0,1h at 169°C)(D).

As well known, peroxides decomposition kinetic is

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

88

of first order, i.e.

k

C

dtdC

/

. Peroxides follow the

Arrhenius equation and hence the reaction constant

is ruled by:

TR

E

g

a

eKTK

(4)

Where

K

and

a

E

are the only two constants to be

determined that define completely the behaviour of

the peroxide at different temperatures. Once known

2/1

t

at a given temperature, it can be easily shown

that:

TR

E

TR

E

g

a

g

a

eTtTt

~

2/12/1

/

~

(5)

Producers furnish, for each commercial peroxides,

values of

K

and

a

E

or, alternatively curves of

2/1

t

at different temperatures.

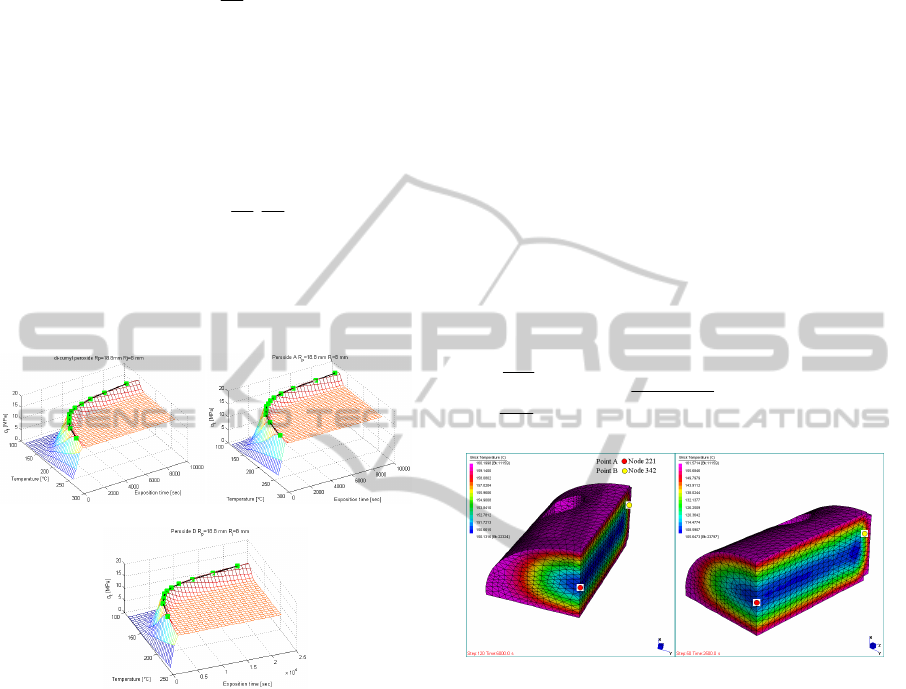

-a -b

-c

Figure 2: High voltage electric cables (green squares

represent GA optimization points). Cure time-

temperature-tensile strength surfaces. –a: di-cumyl-

peroxide C. –b: peroxide A. –c: peroxide D.

2.2 GA Numerical Results

In Figure 2-a,b,c rubber mean tensile strength at

different temperatures and exposition times is

reported for high voltage cables, assuming as

reticulation inducer three different peroxides. The

3D surface is obtained by means of the iterated

solution of problem (3 on an expensive regular grid

of points, whereas green squares represent the GA

best fitness points. As it is possible to notice, the

algorithm proposed is able to reach tensile maximum

strength with sufficient accuracy for all the

simulations performed.

A detailed comparison among all the results

underlines that peroxide choice is crucial. Each

peroxide, in fact, exhibits a different

0,

ˆ

tTT

c

behavior; in some cases, optimal curves

T

ˆ

are

sensibly different resulting in completely different

production line parameters to select during design.

For engineering interest, we have made

additional numerical simulations on realistic 3D

items using again the above GA, but with mixtures

of peroxides, with the aim optimizing again the

curing time and the tensile strength.

When a total initial concentration

0

C

of two

peroxides is present in the mixture, we assume that

each peroxide decomposes separately, following a

first order differential equation. Indicating with

index 1 and 2 peroxide 1 and 2 respectively and with

21

CCC

the sum of peroxides unreacted

concentrations, we obtain:

2211

21

22

2

11

1

CkCk

dt

CCd

Ck

dt

dC

Ck

dt

dC

(6)

Figure 3: Temperature profile of 3D item at

CT

c

160

. –

a: 6000 seconds. –b: 2500 seconds.

Obviously, during vulcanization,

tTT

and

therefore a numerical integration is needed for each

point of the items to vulcanize. In particular, a Finite

Element FEM approach (Evans et al. 2001) is used

to solve the 3D heat transmission problem. In order

to have an insight into this phenomenon, in Figure 3

temperature patches for a 3D docks bumper (only ¼

of the mesh is shown) are represented at 6000 and

2500 seconds, assuming

c

T

=160°C and highlighting

two different nodes with colored dots (one is a node

near the external surface, whereas the other belongs

to the internal core). In the simulations, a 50%-50%

percentage of Peroxide A and E is used.

Temperature-time, residual peroxides

concentration vs time and tensile strength diagrams

for the two nodes are reported in Figure 4, assuming

a curing time equal to 4400 seconds. As it is possible

CROSSLINKING BY PEROXIDE AND SULPHUR VULCANIZATION: CHEMICAL MECHANISMS AND

REACTION KINETIC DETERMINATION - A Comprehensive Numerical Model

89

to notice, Point A reaches a good level of

vulcanization (Figure 4-c left), which is also

addressed by the residual unreacted concentration of

one of the two peroxides (Figure 4-b left). On the

contrary, Point B results over-vulcanized (Figure 4

right), meaning that both peroxides residual

concentration is negligible. As one can note, it is

particularly evident the difference in the resulting

tensile strength at the end of the vulcanization

process.

Point A Point B

-a

-b

-c

Figure 4: Point a & b response. (-a)

t

-

T

, (-b)

t

-peroxide

concentration and (-c)

t

-

t

curves. In the case analyzed

5.0

.

2.3 Alternating Tangent Approach (AT)

The AT approach used in the case of the 3D item is

based on the numerical evaluation of tensile strength

first derivatives with respect to exposition time on

several sections at fixed curing temperatures T

c

and

in the iterated bisection of a determined exposition

time search interval.

At a fixed T

c

temperature, Figure 5, tensile

strength is evaluated on two starting points (points 1

and 2), usually placed at a very under-vulcanized

and a very over-vulcanized exposition time. First

derivatives

dtd

t

/

of tensile strength with respect to

exposition time are needed at the search interval

extremes and are determined through finite

differences.

Middle point first derivative of the search

interval is also needed.

Figure 5: Alternating tangent approach (AT) basic scheme.

Once that first derivatives are at disposal on the

search interval extremes and on the middle point, a

bisection procedure is adopted, reducing the search

interval to one-half. In particular, the new interval is

respectively the right or the left one half depending

on the sign of first derivatives of the extremes with

respect to the middle point one:

intervalsemileft0if

intervalsemiright0if

32

31

dt

d

dt

d

dt

d

dt

d

tt

tt

(7)

The procedure is repeated on the new reduced

interval, until a desired degree of accuracy is

obtained (yellow circle in Figure 5).

3 SULPHUR VULCANIZATION

Sulphur vulcanization chemistry is somewhat

complex and has not been well understood

throughout the century of the practice of the process

since its discovery by Goodyear (1844). In

particular, because of the prohibitive complexity of

the reactions induced by sulphur during crosslinking

-differently to peroxidic curing- no precise reaction

kinetics formulas are available in the technical

literature. However, for EPDM, the basic reactions

involved are commonly accepted to be the

following:

f

v

K

ve

K

vx

K

vv

KK

PPDPQPPPPAP

edcba

54321

*

1

*

1

)()()()()(

(8)

Where the symbols have the following meaning:

-

P

and

A

are the polymer (EPDM) and soluble

sulphureted zinc complex(S8 + accelerators +ZnO +

Step 0: evaluate first

derivative at points 1 and 2

1

2

Step 1: evaluate first

derivative at point 3 (mean

value between abscissae 1

and 2)

3

Step 3: select the new

extreme of the interval on

the bases of the sign of 3

first derivative (negative

1-3 positive 3-2)

4

Step 4: repeat Step 1

substituting original points

with the new extremes

5

Optimal point

Curing time t

t

t

Starting extremes

Extremes at successive iterations

L

L

L

'

L

'

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

90

stearic acid) respectively;

*

1

P

is the pendent sulphur

(crosslink precursor);

v

P

is the reticulated EPDM;

f

v

P

,

x

Q

and

e

D

are the matured cross-link, the

oxidation product and diaryl-disulphide respectively,

5,...,1

K

are kinetic reaction constants, which depend

only on reaction temperature.

Here it is worth noting that reaction (a) in (8)

represents an allylic substitution, reaction (b) is the

disproportionation, whereas reactions (c) (d) and (e)

occurring in parallel are respectively the oxidation,

the de-sulphuration and the de-vulcanization.

From a practical point of view, it is commonly

accepted that the variation of the cure-meter curve,

intended as the progressive increase of rotor

resistance during vulcanization, characterizes

macroscopically the rubber reticulation level.

3.1 Kinetic Model Proposed

Chemical reactions occurring during sulphur

vulcanization reported in Milani & Milani (2010b,

2011a and 2011b) obey the following rate equations:

v

v

v

e

v

x

vex

v

PK

d

t

dP

e

PK

dt

dD

d

PK

dt

dQ

c

PKDKQKPK

dt

dP

b

APK

dt

dP

a

f

f

5

4

3

543

*

12

1

(9)

Differentiating equation (9), after several trivial

arrangements, reticulation law can be written as:

APKK

dt

dP

KPK

dt

dP

K

dt

Pd

v

vv

212

2

2

2

2

~

(10)

being

2

5

2

4

2

35432

2

~

KKKKKKKK

.

The solution of (10) turns out to be:

tPK

tt

v

eKPKKPKPKK

eCeCtP

01

1

2

012

2

01

2

021

21

~

(11)

Provided that the homogeneous term is suitably

substituted with an exponential function, equivalent

to the original one in integral terms.

To fully solve the problem, it is necessary to

determine constants

1

C

and

2

C

. They are found

from initial conditions:

0000

*

2

0

PK

dt

dP

P

t

v

v

(12)

which lead to determine the concentration of

vulcanized polymer within the mixture during the

vulcanization range. The crosslinking density obeys

the following closed form equation:

2

5

2

4

2

35432

22

1

2

012

2

01

2

021

2

2

2

2

01

2

01

1

21

~~

~

~

2/

2

2

1

222

1

22

01

KKKKKKKKK

KPKKPKPKK

KK

K

PK

C

PK

C

eeCeCtP

tPK

tt

v

(13)

Kinetic constants to determine are only three, i.e.

1

K

,

2

K

and

2

~

K

.

The most straightforward method to have a

numerical estimation of kinetic constants is to fit

equation (13) on experimental scorch curve,

normalized scaling the peak value to

0

P

and

translating the initial rotation resistance to zero, as

suggested by Ding and Leonov (1996).

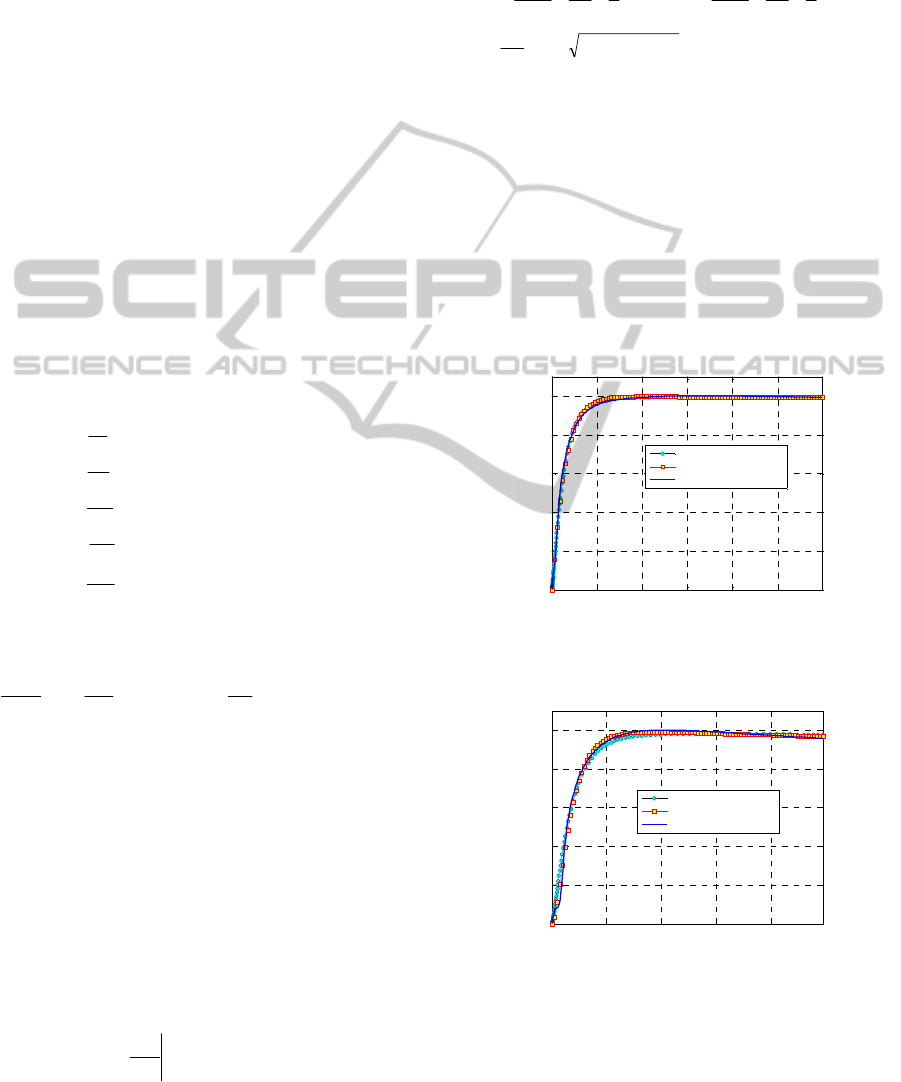

Figure 6: Dutral TER 4049 160°C. Comparison between

experimental data and the numerical models proposed.

Figure 7: Dutral TER 4049 200°C. Comparison between

experimental data and the numerical models proposed.

As a rule, variables

1

K

,

2

K

and

2

~

K

are

estimated through a standard nonlinear least square

routine. Since the problem is rather easy to handle, a

0 20 40 60 80 100

0

0.2

0.4

0.6

0.8

1

Tim e [mi n]

Normalized torque M

t

/M

tmax

Dutral TER 4049 160°C

ODEs system solution

Single DIFF-EQ solution

Experimental

0 2 4 6 8

0

0.2

0.4

0.6

0.8

1

Time [min]

Normalized torque M

t

/M

tmax

Dutral TER 4049 200°C

ODEs system solution

Single DIFF-EQ solution

Experimental

CROSSLINKING BY PEROXIDE AND SULPHUR VULCANIZATION: CHEMICAL MECHANISMS AND

REACTION KINETIC DETERMINATION - A Comprehensive Numerical Model

91

trust-region-reflective algorithm is used. This

algorithm is a subspace trust-region method and is

based on the interior-reflective Newton method.

Each iteration involves the approximate solution of a

linear system using the method of preconditioned

conjugate gradients (PCG).

3.2 Numerical Simulations

To assess model results, some experimental data

available, Milani & Milani (2011b) (cure-meter

curves for a commercial blend called Dutral TER

4049) are considered as reference data. To perform a

numerical optimization of the kinetic model

proposed, experimental cure values are normalized

dividing each point of the curve by the maximum

torque values, so that experimental data are always

within the range 0-1. In Figure 6 and Figure 7, a

comparison between cure curves provided by the

present approach and experimental results is

sketched for Dutral TER 4049, for a temperature

equal to 160°C and 200°C. Data for 180°C are also

available, but are not reported here for the sake of

conciseness.

As it is possible to notice, an almost perfect

agreement between the experimental data and the

numerical procedure proposed is found in both

cases, meaning that the simple second order

differential equation model proposed may represent

a valuable tool for all practitioners interested in a

fast evaluation of the reticulation degree of rubber

compounds vulcanized with accelerated sulphur.

4 CONCLUSIONS

From the results presented in this paper, the

following conclusions can be drawn:

1. Both the GA and the AT approaches are able to

determine optimal input parameters to optimize the

production of medium and high voltage power

cables, as well as of thick 3D items.

2. Numerical simulations have shown how different

mixtures of peroxides may: a) reduce optimal curing

time at almost constant optimized tensile strength or

b) increase optimal tensile strength with an

acceptable increase of curing time. Therefore, the

numerical procedure proposed may represent a

valuable tool for practitioners to obtain high quality

vulcanized items, limiting total curing time required.

3. For sulphur vulcanization, we have proposed a

mathematical kinetic model to predict EPDM

compounds reticulation level, which is based on a

best fitting procedure of experimental cure curves

obtained through rubber process analyzers (RPA

2000) following the ASTM D 5289 method or

ASTM D 2084-81 in a predetermined temperature

range. A simple second order non homogeneous

differential equation model has been derived directly

from the partial reactions occurring in series and

parallel during vulcanization with accelerated

sulphur. The model has demonstrated good

performance when compared to experimental cure-

curves available from a previous experimentation by

the authors.

REFERENCES

ASTM D 2084-81 and ASTM D 5289, Standard Test

Methods for Vulcanized Rubber and Thermoplastic

Elastomers.

Brydson, J. A., 1988. Rubbery Materials and Their

Compounds, Elsevier Science Publishers LTD, Essex.

Ding, R., Leonov, I., 1996. A kinetic model for sulfur

accelerated vulcanization of a natural rubber

compound. Journal of Applied Polymer Science, 61:

45.

Evans, G., Blackledge, J., Yardley, P., 2001. Numerical

methods for partial differential equations. Springer-

Verlag, Berlin, 2nd edition.

Goodyear, C., 1844. US Patent 3633.

Kresja, M. R., Koenig, J. L., 1993. A review of sulphur

cross-linking fundamentals for accelerated and

unaccelerated vulcanization.Rubber Chemistry and

Technology, 66: 376.

Milani, G., Milani, F., 2008. Genetic algorithm for the

optimization of rubber insulated high voltage power

cables production lines. Computers & Chemical

Engineering, 32: 3198-3212.

Milani, G., Milani, F., 2009. Optimization of power cable

production lines for EPM/EPDM elastomers by

Genetic Algorithm with different peroxides. Journal of

Applied Polymer Science, 111(1): 482-507.

Milani, G., Milani, F., 2010b. Optimal vulcanization of

2D-3D EPM/EPDM thick elements through peroxidic

mixtures. Journal of Mathematical Chemistry 47(1),

pp. 229-267.

Milani, G., Milani, F., 2010a. A new simple numerical

model based on experimental scorch curve data fitting

for the interpretation of sulphur vulcanization. Journal

of Mathematical Chemistry, 48: 530–557.

Milani, G., Milani, F., 2011a. A three function numerical

model for the prediction of vulcanization-reversion of

rubber during sulphur curing. Journal of

AppliedPolymer Science, 119(2), pp. 419–437.

Milani, G., Milani, F., 2011b. Simple kinetic model fitting

rheometer data for EPDMacceleratedsulphur. Under

review.

Treloar, L. R. G., 1975. The Physics of Rubber

Elasticity,3d ed., Clarendon Press, Oxford.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

92