ATMOSPHERE CONTROL BY CHEMORESISTIVE

POLYMER COMPOSITES

Gita Sakale, Maris Knite, Marika Novada, Elina Liepa, Santa Stepiņa

Institute of Technical Physics, Riga Technical University, Azenes Street 14/24, Riga, Latvia

Velta Tupureina

Institute of Polymer Materials, Riga Technical University, Azenes Street 14/24, Riga, Latvia

Keywords: Chemoresistive composite, Volatile organic compounds, Carbon nanoparticles.

Abstract: This work reports about polymer-nanostructured carbon composite (PNCC) and it possible application for

relative humidity registration and volatile organic compound (VOC) detection in the air. PNCC have been

produced using high structured carbon black (HSCB) nanoparticles and polyisoprene (PI), ethylene-

vinylacetate (EVA) copolymer, polyvinylacetate (PVAc), polyethylene glycol (PEG) and polyvinylalcohol

(PVA). Matrix material for composite production has been selected with respect to desired analyte to bee

tested. Composites show selective response to particular species of analytes vapour. It has been found that

humidity sensing mechanism changes from proton conductivity to electron tunnelling by addition of HSCB

to PVA matrix. Plasticizer effect on PVAc-NCC ethanol vapour sensitivity has been evaluated.

1 INTRODUCTION

In the spotlight of scientific research are different

kind of sensor materials for odour detection and

inspection. Metal oxide (ZnO, SnO ect.) sensor

materials are already proved themselves as good

sensing materials for detection of ethanol, CO

2

, etc.

and are widely utilized (Yang et al., 2009; Trinh et

al., 2011). Conductive polymers and chemoresistive

polymer composites show multiple VOC selectivity

at room temperature (Kang et al., 2010; Wang et al.,

2010). The greatest selectivity with possibility to

distinguish even individual odour molecules can be

obtained by molecularly imprinted polymers and

biosensors (Van Dorst et al., 2010). With increasing

sensitivity of produced sensor materials,

consequently, application field also enlarges from

environmental control (VOC leakage detection in

chemical and petrochemical industry) to agricultural

(diagnosis of plant disease), food industry (food

quality, storage life, freshness) and medicine

(diagnosis of disease). Mahmoudi (Mahmoudi,

2009) has reported that microbial organisms such as

fungi and bacteria can grow and generate VOC

including different alcohols, aldehydes, ketones,

aromatic compounds, amines, terpenes, chlorinated

hydrocarbons and sulphuric compounds while

metabolizing nutrients. It means that VOC can be a

biomarker for early stage diagnostic of human

diseases or microbial organism discovery in food

and wood.

It is already a well known practice to impart to

polymer conductivity by dispersing conductive

particles in it. When conductive particles are

dispersed in isolating matrix, continuous conductive

network through matrix is formed either by

geometrical or tunnelling contact between particles.

If the composite is exposed to VOC, particles

aggregate forming conductive network are

withdrawn from each other by VOC induced

isolating polymer matrix swelling. Consequently,

electrical resistance of the composite increases and

the presence of VOC can be detected.

Here is presented a polymer/HSCB composite

film capability to selectively detect different VOC or

register relative humidity of the environment. The

influence of structural state of composite matrix

material (rubbery, viscoelastic, crystalline) on VOC

sensitivity is analyzed. Two different relative

humidity sensing mechanisms existing in PVAc-

NCC are described. Also attempts to improve

PVAc-NCC ethanol vapour sensitivity by addition

370

Sakale G., Knite M., Novada M., Liepa E., Stepina S. and Tupureina V..

ATMOSPHERE CONTROL BY CHEMORESISTIVE POLYMER COMPOSITES.

DOI: 10.5220/0003544603700375

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 370-375

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

of plasticizer are demonstrated.

2 MATERIALS AND METHODS

Polymers for PNCC production were selectively

chosen. PI has been selected as highly non-polar

matrix with a purpose to detect non-polar VOC. On

the contrary PEG, PVAc was selected as highly

polar matrix to detect polar VOC like methanol,

ethanol, propanol, butanol, formamide, acetone,

methyl ethyl ketone etc. PVA was chosen for highly

polar solvent vapour presence determination. As

EVA copolymer contains non-polar part – ethylene

and polar part - 29.7% vinyl acetate, it was picked

up to produce composite, which could sense both

polar and non-polar solvents.

For all produced composites high structured

carbon black PRINTEX XE2 (mean diameter 30 nm,

DBP absorption - 380 ml/100 g, BET surface area -

950m

2

/g) as conductive filler was used. Firstly,

HSCB was dispersed in appropriate solvent using

Hielscher UP200S ultrasound homogenizer. Specific

power 1W/ml was applied for 5 minutes. Secondly,

the HSCB dispersion in solvent was added to a

polymer solution in the same solvent. Magnetic

stirring for 1 to 24 hours were applied. After

magnetic stirring polymer-HSCB mixture was

coated on epoxy laminate substrate with copper or

brass wire (in case of PI-NCC) electrodes. The

composite layer on epoxy laminate substrate was

obtained by repeated immersion of the epoxy

laminate into the mixture and subsequent solvent

evaporation from the film. Immersion-evaporation

cycles were repeated up to 4 times. PI-NCC after

solvent evaporation was cured under 30 atm pressure

at 150

o

C for 15 minutes. Brass wire electrodes were

selected for PI-NCC production because at the time

of curing chemical bonds between polyisoprene

rubber and brass wires are formed, which ensures

excellent composite adhesion to electrodes.

Produced samples were in size 10x14mm (width x

length) and with varying thickness.

For PVA-NCC production slightly different

production method was used. Firstly, PVA was

dissolved in water for 6h at 80

o

C. Secondly, HSCB

was dispersed in distilled water using Hielscher

UP200S ultrasound homogenizer. Specific power

2.5W/ml was applied for 5minutes. Thirdly, HSCB

suspension in water was added to 20ml of 10% PVA

solution in water. Obtained mixture was stirred with

glass beads for 10 minutes. The mixture was purred

out in Petri dishes. To obtain hydrogel from the

mixture, it was subjected to repeated freezing (12h at

-12

o

C) and thawing (12h at +25

o

C) cycles. Cycles

were repeated 3 times. Samples with dimensions

5x50x0.3mm were used for measurements. At the

time of freezing and thawing hydrogen crosslinks

are formed in PVA (Stasko, J., Kalnins, M., Dzene,

A., Tupureina, V., 2009). These physical crosslinks

prevents PVA from dissolution in water.

HSCB content in PI-NCC was varied form 2.2 to

6.6 phr (parts per hundred rubber). In case of PEG-

NCC, PVAc-NCC, EVA-NCC HSCB was held

constant 10 parts per hundred polymer (php) and

9php for PVA-NCC, respectively.

3 RESULTS AND DISSCUSION

3.1 Evaluation of Polymer Matrix

Structural State

PEG with molecular weight 40000 was used for

PEG-NCC production. Hydroxyl end groups in

chemical structure of PEG determine it polar nature

(ε =3.37), and single polymer backbone without side

branches ensures highly crystalline (92%) structure

formation.

PVAc with molecular weight 101600 was used

for PVAc-NCC production. PVAc has relatively

large acetate side groups, which act as steric

hindrance for three dimensional structure formation

of PVAc. As a result PVAc has amorphous

structure. EVA copolymer structure is composed of

ethylene and vinylacetate repeating units.

Introduction of vinylacetate in ethylene structure

leads to reduced copolymer crystallinity.

Differential scanning calorimetry (DSC) was used

for matrix material structural state analyzes, when it

is pure as well as in composite content. DSC

measurements were carried out only for composites

indented for detection of polar VOC (see Table 1).

Glass transition temperature (T

g

) and crystallinity

has been chosen as parameters for evaluation

because both greatly influence the composite VOC

sensitivity. T

g

indicate how flexible are polymer

macromolecules at room temperature. As lower

value of Tg as more rubbery like amorpous polymer

is and more flexible are polymer macromolecules.

Therefore more rapidly segmental motions of the

polymer can be performed by absorption of analyte.

VOC molecule absorption and polymer swelling

would be more favourable by hyperelastic than by

stiff and brittle matrix. Segmental motions can be

made more easily in amorphous structure than in

closely packed crystalline. It is seen in Table 1, that

crystallinity of EVA and PEG decreases, when

ATMOSPHERE CONTROL BY CHEMORESISTIVE POLYMER COMPOSITES

371

HSCB are introduced in polymer matrix. It seems

like that electroconductive grid formed by HSCB

particles in matrix acts as hindrance for polymer

crystallization. Crystallinity of EVA and EVA-NCC

has been calculated using heat of fusion of 100%

crystalline polyethylene 293.6 J/g (on line data

base). Crystallinity of PEG and PEG-NCC has been

determined using heat of fusion of 100% crystalline

PEG 196.8 J/g (Nalawade, Picchioni, Janssen,

2007). HSCB addition to EVA and PEG has no

significant effect on T

g

. On the contrary addition of

HSCB to PVAc matrix has notable effect on T

g

,

which changes from 39.07

0

C to 3.28

0

C. It means

that PVAc chain mobility enhances with addition of

HSCB. Similar decrease of T

g

by addition of B

2

O

3

,

Al

2

O

3

or SiC to polymer have been observed by

Sundar and others (Sundar, Selladurai, 2006;

Ahmad, et. al 2009; Koo Choi, Hee Shin, 1996).

Table 1: DSC results of pure polymers and composites.

Material T

g

,

0

C Crystallinity, %

PVAc 39.07 -

PVAc-NCC 3.28 -

EVA -25.35 7.4

EVA-NCC -25.99 1.5

PEG -60.55 92

PEG-NCC -59.47 67.5

3.2 Composite Film Thickness Impact

on Sensitivity

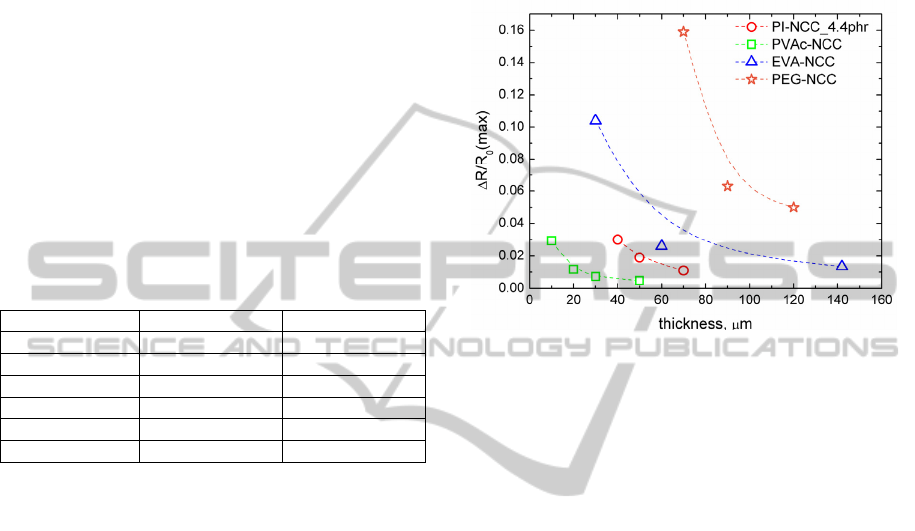

PI-NCC, PEG-NCC, EVA-NCC and PVAc-NCC

electrical resistance response to VOC has been

determined (Fig.1). PI-NCC was exposed to non-

polar solvent - toluene, but PEG-NCC, EVA-NCC

and PVAc-NCC to polar solvent - ethanol vapour.

Data available in Fig.1 indicate that the best ethanol

vapour sensitivity has PEG-NCC followed by EVA-

NCC and PVAc-NCC. It can be seen that PEG-NCC

and EVA-NCC change in thickness has greater

impact on vapour sensitivity than PVAc-NCC and

PI-NCC.

Let us analize now VOC sensitivity of

composites versus thickness regarding its structural

state. As determined by DSC the EVA-NCC is

slightly crystalline and the PEG-NCC is highly

crystalline. Both these composites show greater

thickness impact on VOC sensitivity, than

amorphous polymer composites like PVAc-NCC

and PI-NCC. Explanation could be as follows. If the

composite film is rather thick, then larger crystalline

structures have been grown during formation of the

sample. These larger crystalline structures are harder

to dissolve by absorbed VOC. In amorphous

polymer structures exist a lot of free volume

cavities, where diffusion of analyte occurs. But in

crystalline polymer structures there are remarkably

less free volume cavities. Analyte diffusion in the

composite can take place only by dissolution of

crystalline structure, molecule rearrangement and

free volume cavities formation.

Figure 1: Relative electrical resistance change in VOC

versus composite thickness. PI-NCC samples exposed to

toluene (0.008ml/l). PVAc-NCC, EVA-NCC and PEG-

NCC samples exposed to ethanol (0.1ml/l).

3.3 Selective Detection of VOC

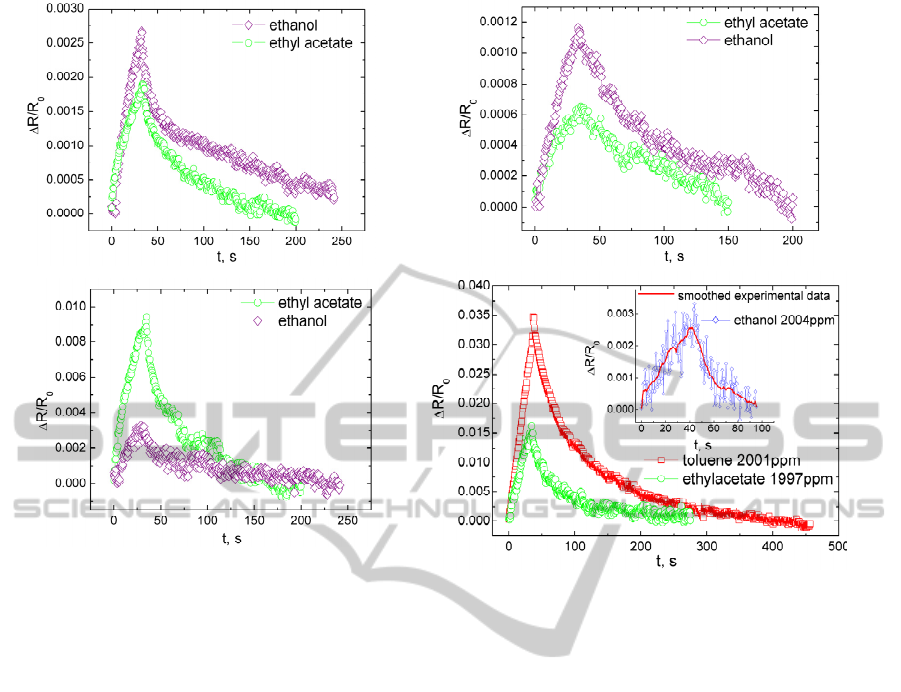

PEG-NCC, PVAc-NCC, EVA-NCC and PI-NCC

selectivity to one specific class of solvents (polar or

non-polar) has been determined. Relative electrical

resistance change of PEG-NCC, PVAc-NCC and

EVA-NCC exposed to the same concentration

(~9100ppm) of polar (ethanol) vapour and weakly

polar (ethyl acetate) vapour is shown in Fig.2 (a, b, c).

Because of PEG-NCC and PVAc-NCC polar

matrix nature greater electrical resistance change can

be observed, when composites are exposed to

ethanol vapour. EVA-NCC shows sufficient

sensitivity to both ethanol and ethyl acetate vapour.

It is related to dual nature of EVA matrix. Rather

great part of EVA is ethylene (70.3%), therefore also

good sensitivity to ethyl acetate is observed. In Fig.2

(d) can be seen that PI-NCC has high sensitivity to

non-polar VOC, but electrical resistance response to

polar VOC is weak and dissipated.

Advantage of our produced composites

comparing to other polymer/conductive filler

composites is good sensitivity and fast reversibility

even if the composite is exposed to quite large VOC

concentrations (~9100ppm) (Choudhury, 2009).

Obtained results in Fig.2 evidence that grater role

plays matrix material compatibility with VOC than

the structural state of matrix material. PEG-NCC is

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

372

b

)

)

d)

a

)

Figure 2: PEG-NCC (a), PVAc-NCC (b), EVA-NCC (c) relative electrical resistance change versus time, when samples

exposed to ethanol (9069ppm) and ethyl acetate (9105ppm). PI-NCC (d) relative electrical resistance change versus time,

when sample exposed to different VOC. Thickness of tested samples were as follows: PEG-NCC 110µm, PVAc-NCC

40µm, EVA-NCC 80µm and PI-NCC 40µm.

the most crystalline of all tested composites, but it

shows unexpectedly good VOC sensitivity due to

more polar like nature than PVAc-NCC and EVA-

NCC.

If we compare PI-NCC and PEG-NCC, PVAc-

NCC and EVA-NCC ethyl acetate sensitivity, then

we can observe that PI-NCC has greater relative

electrical resistance change than PEG-NCC, PVAc-

NCC and EVA-NCC. Even the PI-NCC is exposed

to reduced ethyl acetate concentration. But electrical

resistance relaxation time for PI-NCC is similar to

other tested composites. It is a challenge in future to

produce sensor material on the base of polymer

composite with highest possible sensitivity and with

as short as possible relaxation time. Fast recovery of

sensor material after analyte detection is very

important for alarm systems to exclude delayed

warning of VOC leakage. More adequate

comparison of PEG-NCC, EVA-NCC, PVAc-NCC

and PI-NCC responses will be made, when

percolation threshold for PEG-NCC, EVA-NCC,

PVAc-NCC will be determined and the most

sensitive polymer/HSCB composition found.

3.4 PI-NCC VOC Sensitivity Versus

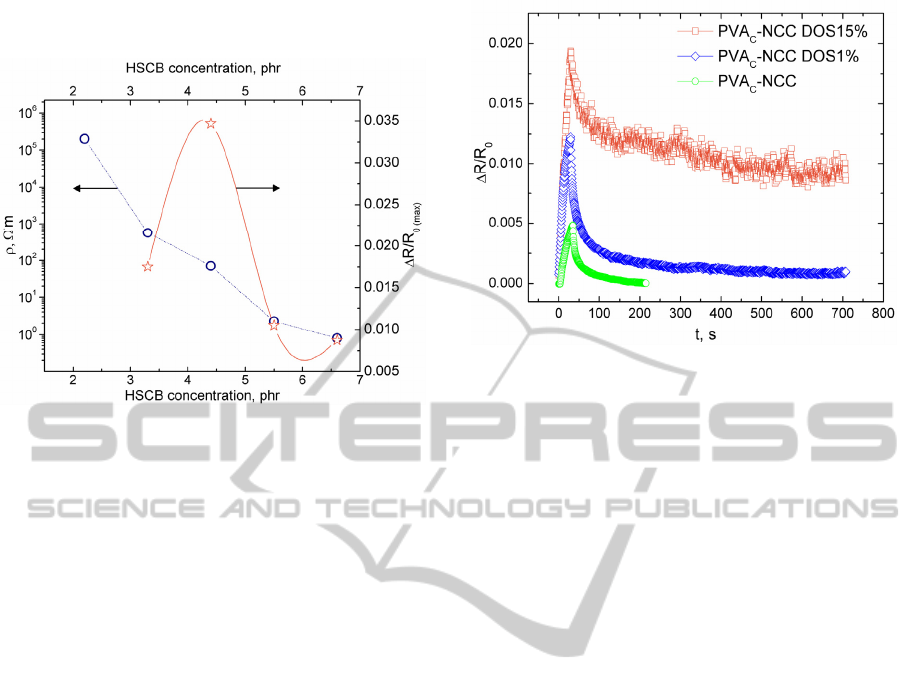

HSCB Content

PI-NCC has been produced varying content of

HSCB from 2.2 to 6.6phr. PI-NCC transition from

isolator to electro conductive composite is shown in

Fig.3. PI-NCC specific electrical resistance

decreases with development of percolative HSCB

structure. Maximal relative electrical resistance

change of PI-NCC exposed to toluene vapour is also

displayed in Fig.3. Samples were held in vapour for

30s and then left in the air for electrical resistance

relaxation. Maximal relative electrical resistance

change is the highest obtained value of ΔR/R

0

, when

PI-NCC sample exposed to toluene vapour for 30s.

PI-NCC response to vapours are immediate,

electrical resistance starts to increase at the moment

of samples introduction to vapour. VOC sensor

effect of PI-NCC is reversible. Electrical resistance

of the composite PI-NCC_4.4phr shows the best

sensitivity. It is characteristically for

polymer/conductive nanoparticle composites to

exhibit the highest sensitivity in vicinity of isolator-

ATMOSPHERE CONTROL BY CHEMORESISTIVE POLYMER COMPOSITES

373

conductor transition (slightly above percolation

threshold).

Figure 3: PI-NCC specific resistance versus HSCB

concentration and PI-NCC toluene vapour sensitivity

(ΔR/R

0(max)

) versus HSCB loading in the composite.

Thickness of samples is 40µm. Toluene vapour

concentration is 2001ppm.

3.5 Plasticizer Impact on PVAc-NCC

Sensitivity

The worst ethanol vapour sensitivity has been

determined for PVAc-NCC despite the fact that

PVAc-NCC samples were produced with the

smallest thickness (Fig.1). It is not clear why EVA-

NCC shows better ethanol vapour sensitivity than

PVAc-NCC? Copolymer for EVA-NCC production

contains only 29.7% vinyl acetate. This can be

explained as fallow. When in a flexible (ethylene)

backbone stiff units (vinyl acetate) are introduced,

the stiff units are able to move, rearrange faster

under external influence.

We decided that PVAc still has insufficient

polymer chain mobility. Plasticizers can improve it.

1% and 15% of plasticizer di-n-octyl sebacate

(DOS) was added to PVAc-NCC and ethanol sensor

effect has been determined. Obtained results are

summarized in Fig.4. All tested samples were

exposed to ethanol vapour for 30s and then left in

the air for electrical resistance relaxation. The

plasticizer addition to the composite significantly

improves PVAc-NCC ethanol vapour sensitivity.

But PVAc-NCC electrical resistance reversibility

worsens at high plasticizer loadings.

Figure 4: Relative electrical resistance change for PVAc-

NCC with different DOS content. Thickness of samples is

50µm. Ethanol vapour concentration is 0,11ml/l.

3.6 PVA-NCC Sensitivity to Relative

Humidity

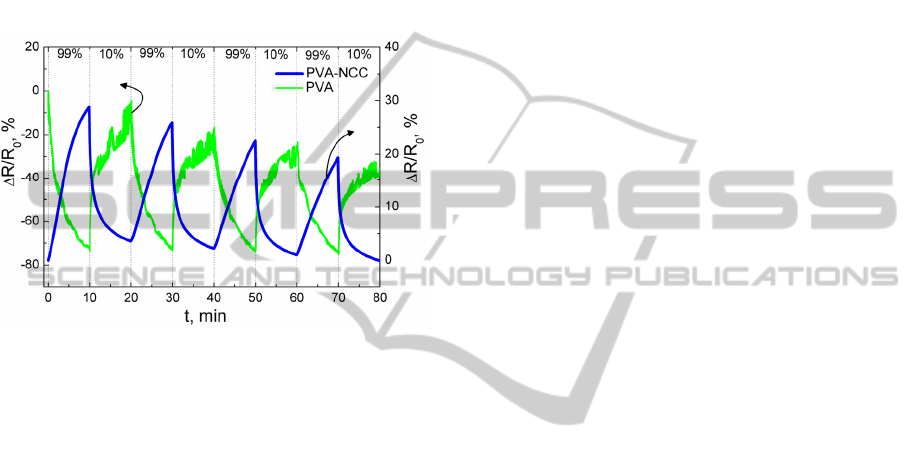

Pure PVA and PVA-NCC electrical resistance

change was registered sequentially exposing samples

to 99% and 10% relative humidity (RH) (Fig. 5).

99% and 10% RH was obtained by using K

2

SO

4

and

ZnCl

2

oversaturated salt solution in water. Electrical

resistance of pure PVA decreases, when it is

exposed to 99% RH. On contrary, PVA-NCC

electrical resistance increases. Totally different RH

sensing mechanisms can explain such difference in

electrical resistance responses.

PVA consists of [–CH

2

-CH(OH)-]

n

repeating unit.

OH side group attached to the second C atom

determines PVA high hydrophilicity. If PVA is

exposed to high RH, water molecules adsorbe on the

surface by bonding to PVA OH side groups. It is

known that water normally exists as a mixture of

molecules, hydroxide ions (OH

-

) and hydronium

ions (H

3

O

+

). The third H

+

ion of hydronium ion can

perform hopping between adjacent adsorbed water

molecules. As a result proton conductivity is

realized in PVA and electrical resistance of pure

PVA at elevated RH decreases.

PVA-NCC case is more complicated. It is believed

that in PVA-NCC coexist two sensing mechanisms,

which counteract to each other. The first sensing

mechanism is the same as for pure PVA, that is,

proton conductivity. The second sensing mechanism

is charge tunnelling. There we should remember that

the composite consists of PVA with homogenously

dispersed HSCB. The HSCB nanoparticles form

conductive network throughout PVA matrix. When

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

374

water molecules are adsorbed by highly hydrophilic

PVA, it swells and HSCB aggregates are withdrawn

from each other. As a result tunnelling currents in

thin layers of PVA between HSCB aggregates

decreases and PVA-NCC electrical resistance

increases.

For both PVA and PVA-NCC RH sensitivity

decreases with each measuring cycle. It can be

related to PVA great hydrophilic nature, at the time

of electrical resistance relaxation not all water

molecules are desorbed from PVA matrix.

Figure 5: Relative electrical resistance change versus time

of pure PVA and PVA-NCC, when samples were

sequentially exposed to 99% and 10% RH.

4 CONCLUSIONS

In this work possibility to use polymer

chemoresistive composites for VOC detection and

RH registration have been presented and following

conclusions can be made. Selectivity of the

composite can be managed with respect to desired

analyte. Sensitivity of the composite with stiff

polymer matrix can be greatly increased by addition

of plasticizer. The most sensitive VOC sensor

material can be obtained by choosing composite

with composition at the vicinity of percolation

threshold. In PVA-NCC two electrical resistance

change mechanisms exist, which compete to each

other. Composite matrix compatibility with analyte

vapour has greater influence on composite

sensitivity than composite material structural state.

Future research work would be devoted to

percolation transition determination for PEG-NCC,

PVAc-NCC and EVA-NCC.

ACKNOWLEDGEMENTS

This research was supported by Latvian National

Programme in Materials Science.

This work has been supported by the European

Social Fund within the project “Support for the

implementation of doctoral studies at Riga Technical

University”.

REFERENCES

Yang, Z. et al., 2009. Ethanol gas sensor based on Al-

doped ZnO nanomaterial with many gas diffusing

channels. Sensors and Actuators B: Chemical, 140(2),

pp.549-556.

Trinh, T. T. et al., 2011. Improving the ethanol sensing of

ZnO nano-particle thin films—The correlation

between the grain size and the sensing mechanism.

Sensors and Actuators B: Chemical, 152(1), pp.73-81.

Kang, N. K. et al., 2010. Evaluation of the limit-of-

detection capability of carbon black-polymer

composite sensors for volatile breath biomarkers.

Sensors and Actuators B: Chemical, 147(1), pp.55-60.

Wang, Y. et al., 2010. Flexible gas sensors with assembled

carbon nanotube thin films for DMMP vapor

detection. Sensors and Actuators B: Chemical, 150(2),

pp.708-714.

Van Dorst, B. et al., 2010. Recent advances in recognition

elements of food and environmental biosensors: a

review. Biosensors & Bioelectronics, 26(4), pp.1178-

1194.

Mahmoudi, E., 2009. Electronic Nose Technology and its

Applications. Sensors & Transducers Journal, 107 (8),

pp. 17-25.

Stasko, J., Kalnins, M., Dzene, A., Tupureina, V., 2009.

Poly(vinyl alcohol) hydrogels. Proceedings of the

Estonian Academy of Sciences, 58 (1) pp. 63–66.

Online data base http://athas.prz.rzeszow.pl/Default. aspx?

op=db

Nalawade, S., Picchioni, F. & Janssen, L., 2007. Batch

production of micron size particles from poly(ethylene

glycol) using supercritical CO

2

as a processing

solvent. Chemical Engineering Science, 62(6),

pp.1712-1720.

Sundar, M., Selladurai, S., 2006. Effect of fillers on

magnesium–poly (ethylene oxide) solid polymer

electrolyte. Ionics, 12 (4-5), pp.281-286.

Choudhury, A., 2009. Polyaniline/silver nanocomposites:

dielectric properties and ethanol vapour sensitivity.

Sensors and Actuators B, 138, pp. 318–325.

Ahmad, A., et. al 2009. Preparation and characterization

of PVC-Al

2

O

3

-LiClO

4

composite polymeric

electrolyte. Sains Malaysiana, 38 (4), pp.483–487.

Koo Choi, B., Hee Shin, K., 1996. Effects of SiC fillers on

the electrical and mechanical properties of

(PEO)

16

LiClO

4

electrolytes. Solid State Ionics, 86-88

(1), pp. 303-306.

ATMOSPHERE CONTROL BY CHEMORESISTIVE POLYMER COMPOSITES

375