PARAMETER ESTIMATION OF AN INDUSTRIAL EVAPORATOR

WITH HYBRID DYNAMICS BY A SMOOTHING APPROACH

Ines Mynttinen

1

, Erich Runge

2

and Pu Li

3

1

Institute of Automation and System Engineering, Technische Universit¨at Ilmenau

Gustav-Kirchhoff-Strasse 1, Ilmenau, Germany

2

Institute of Physics, Technische Universit¨at Ilmenau, Weimarer Strasse 32, Ilmenau, Germany

3

Department of Computer Science and Automation, Technische Universit¨at Ilmenau, Ilmenau, Germany

Keywords:

Parameter estimation, Dynamic optimization, Hybrid systems, Smoothing method.

Abstract:

Evaporation systems are essential in process industries. Due to phase transitions and changes of operating

modes these systems has to be classified as hybrid systems and the simulation and optimization based on

detailed models is often a challenging if not an intractable task. In this study we apply a smoothing approach

in order to modify the hybrid model such that the discrete transitions are integrated into a system of differential

algebraic equations leading to exclusively smooth trajectories. The simulation results of the smooth model are

compared to those of the original hybrid model. With a view to parameter estimation the sensitivity with

respect to the smoothing parameter as well as the parameters to be estimated are calculated. The parameter

estimation is carried out for the smooth model and the dependence of the optimization results on the smoothing

parameter is investigated.

1 INTRODUCTION

Nowadays, simulation and optimization based on

physical models are indispensable tools to improve

design and operation of complex industrial systems.

Optimization problems occur for many tasks such as

parameter estimation, data validation, safety verifica-

tion and model predictive control. The objective of

the respective optimization is subject to the dynamic

model equations of the process under consideration

and possibly to additional equality and inequality con-

straints resulting, e.g., from safety demands. State-

of-the-art methods allow for successfully solving op-

timization problems which include only continuous

system models expressed as a set of differential al-

gebraic equations (DAE). However, in many fields,

e. g., chemical processes, power plants, oil refineries,

continuous and discrete state dynamics are coupled

strongly. Such systems with mixed continuous and

discrete dynamics are called hybrid systems. The dis-

crete dynamics result from instantaneous autonomous

or controlled (externally triggered) transitions from

one operating regime to another. Between these tran-

sition points, the state variables of the system evolve

continuously according to the DAE of the respective

operation mode. Due to the mixed discrete-continuo-

us dynamics, the trajectories of the state variables are

in general non-smooth or even discontinuous, which

may impede the optimization of such systems. Sev-

eral approaches, e.g., mixed-integer programming,

heuristic methods, relaxation and penalization strate-

gies have been proposed to tackle this problem. Since

relaxation strategies are most promising with regard

to the computation time, they will be studied in this

paper. Up to now mostly relatively small systems

have been studied using relaxation methods. In this

study, a large-scale industrial evaporator with switch-

ing behavior is formulated as a hybrid model and as a

relaxed continuous model, respectively. Both models

are simulated and the parameter sensitivities are cal-

culated over the whole time horizon. For the smooth

model, results of the parameter estimation and the de-

pendence of the solution on the reformulation param-

eter are shown.

The paper is organized as follows. The challenges

and solution approaches for simulation and optimiza-

tion of hybrid dynamic systems are discussed in Sec-

tion 2. Section 3 presents the evaporator model in its

hybrid and relaxed form. In Section 4, the simulation

results of the relaxed (and consequently smooth con-

tinuous) model are compared with those of the orig-

inal hybrid model. Section 5 applies our smoothing

31

Mynttinen I., Runge E. and Li P..

PARAMETER ESTIMATION OF AN INDUSTRIAL EVAPORATOR WITH HYBRID DYNAMICS BY A SMOOTHING APPROACH.

DOI: 10.5220/0003575500310036

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2011), pages

31-36

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

method to two fundamental tasks of process engineer-

ing, namely parameter estimation and the calculation

of sensitivities. Section 6 summarizes the results and

concludes the paper.

2 OPTIMIZATION OF HYBRID

SYSTEMS

Mathematically, discrete transitions in hybrid sys-

tems are often formulated in terms of complementar-

ity conditions. In actual numerical simulation, dis-

crete transitions are almost always handled through

embedded logical statements. At the zero-crossing

points of some switching function, the initial condi-

tions are updated and the appropriate set of equations

is solved restarting at this point in time (Barton and

Lee, 2002). Systems with so-called Filippov solu-

tions that remain for a while at the zero-crossing re-

quire additional analysis. Since they do not pose a

particular problem for our approach, we will not dis-

cuss them further here. A profound analysis and nu-

merical simulation results of hybrid systems can be

found in (Mehrmann and Wunderlich, 2009; Goebel

et al., 2009). For optimization tasks, the hybrid sim-

ulation can be embedded into a heuristic search al-

gorithm. For instance, particle swarm optimization

has been applied by (Pappala and Erlich, 2008) to

the unit commitment problem. These methods suf-

fer from high computational cost when many func-

tion evaluations are needed (i.e. in a high dimen-

sional search space). Alternatively one can consider

the problem as a constrained optimization problem

subject to the dynamic model equations. This leads

to a dynamic nonlinear program (NLP). In the so-

called direct method, the DAE system is discretized

resulting in a large-scale NLP with equality (and pos-

sibly inequality) constraints, which can be solved by

means of a NLP solver with a gradient-based search.

However this NLP-based optimization of hybrid sys-

tems is an extremely challenging task due to the non-

smoothness of the objective function or constraints

which result from instantaneous mode transitions. As

a consequence, NLP regularity cannot be presumed

and NLP solvers may fail. Essentially three different

approaches can be used to overcome this difficulty.

Mixed-integer methods have been applied success-

fully to optimal control problems by (Sonntag et al.,

2006) and (Barton et al., 2006), where a graph search

algorithm explores the state space of the discrete vari-

ables. An embedded NLP is used to find the local

optima in the continuous state space. The complex-

ity study in (Till et al., 2004) indicates that for sys-

tems with many decision variables solving the prob-

lem becomes computationally expensive. The sec-

ond approach applied, e.g., by (Prada et al., 2007)

and (Voelker et al., 2007) comprises sequential op-

timization methods. Here, the optimization layer ex-

clusively contains continuous variables. The hybrid

system is put into the simulation layer and solved

by any simulator which is capable to treat discon-

tinuities. Again, the necessity of many simulation

runs increases the computational cost. Reformulation

strategies, which represent the third class of methods,

introduce additional variables and parameters to re-

move the non-smoothness related to the complemen-

tarity conditions from the problem while retaining the

desired features. Reformulation strategies have been

studied by (Baumrucker et al., 2008; Sager, 2009;

Ralph and Wright, 2004). Most reformulation strate-

gies fall into one of the following two classes: (i)

Relaxation methods transform the complementarities

into a set of relaxed equality or inequality constraints,

e.g., by the smoothing discussed in this contribution.

A sequence of relaxed problems is solved in order to

approach the solution of the original problem. (ii) Pe-

nalization methods introduce a penalization term into

the objective function which measures the violation

of the complementarity condition.

3 MODEL OF THE EVAPORATOR

The evaporation of volatile components to concen-

trate non-volatile components within a mixture is a

common technology in process engineering. Usually

multi-stage systems built up from several identical

single evaporators are used. Such a single evaporator

model is considered in this paper following (Sonntag

et al., 2006). The system consists of an evaporation

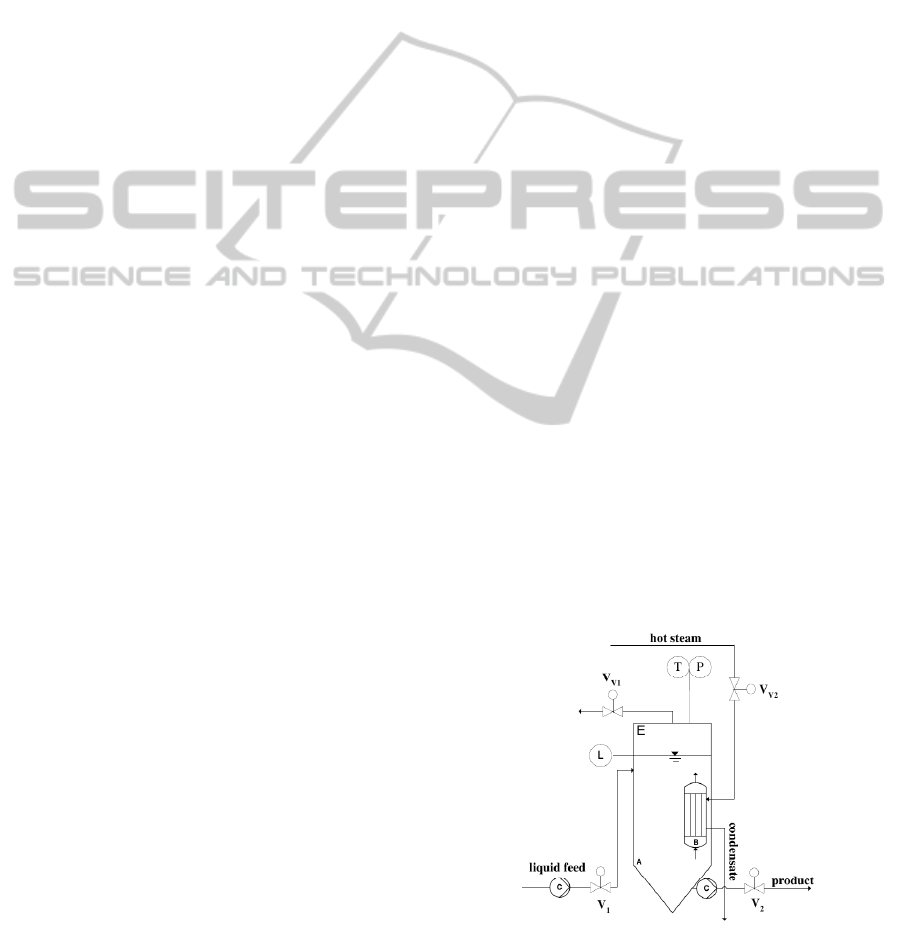

Figure 1: Evaporator model (Sonntag et al., 2006).

tank and a heat exchanger (see Figure 1). The tank is

fed through the valveV

1

with a mixture of three liquid

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

32

components A, B, C with mass fractions w

A

, w

B

, w

C

,

where A is a hydrocarbonof high molar mass and thus

has a very low vapor pressure (implemented as P

0

A

= 0

in the model) compared to water (B) and ethanol (C).

Inside the tank, the volatile components are evapo-

rated. Hence the mass fraction of the non-volatile

component A in the liquid is increased. This prod-

uct will be drained from the tank through the valve

V

2

when the desired concentration of A is reached.

The vapor which consists of B and C with the mass

fractions ξ

B

, ξ

C

determined by the phase equilibrium

escapes from the tank through the valve V

v1

. In order

to heat the tank, hot vapor is supplied to the heat ex-

changer, where the vapor condensates and leaves the

heat exchanger as a liquid.

Depending on the pressure inside the evaporator

and the temperature difference between the heat ex-

changer and the tank, M = 4 operating modes can

be distinguished: If the temperature of the heat ex-

changer is higher than that of the tank, the heat ex-

changer operates in the mode ’heating’ (H), other-

wise ’non-heating’ (NH). Inside the tank, the tran-

sition from the mode ’non-evaporating’ (NE) to the

mode ’evaporating’ (E) occurs as soon as the pres-

sure reaches a certain threshold. Hence, during oper-

ation the system may visit the four operating modes:

NE/NH (m = 1), NE/H (m = 2), E/H (m = 3) and

E/NH (m = 4). Thus, the evaporator model pos-

sesses the typical features of a hybrid system with au-

tonomous mode transitions.

3.1 The Hybrid Evaporator Model

The hybrid model of the evaporator consists of four

sets of DAE f

(m)

( ˙x,x, p) = 0, m = 1,...,M which can

be found in (Sonntag and Stursberg, 2005). The

tank and the heat exchanger change their operation

mode when the respective state-dependent switching

function ψ

(1)

(p) = p− p

c

, p

c

= 0.4bar or ψ

(2)

(T) =

T − T

heatex

crosses 0. T and p denote the tempera-

ture and the pressure in the tank. As a consequence of

this zero-crossing, the dynamics change and the state

variables immediately before the switch x

−

have to

be mapped onto the state variables immediately after

the switch x

+

using the so-called transition functions

x

+

= T (x

−

). For instance, for the vapor mass fraction

ξ

B

the transition function from the non-evaporating

modes (m = 1,2) to the evaporating modes (m = 3, 4)

reads

ξ

+

B

= ξ

−

B

+

w

B

P

0

B

(T)

w

A

P

0

A

(T) + w

B

P

0

B

(T) + w

C

P

0

C

(T)

(1)

with the temperature T

+

= T

−

= T and the liquid

mass fractions w

+

= w

−

= w.

3.2 A Smooth Evaporator Model

State trajectories are in general non-smooth or even

discontinuous at the transition points. If such a model

is included into an optimization problem, these points

are severe obstacles for gradient-based optimization

algorithms. In order to make the optimization of hy-

brid systems accessible to NLP solvers, the comple-

mentarity condition of the original problem is relaxed,

i.e., the strict complementarity conditions are fulfilled

only approximately. In our smoothing approach, we

replace the if-else-statement by the smoothing func-

tion

ϕ(x) =

1+ exp

−

ψ(x)

τ

−1

(2)

with the small smoothing parameter τ. The model

equations are combined in one single set of equations

according to

f( ˙x,x, p) = ϕ(x) f

(1)

( ˙x,x, p)

+ (1 − ϕ(x)) f

(2)

( ˙x,x, p). (3)

This reproduces the switching behavior of the hybrid

model in the limit τ → 0.

4 SIMULATION RESULTS

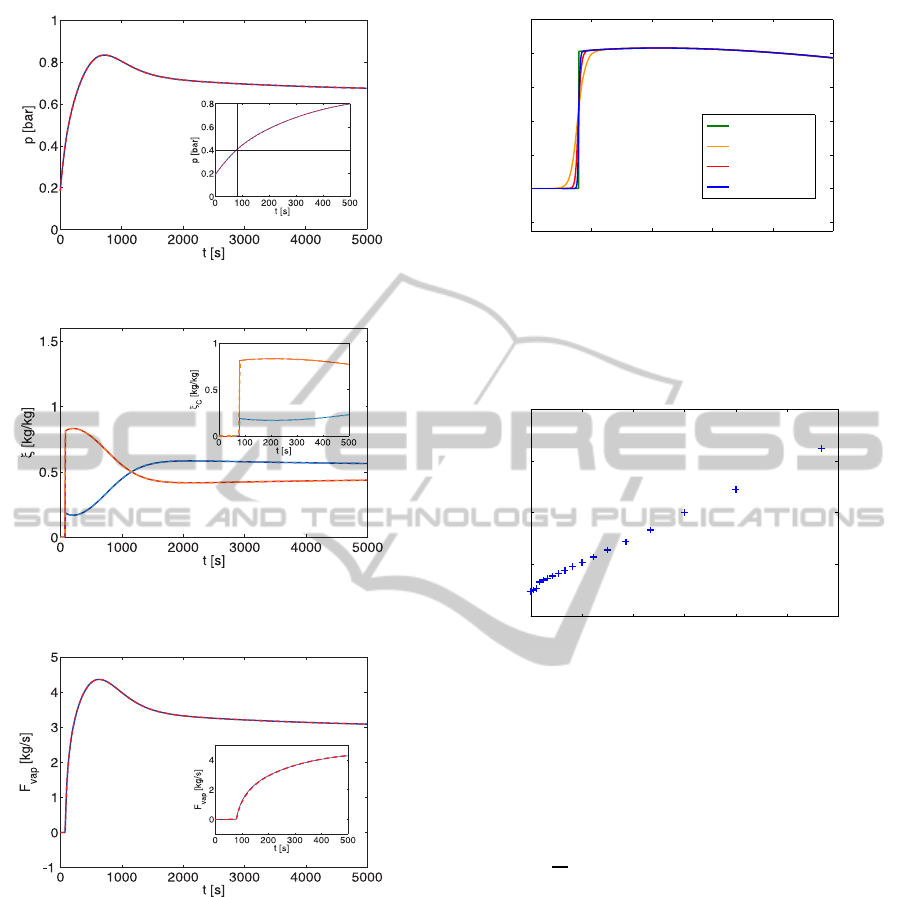

Figure 2 shows that the trajectories of the smooth

model with smoothing parameter τ = 0.002bar and

of the original hybrid model deviate only marginally

from each other. When the pressure meets the tran-

sition condition p = p

c

(see inset of Figure 2(a)) the

evaporator switches from the non-evaporating mode

to the evaporating mode. As a consequence, the mass

fractions of the volatile components B and C jump ac-

cording to Eq. 1 from 0 in the non-evaporating mode

(no vapor is present) to the finite values given by the

phase equilibrium (see Figure 2(b)) and vaporstarts to

escape from the tank (Figure 2(c)). The evaporation

of the volatile components B and C leads to a decrease

of their mass fractions w

B

, w

C

in the liquid. The de-

crease of w

C

(ethanol) is more pronounced due to

the higher vapor pressure and thus the higher outflow

of C. Consequently, the vapor mass fractions cross

each other near t = 1150s (Figure 2(b)). Since the

pressure in the evaporator and also the vapor outflow

(Figure 2(a) and 2(c)) depend on the (temperature-

dependent) vapor pressure and the mass fractions of

all liquid components, both first increase due to the

increasing temperature and later decrease due to the

reduced mass fractions w

B

, w

C

in the liquid.

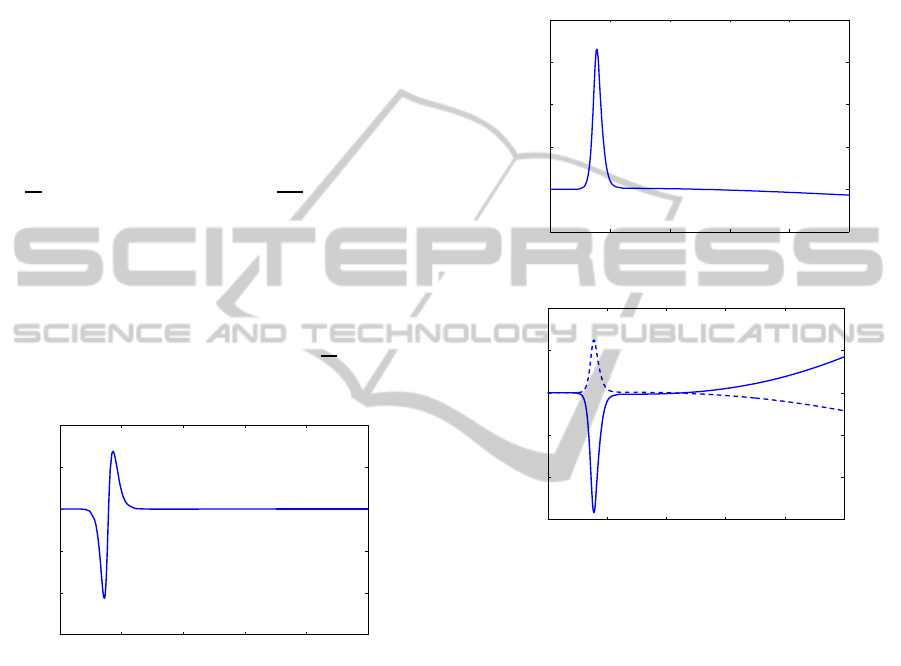

Figure 3 demonstrates that the smooth model ap-

proximates the hybrid model the better the smaller

PARAMETER ESTIMATION OF AN INDUSTRIAL EVAPORATOR WITH HYBRID DYNAMICS BY A

SMOOTHING APPROACH

33

(a) Pressure inside the evaporator for the hybrid model (blue) and the

smooth model (red).

(b) Mass fractions of the volatile components B (hybrid model: dark blue,

smooth model: light blue) and C (hybrid model: red, smooth model: orange)

in the vapor.

(c) Vapor flow from the evaporator for the hybrid model (blue) and the

smooth model (red).

Figure 2: Simulation results of the hybrid and the smooth

model.

the smoothing parameter τ is chosen: The slope of

the state trajectory ξ

C

increases and the transition re-

gion narrows. In the transition region, the dynamics is

given by the linear combination (Eq. 3) of both oper-

ation modes involved. It is important to note that the

trajectories of the hybrid model and the smooth ap-

proximation are nearly identical outside the transition

region. Obviously, the smoothing only extends the

transition time but does not drive the system to a dif-

ferent region of the state space. From this result we

conclude that the smoothing approach is well suited

0 100 200 300 400 500

−0.2

0

0.2

0.4

0.6

0.8

t [s]

ξ

C

[kg/kg]

hybrid

τ=0.01 bar

τ=0.004 bar

τ=0.002 bar

Figure 3: Mass fraction ξ

C

from simulations with several

values of the smoothing parameter.

for the evaporator model.

2 4 6 8 10 12 14

x 10

−3

0

1

2

3

4

x 10

−3

τ [bar]

s [kg

2

/kg

2

]

Figure 4: Deviation of the smooth model from the hybrid

model as a function of the smoothing parameter.

For a more quantitative analysis of the convergence

of the solutions of the relaxed model to that of the

original model, we consider in Figure 4 the average

squared deviation

s =

1

N

N

∑

i=1

ξ

(hybrid)

C

(t

i

) − ξ

(smooth)

C

(t

i

)

2

(4)

between the vapor mass fractions ξ

C

calculated with

the hybrid and the smooth model. The average

squared deviation is found to follow approximately

s ∝ τ and is dominated by the finite width of the tran-

sition region.

5 PARAMETER ESTIMATION

AND SENSITIVITY ANALYSIS

A fundamental task frequently occurring in process

engineering is parameter estimation. Parameter esti-

mation in general aims at extracting the best guesses

of the parameters determining the dynamics of the

system under consideration based on a series of

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

34

measurements x

(m)

ij

of several state variables x

i

, i =

1,...,M at different points in time t

j

, j = 1,...,N. It

is useful to combine the parameter estimation of a hy-

brid system with the sensitivity analysis for at least

two reasons: First, the sensitivities of the measured

state variables with respect to the parameters to be

estimated allow to evaluate the applicability of cer-

tain data in a parameter estimation problem. Second,

the sensitivity with respect to the smoothing param-

eter is needed to predict the suitability of the smooth

model for parameter estimation. The sensitivity of the

state variable ξ

C

with respect to the smoothing pa-

rameter (Figure 5) quantifies the observation already

stated qualitatively in Section 4 that the influence of

the smoothing is restricted to the transition region,

i.e.,

dξ

dτ

≈ 0 outside. The shape of

dξ

C

dτ

is easily un-

derstood in view of the trajectory shown in Figure 3.

As τ increases, i.e., ∆τ = τ

2

−τ

1

> 0, the curve ξ

C

(τ

2

)

lies above that of ξ

C

(τ

1

) as long as p < p

c

and thus

∆ξ

C

= ξ

C

(τ

2

) − ξ

C

(τ

1

) is negative, whereas it is posi-

tive when p > p

c

. In Figure 5, the sensitivity is calcu-

lated at the rather large parameter value τ = 0.01bar.

A smaller τ yields narrower regions with

dξ

dτ

6= 0 (not

shown).

0 100 200 300 400 500

−3

−2

−1

0

1

2

x 10

−3

t [s]

dξ

C

/dτ |

τ=0.01 bar

Figure 5: Sensitivity with respect to the smoothing parame-

ter.

Below, we will estimate the coefficient k of the

heat transfer from the heat exchanger to the tank,

the valve throughputs of the liquid inflow (V

1

) and

the liquid outflow (V

2

) based on measurements of the

ethanol vapor mass fraction ξ

C

. This choice of the

measured variable is due to the fact that ξ

C

is one of

the quantities with the most significant hybrid behav-

ior, which shows up as a jump at the mode transition

(Figure 2(b)). As can be seen in Figure 6, the corre-

sponding sensitivities are relatively large around the

mode transition. The most dominant influence of the

heat transfer and the liquid in- and outflow, i.e., the

mass of liquid to be heated is indirect via the tran-

sition time NE → E. An increase of the heat trans-

fer coefficient or a decrease of the liquid inflow shifts

the curve ξ

C

(t) to the left, i.e., accelerates the pro-

cess. Hence the respective sensitivities are positive

and negative in the first time period and change sign

when ξ

C

(t) exceeds its maximum. Based on Figure 6,

one can expect to find the correct parameter values by

means of parameter estimation, if ξ

C

data are avail-

able around the transitions or in the late time period.

0 100 200 300 400 500

−0.01

0

0.01

0.02

0.03

0.04

t [s]

dξ

C

/dk |

k=4 kW/m

2

K

(a) Sensitivity with respect to the heat transfer coefficient.

0 100 200 300 400 500

−0.3

−0.2

−0.1

0

0.1

0.2

t [s]

dξ

C

/dV|

V

1

=7.0 kg/s,V

2

=2.0kg/s

* 10

(b) Sensitivity with respect to the valve throughputs (liquid inlet: solid, liq-

uid outlet: dashed).

Figure 6: Sensitivities of the mass fraction of component C.

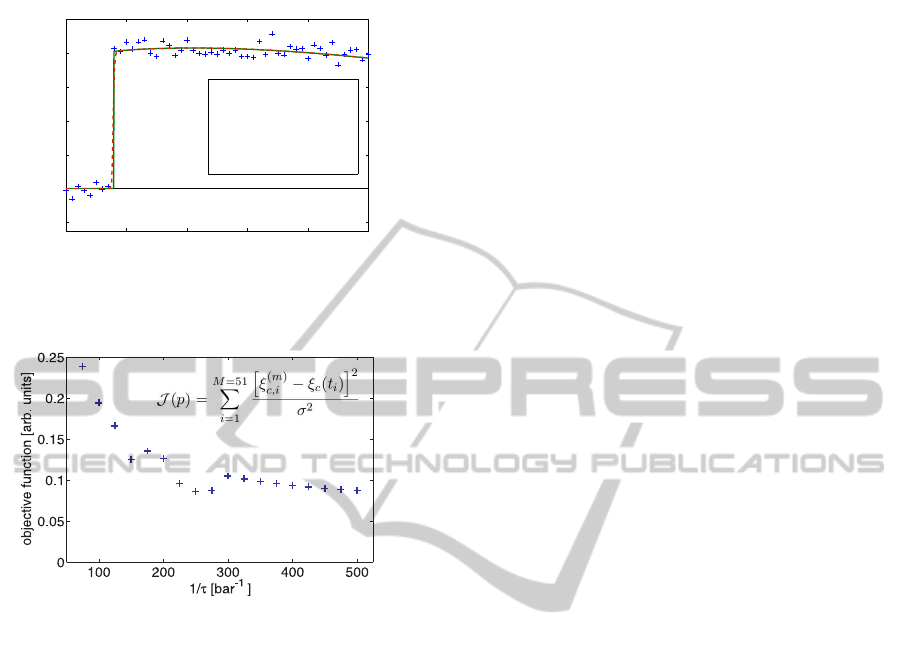

The ’measurement data’ for our parameter esti-

mation have been generated by simulation of the hy-

brid system with added Gaussian distributed mea-

surement error (σ = 0.04kg/kg). We use a series

of 51 equidistant data points within the time hori-

zon t ∈ [0,500] s. As usual, the parameter esti-

mation problem is formulated as least-square opti-

mization. Figure 7 shows the simulation results of

the hybrid model and the optimization result for a

particular realization of ’measurement data’. The

corresponding optimal parameter values (k

(opt)

=

4.070kW/m

2

K, V

(opt)

1

= 6.968kg/s and V

(opt)

2

=

1.950kg/s) agree very well with the values used for

the data generation (k

(opt)

= 4.0kW/m

2

K, V

(opt)

1

=

7.0kg/s and V

(opt)

2

= 2.0kg/s). The optimal param-

eters are quite robust regarding the smoothing pa-

rameter (not shown). However, the optimal objec-

tive function values are considerably influenced by

PARAMETER ESTIMATION OF AN INDUSTRIAL EVAPORATOR WITH HYBRID DYNAMICS BY A

SMOOTHING APPROACH

35

the smoothing parameter (see Figure 8).

0 100 200 300 400 500

−0.2

0

0.2

0.4

0.6

0.8

t [s]

ξ

C

[kg/kg]

k

(opt)

= 4.070 kW/m

2

K

V

1

(opt)

= 6.968 kg/s

V

2

(opt)

= 1.950 kg/s

Figure 7: Parameter estimation result (dashed), measure-

ment (cross) and simulation of the hybrid model (solid).

Figure 8: Optimal objective function values as a function of

the smoothing parameter.

6 CONCLUSIONS

In this study, we carried out the parameter estimation

accompaniedby sensitivity analysis for a hybrid evap-

orating system using a smoothing approach. We first

investigated a smooth approximated model by means

of simulation of the evaporator dynamics for differ-

ent values of the smoothing parameter. Performing

the sensitivity analysis with respect to the parame-

ters to be estimated we could evaluate the usability

of the measurement of a certain variable for the pa-

rameter estimation. The sensitivity with respect to the

smoothing parameter is studied to evaluate the suit-

ability of the smooth model for the purpose of param-

eter estimation. It is shown the proposed method can

successfully determine the correct parameter values.

The results turned out to be quite robust against the

variation of the smoothing parameter. Future work

will extend the model for control tasks and finally op-

timize the plant operations.

REFERENCES

Barton, P. I. and Lee, C. K. (2002). Modeling, simulation,

sensitivity analysis, and optimization of hybrid sys-

tems. ACMT. Model. Comp. S., 12(4):256–289.

Barton, P. I., Lee, C. K., and Yunt, M. (2006). Optimiza-

tion of hybrid systems. Comp. Chem. Eng., 30(10-

12):1576–1589.

Baumrucker, B. T., Renfro, J. G., and Biegler, L. T. (2008).

MPEC problem formulations and solution strategies

with chemical engineering applications. Comp. Chem.

Eng., 32(12):2903–2913.

Goebel, R., Sanfelice, R. G., and Teel, A. R. (2009). Hybrid

dynamical systems. IEEE Control Syst. Mag., pages

28–93.

Mehrmann, V. and Wunderlich, L. (2009). Hybrid systems

of differential-algebraic equations - analysis and nu-

merical solution. J. Process Contr., 19(8):1218–1228.

Pappala, V. S. and Erlich, I. (2008). A new approach for

solving the unit commitment problem by adaptive par-

ticle swarm optimization. In Power and Energy Soci-

ety General Meeting, 2008 IEEE, pages 1–6.

Prada, C. D., Cristea, S., and Rosano, J. J. (2007). Optimal

start-up of an evaporation station. In 8th International

IFAC Symposium on Dynamics and Control of Process

Systems, volume 3, pages 115–120.

Ralph, D. and Wright, S. J. (2004). Some properties of

regularization and penalization schemes for MPECs.

Optim. Method. Softw., 19(5):527–556.

Sager, S. (2009). Reformulations and algorithms for the op-

timization of switching decisions in nonlinear optimal

control. J. Process Contr., 19(8):1238–1247.

Sonntag, C., Stursberg, O., and Engell, S. (2006). Dynamic

optimization of an industrial evaporator using graph

search with embedded nonlinear programming. In 2nd

IFAC Conference on Analysis and Design of Hybrid

Systems, pages 211–216.

Sonntag, C. and Stursberg, O. (2005). Safety verification of

a discretely controlled evaporation system. In Techni-

cal Report, HYCON, pages 1–20.

Till, J., Engell, S., Panek, S., and Stursberg, O. (2004). Ap-

plied hybrid system optimization: An empirical inves-

tigation of complexity. Control Eng. Pract., 12:1291–

1303.

Voelker, A., Sonntag, C., Lohmann, S., and Engell, S.

(2007). Optimization-based safety analysis of an

industrial-scale evaporation system with hybrid dy-

namics. In 8th International IFAC Symposium on Dy-

namics and Control of Process Systems, volume 1,

pages 117–122.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

36