RETROFIT OF CRUDE PREHEAT TRAIN WITH MULTIPLE

TYPES OF CRUDE

Kitipat Siemanond

1,2

and Supachai Kosol

1,2

1

The Petroleum and Petrochemical College, Chulalongkorn University, Bangkok 10330, Thailand

2

National Center of Excellence for Petroleum, Petrochemicals, and Advanced Material

Chulalongkorn University, Bangkok 10330, Thailand

Keywords: Heat Exchanger Network (HEN), Pinch analysis, Mixed integer linear programming, Stage model, Retrofit.

Abstract: This study explores the retrofitting of the crude preheat train of a crude distillation unit (CDU) processing

two types of crude--light and heavy--for a period of 200 and 150 days per year, respectively, with the aim of

finding the optimal design that would yield the highest net present value (NPV). A mathematical

programming model using GAMS software of heat exchanger network (HEN) called stage model (Zamora

and Grossmann, 1996) is applied to carry out the retrofit. The base case CDU is simulated by PRO II

software. Using pinch analysis, the composite curves show the retrofit potential of base cases with light and

heavy crude. The 10-stage model generates six retrofit designs--Designs 1, 2, 3, 4, 5, and 6--of which

Designs 1, 2, and 3 are suitable for light crude and Designs 4, 5, and 6 are suitable for heavy crude. Using a

graphical technique of searching for optimization with maximized NPVs of all designs, it is shown that

Design 2 is the optimal retrofit design processing both types of crude, yielding the highest NPV of

$11,529,511 for a 5-year lifetime and resulting in furnace duty saving of 32%.

1 INTRODUCTION

The crude distillation unit (CDU), as shown in

Figure 1, is one of the largest energy-consuming

units in a refinery. It has a complex heat exchanger

network (HEN) of crude preheat train which

transfers heat from hot-product and pump-around

streams to preheat crude before it enters the CDU,

resulting in energy saving in crude furnace and

coolers of CDU. For this study, PRO II software is

used to simulate base case CDU operated under

Arabian light (light crude) and Bacha quero (heavy

crude) with different distillation curves (Figure 2).

The volumes of crude products from CDU of light

and heavy crude are found in Table 1. CDU of light

and heavy crude of 5000 barrels/hr consumes

different steam and condenser duties (Table 2).

This work focuses on retrofitting the base case crude

preheat train of light and heavy crude by using a

graphically searching technique with n-stage model.

2 LITERATURE SURVEY

In the 1970s, pinch technology, or process heat inte-

Figure 1: Crude distillation unit.

gration, which aids the design of an efficient HEN

by the use of composite curves (T-Q diagram), as

shown in Figure 3, was developed. This technology

has enabled a theoretical approach to design an

optimal HEN and find retrofit potential of the

process. The composite curves consist of hot and

303

Siemanond K. and Kosol S..

RETROFIT OF CRUDE PREHEAT TRAIN WITH MULTIPLE TYPES OF CRUDE.

DOI: 10.5220/0003577203030308

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2011), pages

303-308

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 2: Distillation curves of crude.

Table 1: Products from light and heavy crude.

Table 2: Steam and condenser duties of CDU.

cold composite lines presenting the relationships

between temperature (T) and heat content (Q) for

heat sources and sinks in the system. A pinch point

of two lines indicates a heat recovery approach

temperature (HRAT) or a thermodynamic constraint

on heat exchange. Shifting the cold composite curve

to the left improves heat recovery, or energy saving,

by increasing the heat-exchanger area.

The retrofit technique by Tjoe and Linnhoff

(1986) using pinch technology or thermodynamic

method applies targeting procedures to energy-area

tradeoffs which subsequently translate into

investment savings plots. Yee and Grossmann

(1990) proposed assignment-transshipment models

for structural modifications and a two-stage

approach. Ciric and Floudas (1988) proposed a

retrofit strategy using a decomposition method.

Briones and Kokossis (1998) used the hypertargets

or conceptual programming approach for retrofitting

industrial heat exchanger networks.

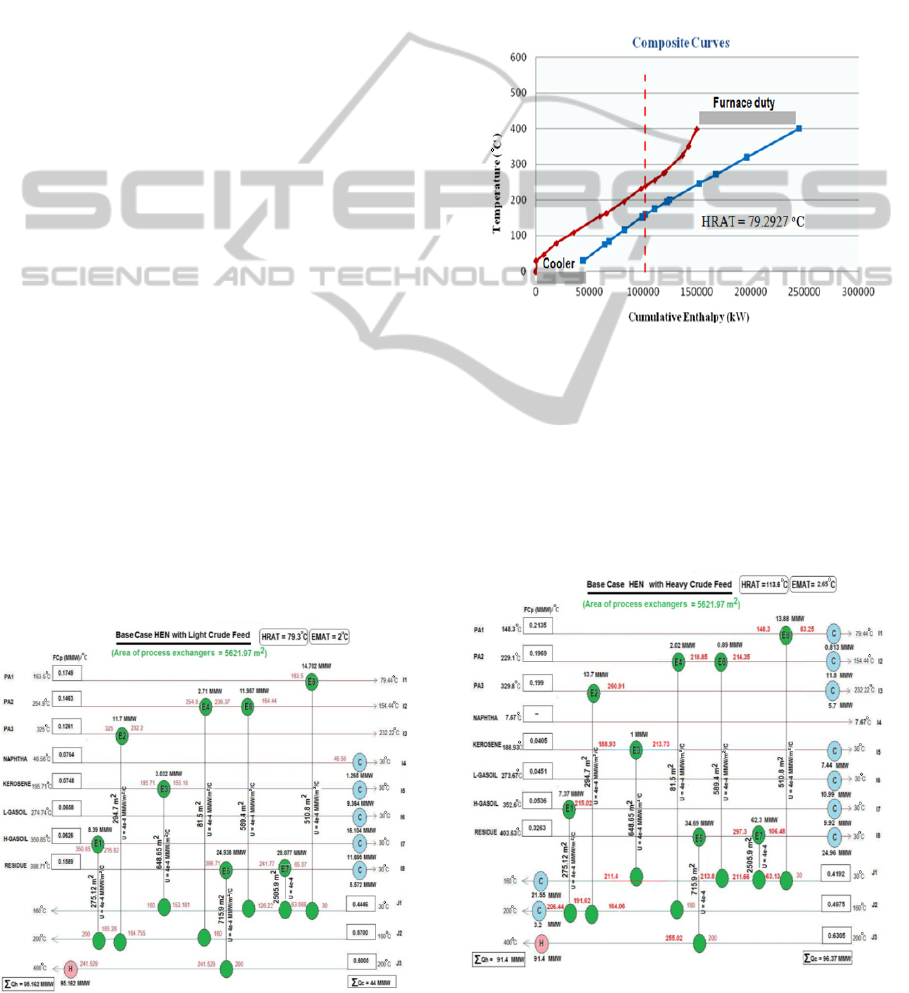

Figure 3: Composite curves.

3 N-STAGE MODEL

The stage model developed by GAMS software is

based on the stage-wise superstructure representa-

tion proposed by Zamora and Grossmann (1996), as

shown in Figure 4. Within each stage of

superstructure, possible exchanger between any pair

of hot and cold streams can occur. Heater and

coolers are placed at the end of cold and hot streams,

respectively. The objective function of the model is

to minimize the duties of heater, cooler and number

of exchangers under the constraint functions of

energy balance, thermodynamics, logical, and

retrofit constraints. The target temperatures and flow

rates of hot and cold streams are fixed and the stage

model will design HEN into n stages with the

minimum utility usages and number of exchangers

for fixed EMAT (Exchanger Minimum Approach

Temperature).

Figure 4: n-stage model structure.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

304

Generally, the number of stages in the

superstructure is set equal to the maximum

cardinality of the hot and cold sets of streams,

although sometimes it is necessary to increase the

number of stages to allow designs with minimum

energy consumption. The purpose of the retrofit

model is to minimize the number of exchangers

under constraint functions of energy balance,

thermodynamics, logical constraint and retrofit

constraint. The retrofit constraint is shown in

equation (1):

∑∑∑

===

≤

111

1

ijk

Zijk

(1)

where Zijk is a binary variable of existing exchanger

matches between hot (i) and cold (j) streams at stage

k. This constraint helps retrofit HEN by keeping

base case exchangers in the same location in the

retrofit design.

4 RESULTS AND DISCUSSION

4.1 Base Case

This case study focuses on retrofitting a base case

crude preheat train of light and heavy crude for 200

and 150 days per year, respectively. The base case

consists of eight hot product streams (PA1, PA2,

PA3, Naphtha, Kerosene, Light Gasoil, Heavy

Gasoil, and Residue), three cold crude streams (J1,

J2, and J3), as seen in Figure 1, and eight process

exchangers (E1, E2, E3, E4, E5, E6, E7, and E8)

with an area of 5621.97 m

2

, as shown in Figures 5

and 7. The base case crude preheat train is operated

under light and heavy crude for 350 working days

per year.

Figure 5: Base case HEN with light crude feed.

4.1.1 Base Case of Light Crude

The structure of base case crude preheat train

operated under light crude for 200 days per year for

the lifetime of 5 years is shown in Figure 5. It

consumes furnace and cooler duties of 95.162 and

44 MMW, respectively, at HRAT = 79.3

o

C.

The composite curves of this base case, as shown

in Figure 6, show a retrofit potential, meaning

retrofit of this base case to reduce furnace and cooler

duties is possible.

Figure 6: Composite curves of base case of light crude

HEN.

4.1.2 Base Case of Heavy Crude

The structure of base case crude preheat train

operated under heavy crude for 150 days per year for

a lifetime of 5 years is shown in Figure 7. It

consumes furnace and cooler duties of 91.4 and

96.37 MMW, respectively, at HRAT = 113.6

o

C.

Figure 7: Base case HEN with heavy crude feed.

ETROFIT OF CRUDE PREHEAT TRAIN WITH MULTIPLE TYPES OF CRUDE

305

The composite curves of this base case, as shown in

Figure 8, also show a retrofit potential.

Figure 8: Composite curves of base case of heavy crude

HEN.

The retrofit with 10-stage model is applied to the

base-case HEN and gives six retrofit designs:

Designs 1, 2, 3, 4, 5, and 6. Designs 1, 2, and 3 are

suitable for light crude for 200 days per year while

Designs 4, 5, and 6 are suitable for heavy crude for

150 days per year.

4.2 The Optimal Retrofit Case

The base case of light crude is retrofitted by 10-

stage model using GAMS, generating six retrofit

designs at different HRATs, selectively, with

different furnace duty (hot utilities) and cooler duty

(cold utilities), as shown in Tables 3, 4, and 5.

Table 3: Six retrofit designs with exchanger area.

Table 4: Six retrofit designs for light crude.

Table 5: Six retrofit designs for heavy crude.

The net present value (NPV) is based on future cash

flows for a certain number of years, n, and a specific

annual interest rate. The NPV is calculated as

follows:

(2)

Table 6 shows the NPV for each retrofit design.

Table 6: NPV of six retrofit designs.

The economic data including utility and

investment costs for this retrofit case are as follows.

The lifetime of this retrofit project is 5 years and

the annual interest rate is 10% (350 working days

per year). The cost of hot and cold utilities are

0.4431 and 0.0222 cents per megajoule,

respectively. The maximum exchanger area added to

and removed from existing exchanger shells are 10%

and 40%, respectively. The maximum limit of area

per shell is 5,000 m

2

and one exchanger can contain

up to 4 shells. The constraint of this retrofit case is

that there is no splitting on hot streams. The cost for

stream splitting and repiping is $20,000. The

investment costs of area are shown in equation (3),

(4), (5), and (6).

Exchanger ($) = 26,460 + [389×Area (m

2

)]

(3)

Area addition ($) = 13,230 + [857×Area

added

(m

2

)]

(4)

Area reduction ($) = 13,230 + [5×Area

reduced

(m

2

)]

(5)

N

ew shell ($) = 26,460 + [857×Area

shell

(m

2

)]

(6)

The optimal retrofit design (Retrofit Design 2)

from the graphically searching technique is the one

with HRAT = 27.43

o

C, giving the highest NPV of

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

306

$11,529,511 for a lifetime of 5 years, as shown in

Figure 9.

Figure 9: Graphical technique for searching optimization.

Details of Retrofit Design 2 are provided in

Table 7 and Figures 10 and 11. It will be applied to

handle light and heavy crude, giving different

furnace and cooler duties.

Table 7: Exchanger details of Retrofit Design 2.

5 CONCLUSIONS

The 10-stage model of HEN generates six retrofit

designs of crude preheat train. Designs 1, 2, and 3

are suitable for light crude for 200 days per year, and

Designs 4, 5, and 6 are suitable for heavy crude for

150 days per year. In comparing the NPV of the six

designs, it is shown that the optimal retrofit design

handling light crude for 200 days and heavy crude

for 150 days per year is Retrofit Design 2, which

gives the optimal NPV of $11,529,511 for a 5-year

lifetime and results in 32% saving at the furnace.

Figure 10: Design 2 with light crude feed.

Figure 11: Design 2 with heavy crude feed.

ACKNOWLEDGEMENTS

The authors would like to express their gratitude to

the Government Budget Bureau, the Petroleum and

Petrochemical College, Chulalongkorn University,

and the National Center of Excellence for

Petroleum, Petrochemicals and Advanced Materials

ETROFIT OF CRUDE PREHEAT TRAIN WITH MULTIPLE TYPES OF CRUDE

307

for funding support. The invaluable assistance of

Prof. Miguel Bagajewicz for educating us in

mathematical programming, GAMS, is also

gratefully acknowledged.

REFERENCES

Briones, V., Kokossis, A. C., 1998. Hypertargets: a

conceptual programming approach for the optimisa-

tion of industrial heat exchanger networks — II.

Retrofit design. Chemical Engineering Science 54,

541-561.

Ciric, A.

R., Floudas, C. A., 1988. A retrofit approach for

heat exchanger networks. Computers and Chemical

Engineering 13, 703-713.

Tjoe, T. N., & Linhoff, B., 1986. Using pinch technology

for process retrofit. Chemical Engineering 28, 47-60.

Yee, T. F., Grossmann, I. E., 1990. Simultaneous

optimisation models for heat integration — II. Heat

exchanger network synthesis. Computers and

Chemical Engineering 14, 1165-1184.

Zamora, J. M., Grossmann, I. E., 1996. A global MINLP

optimization algorithm for the synthesis of heat

exchanger networks with no stream splits. Computers

and Chemical Engineering 22, 367-384.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

308