THE EFFECT OF FLUID VISCOSITY IN T-SHAPED

MICROMIXERS

Mina Roudgar, Elizabetta Brunazzi, Chiara Galletti and Roberto Mauri

Department of Chemical Engineering, Industrial Chemistry and Materials Science, University of Pisa

Via Diotisalvi 2, 56126 Pisa, Italy

Keywords: Micromixers, CFD.

Abstract: Effective mixing in small volumes is a crucial step in many chemical and biochemical processes, where

microreactors are to ensure a fast homogenization of the reactants. Physically, liquid flows in microfluidic

channels are characterized by low values of the Reynolds number and, in general, large values of the

massive Peclet number. Accordingly, since general strategies of flow control in microfluidic devices should

not depend on inertial effects, reduction of the mixing length requires that there must be transverse flow

components. In this paper, three-dimensional numerical simulations were performed to study the flow

dynamics and mixing characteristics of liquids flows inside T-shaped micromixers, when the two inlet fluids

are either both water or water and ethanol. In particular we showed that, contrary to what one could think

beforehand, the mixing efficiency of water-ethanol systems is lower than the corresponding water-water

case.

1 INTRODUCTION

Mixing two different fluids in a micromixer is one of

the most basic and revealing case in the general

subject of microfluidics. Due to the small size of the

device, fluids flows are typically laminar, so that, in

simple channels (i.e. with smooth walls), pressure

driven flows are laminar and uniaxial, so that

confluencing liquids tend to flow side by side and

mixing between the two streams is purely diffusive.

To reduce the mixing length, we must induce

transverse flow components that stretch and fold

fluid volumes over the cross section of the channel.

This can be achieved using active or passive

mechanisms (Nguyen and Wu, 2005; Hessel et al.,

2005) .In general, active micro-mixers use external

energy sources, to induce transversal flows and thus

enhance mixing processes, while passive micro-

mixers usually achieve the same effect by using

clever channel geometries to stir or laminate fluids

without external disturbances.The operation of the

passive micromixer is easier and simpler because of

no additional moving parts or energy sources (Yang

and Lin, 2006; Yang et al., 2005; Kim et al., 2004;

Aubin et al., 2005; Wang and Yang, 2006; Wang et

al., 2007).

The simplest designs of a passive micromixers

are T- or Y-shapes. These micromixers are quite

suitable to carry out basic fundamental studies to

understand mixing at the microscale.

Most of the previous works on T- or Y- shape

micromixers is directed towards analyzing mixing

for a wide range of Reynolds numbers and finding

various flow types. It is well known, that the mixing

performance varies significantly with Reynolds

number.

The present study focuses on the effect of the

viscosity difference between the two inlet fluids on

the mixing efficiency in T-type passive micro mixers

for a range of the Reynolds numbers (1 -300). To do

that, a commercial Computational Fluid Dynamic

(CFD) code, FLUENT 6.3 by Ansys Inc., is used to

solve the three-dimensional flow and mass transfer

equations in the proposed geometrical

configurations.

2 SIMULATION TECHNIQUE

2.1 Governing Equations

Consider two fluids converging into a T junction:

the two inlet streams have at the same temperature,

so that, as the heat of mixing has a negligible effect

343

Roudgar M., Brunazzi E., Galletti C. and Mauri R..

THE EFFECT OF FLUID VISCOSITY IN T-SHAPED MICROMIXERS.

DOI: 10.5220/0003601303430347

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2011), pages

343-347

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

here, we may assume that the process is isothermal.

In general, density and viscosity are known

functions of the composition, so that the governing

equations are:

,0=⋅∇+

∂

∂

v

ρ

ρ

t

(1)

()

()

[

]

,gp

ρμρ

+

+

∇+∇⋅∇=∇+∇⋅+ vvvvv

(2)

()

.

2

cDcc ∇=⋅∇+ v

(3)

Here, v denotes the velocity vector, ρ the fluid

density, p the pressure,

μ

the viscosity, g the gravity

acceleration, D the molecular diffusivity (which here

is assumed to be constant) and c the concentration of

one of the two inlet fluids. If the two fluids are

identical, we can imagine adding a very small

amount of contaminant, i.e. a dye, to one of the

fluids (which therefore continue to have the same

physical properties) and therefore c indicates the dye

concentration.

As mentioned in the Introduction, the

characteristics of the velocity and concentration

fields can be described through the Reynolds and

Peclet numbers,

,;

Re

D

Ud

Pe

N

Ud

N ==

ν

(4)

where U is the mean velocity, while the

characteristic fluid length d is assumed to be the

hydraulic diameter D

h

, i.e.,

()

HW

WH

h

Dd

+

==

2

,

(5)

where W and H are the channel width and height,

respectively (see Figure 1).

2.2 Characterization of the Degree

of Mixing

Based on the above considerations, we will use a

definition of mixing efficiency based on material

fluxes, instead of concentration, as the former, not

the letter, are conserved quantities. Accordingly, we

define a cup mixing flow variance as:

dydz

A

cm

cv

zyxczyv

A

x

cm

2

1

),,(),(

1

)(

2

∫

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

−=

σ

i.e.

,

2

1

1

1

2

∑

=

−=

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

N

i

cv

i

c

i

v

N

cm

cm

σ

(6)

where ̅̅

is the (constant) contaminant flux.

For sake of convenience, here we will use the

following definition of degree of mixing,

cmm

σδ

−= 1

(7)

We expect that

δ

m

increases monotonically with x,

tending asymptotically to 1 as the two fluids mix

completely.

2.3 The Inlet Velocity Profile

and the Mixing Zone

The fully developed velocity profile in a closed

rectangular conduit can be easily obtained by

solving the Navier-Stokes equations with no-slip

boundary conditions at the walls and a constant axial

pressure gradient G. For our purposes, the most

convenient form of this solution is (Chatwin and

Sullivan, 1982):

() ()

()

()

()

()

[]

Y

z

kSinh

k

Tanh

Y

z

kCosh

Y

y

k

oddk

k

GY

yYy

G

zyv

π

η

π

ππ

μπ

μ

2

sin

3

1

3

2

4

2

,

−

∑

−−−=

(8)

where Y and Z are the sizes of the conduit, while

η

=Y/Z is the aspect ratio.

From this expression, we can derive the pressure

gradient G as a function of mean velocity

v , finding:

1

2

5

1

5

192

1

2

12

−

∑

−−=

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎠

⎞

⎜

⎝

⎛

η

π

η

π

μ

k

Tanh

oddk

k

Y

v

G

(9)

We have assumed that the velocity profile

remains fully developed, and therefore given by the

above expression, up to a certain distance from the T

junction, where the influence of vortices and

engulfment of the mixing zone starts to be felt. For

the value of this distance, we used the results given

by Soleymani et al. (2009); who determined it by

numerical simulation.

3 RESULTS AND DISCUSSION

3.1 Numerical Scheme

The geometric setting of our simulation, as shown in

Figure 1, is identical to the one used by Bothe

(2006), with two 100

μ

m

×

100

μ

m inlet square

channels and a 200

μ

m

×

100

μ

m mixing channel. The

simulations were conducted using 2.5 μm body-fitted

structured grids in all directions, created by

GAMBIT.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

344

At the walls, no-slip and no-mass-flux boundary

conditions were applied, while mass flow rates with

uniform velocity and uniform concentration fields,

were imposed at the entrances. In addition, a

condition of average pressure outlet was set at the

exit of the micromixer. A second order

discretization scheme was used to solve all

equations, using FLUENT 6.3 by Ansys Inc.

Simulation were typically considered converging

when the normalized residuals for velocities fell

below 1× 10

-6

.

Figure 1: Schematics of the T-mixer.

The values of density and viscosity were set

equal to 10

3

kg m

-3

and 10

-3

kg m

-1

s

-1

for water and

789 kg m

-3

and 1.2×10

-3

kg m

-1

s

-1

for ethanol,

respectively , while the diffusion coefficient was set

equal to D = 3.23× 10

-10

m

2

s

-1

, corresponding to

that of a water - ink mixture , as this value is very

close to the self- diffusivity of pure water and of

ethanol as well.

In our simulations, we compared the water-water

case with the water-ethanol case, presenting them

side by side.

3.2 Equal Inlet Velocity

At small flow rates, as wall shear stresses are small,

the two streams behave in the same way, so that the

velocity profile is symmetric along the y-direction

(i.e. along channel width), both near the walls and at

the center of the conduit (see Figure 2 , 3.a and 3.e ).

In fact, at small Reynolds number (Re<30), the flow

patterns in water-water systems is very similar to

those in water-ethanol systems, so that mixing

occurs mainly by mass diffusion and it is therefore

very slow rates with uniform velocity and uniform

concentration fields, were imposed at the entrances.

In addition, a condition of average pressure outlet

was set at the exit of the micromixer.

By increasing the Reynolds number, we see

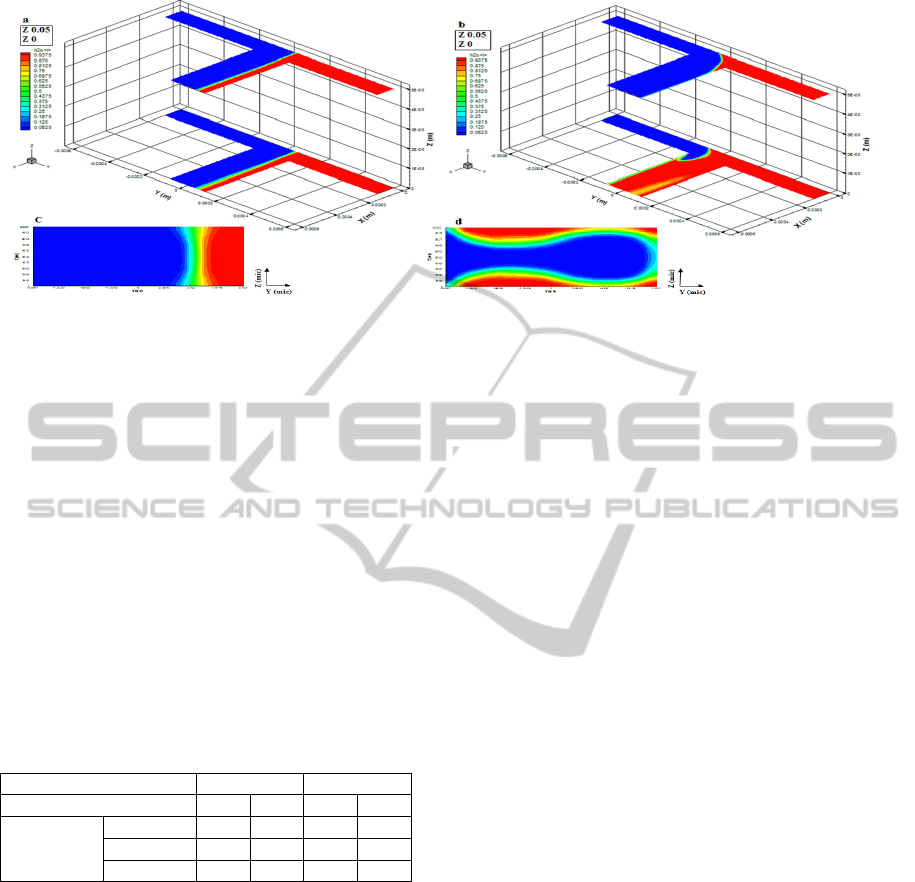

Figure 2: Mass fraction contour plot at Re = 10 for a

water-ethanol system along the mixing channel close to

the wall and at the channel center.

changes in the flow patterns. In fact, to compensate

for its larger viscosity, ethanol moves slower than

water, so that the pressure drops of the two fluid

streams are equalized. This causes the water moving

to the channel center, while ethanol is driven to the

walls. This phenomenon is more evident when we

move from the channel center to the walls, because

of higher wall shear stresses (see Figure 3.b and 3.f).

Note that the different residence times of the two

fluids does not favor mixing by diffusion in the y-

direction and hence the water-ethanol degree of

mixing in smaller than its water-water counterpart.

At further higher Reynolds numbers, we saw

significant difference in flow patterns and degree of

mixing because of the appearance of the vortices an

engulfment. In fact, as we see in Figure 3.c and 3. d,

in water-water systems, as we move from Re = 100

to Re = 200, we see the appearance of symmetric

vortices and engulfment flows, thus confirming the

results by Bothe (2006). On the other hand, as

shown in Figure 3.g, 3.h and 3.i for water–ethanol

systems the onset of the engulfment regime occurs at

a higher Reynolds number, between. Concomitantly,

in table 1 we see that the two systems exhibit a very

large difference in the degree of mixing δ

m

and wall

shear stresses at the outlet of the micro T-mixer.

3.3 Unequal Inlet Velocity

Our simulation shows that when the two inlet

streams have different velocities (and flow rates as

well), the mixing process is radically different,

depending on whether the majority fluid is water or

ethanol. First, let us consider the behavior of a

water-water system. At low Reynolds number, when

the velocity of the two streams are different from

each other, in Figures 4.a and 4.c we see that, as

expected, the interface moves towards one of the

walls, where the velocity is lower than that at the

centerline (which corresponds to the velocity

experienced by the interface region in the equal

THE EFFECT OF FLUID VISCOSITY IN T-SHAPED MICROMIXERS

345

Figure 3: Mass fraction contour plot at different Reynolds number for water-water and b water-ethanol systems at the outlet

cross section.

Table 1: Degree of mixing δ

m

and wall shear stresses at the outlet of the micro T-mixer for water-water and water-ethanol

systems at different Reynolds numbers.

W+W W+E

Re

mix

σ%(mixing

efficiency)

τ(shear stress, mixing)(Pa) σ% τ(inlet channel) τ(mixing channel)

τ

0

(z=0) τ

c

(center) τ

0Water

τ

0Ethanol

τ

0

τ

c

1 4 0.47 0.05 3.2 0.57 0.63 0.514 0.056

10 2 4.7 0.51 1.2 5.31 6.33 5.16 0.57

20 - - - 1.6 10.4 12.7 10 1.1

30 - - - 2 16.3 19.7 15.8 1.66

40 - - - 2.2 22.1 26 21.4 2.2

50 3.6 25 2.5 2.4 28 32.7 27 2.8

100 10 57.4 5.11 5.8 68.5 60 61 5.6

200 26.4 142 12 8.9 133 149 148.4 12

300 41 31 218 235 248 21

Figure 4: Mass fraction contour plots of water-water systems at a velocity ratio V

1

/V

2

=

β

=5 along the mixing channel

(close to the wall and at the channel center) and at the outlet cross section for a) and c) Re = 1; c) and d) Re = 100 .

velocity case). Accordingly, as the diffusion time is

larger than that in the equal velocity case, the mixing

degree increases also. Then, at larger Reynolds

numbers, in Figures 4.b and 4.d we see that the

faster fluid stream hops to the opposite side of the

mixing channel, leaving the slower fluid close to the

walls, resulting in an increase of a mixing efficiency.

In water-ethanol systems, when the water stream is

faster, we observe a behavior that is very similar to

that of water-water systems, although, as shown in

Table 2, the degree of mixing is smaller.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

346

Figure 5: Mass fraction contour plots of water-ethanol systems at a velocity ratio V

e

/V

w

=

β

=5 along the mixing channel

(close to the wall and at the channel center) and at the outlet cross section for a) and c) Re = 1; c) and d) Re = 100 .

On the other hand, for water-ethanol systems

with ethanol being the faster stream, the behavior is

radically different, as shown in Figure 7. In fact, in

this case, comparing Fig. 4.d with 5.d, we see that at

high Reynolds number, the faster stream, i.e.

ethanol, now tends to hop to the opposite side even

more easily, generating a phase pattern that is quite

different. In addition, at low Reynolds number,

comparing 4.c with 5.c, we see that the interface

region is thicker and therefore the degree of mixing

is higher. These observations are summarized in

Table 2.

Table 2: Degree of mixing δ

m

at the outlet of the micro T-

mixer for water-water and water-ethanol systems at

different Reynolds numbers and inlet velocity ratios.

Systems W+W W+E

Re 1 100 1 100

σ%(mixing

efficiency)

V1/V2=5 9.5 28 - -

Vw/Ve=5 - - 5.7 23

Ve/Vw=5 - - 15.8 27

4 CONCLUSIONS

Three-dimensional numerical simulations were

performed to study the flow dynamics and mixing

characteristics of liquids flows inside T-shaped

micromixers, when the two inlet fluids are either

both water or water and ethanol. In particular we

showed that, predictably, the degree of mixing is

larger for unequal inlet flow rates. On the other

hand, contrary to what one could think beforehand,

the mixing efficiency of water-ethanol systems is

lower than the corresponding water-water case.

REFERENCES

Nguyen, N. T., & Wu, Z. G., (2005). Micromixers-a

review. Journal of Micromechanics and

Microengineering, 15, R1–R16.

Hessel, V., Lowe, H., Schonfeld, F. (2005). Micromixers-a

review on passive and active mixing principles.

Chemical Engineering Science, 60, 2479– 2501.

Yang, J. T., & Lin, K. W. (2006). Mixing and separation

of two-fluid flow in a micro planar serpentine channel.

Journal of Micromechanics and Microengineering,

16, 2439–2448.

Yang, J. T., Huang, K. J., Lin, Y. C. (2005). Geometric

effects on fluid mixing in passive grooved

micromixers. Lab on a Chip, 5, 1140–1147.

Kim, D. S., Lee, S. W., Kwon, T. H., Lee, S. S. (2004). A

barrier-embedded chaotic micromixer. Journal of

Micromechanics and Microengineering ,14, 798–805.

Aubin, J., Fletcher, D. F., Xuereb, C. (2005). Design of

micromixers using CFD modeling. Chemical

Engineering Science, 60, 2503–2516.

Wang, L., & Yang, J. T. (2006) An overlapping crisscross

micromixer using chaotic mixing principles. Journal

of Micromechanics and Microengineering, 16, 2684–2691.

Wang, L., Yang, J. T., Lyu, P. C. (2007). An overlapping

crisscross micromixer. Chemical Engineering Science,

62, 711–720.

Chatwin, P. C. & Sullivan, P. J. (1982). The effect of

aspect ratio on the longitudinal diffusivity in

rectangular channels. Journal of Fluid Mechanic, 120,

347-358.

Bothe, D., Sternich, C., Warnecke, H. J. (2006). Fluid

mixing in a T-shaped micro-mixer. Chemical

Engineering Science, 61, 2950–2958.

Lee, S., Lee, H. Y., Lee, I. F., Tseng, C.Y. (2004). Ink

diffusion in water. European Journal of Physics, 25,

331–336.

Soleymani, A., Yousefi. H., Ratchananusorn, W.,

Turunen, I. (2010). Pressure drop in micro T-mixers.

Journal of Micromechanics and Microengineering, 20,

015-029.

THE EFFECT OF FLUID VISCOSITY IN T-SHAPED MICROMIXERS

347