SIMULATION OF BIOMASS PARTIAL OXIDATION

V. Tukač

1

, J. Hanika

2

, V. Veselý

2

, J. Lederer

3

and D. Kovač

3

1

Institute of Chemical Technology Prague, Technická 5, 166 28, 6, Prague, Czech Republic

2

Institute of Chemical Process Fundamentals, Czech Academy of Sciences, v.v.i., 165 02, 6, Prague, Czech Republic

3

VUANCH, a.s., Revoluční 84, 400 01, Ústí n. Labem, Czech Republic

Keywords: Simulation, Biomass, Partial oxidation.

Abstract: Gasification of biomass by partial oxidation produces both syn-gas with high hydrogen content and explore

energy of renewable sources. The objective of this work was to develop computer models of pilot reactor

unit operated partial oxidation of rape meal/mineral oil suspension. The models were developed in process

simulator ASPEN Plus based both on Gibbs free energy minimization and reaction kinetic approach.

Alternative biomass characterizations were used: analogy with coal composition and representative

compounds of biopolymer structure. Flow characteristic of gasification reactor was tested by CFD method

in COMSOL Multiphysic. Simulated results were compared with pilot plant experiments with successful

agreement.

1 INTRODUCTION

Nowadays hydrogen demand caused by deep fuel

refining and the other sustainable processes leads to

utilization of new raw materials. Simultaneously,

extensive biodiesel production creates great amount

of biomass wastes transcendent over feeding

potential of farm animals. One of potentially useful

process of hydrogen production from renewable

natural sources seems to be partial oxidation (POX)

and gasification of biomass material like rape meal

from rape oil production and/or distillery slop

originated from bioethanol (Tukač, 2009).

The goal of this work was to develop simulation

models of pilot POX reactor working with mixture

of fuel oil and biomass.

2 EXPERIMENTAL

Experimental pilot plant unit was constructed in

UNIPETROL RPA Litvinov, consisted of water

steam generator, continuous suspension batcher,

gasification reactor equipped by co-annular feeding

jet burner and water quench and tubular heat

exchanger. Pilot POX reactor of I.D. 0.3 m and

overall length 2 m was equipped by 5 x 3 kW

electrical heating to reach temperature about 1200

°C. Suspension of dry biomass in mineral oil was

partially combusted in oxygen - water steam

atmosphere to produce carbon monoxide, dioxide

and hydrogen contained gaseous product.

3 PROCESS SIMULATION

Two different approaches were used to develop

mathematical models. First method consists in

formulation of steady state balancing models created

in process simulator Aspen Plus. Pseudo

homogeneous CSTR reactor model was used to fit

both reaction kinetics and chemical equilibrium on

experimental data. Chemical and phase equilibrium

was calculated by minimization of Gibbs function,

Peng-Robinson equation of state with Boston-

Mathias alpha function was used to describe real

behavior of gases. Another modelling employs CFD

capability of COMSOL Multiphysics (PDE solver

by finite element method) to find steady state gas

velocity, profiles inside of gasification reactor.

Complicated chemical composition was solved

by concept of representative chemical compounds

resulting in the same elemental composition as the

original raw material.

422

Tuka

ˇ

c V., Hanika J., Veselý V., Lederer J. and Kova

ˇ

c D..

SIMULATION OF BIOMASS PARTIAL OXIDATION.

DOI: 10.5220/0003617704220424

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2011), pages

422-424

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

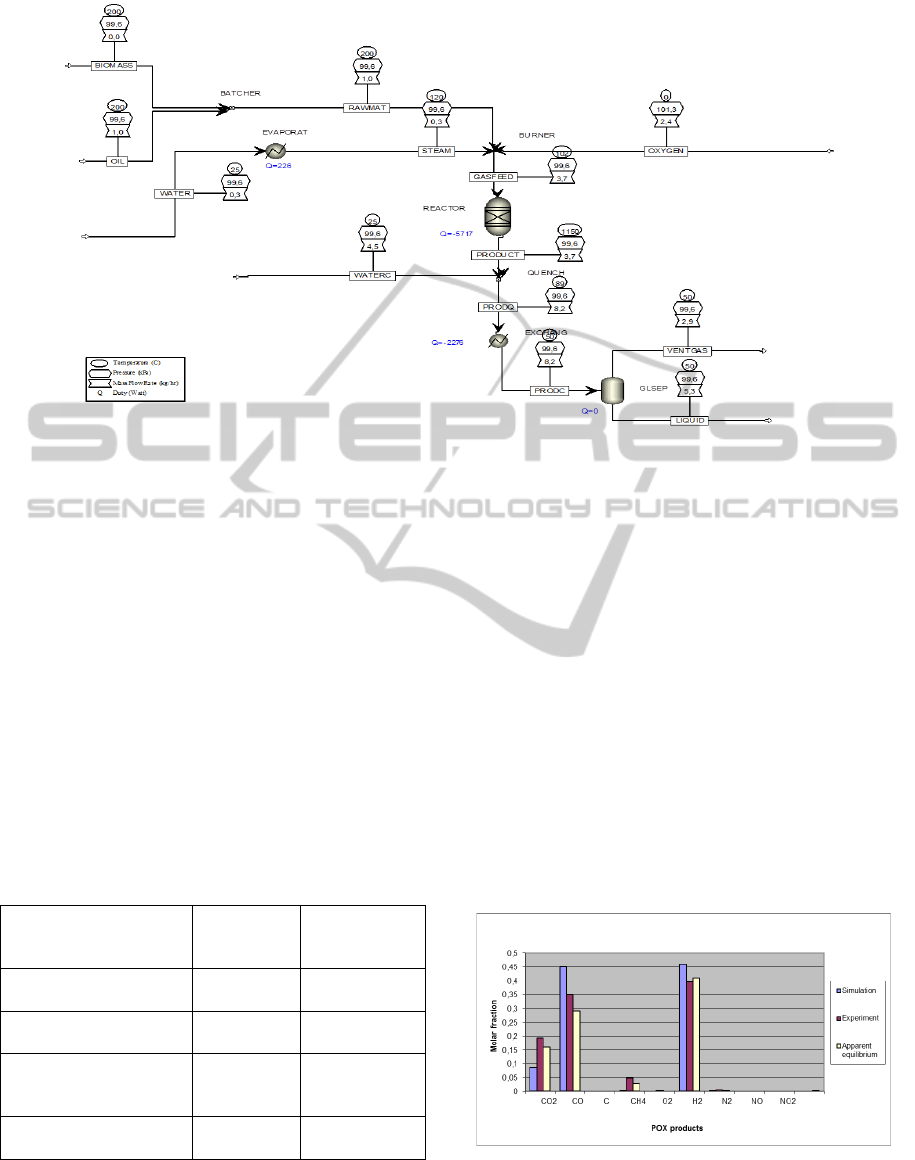

Figure 1: Aspen Plus flowchart of basic part of pilot POX unit.

In the Fig. 1 simplified flowchart of main part of

pilot POX unit formulated in Aspen Plus is

presented. Simulation model incorporates biomass,

oil, water and oxygen input streams included water

quench of flue gas after reactor.

Models of apparatus incorporate heat exchangers

and phase separator. Two reaction models were

used: i) chemical and phase equilibrium calculated

by minimization of Gibbs function and ii) power law

formal kinetics for gasification.

In the following Tab. I simulated results of

chemical equilibrium for 10 % content of biomass in

mineral oil are presented. Adiabatic temperature rise

exceeds 800 K for both biomass tested, also

prospected products concentration is very promising.

Table 1: Simulated results of gasification of biomass in oil

suspension.

Variable 10 % rape

meal

10 %

distillery

slop

Adiabatic temperature

in reactor, °C

1038 1067

Hydrogen portion in

flue gases, % vol.

48.7 48.5

Carbon monoxide

portion in flue gases,

% vol

35.8 36.0

Molar ratio of carbon

monoxide/dioxide

8.08 8.44

Comparison of equilibrium simulation with

experiments with 5 % wt. biomass-oil suspension

gasification is shown in Fig. 2. Almost the same

hydrogen concentration verifies results of simulation

balance. On the other hand, lower experimental

concentration of carbon monoxide together with

higher value of carbon dioxide concentration implies

that presumptions of both ideal mixing in reactor

and/or complete chemical equilibrium are not

fulfilled. Also method to fit apparent equilibrium

temperature (

Bruggemann, 2010) corresponding to

experimental composition was treated. The resulting

temperature approach was found cca -500 °C and

both carbon oxide and methane concentration are

affected. In this case, it is possible to see in the Fig.

2. better agreement of that simulation with

experimental results.

Fitting of experiments by simple power law kinetic

of partial oxidation, water gas shift, steam reforming

and carbon monoxide oxidation the good agreement

was found with published data (Robinson, 2008).

Figure 2: Examples of 5 %wt. biomass in oil gasification

by oxygen – water atmosphere, mean experimental

temperature 1152 °C, apparent equilibrium temperature

672 °C.

SIMULATION OF BIOMASS PARTIAL OXIDATION

423

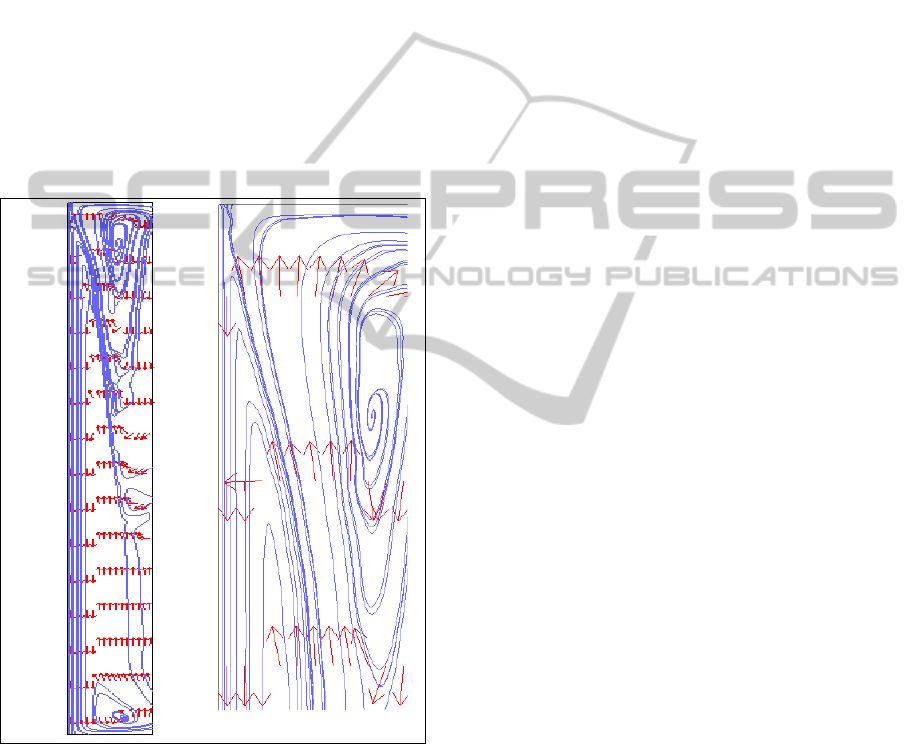

Hydrogen production depend both on oxygen

and water steam ratio to biomass and hydrocarbon

raw material mixture and also on flow characteristic

and internal mixing in the reactor. Distribution of

residence time of biomass particles in the reactor

affects results due to different rate of consecutive

reaction steps: pyrolysis, water gas shift and steam

reforming reactions. CFD modelling can help to

understand complex phenomena in the reactor. To

evaluate axial mixing in the reactor axial symmetric

cylindrical model in COMSOL multiphysics was

created. Fluid flow was described by Navier Stokes

equation and turbulence by k-ε model (

Cammarata,

2007). Resulting flow character is presented in Fig.

3, exhibiting vortexes in upper and bottom reactor

part and main stream in reactor axis. To choose

appropriate hydrodynamic model (

Bruggemann, 2010)

some RTD measurement should be necessary.

a)

b)

Figure 3: a) Velocity stream lines in longitudinal cross-

section of axial symmetric reactor model. Left edge – axis,

right border – wall.. b) Detail of jet nozzle vicinity.

4 CONCLUSIONS

Variant thermodynamic calculations of equilibrium

balances of biomass partial oxidation were made by

process simulator Aspen Plus. Prospective results

were found both for rape meal and distillery slops oil

suspension oxidation.

Comparison of equilibrium reactor model with

preliminary experiments shows good agreement, but

for existing deviations mixing structure in reactor is

suspected. The best results were acquired by model

with equilibrium temperature approach.

CFD results of 2D axial symmetric FEM model

invoke a need for experimental RTD identification

of axial mixing flow character.

ACKNOWLEDGEMENTS

Grant of Ministry of Industry and Commerce of CR

no. MPO 2A-2TP1/024 is gratefully acknowledged.

REFERENCES

Tukač, V., Hanika, J., Veselý, V., Lederer, J., Nečesaný, .,

F., 2009. Possibility of hydrogen production by partial

oxidation of waste biomass, CHEMagazín XIX (3)

8 – 9.

Robinson, P. J., Luyben, W. L., 2008. Simple dynamic

gasifier model that runs in Aspen Dynamics, Ind. Eng.

Chem. Res. 47 (20) 7784-7792.

Cammarata, G., Petrone, G., 2007, Radiating effect of

participating media in flameless industrial reactor, Int.

Jnl. of Multiphysics 1 (4), 393 – 406.

Bruggemann, P., Seifert, P., Meyer, B., Muller-Hagedorn,

M., 2010. Influence of temperatute and pressure on the

non-catalytic partial oxidation of natural gas, Chem.

Prod. Proc. Modelling, 5 (1), A1 1 – 24.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

424