A NEW DEVELOPMENT DESIGN CAE EMPLOYMENT MODEL

Applying Numerical Simulation to Automobile Bottleneck Technology

Kakuro Amasaka

College of Science and Engineering, Aoyama Gakuin University, Kanagawa-ken, Japan

Keywords: New Development Design CAE Employment Model, Numerical simulation, Automobile bottleneck

technology, Transaxle oil seal leakage simulation.

Abstract: With the rapid move towards global production, it has become increasingly critical for manufacturers to

drastically cut back on the time it takes to move a product from design to production while ensuring quality.

This research addresses the necessity reforming the business processes associated with development design

in particular, proposing a “New Development Design CAE Employment Model” using four core models:

the “Highly Reliable CAE Analysis Technology Component Model”, the “Highly Precise CAE Analysis

Model”, the “Total QA High Cyclization Business Process Model”, and the “Intellectual Customer Data

Collection/Analysis Integrated Model” that takes manufacturers away from conventional preproduction and

prototype testing methods and towards a better predictive evaluation method. The effectiveness of the model

is verified by successfully applying it to the technological problem “automotive transaxle oil seal leakage”

of development design bottlenecks at auto manufacturers.

1 INTRODUCTION

This research focuses on reforming the business

processes associated with development design, one

of the critical components of manufacturing with the

rapid move towards global production. In recent

years, the author has been looking to move away

from the repeated trial-and-error–based

preproduction and prototype testing traditionally

practiced in the development design process

(conventional prototype testing methods) and

towards more predictive evaluation methods. To

achieve this aim, the author created a “New

Development Design CAE Employment Model” that

will shorten development times and help

manufacturers simultaneously achieve optimum

quality, cost, and delivery (QCD).

The author has created four core models that

make up the new CAE model: the “Highly Reliable

CAE Analysis Technology Component Model”, the

“Highly Precise CAE Analysis Model”, the “Total

QA High Cyclization Business Process Model”, and

the “Intellectual Customer Data Collection/Analysis

Integrated Model”. Statistical science was used to

organically and intelligently put these models to

work, and they were successfully employed in

resolving the technological problem “automotive

transaxle oil seal leakage” of development design

bottlenecks at auto manufacturers by utilizing the

“Highly Assurance CAE Analysis Model”, the “Oil

Seal Simulator”, the “CAE Qualitative Model”,

CAE analysis (2D and 3D), and quality

improvement. The “New Development Design

CAE Employment Model” was then applied to

similar technical problems, where its effectiveness

was verified.

2 CAE IN DEVELOPMENT

DESIGN – APPLICATION AND

ISSUES

The time between product design and production has

been drastically shortened in recent years with the

rapid spread of global production. Quality assurance,

or QA, has become increasingly critical, making it

essential that the development design process—a

critical component of QA—be reformed to ensure

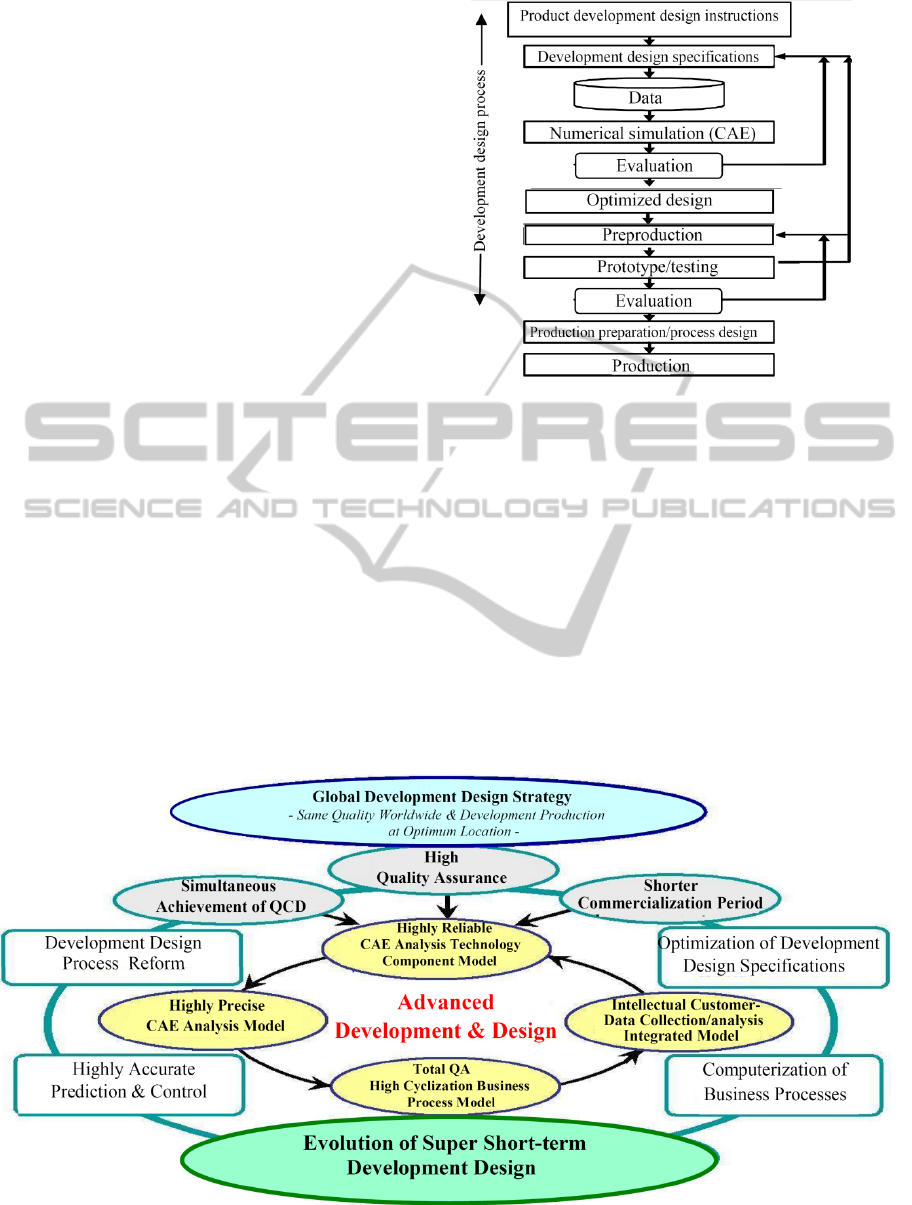

quality (Kume, 1999: Amasaka, 2010a). Figure 1

shows the typical product development design

process currently used by many companies

(Amasaka, Ed., 2007a). The figure shows that

companies first create product development design

114

Amasaka K..

A NEW DEVELOPMENT DESIGN CAE EMPLOYMENT MODEL - Applying Numerical Simulation to Automobile Bottleneck Technology.

DOI: 10.5220/0003637201140124

In Proceedings of the International Conference on Evolutionary Computation Theory and Applications (ECTA-2011), pages 114-124

ISBN: 978-989-8425-83-6

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

instructions based on market research and planning.

They then use these instructions to make specific

development design specifications (drawings) and to

promptly convert them to digital format so that they

can be suitably processed and applied. The data is

primarily used in numerical simulations known as

computer-aided engineering, or CAE.

CAE and other numerical simulations have been

applied to a wide variety of business processes in

recent years, including research and development,

design, preproduction and testing/evaluations,

production technology, production preparation, and

manufacturing. These and other applications are

expected to have effective results (Magoshi, et al.,

2003:Leo, et al., 2004: Amasaka, 2010a). In this age

of global quality competition, using CAE for

predictive evaluation method in design work is

expected to contribute a great deal to shortening

development design time and improving quality

(Amasaka, 2007, 2008, 2010b). However, in the

case of automotive production, much of the

development design process is guided by unspoken

experiential knowledge and rules of thumb, leading

to prototype testing guided by repeated trial-and-

error efforts; in other words, a series of

improvements based on conventional prototype

testing methods. This not only draws out the

development design process, but also results in

enormous testing costs.

Previous forms of CAE analysis were not

sufficiently precise, yielding figures that deviated as

much as 10–30% from prototype testing evaluations

(absolute values). This meant that CAE was hardly

Figure 1: CAE in the development design process.

reliable enough to be an adequate substitute for

prototype testing (Amasaka, 2007, 2008). As a

result, manufacturers were not able to cut out

preproduction and prototype testing (a necessity for

shortening development design time) despite the

enormous amount of funds they invested in CAE

development. This means that many companies are

now stuck with applying CAE only to the

monitoring task of comparative evaluations of old

and new products.

The only way get CAE analysis to function at a

sufficient level and firmly establish it as part of (1)

preventing recurrence of the pressing technical

problem of bottlenecking and (2) the development

Figure 2: New Development Design CAE Employment Model.

A NEW DEVELOPMENT DESIGN CAE EMPLOYMENT MODEL - Applying Numerical Simulation to Automobile

Bottleneck Technology

115

design process for new products, is to make it more

precise. Specifically, this means setting up highly

reliable CAE analysis that reduce the deviation, or

gap, with prototype testing evaluations (absolute

values) to 5% or less (Amasaka, 2008, 2010b).

3 CONSTRUCTING A NEW

DEVELOPMENT DESIGN CAE

EMPLOYING MODEL

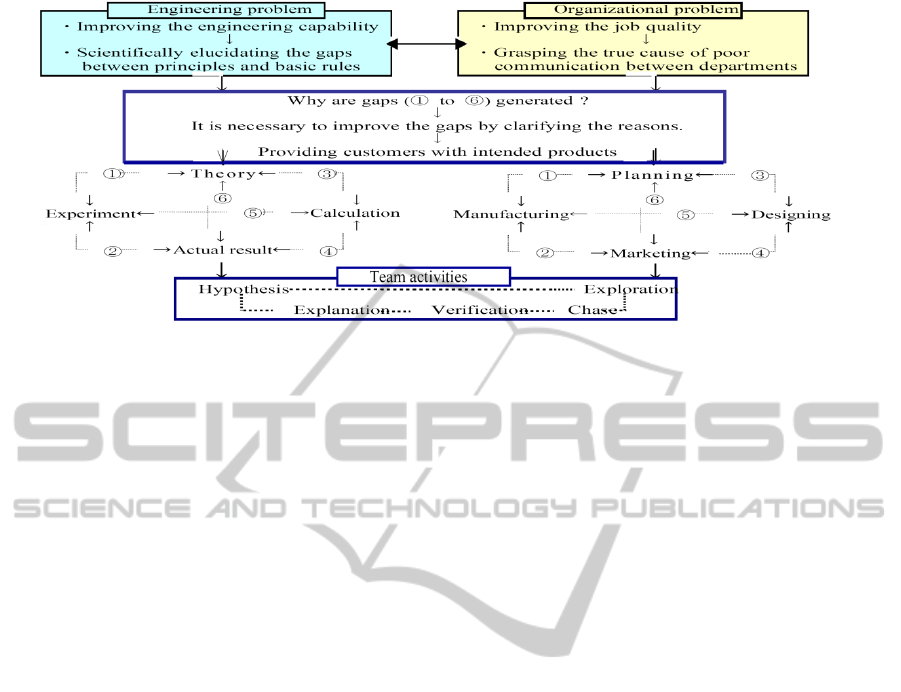

The author has created the “New Development

Design CAE Employment Model” for the advanced

development and design shown in Figure 2 as a way

of overcoming these pressing problems in

development design. As the figure shows, technical

issues that must be resolved by development design

departments include development design process

reform, design process reform, high accuracy of the

prediction and control, computerization of business

process, and optimization of development design

specifications.

In terms of a methodology for resolving these

issues, the author has created four core models: the

“High Reliable CAE Analysis Technology

Component Model”, the “Highly Precise CAE

Analysis Model”, the “Total QA High Cyclization

Business Process Model”, and the “Intellectual

Customer Data Collection/Analysis Integrated

System”. The organically integrated and intelligent

application of these four models is essential. An

overview of each is given below.

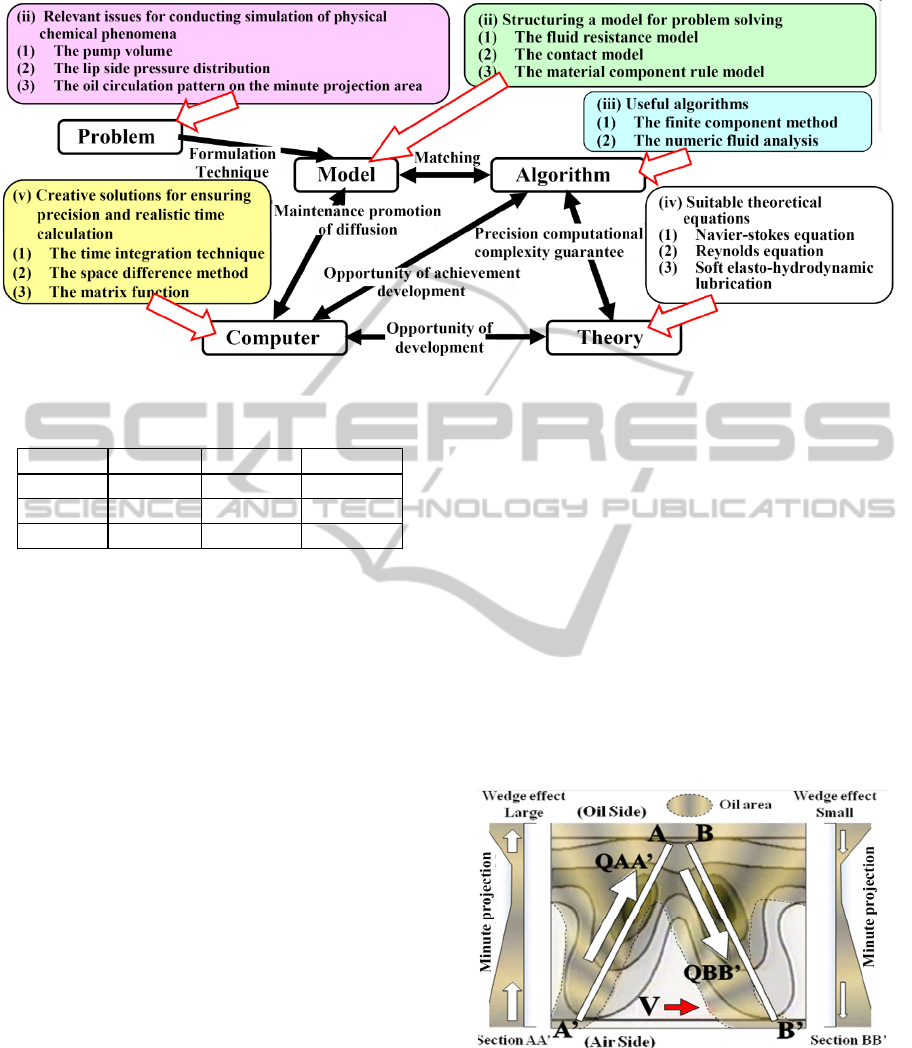

3.1 The Highly Reliable CAE Analysis

Technology Component Model

The Highly Reliable CAE Analysis Technology

Component Model (problem-model-algorithm-

theory-computer) shown in Figure 3 was designed to

make the shift from conventional prototype testing

methods to effectively applying CAE in predictive

evaluation methods. The comprehensive issuance of

this model is essential to achieving the desired shift.

(Amasaka, Ed., 2007b: Amasaka, 2008, 2010b).

Figure 3: Highly Reliable CAE Analysis Technology

Component Model.

More specifically, the critical aspects of this

model include (i) Defining the problem (physically

checking the actual item) in order to clarify the

mechanism of the defect, using visualization

technology to identify the dynamic behavior of the

technical issue; (ii) full use of formulization

techniques to generate logical modeling (statistical

calculations, model application); (iii) constructing

compatible algorithms (calculation methods); (iv)

developing theories (establishing theories required to

clarify problems) that ensure the precision of

numerical calculations and sufficient computational

capability; and (v) comprehensively putting the

above processes in action using computer (selection

of calculation technology).

Figure 4: Highly Reliable CAE Analysis Model.

ECTA 2011 - International Conference on Evolutionary Computation Theory and Applications

116

Figure 5: Total QA hight Cyclization Business Process System.

3.2 The Highly Precise CAE Analysis

Model

In order to minimize discrepancies in results

obtained from testing of actual products and CAE, it

is necessary to properly formalize the expertise of

the many technical analysts required for CAE

analysis.

To achieve this, the author (Amasaka, 2008:

Takahashi, et al., 2010) proposes the use of the

Highly Precise CAE Analysis Model shown in

Figure 4 to enable highly precise absolute analysis.

Functional failures are a recurring cause of

market claims in automotive development design,

making it necessary to clarify relevant technical

issues such as the reasons and mechanisms by which

such failures occur. This should be done according

to the following steps.

STEP 1 Extracting the problem: Investigate and

analyze the causal relationships that become

apparent and infer the mechanisms through which

failures occur, employing the latest “statistical

science methods” backed up by expertise

accumulated through the cooperative efforts of

internal and external specialists (Amasaka, 2003).

STEP 2 Visualizing the problem: Test actual

products demonstrating the failure mechanisms to

visualize the dynamic behavior of the problem. In

order to accurately analyze the failure and its causes,

it is necessary to uncover any underlying factors that

were not evident from previous findings and may

have been overlooked. A logical reasoning process

must be applied to demonstrate the mechanisms of

the failure, employing tools and principles such as

statistical science methods.

STEP 3 Testing & CAE analysis: Consolidate

the findings and apply statistical simulation to create

a two-dimensional model integrated on a qualitative

level where the visualization produced through

actual testing can be reproduced. When creating this

two-dimensional model, it is necessary to conduct

tests to produce a model (qualitative modeling) of

the causal relationships involved in undefined failure

mechanisms. Precise calculation methods, analysis

models and algorithms must be properly selected in

order to clarify boundary conditions and contact

situations, as well as to enable highly accurate

statistical simulation. It is essential to use such tools

to minimize discrepancies between actual testing

and CAE absolute evaluation. The findings from

such analysis should then be used for more detailed

three-dimensional analysis.

STEP 4 Highly reliable CAE: Conduct accurate

testing of actual products based on the findings from

STEP 3 to gain a more explicit understanding of the

failure mechanisms. Consolidate the findings from

the processes involved and conduct statistical

simulation (quantitative modeling) with a high level

of credibility to enable the prediction and control of

absolute values.

STEP 5 Predictive evaluation CAE analysis: In

this final step, identify the primary factors from the

results of the statistical simulation in STEP 4 to be

used for prediction and evaluation. The new findings

obtained, design concepts, and formulation models

should be shared and disseminated. Utilizing models

with a higher level of analytic accuracy enables

manufacturers to move from relative evaluation to

absolute evaluation of analysis results in the actual

development process. The authors believe that this

will lead to the future establishment of design

frameworks involving predictive evaluation.

A NEW DEVELOPMENT DESIGN CAE EMPLOYMENT MODEL - Applying Numerical Simulation to Automobile

Bottleneck Technology

117

3.3 Total QA High Cyclization

Business Process Model

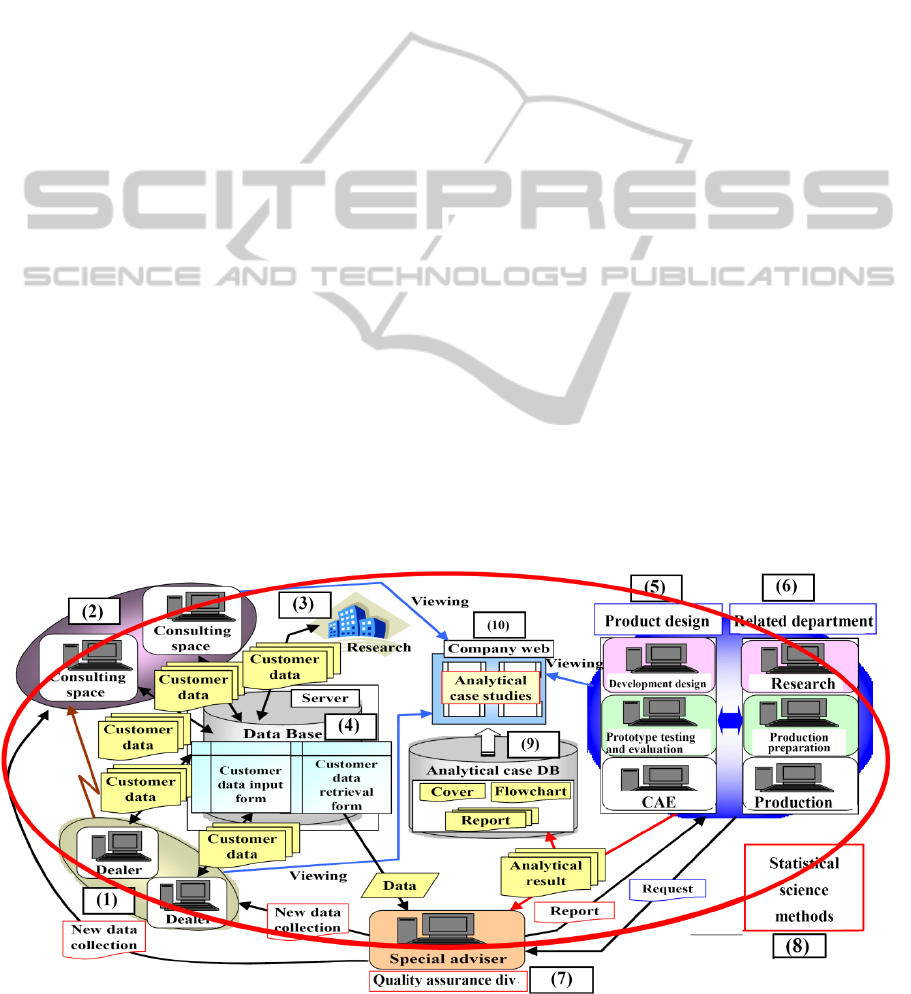

As the first step, the author proposes the

development design business process model. This

model is created from the standpoint of

Verification/Validation (divergence of CAE from

theory and divergence of CAE from testing) in order

to make highly reliable CAE analysis that is

consistent with the market testing theory profile

possible. The author (Amasaka, 2008) therefore

recommends the introduction and utilization of the

Total QA (Quality Assurance) High Cyclization

Business Process System, which systematically and

strategically realizes high quality assurance by

incorporating analyses made via the core

technologies of Science SQC (Amasaka, 2004) as

shown in Figure 5. For example, in order to solve

the pending issue of a technology problem in the

market, it is necessary to create a universal solution

(general solution) by clarifying the existing six gaps

(1 to 6 in the figure below) in the process consisting

of theory (technological design model), experiment

(prototype to production), calculation (simulation),

and actual result (market) as shown on the lower left

of Figure 5 below.

To accomplish this, the clarification of the six

gaps (1 to 6) in the business processes across the

divisions, shown in the lower right of Figure 5

below, is of primary importance. By taking these

steps, the intelligent technical information owned by

the related divisions inside and outside the

corporation will be fully linked, thus reforming the

business processes involved in development design.

3.4 The Intellectual Customer Data

Collection/Analysis Integrated

Model

Collecting, organizing, and analyzing different types

of technical information is a critical part of the

development design process. For this reason, it is

important that manufacturers set up a comprehensive

networking system that makes full use of digital

engineering and information technology, allowing

them to collect and analyze customer information in

real time. Figure 6 shows the Intellectual Customer

Data Collection/Analysis Integrated Model

developed by the author (Amasaka, 2004, 2005a,

2010a), which uses the Total Technical Intelligence

System (TTIS) and the Customer Science Utilizing

Customer Information Analysis and Navigation

System (CS-CIANS)—two of the core methods of

Science SQC.

As indicated in the figure, the system allows

companies to collect customer data from (1)

domestic and overseas dealers and (2) consulting

spaces as well as (3) customer quality information in

real time from research firms and the like using (4)

customer data input forms and customer data

retrieval forms. This information is then stored in a

searchable database. The system then uses a

company web that allows (5) divisions involved in

product design and (6) other related divisions to

obtain customer data and analyze it from multiple

angles.

This enables the partnering of preproduction,

testing/evaluation, and numerical simulations

(CAE), and further strengthens mutual collaboration

Figure 6: Intellectual Customer Data Collection/Analysis Integrated System.

ECTA 2011 - International Conference on Evolutionary Computation Theory and Applications

118

between related divisions and (7) the special advisor

in the quality assurance division. Customer data is

analyzed making full use of (8) statistical science

methods, which allows optimization of development

design specifications in real time, and then (9)

recorded in a database of analytical cases.

Additional analysis results are recorded as (10)

analytical case studies, where they can be viewed

using the company web and used by related

departments as technical assets. The next chapter

presents some application examples where these

core models were put to work in a comprehensive

way. The case examples verify the effectiveness of

the New Development Design CAE Deployment

Model created by the author.

4 APPLICATION

This chapter presents the case of automotive

transaxle oil seal leakage, a technical reliability

problem that generates bottlenecks for auto

manufacturers around the world. The author applied

his New Development Design CAE Employment

Model to resolve this issue. The model was then

applied to similar technical problems, where its

effectiveness was verified.

4.1 Automotive Transaxle Oil Seal

Leakage

The key to resolving problems where the faulty

mechanism is unclear is to use an empirical

approach and apply technology that allows

visualization of the dynamic behavior at the moment

the problem occurs. The structure of the problem

must then be unraveled so that an accurate model of

cause-and-effect relationships can be built. To

achieve this, the authors (Amasaka, 2004, 2005b,

2008, 2010b: Amasaka, Ed., 2007b: Ito, et al, 2010a,

2010b) applied the following analytical process: (1)

understand the phenomenon, (2) conduct a

visualization experiment, (3) conceptualize the

problem logically, (4) apply CAE analysis, and (5)

optimize the design. The result was a plan to resolve

oil leaks caused by age-related wear to the transaxle

oil seal lip.Figure 7 uses a relational diagram to

organize related causes and knowledge previously

collected on the problem. Because the mechanism

causing the oil leak was unknown, the pathway by

which it was generated is not clearly shown. Areas

of dynamic behavior that needed to be visualized

were specified and tested using a visualization

device.

Figure 7: Estimation of the Oil leakage mechanism.

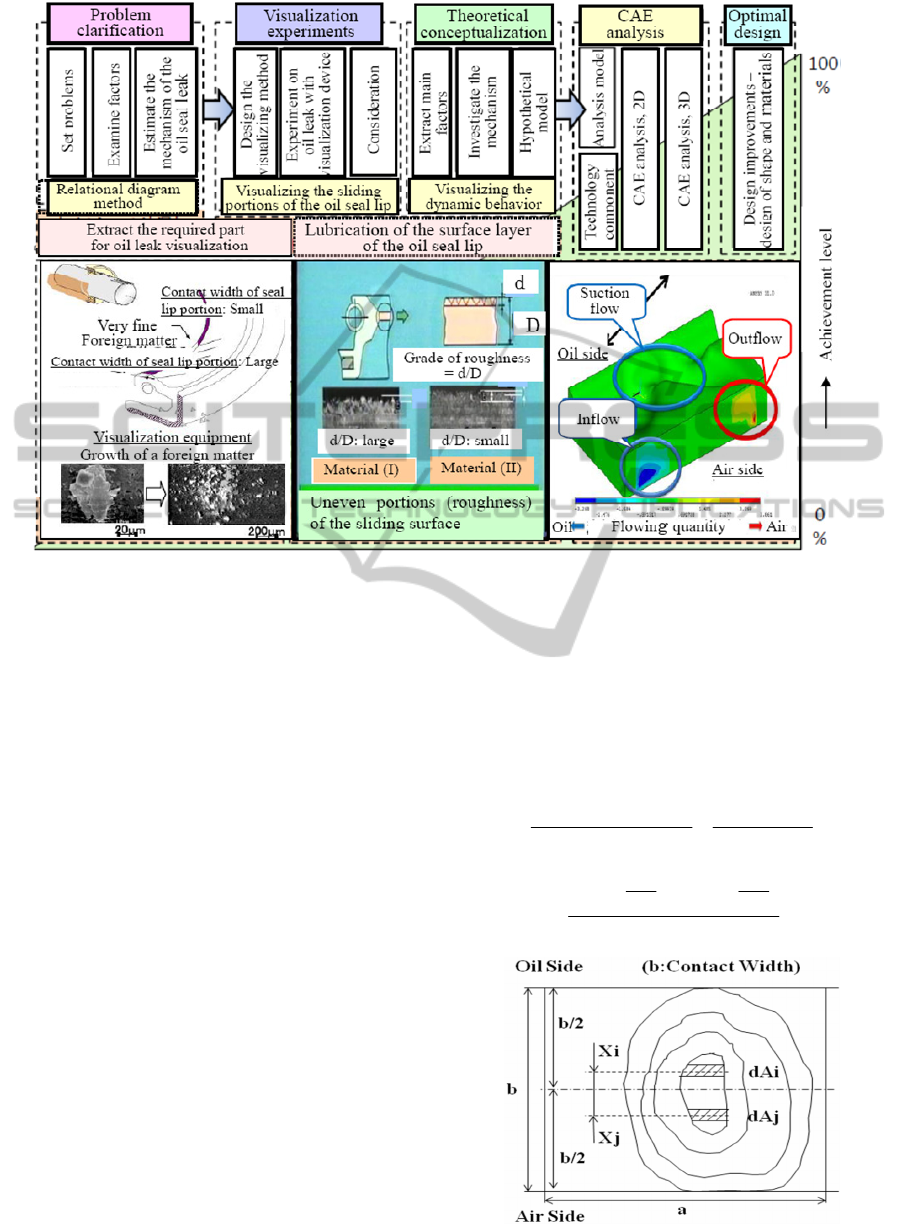

4.1.1 Highly Accurate CAE Analysis Model

Using Science SQC Approach

The problem is an unknown mechanism causing an

oil seal leakage on the surface of the drive shaft

during high-speed rotation (Lopez, et al., 1997).

Now, the authors will discuss the application of

highly accurate CAE analysis for drive train oil seal

leaks through a partnership between company C

(automotive assembly company) and company D

(parts supply company) as an example of cases

where the mechanism of technical problems is

unknown. As shown in Figure 8, the authors applied

an optimal CAE design approach to prevent

automobile oil seal leaks, incorporating Science

SQC approach methods.

As the figure shows, the authors contributed to

solving the problem of drive train oil seal leaks,

which is a bottleneck technological problem for

automotive manufacturers worldwide. This was

achieved through an analysis process involving

problem clarification, visualization experiments,

theoretical conceptualization, CAE analysis, and

optimal design. First, the authors began by

developing a device for visualizing the ascertained

phenomena in order to estimate the unknown

mechanisms involved in the leaks. This made it

possible to estimate the mechanism of the oil seal

leaks by visualizing the dynamic behavior involved

in the process whereby metal particles (foreign

matter) from gear rotation wear, found around the

rotating and sliding portions of the oil seal lip,

become mechanically fused and accumulate.

Next, the findings obtained were used to

formulate the following design countermeasures.

(i) Strengthen gear surfaces to prevent

occurrence of foreign matter even after 100,000 km

(improve quality of materials and heat treatments)

(ii) Formulate a design plan to scientifically

ensure optimum lubrication of the surface layer of

A NEW DEVELOPMENT DESIGN CAE EMPLOYMENT MODEL - Applying Numerical Simulation to Automobile

Bottleneck Technology

119

Figure 8: Highly Accurate CAE Analysis Model using Science SQC approach.

the oil seal lip (uneven portions of the sliding

surface) where it rotates in contact with the drive

shaft.

4.1.2 Sliding Surface Visualization

Experiment

The sliding side observation experiment was

conducted using three types of seals made of

different materials and shapes. Here, two seal

characteristic values are defined: (1) XG and (2) AR

as shown in Figure 9. XG is the distance that the true

contact area center of gravity is biased from the

sliding side center to either the oil side (1>XG>0) or

the atmospheric side (-1<XG<0); it is the

characteristic value that shows the extent true

contact area distribution bias axially. XG can be

interpreted as the maximum pressure position of the

contact pressure distribution. AR is a characteristic

value indicating roughness on the seal sliding side

level, and shows the proportion of the visible touch

area that is the real contact area.

Table 1 shows the characteristic seal values and

the outcome of the experiments for the three types.

In addition, leakage stopping can be classified

according to both characteristic values by looking at

the relationship between these two characteristic

values and the observed state of the leakage stopping

shown in Table 1. Sealing is achieved only in Seal 1

in the table, and sliding surfaces show the

characteristic values XG>0 and AR<0.05 (5%). It is

evident that the unique sliding side structure to

ensure sealing has minute surface roughness

(existence of minute projections) and the true

contact area is biased towards the oil side (Sato et

al., 1999: Kameike et al., 2000).

(1)

(2)

Figure 9: Pattern Diagram of the Sliding Side.

()

()

ba

A

R

×

==

area Shaded

area touch visibleThe

areacontact real The

∑∑

∑∑

+

⎟

⎠

⎞

⎜

⎝

⎛

−

⎟

⎠

⎞

⎜

⎝

⎛

=

dAjdAi

b

Xj

dAj

b

Xi

dAi

X

G

2/2/

ECTA 2011 - International Conference on Evolutionary Computation Theory and Applications

120

Figure 10. Technology Component Model of the “Oil Seal Simulator”.

Table 1: Outcome of the Experiments.

Type 1 Type 2 Type 3

X

G

0.02 0.47 0.04

A

R

0.14 0.05 -0.21

result Sealing Leakage Leakage

4.1.3 Technological Component Model of

the Oil Seal Simulator

In order to conduct a numerical analysis based on

the knowledge gained from the visualization

experiment, it is necessary to select the kinds of

technological elements involved. Appropriate

selection of technological elements (defining the

problem, modeling, algorithms, theory, and

computer technology) is a critical part of generating

highly reliable CAE analysis results.

Organically linking these technological elements

is what will make the CAE analysis a success.

The authors thus added the needed technological

component to the “Oil Seal Simulator” as shown in

Figure 10. In addressing the oil leakage

phenomenon, the problem is understanding the

pump volume and lip side pressure distribution that

directs the behavior and the oil circulation pattern on

the minute projection area of sliding surfaces. The

fluid resistance model, the contact model, and the

material component rule model were used to solve

these problems. The finite element method and

numeric fluid were analyzed as a convenient

algorithm. The Reynolds equation, Soft Elasto-

Hydrodynamic Lubrication, and Navier-Stokes

equation were appropriate theoretical formulas.

Accuracy is ensured, and the time integration

method, space difference method, and procession

method were the computer technologies used to

perform calculations in a realistic timeframe. Each

of the above elements was used to construct the oil

seal simulator.

4.1.4 CAE Qualitative Model of the Basic

Oil Seal Lip Structure

The visualization experiment yielded the conditions

on the sliding surface of the oil seal lip as a basic

structural element. The authors then used this

element to construct the CAE qualitative model of

the basic oil seal lip structure shown in Figure 11 in

order to demonstrate sealing conditions. The model

uses a statistical approximation of the slight

roughness on the sliding surface to show the wedge

effect created by minute projections.

Figure 11: CAE Qualitative Model of the Basic Oil Seal

Lip Structure.

In looking at seal conditions on the sliding

surfaces as a whole, the authors concluded that the

volume of inflow was greater at QAA’ than the

outflow at QBB’, based on the fact that minute

projections in section AA’ created a larger wedge

A NEW DEVELOPMENT DESIGN CAE EMPLOYMENT MODEL - Applying Numerical Simulation to Automobile

Bottleneck Technology

121

effect than the minute projections in section BB’.

These conditions also generated the oil circulation

pattern on the minute projection area of sliding

surfaces, which meant that wear could be prevented

by separating the two surfaces (Sato, et al., 1999:

Kameike, et al., 2000: Dong, et al., 2011).

4.1.5 CAE Analysis (2D and 3D)

Using the technological elements mentioned above,

a two-dimensional CAE analysis was used to

conduct a numerical simulation that would

accurately describe the behavior of the oil on the

problematic minute projection areas. Figure 12

shows the results of this analysis. It shows the space

between the shaft near minute projection AA’ and

minute projection BB’ and the seal where oil is

getting trapped. This two-dimensional analysis

shows that shear stress is being generated by the

fluid (oil) due to the rotation of the shaft and that the

seal side flow direction is being reversed as the

minute projections narrow the fluid channel. Next, a

three-dimensional analysis was conducted using a

structural model of the sliding surfaces as a whole.

The model took into account the direction of oil flow

in a third dimension (depth) based on the knowledge

gained from the visualization experiment and the

two-dimensional CAE analysis. The model was used

to do a numerical simulation of the oil film present

on the sliding surfaces.

Figure 12: A two-dimensional analysis.

Figure 13: A three-dimensional analysis.

Figure 14: Reduction in market complaint rate.

The analytical model shown in Figure 13 was

constructed based the CAE qualitative model of the

basic oil seal lip structure shown in Figure 11. By

imposing conditions such as shaft rotation speed, the

amount of oil flow on the oil side and air side could

be calculated. The oil flow to the seal side and to the

air side was compared, producing similar results to

the visualization experiment.

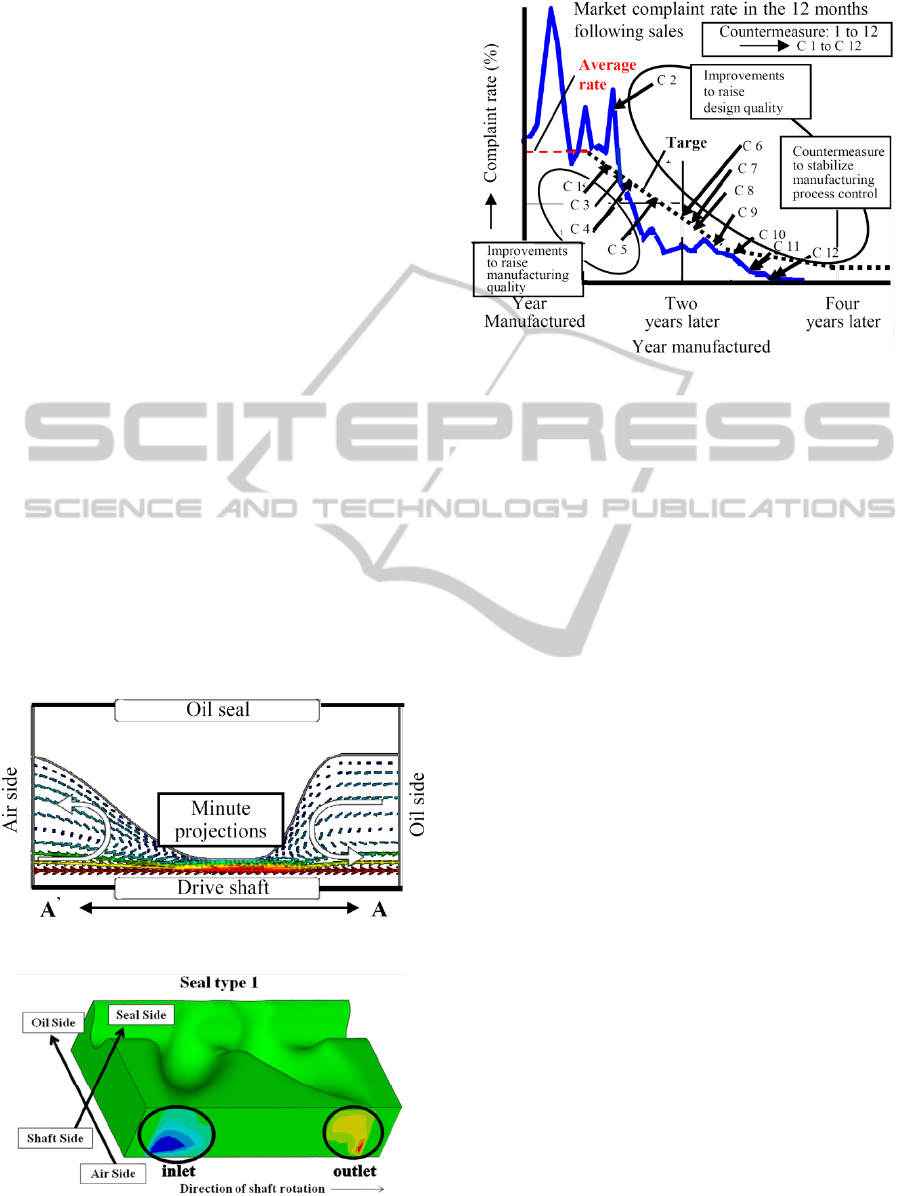

4.1.6 Quality Improvement

The visualization experiment above allowed the

dynamic behavior of the oil leak to be visualized;

more specifically, the dynamic behavior involved in

the process whereby metal particles (foreign matter)

from gear rotation wear, found around the rotating

and sliding portions of the oil seal lip, become

mechanically fused and accumulate. This

phenomenon was then reproduced in a two- and

three-dimensional CAE analysis with high precision

(with a deviation of around 3% versus prototype

testing evaluations). This information made it

possible to gain an approximate understanding of the

oil seal leak mechanism and optimize design

parameters using a numerical simulation.

These results led to two measures to improve

design quality (shape and materials): (1) strengthen

gear surfaces to prevent occurrence of foreign matter

even after the B10 life (L10 Bearing to MTBF

(Mean Time Between Failures)) to over 400,000 km

(improve quality of materials and heat treatments)

and (2) formulate a design plan to scientifically

ensure optimum lubrication of the surface layer of

the oil seal lip (uneven portions of the sliding

surface) where it rotates in contact with the drive

shaft. As shown in Figure 14, the result of these

countermeasures was a reduction in oil seal leaks

ECTA 2011 - International Conference on Evolutionary Computation Theory and Applications

122

(market complaints) to less than 1/20th their original

incidence.

4.2 Application to Similar Problems

With its effectiveness verified, the authors were able

to apply the New Development Design CAE

Employment Model to critical development design

technologies for automotive production, including

predicting and controlling the special characteristics

of automobile lifting power, anti-vibration design of

door mirrors (Amasaka, 2010b), urethane seat foam

molding (Amasaka, 2007), and loosening bolts

(Yamada and Amasaka, 2011:). In each of these

cases as well, discrepancy was 3–5% versus

prototype testing. Based on the achieved results, the

model is now being used as an intelligent support

tool for optimizing product design processes.

5 CONCLUSIONS

This research addresses the necessity reforming the

business processes associated with development

design, a critical component of manufacturing, by

proposing a New Development Design CAE

Employment Model that takes manufacturers away

from conventional preproduction and prototype

testing methods and towards a better predictive

evaluation method. The effectiveness of the model

was verified by successfully applying it to the

technological problem of development design

bottlenecks at auto manufacturers. The author wants

to make it further established as "Optimal CAE

Design Approach Mode" by deployment of this

model from now on.

ACKNOWLEDGEMENTS

The author would like to acknowledge the generous

support received from the following researchers. All

those at Working Group No. 4) studies in JSQC,

study group on the ideal situation for quality

management in the manufacturing industry, and

those connected with the Amasaka laboratory at

Aoyama Gakuin University.

REFERENCES

Amasaka, K., 2004, Science SQC, New Quality Control

Principle – The Quality Control of Toyota, Springer.

Amasaka, K., 2005a, Constructing a Customer Science

Application System “CS-CIANS”, WSEAS

Transactions on Business and Economics, Issue 3,

Vol. 2, pp. 135-142.

Amasaka, K.,, 2005b, Interim Report of WG4’s studies in

JSQC Research on Simulation and SQC(1)-A Study of

the High Quality Assurance CAE Model for Car

Development Design,, 1st Technical Conference

Nagano, Japan, pp. 93-98.

Amasaka, K., 2007, Highly Reliable CAE Model, The

Key to Strategic Development of Advanced TDS,

Journal of Advanced Manufacturing Systems, Vol. 6,

No. 2, pp. 159-176.

Amasaka, K., 2008, An Integrated Intelligence

Development Design CAE Model Utilizing New JIT,

Journal of Advanced Manufacturing Systems, Vol. 7,

No. 2, pp. 221-241.

Amasaka. K., 2010a. Chapter 4.Product Design, Quality

Assurance Guidebook, New ed,. JSOC, pp. 87-101.

Amasaka, K., 2010b, Proposal and Effectiveness of a High

Quality Assurance CAE Analysis Model, Current

Development in Theory and Applications of Computer

Science, Engineering and Technology, Vol. 2, No. 1/2,

August/November Issue, pp. 23-48.

Amasaka, K., (Ed), 2007a, Establishment of a Needed

Design Quality Assurance Framework for Numerical

Simulation in Automobile Production, Working Group

No. 4 Studies in JSQC.

Amasaka, K., (Ed)., 2007b, New Japan Model - Science

TQM, Study Group on the Ideal Situation of Quality

Management in the Manufacturing Industry, Maruzen.

Ito, T., Sato, M., Yamaji, M., and Amasaka, K., 2010a, An

Analysis of Bottleneck Technology by Using

Experiments and CAE, International Business &

Economics Research Journal, Vol. 9, No. 12, pp. 123-

129.

Ito, T., Matsuura, S., and Amasaka, K., 2010b, Optimized

Design using High Quality Assurance CAE, The

Japanese Society for Quality Control, The 40th

Annual Technical Conference, Seijyo University,

Japan, pp.189-192.

Dong, Y, Fan, X,, and Liu, B., 2011, Numerical

Simulation and Technology Optimization of Rear Oil

Seal Bearing Die Casting Based on ProCast,

Advanced Materials Research, Volx, 89-193, pp. 189-

193.

Leo, J. D. V., Annos, N., and Oscarsson, 2004, Simulation

Based Decision Support for Manufacturing System

Life Cycle Management, Journal of Advanced

Manufacturing Systems, Vol. 3, No. 2, pp. 115-128.

Kameike, M., Ono, S., and Nakamura, K., 2000, The

Helical Seal: Sealing Concept and Rib Design Sealing

Technology, International 77 pp. 7-11.

Kume, H., 1999, Quality Management in Design

Development, JUSE.

Lopez, A.M., Nakamura, K., and Seki, K., 1997, A Study

on the Sealing Characteristics of lip Seals with Helical

Ribs, in Proc. 15th Int. Conf. British Hydromechanics

Research Group Ltd Fluid Sealing, pp. 1-11.

A NEW DEVELOPMENT DESIGN CAE EMPLOYMENT MODEL - Applying Numerical Simulation to Automobile

Bottleneck Technology

123

Magoshi, Y, Fujisawa, H., and Sugiura,.T., 2003,

Simulation Technology Applied to Vehicle

Development, Journal of Society of Automotive

Engineers of Japan, Vol. 53, No. 3, pp. 95-100.

Sato, Y., Toda, A., Ono, S., Nakamura, K., 1999, A Study

of the Sealing Mechanism of Radial Lip Seal with

Helical Robs–Measurement of the Lubricant

Fluid Behavior under Sealing Contact, SAE Technical

Paper Series, 1999-01-0878.

Yamada, H., and Amasaka, K., 2011, Highly Reliable

CAE Analysis Approach- Application in Automotive

Bolt Analysis, China-USA Business Review, Vol. 10,

No. 3, pp. 199- 205.

ECTA 2011 - International Conference on Evolutionary Computation Theory and Applications

124