CHAOTIC ANALYSIS OF METAL CUTTING WITH

NONLINEAR SUSPENSION

Cai-Wan Chang-Jian, Hsieh-Chung Hsu, Guan-I Wu and Cheng-I Weng

1

Department of Mechanical and Automation Engineering, I-Shou University, 1, Section 1, Hsueh-Cheng Rd.

Ta-Hsu Hsiang, Kaohsiung County, Taiwan 840, R.O.C.

Keywords: Chaos, Cutting, Nonlinear suspension.

Abstract: This study performs a systematic analysis of dynamic behavior of cutting process of machine tool with

unbalance force induced from mass eccentricity of work-piece, nonlinear cutting force and nonlinear

suspension effect. Phase diagrams, power spectra, bifurcation diagrams and Poincaré section are applied to

identify the dynamic motions in this study. The simulation results show that the non-periodic dynamic

responses are very abundant in cutting process of machine tool. The results presented in this study provide

an understanding of the operating conditions under which undesirable dynamic motion takes place in this

kind of system and therefore serve as a useful source of reference for engineers in designing and controlling

such systems.

1 INTRODUCTION

Since the mechanisms among tool, workpiece and

chip are complicated in the cutting process, the

analytical difficulties are increased in studying

related academic researches and the complete

studying is also hard to achieve. There are many

significant and dramatic investigations are

performed before. The dynamics analysis of cutting

based on the model of Hastings, Oxley and

Stevenson was the most popular model for many

studies and many studies are based on the

mathematical model proposed by them (Hastings et

al., 1971). Grabec presented a series of papers

discussing chaotic dynamic responses occurring in

cutting machines and also found some mechanisms

of chaos in the cutting process (Grabec, 1988).

Altintas, Eynian and Onozuka investigated the

influence of vibrations on the cutting forces (Altintas

et al., 2008). Powalka, Pajor and Berczynski

presented a special experiment used for cutting force

identification to eliminate the regenerative

phenomenon and also to improve the accuracy

(Powalka et al., 2009). Hamed, Firooz, Mohammad

and Mohammad proposed a single degree of

freedom dynamic system including quadratic and

cubic structural nonlinearities and found abundant

nonlinear behaviors (Hamed et al., 2010). Therefore,

we would know that cutting process is a highly

nonlinear phenomenon and the linearization or

simplification of analyzing cutting process may

cause some simulation errors.

The related literatures are very comprehensive,

some assumptions or linearization are performed in

order to simplify the simulation model and

economize simulation time. The assumptions or

linearization may lead some dramatic errors

comparing with real state. In this study, we consider

the nonlinear dynamic responses in cutting process

of machine tool with nonlinear suspension effect and

also take the nonlinear cutting force into

consideration. The nonlinear dynamic equations are

solved using the fourth order Runge-Kutta method.

The dynamic trajectories, power spectrum, Poincaré

maps and bifurcation diagrams are applied to

analyze dynamic motions.

2 MATHEMATICAL MODELING

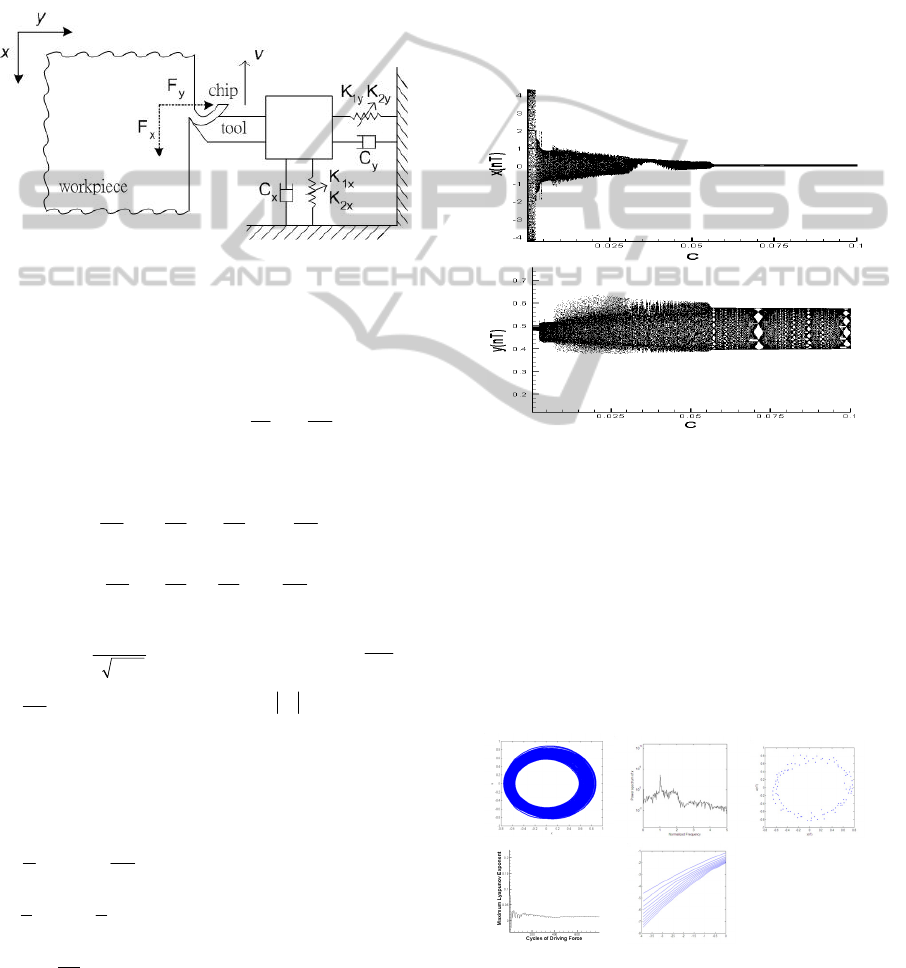

Fig. 1 represents the model of metal cutting under

nonlinear suspension. K

1x

and K

2x

are the first and

second equivalent stiffness coefficients in the

vertical direction; K

1y

and K

2y

are the first and

second equivalent stiffness coefficients in the

horizontal direction; C

x

and C

y

are the damping

501

Chang-Jian C., Hsu H., Wu G. and Weng C..

CHAOTIC ANALYSIS OF METAL CUTTING WITH NONLINEAR SUSPENSION.

DOI: 10.5220/0003645305010504

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (MSIE-2011), pages 501-504

ISBN: 978-989-8425-75-1

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

coefficients of the supported structure in the vertical

and horizontal directions respectively; F

x

and F

y

are

the components of external excited cutting forces; F

y

is the cutting force dependence on the cutting speed

and chip thickness; F

x

is the thrust force which is

related to the main cutting force through a related

frictional coefficient μ (F

x

=μF

y

). The nonlinear parts

of dynamic equations include nonlinear suspension

term (hard spring case) and the nonlinear cutting and

thrust force term.

Figure 1: Model of metal cutting under nonlinear

suspension.

3

12

x

M

xCxKxKx F++ + =

(1)

3

12 y

M

yCyKyKy F++ + =

(2)

Let X= x

/h

0

; Y= y/h

0

;

τ

=

ω

t;

dd

dt d

ω

τ

= ; (

•

)

denotes d/dt and(′)denotes d/dτ.

3

22

21

x

F

XXXX

s

p

ss

ξα

′′ ′

+++ =

(3)

3

22

21

y

F

YYYY

s

p

ss

ξα

′′ ′

+++ =

(4)

where

1

2

C

K

M

ξ

=

,

2

0

pMh

ω

=

,

2

2

2

n

s

ω

ω

=

,

2

2

0

1

K

h

K

α

=

,

yx

F

F

μ

=

,

2

01

[( 1) 1]()

xr

FqhCV Hh=−+

,

22

23

[ ( 1) 1][ ( 1) 1] ( ) sgn( )

f

xf

Cv Ch HF V

μ

=−+−+

[2-3],

0r

VVX

′

=−

,

0f

VVRY

′

=−

,

0

hh Y=−

, and

2

04

[ ( 1) 1]

r

RRCV=−+

.

()

x

H

F

may be approximated

as

1

[1 tanh( )]

2

x

F

ε

+ , ()

H

h may be approximated

as

1

[1 tanh( )]

2

h

ε

+

and

sgn( )

f

V

may be approximated

as

tanh( )

f

v

ε

.

The fourth order Runge-Kutta method is applied

to carry out the numerical analysis. These numerical

data are then used to generate the dynamic

trajectories, power spectrum, Poincaré maps and

bifurcation diagrams.

3 NUMERICAL RESULTS AND

DISCUSSIONS

In the present study, the nonlinear dynamics of the

cutting system shown in Figure 1 are analyzed using

Poincaré maps, bifurcation diagrams, the Lyapunov

exponent and the fractal dimension.

Figure 2: Bifurcation diagrams for geometric center of

cutting system using dimensionless damping ratio,

ξ

, as

bifurcation parameter.

The nonlinear dynamic equations presented in

Eqs. (3) to (4) for the cutting system with nonlinear

suspension effects and strongly nonlinear cutting

force were solved using the fourth order

Runge-Kutta method. The time step in the iterative

solution procedure was assigned a value of

π

/300

and the termination criterion was specified as an

error tolerance of less than 0.0001.

Figure 3: Simulation results obtained for cutting system

with

ξ

=0.015 (x).

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

502

Figure 4: Simulation results obtained for cutting system

with

ξ

=0.015 (y).

Figure 5: Simulation results obtained for cutting system

with

ξ

=0.025 (x).

Figure 6: Simulation results obtained for cutting system

with

ξ

=0.025 (y).

In practical cutting systems, dimensionless damping

coefficient

ξ

is commonly used as a control

parameter. Accordingly, the dynamic behavior of the

current cutting system was examined using the

dimensionless damping coefficient

ξ

as a

bifurcation control parameter. Figure 2 presents the

bifurcation diagrams for the cutting system

displacement against the dimensionless damping

coefficient

ξ

. The bifurcation diagrams show that

the geometric center of cutting system performs

non-synchronous motions in horizontal and vertical

directions. The strongly non-periodic or even chaotic

motions occurring at lower dimensionless damping

coefficient and convergent its non-periodic dynamic

responses to be periodic motions and the vibration

amplitude also decreased at higher values in the

horizontal direction, i.e.

0.0575

ξ

>

. The above

simulation result is seemed to be satisfied natural

phenomenon. Though in the meantime, the dynamic

responses of the cutting system in the vertical

direction behave strongly different comparing with

horizontal cases. As damping coefficient increases,

the dynamic motions still perform non-periodic

response and even for higher values (

0.0575

ξ

> ).

Thus we found very interesting non-synchronous

motions in vertical and horizontal directions

especially at higher damping coefficients. As we

know, we may think the cutting system or other

vibrating machine system would become steady at

higher damping coefficient but actually the

suspension of this system is highly nonlinear

(Naturally or technically speaking, the suspension of

those machine systems should be nonlinear case).

Thus we may not seem they to be synchronous

behaviors in the vertical and horizontal directions of

the cutting systems and it may provide some

interesting or considerable information to analyze or

control these kind of systems. Figures 3 to 6 are the

phase diagrams, power spectra, Poincaré Map,

Lyapunov exponent and fractal dimension of the

cutting system found chaotic motions at

0.015 0.025and

ξ

=

in vertical and horizontal

directions. It also shows that the dynamic responses

are synchronous in vertical and horizontal directions

from observing simulation results, firstly. Secondly,

Phase diagrams show disordered dynamic behaviors;

power spectra reveal numerous excitation

frequencies; the return points in the Poincaré maps

form geometrically fractal structures; the maximum

Lyapunov exponent is positive; the fractal

dimensions are found to be non-integer. Thus we

may conclude that the dynamic motions perform

chaotic motions at the above control parameters with

the simulation results are corresponding with one

another. The dimensionless rotating speed s is also

an important control parameters to analyze dynamic

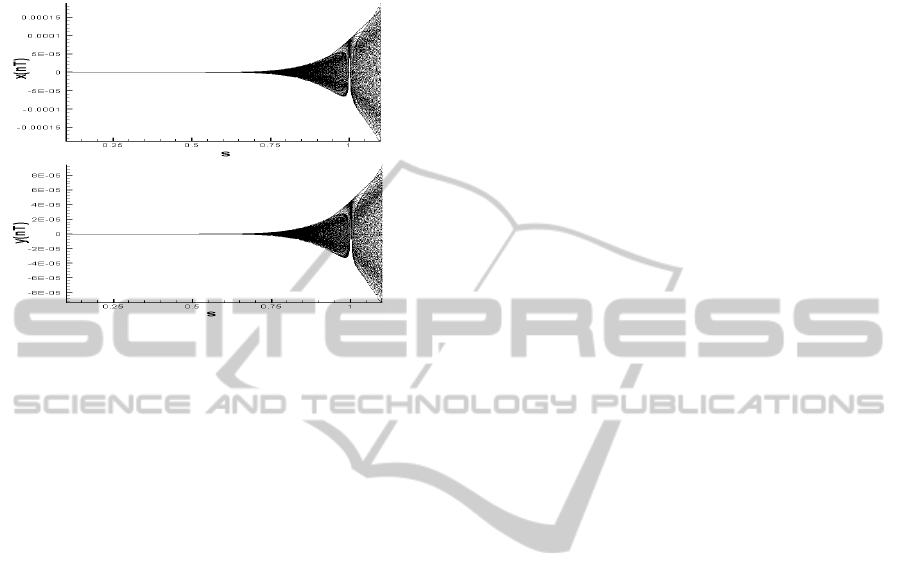

responses of rotating machines. Figure 7 present the

bifurcation diagrams for the dimensionless

displacement in the vertical and horizontal direction

of the cutting system using the dimensionless

rotating speed s as a bifurcation parameter. It can be

observed that the cutting system behaves periodic

motions at low rotating speeds and exhibits

CHAOTIC ANALYSIS OF METAL CUTTING WITH NONLINEAR SUSPENSION

503

non-periodic or even chaotic motions at high values

of the dimensionless rotating speed. Besides, we also

found that they are synchronous in the vertical and

horizontal directions.

Figure 7: Bifurcation diagrams for geometric center of

cutting system using dimensionless rotating speed, s, as

bifurcation parameter.

4 CONCLUSIONS

This work shows that chaotic behavior exists in the

cutting system with nonlinear suspension and

nonlinear cutting force. Some interesting and useful

simulation results are also found in this study.

Specially, we found that dynamic responses behave

non-synchronous in the vertical and horizontal

directions with the increasing of the value of

dimensionless damping coefficient. It is well known

that if a nonlinear dynamic system behavior is

chaotic, the resulting broad band vibration with

comparatively large vibrational amplitude will

enhance the probability of fatigue failure. In order to

increase the working life of cutting system or

enhance the performance of cutting system, it is

important not to operate the whole system at chaotic

motions. Therefore, this study may aid the

theoretical understanding of nonlinear systems of

cutting machine tool and escape the undesired

dynamic responses for machining.

REFERENCE

Altintas, Y., Eynian, M. and Onozuka, H. (2008).

Identification of dynamic cutting force coefficients

and chatter stability with process damping. Annals of

CIRP, 57, 371-374.

Grabec, I. (1988). Chaotic dynamics of the cutting process.

International Journal of Machine Tools and

Manufacture, 28, 19-32.

Grabec, I. (1988). Explanation of random vibrations in

cutting on grounds of deterministic chaos. Robotics

and Computer-Integrated Manufacturing, 4, 129-134.

Hastings, W. F., Oxley, P. L. B. and Stevenson, M. G.

(1971) Proceedings of the 12th International Machine

Design and Research Conference, Manchester,

(MacMillan).

Hamed, M., Firooz, B. N., Mohammad, R. M. and

Mohammad, T. A. (2010). Nonlinear behaviour of

regenerative chatter in turning process with a worn

tool: Forced oscillation and stability analysis.

Mechanism and Machine Theory, 45, 1050-1066.

Powalka, B., Pajor, M. and Berczynski, S. (2009).

Identification of nonlinear cutting process model in

turning. Advances in Manufacturing Science and

Technology, 33(3), 17-25.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

504