NONLINEAR METAMODELING

AND ROBUST OPTIMIZATION IN AUTOMOTIVE DESIGN

Tanja Clees, Igor Nikitin, Lialia Nikitina and Clemens-August Thole

Fraunhofer Institute for Algorithms and Scientific Computing, Schloss Birlinghoven, 53754, Sankt Augustin, Germany

Keywords: Surrogate models, Bulky data, Multiobjective optimization, Stochastic analysis.

Abstract: We overview the methods for nonlinear metamodeling of a simulation database featuring continuous

exploration of simulation results, tolerance prediction, sensitivity analysis, robust multiobjective

optimization and rapid interpolation of bulky FEM data. Large scatter of simulation results, in crash-test

simulations caused for example by buckling, is still a challenging issue for increasing predictability of

simulation and accuracy of optimization results. For industrially relevant simulations with large scatter,

novel stochastic methods are introduced and their efficiency is demonstrated for benchmark cases.

1 INTRODUCTION

Simulation is an integral component of virtual

product development today. The task of simulation

consists mainly in solution of physical models in the

form of ordinary or partial differential equations.

From the viewpoint of product development the real

purpose is product optimization, and the simulation

is "only" means for the purpose. Optimization means

searching for the best possible product with respect

to multiple objectives (multiobjective optimization),

e.g. total weight, fuel consumption and production

costs, while the simulation provides an evaluation of

objectives for a particular sample of a virtual

product.

The optimization process usually requires a

number of simulation runs, the results form a

simulation dataset. To keep simulation time as short

as possible, "Design of Experiments" (DoE, (Tukey

1997)) is applied, where a space of design variables

is sampled by a limited number of simulations. On

the basis of these samples, a surrogate model is

constructed, e.g. a response surface (Donoho, 2000),

which describes the dependence between design

variables and design objectives. Modern surrogate

models (Jones et al. 1998; Keane et al. 2005; Nikitin

et al. 2008-2010) describe not only the value of a

design objective but also its tolerance limits, which

allow to control precision of the result. Moreover,

not only scalar design objectives but whole

simulation results, even highly resolved in

space/time, (”bulky” dataset) can be modeled

(Nikitin et al., 2008-2010).

In this paper we will concentrate on stochastic

aspects of simulation processes. Industrial

simulations, e.g. virtual crash tests, often possess a

random component, related to physical and

numerical instabilities of the underlying simulation

model and uncertainties of its control parameters.

Under these conditions the user is interested not only

in the mean value of an optimization criterion, e.g.

crash intrusion, but also in its scatter over

simulations. In practice, it is required to fulfil

optimization objectives with a certain confidence,

e.g. 6-sigma. This task belongs to the scope of

robustness or reliability analysis.

Often, the confidence intervals are so large that

one has to reduce scatter before optimization. There

is a part of scatter deterministically related to the

variation of design variables, which can be found by

means of sensitivity analysis. The other part is

purely stochastic. It can be triggered by microscopic

variations of design variables and - even if they are

fixed - by the numerical process itself, e.g. by

random scheduling in multiprocessing simulation.

These microscopic sources are then amplified by

inherent physical instabilities of the model related

e.g. to buckling, contact phenomena or material

failure. Stochastic analysis allows to track the

sources of scatter, to reconstruct causal chains and to

identify hidden parameters describing chaotic

behavior of the model. If uncontrolled, these

parameters propagate scatter to the optimization

483

Clees T., Nikitin I., Nikitina L. and Thole C..

NONLINEAR METAMODELING AND ROBUST OPTIMIZATION IN AUTOMOTIVE DESIGN.

DOI: 10.5220/0003646704830491

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SDDOM-2011), pages

483-491

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

objectives. The challenge is to put them under

control, at least partially, e.g. by predeformation of

buckling parts, adjustment of contact conditions,

placement of additional welding points etc. In this

way the scatter of simulation can be suppressed and

optimization becomes more robust.

In Sec.2 we will overview the methods for

metamodeling of bulky simulation results; in Sec.3

we describe stochastic methods for reliability and

causal analysis; Sec.4 presents applications of these

methods to real-life examples in automotive design.

The approaches presented in this paper have been

implemented in software tools DiffCrash (Thole et al

2003-2008) and DesParO (Nikitin et al., 2008-2010)

and have been subjects of international patent

applications (DPMA 10 2009 057295.3 and PCT/

EP2010/061439).

2 RBF METAMODEL

Numerical simulations define a mapping y=f(x):

R

n

→R

m

from n-dimensional space of simulation

parameters to m-dimensional space of simulation

results. In crash test simulation the dimensionality of

simulation parameters x is moderate (n~10-30),

while simulation results y are dynamical fields

sampled on a large grid, typically containing

millions of nodes and hundreds of time steps,

resulting in values of m~10

8

. High computational

complexity of crash test models restricts the number

of simulations available for analysis (typically

Nexp<10

3

) which is preferred to be as small as

possible.

Metamodeling with radial basis functions (RBF)

is a representation of the form

f(x)=∑

i=1..

Nex

p

c

i

Φ

(|x-x

i

|),

(1)

where Φ() are special functions, depending only on

the Euclidean distance between the points x and x

i

.

The coefficients c

i

can be obtained by solving a

linear system

y

i

=∑

j

c

j

Φ(|x

i

-x

j

|)

(2)

where y

i

=f(x

i

). The solution can be found by direct

inversion of the moderately sized Nexp*Nexp

system matrix Φ

ij

=Φ(|x

i

-x

j

|). The result can be

written in a form of weighted sum f(x)=∑

i

w

i

(x)y

i

,

with the weights

w

i

(x)=∑

j

Φ

-1

i

j

Φ(|x-x

j

|).

(3)

A suitable choice for the RBF, providing non-

degeneracy of Φ-matrix for all finite datasets of

distinct points and all dimensions n, is the multi-

quadric function (Buhmann 2003) Φ(r)=(b

2

+r

2

)

1/2

,

where b is a constant defining smoothness of the

function near data point x=x

i

. RBF interpolation can

also be combined with polynomial detrending,

adding a polynomial part p():

f(x)=

∑

i=1..Nex

p

c

i

Φ

(|x-x

i

|)+p(x).

(4)

This allows reconstructing exactly polynomial

(including linear) dependencies and generally

improving precision of interpolation. The precision

can be controlled via the following cross-validation

procedure: the data point is removed, data are

interpolated to this point and compared with the

actual value at this point. For an RBF metamodel

this procedure leads to a direct formula (Nikitin et

al., 2010)

err

i

= f

inter

p

ol

(x

i

)-f

actual

(x

i

) = -c

i

/(Φ

-1

)

ii

.

(5)

Specifics of Bulky Data: although RBF metamodel

is directly applicable for interpolation of

multidimensional data, it contains one matrix-vector

multiplication f(x)=yw(x), comprising O(mNexp)

floating point operations per every interpolation.

Here y

ij

, i=1..m, j=1..Nexp is the data matrix, where

every column forms one experiment, every row

forms a data item varied in experiments.

Dimensional reduction technique applicable for

acceleration of this computation is provided by

principal component analysis (PCA). At first, an

average value is row-wise subtracted, forming

centered data matrix dy

ij

= y

ij

- <y

i

>. For this matrix

a singular value decomposition (SVD) is written:

dy=UΛV

T

, where Λ is a diagonal matrix of size

Nexp*Nexp, U is a column-orthogonal matrix of

size m*Nexp, V an orthogonal square matrix of size

Nexp*Nexp:

U

T

U=1, V

T

V=VV

T

=1. (6)

A computationally efficient method (Nikitin et al

2010) for this decomposition in the case m>>Nexp

is to find Gram matrix G=dy

T

dy, to perform its

spectral decomposition G=VΛ

2

V

T

, and to compute

the remaining U-matrix with post-multiplication

U=dyVΛ

-1

. The Λ values are non-negative and

sorted in non-ascending order. If all these values in

the range k>Nmod are omitted (set to zero), the

resulting reconstruction of y-matrix will have a

deviation δy. L

2

-norm of this deviation gives

err

2

=

∑

i

j

δ

y

i

j

2

=

∑

k>Nmod

Λ

k

2

(7)

(Parseval’s criterion). This formula allows

controlling precision of reconstructed y-matrix.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

484

.

Usually Λ

k

rapidly decreases with k, and a few first

Λ values give sufficient precision. The result of

interpolation is represented as a product df=Ψg of

SVD modes Ψ=UΛ (principal components) to SVD-

transformed RBF weights g=V

T

w. Finally one has

f(x)=<y>+df(x), computational cost of interpolation

is reduced to O(m Nmod), plus once-charged O(m

Nexp

2

) cost of SVD. This method is convenient

when interpolation should be performed many times

(>>Nexp), e.g. for interactive exploration of

database.

More generally, for representation of bulky data

one can use clustering techniques (Nikitin et al.,

2010). They also decompose bulky data over a few

basis vectors (modes) and accelerate linear algebra

operations with them.

3 RELIABILITY ANALYSIS

The purpose of reliability analysis is an estimation

of confidence limits (CL) for simulation results:

P(y<CL)=C, where P is probability measure and C is

a user specified confidence level. For example,

median corresponds to 50% CL, i.e. P(y<med)=0.5;

while 68% CL corresponds to confidence interval

[CLmin,CLmax], where P(y<CLmin)=0.16,

P(y≥CLmax)=1-P(y<CLmax)=0.16; etc. Several

methods for solution of this task are available.

3.1 First Order Reliability Method

(FORM)

FORM is applicable for linear mapping f(x) and

normal distribution of simulation parameters:

ρ

(x)~exp(-(x-x

0

)

T

cov

x

-1

(x-x

0

)/2).

(8)

Here x

0

=<x> is mean value of x and

(cov

x

)

i

j

=<(x-x

0

)

i

(x-x

0

)

j

> (9)

is covariance matrix of x. In this case y is also

normally distributed, with mean value

y

0

=<y>=med(y)=f(x

0

(10)

and covariance matrix

cov

y

= J cov

x

J

T

, (11)

where J

ij

= ∂f

i

/∂x

j

is Jacoby matrix of f(x), called

also sensitivity matrix. The diagonal part of cov

y

gives standard deviations σ

y

2

directly defining

CL(y), e.g.

CL

min/max

(68%)=<y>±σ

y

,

(12)

CL

min/max

(99.7%)=<y>±3σ

y

.

(13)

In particular, when simulation parameters are

independent random values, cov

x

becomes diagonal:

cov

x

=diag(σ

x

2

), and

σ

y

i

2

=

∑

j

=1..n

(

∂

f

i

/

∂

x

j

)

2

σ

x

j

2

.

(14)

A finite difference scheme used to compute Jacoby

matrix of f(x) requires Nexp=O(n) simulations, e.g.

2n for central difference scheme plus one

experiment at x

0

, Nexp=2n+1. The algorithm

possesses computational complexity O(nm) and can

be implemented efficiently as reading data from

Nexp simultaneously open data streams and writing

CL to a single output data stream. In this way the

memory requirements can be minimized and

parallelization can be done straightforwardly.

3.2 Second Order Reliability

Method (SORM)

SORM is applicable for slightly non-linear mapping

f(x), which can be approximated by quadratic

functions. The distributions ρ(x) are normal or can

be cast to normal ones by a suitable transformation

of parameter. For quadratic approximations CL can

be explicitly computed (Cizelj et al., 1994) using

main curvatures in the space of normalized variables

z

i

=(x-x

0

)

i

/σ

xi

, i.e. eigenvalues of Hesse matrix

H

i

jk

=∂

2

f

i

/∂z

j

∂z

k

. These eigenvalues can be also used

to estimate non-linearity of the mapping f(z), by

maximizing the 1st and 2nd Taylor's terms over a

ball of radius R:

max

|z|≤R

Jz=|J|R, max

|z|≤R

|z

T

Hz/2|=Hmax R

2

/2,

(15)

so that the linear term prevails over quadratic one, in

this ball, iff |J|>>Hmax R/2. Here

J

ij

=

∂

f

i

/

∂

z

j

, |J|=(

∑

j

J

ij

2

)

1/2

(16)

and Hmax is maximal absolute eigenvalue of H.

Both this criterion and estimation of main curvatures

require full Hesse matrix, i.e. Nexp=O(n

2

)

simulations. Practically, the usability of SORM is

limited, because strongly non-linear functions would

involve higher order terms and because distributions

of simulation parameters can strongly deviate from

normal ones.

3.3 Confidence Limits Determination

with Monte Carlo Method

(CL-MC)

In the case of non-linear mapping f(x) and arbitrary

distribution ρ(x) general Monte Carlo method is

applicable. The method is based on estimation of

probability

NONLINEAR METAMODELING AND ROBUST OPTIMIZATION IN AUTOMOTIVE DESIGN

485

P

N

(y<CL) = num.of (y

n

<CL)/N

(17)

for a finite sample {y

1

,...,y

N

}. By the law of large

numbers (van der Vaart, 1998), F

N

=P

N

(y<CL) is

consistent unbiased estimator for F=P(y<CL), i.e.

F

N

→F with probability 1, when N→∞ and <F

N

> =

F for all finite N. By the central limit theorem (van

der Vaart 1998), the error of such estimation

err

N

=F

N

-F at large N is distributed normally with

zero mean and standard deviation σ∼(F(1-F)/N)

1/2

.

Algorithmically the method consists of three phases:

(CL1) generation of N random points in parameter

space according to user specified distribution ρ(x),

(CL2) numerical simulations for given parameter

values,

(CL3) determination of confidence limits by one-

pass reading of simulation results, sorting m samples

{y

1

,...,y

N

} and selection of k-th item in every sample

with k=[(N-1)F+1] as a representative for CL.

The analysis phase of the algorithm possesses

computational complexity O(mN log N) and can be

efficiently implemented using data stream operations

similar to FORM. Precision of the method is

estimated using standard deviation formula above.

Remarkably, the precision depends neither on

dimension of parameter space n, nor on the length of

simulation result m, but only on sample size

N=Nexp and user-specified confidence level F=C.

For instance, CL determination at the level 68%

(F=0.16) with 4% precision requires Nexp=84, while

for 68%±1% one needs Nexp=1344.

3.4 Monte Carlo Combined with RBF

Metamodel (MC-RBF)

Large sample size is required for precise

determination of CL with Monte Carlo method. To

reduce the number of required simulations, RBF

metamodel can represent the mapping f(x) during

analysis phase of CL-MC. While a metamodel can

be constructed using a moderate number of

simulations, e.g. Nexp~100, determination of CL

can be done with N>>Nexp. Application of RBF

metamodel for CL computation proceeds similarly

to CL-MC. The only difference is that Nexp

parameter points generated at phase (CL1) are used

as input for the metamodel. They should not

necessarily possess user specified distribution, but

one providing better precision of metamodel, i.e.

better covering "the corners" of parameter space. It

is especially important for populating tails of

distribution, corresponding to high confidence e.g.

99.7% CL. Uniform distribution is suitable for this

purpose. Then, after numerical simulations at phase

(CL2), and after filtering out failed experiments, the

actual distribution ρ(x) is used to generate N

parameter points, and construct RBF weight matrix

w

ij

=w

i

(x

j

), i=1..Nexp, j=1..N. This matrix is used in

phase (CL3) for multiplication with simulation

results y

ik

, k=1..m, comprising O(m N Nexp)

operations, which usually prevails over O(m N log

N) operations needed for sorting of interpolated

samples.

4 CAUSAL ANALYSIS

Causal analysis is determination of cause-effect

relationships between events. In context of crash test

analysis, this usually means identification of events

or properties causing the scatter of the results. This

allows to find sources of physical or numerical

instabilities of the system and helps to reduce or

completely eliminate them.

Causal analysis is generally performed by means

of statistical methods, particularly, by estimation of

correlation of events. It is commonly known that

correlation does not imply causation (this logical

error is often referred as "cum hoc ergo propter

hoc": "with this, therefore because of this"). Instead,

strong correlation of two events does mean that they

belong to the same causal chain. Two strongly

correlated events either have direct causal relation or

they have a common cause, i.e. a third event in the

past, triggering these two ones. This common cause

will be revealed, if the whole causal chain i.e. a

complete sequence of causally related events will be

reconstructed. Practical application of causal

analysis requires formal methods for reconstruction

of causal chains.

A practical problem of causal analysis in crash-

test simulations is often not a removal of a prime

cause of scatter, which is the crash event itself. It is

more an observation of propagation paths of the

scatter, with a purpose to prevent this propagation,

by finding regions where scatter is amplified (e.g.

break of a welding point, pillar buckling, slipping of

two contact surfaces etc). Since a small cause can

have large effect, formally earliest events in the

causal chain can have a microscopic amplitude

("butterfly effect"). Therefore it is reasonable to

search for amplifying factors and try to eliminate

them, not the microscopic sources.

As input for causal analysis the centered data

matrix dy

ij

, i=1..m, j=1..Nexp is used. Here every

column forms one experiment, every row forms a

data item varied in experiments, and the mean value

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

486

.

<y> is row-wise subtracted from the matrix. Then

every data item is transformed to a z-score vector

(Larsen and Marx, 2001):

z

ij

=dy

ij

/|dy

i

|, |dy

i

|=sqrt(∑

j

dy

ij

2

),

(18)

or by means of the equivalent alternative formula

z

ij

=dy

ij

/(s(y

i

)(N

exp

)

1/2

), s(y

i

)=(∑

j

dy

ij

2

/N

exp

)

1/2

.

(19)

Here s(y

i

) is the root mean square deviation of the i-

th data item, which can serve as a measure of scatter.

In this way the data items are transformed to m

vectors in Nexp-dimensional space. All these z-

vectors belong to an (Nexp-2)-dimensional unit-

norm sphere, formed by intersection of a sphere

|z|=1 with a hyperplane ∑

j

z

ij

=0. The scalar product

of two z-vectors is equal to Pearson's correlator of

data items:

(z

1

,z

2

) = ∑

j

z

1j

z

2j

= corr(y

1

,y

2

).

(20)

An important role of this representation is the

following. Strongly correlated data items correspond

either to coincident (z

1

=z

2

) or opposite (z

1

=-z

2

) z-

vectors. If not the sign but only the fact of

dependence is of interest, one can glue opposite

points together formally considering a sphere of z-

vectors as projective space. Using this

representation, one can apply (Nikitin et al., 2010)

general purpose clustering methods such as k-means

to group data items distributed on this sphere to a

few strongly correlated components.

In spite of their numerical efficiency, these

clustering methods neglect temporal ordering of

events, while in causal analysis the task is to find an

earliest physically significant event in the causal

chain. In crash test simulation such events

correspond to bifurcation points, where the scatter

appears "ex nihilo". Such points are clearly visible

as spikes in dynamical scatter plots s(y), the problem

is that there are too many of them. Although

decision between potential candidates by a formal

algorithm can be difficult, an engineering knowledge

allows to narrow the search to significant parts

where scatter propagation can be really initiated by

physical effects, such as buckling of longitudinal,

break of welding point etc. The other problem is that

in bifurcation points new scatter is just appeared and

it is generally hidden under the consequences of

previous effects. At first one needs to separate

scatter contributions.

Considering two data items dy(a) and dy(b), one

can define contribution relevant to the data item (a)

in (b) as follows:

dy|

a

(b) = corr(a,b)s(b)z(a).

(21)

After subtraction of this contribution a residual

dy(b)-dy|

a

(b) does not correlate with dy(a), and the

scatter does not increase.

s

2

|

a

(b)=<(dy(b)-dy|

a

(b))

2

>=s

2

(b)(1-corr

2

(a,b))

(22)

Armed with this subtraction procedure, we

propose the following algorithm for causal analysis.

Temporal Clustering:

(T1) visualize scatter state-by-state;

(T2) isolate bifurcation point;

(T3) subtract its contribution from the scatter in

consequent states;

(T4) if scatter is still remaining, goto (T1).

Here subtraction of scatter from previous

bifurcations reveals new bifurcations hidden under

the consequences of previous ones. The remaining

scatter monotonously falls during the iterations, and

the iterations can be stopped when the scatter

becomes small everywhere or in the regions of

interest.

The geometrical meaning of subtraction

procedure: b-b|

a

=b-(a,b)/(a,a)a is an orthogonal

projection in the space of data items and the whole

sequence is Gram-Schmidt (GS) orthonormalization

procedure applied in the order of appearance of

bifurcation points a

i

. The obtained orthonormal basis

g

i

=GS(a

i

) can be used for reconstruction of all data

by the formula:

dy=

∑

i

Ψ

i

g

i

+res,

Ψ

i

=(dyg

i

).

(23)

The norm of residual is controlled by remaining

scatter, which is small according to our stop

criterion:

|res|

2

/Nexp=s

⊥

2

(y)=s

2

(y)-∑

i

Ψ

i

2

/Nexp.

(24)

Algorithmically every i-th iteration one computes a

scalar field Ψ

i

describing contribution of i-th

bifurcation point to scatter of the model and a scalar

field s

i⊥

2

(y) used for determination of the next

bifurcation point a

i+1

, or for stop criterion

s

i⊥

2

(y)<threshold. This requires O(mNexp) floating

point operations per iteration.

Matrix decomposition of the form dy=Ψg is

similar to PCA described above, with the other

meaning of the modes Ψ. Like in PCA, Ψ are scalar

fields distributed over dynamical model which are

common for all experiments. They have the other

temporal profile than PCA modes, reflecting causal

structure of scatter: they start at corresponding

bifurcation points and propagate forward in time.

Differently from PCA modes, they are not

orthogonal columnwise, i.e. with respect to scalar

product over the model. g-coefficients form

NONLINEAR METAMODELING AND ROBUST OPTIMIZATION IN AUTOMOTIVE DESIGN

487

Nexp*Nmod columnwise orthonormal matrix. Like

corresponding matrix in PCA, they define an

orthonormal basis in the space of experiments, with

respect to the scalar product coincident with

Pearson's correlator.

The scatter associated with design variables can

be treated by the same method, if one puts data items

containing variation of design variables as the first

candidates for bifurcation points. The corresponding

Ψ-modes will represent sensitivities of simulation

results to variation of parameters. The remaining

scatter represents indeterministic part of the

dependence. The corresponding Ψ-modes are

bifurcation profiles and their g-coefficients are those

hidden variables which govern purely stochastic

behavior of the model. One can either take hidden

variables into account when performing reliability

analysis, or try to put them under control for

reducing scatter of the model.

5 EXAMPLES

5.1 Audi B-pillar Crash Test

The model shown on Fig.1 contains 10 thousand

nodes, 45 timesteps, 101 simulations. Two

parameters are varied representing thicknesses of

two layers composing a part of a B-pillar. The

purpose is to find a Pareto-optimal combination of

parameters simultaneously minimizing the total

mass of the part and crash intrusion in the contact

area. To solve this problem, we have applied the

methods described in Sec.2, namely RBF

metamodeling of target criteria for multiobjective

optimization and PCA for compact representation of

bulky data. Based on these methods, our interactive

optimization tool DesParO supports real-time

interpolation of bulky data, with response times in

the range of milliseconds. As a result, the user can

interactively change parameter values and

immediately see variations of complete simulation

result, even on an ordinary laptop computer.

In more details, Fig.1 shows the optimization

problem loaded in the Metamodel Explorer, where

design variables (thicknesses1,2) are presented at the

left and design objectives (intrusion and mass) at the

right. First, the user imposes constraints on design

objectives, trying to minimize intrusion and mass

simultaneously, as indicated by red ovals on Fig.1

(upper part). As a result, “islands” of available

solutions become visible along the axes of design

variables. Exploration of these islands by moving

corresponding sliders shows that there are two

optimal configurations, related cross-like, as

indicated on Fig.1 (middle). For these

configurations, both constraints on mass and

intrusion are satisfied, while they correspond to

physically different solutions, distinguished by an

auxiliary velocity criterion. For every criterion also

its tolerance is shown corresponding to 1-sigma

confidence limits, as indicated by horizontal bars

under the corresponding slider as well as +/- errors

in the value box. This indication allows satisfying

constraints with 3-sigma (99.7%) confidence, as

shown on the images. The Geometry Viewer, shown

at the bottom of Fig.1, allows to inspect the optimal

design in full details. E.g. on the two images at the

bottom, one can see the difference between small

and large thickness values resulting in softer or

stiffer crash behavior.

While performing constraint optimization, the

user immediately sees how small mass solutions

disappear when intrusion is minimized. This gives

an intuitive feeling for the trade-off (Pareto

behavior) between optimization objectives. With

these capabilities and complementary information

such as auxiliary criteria and interactive

interpolation of bulky simulation results, “the”

optimal solution, i.e. a single representative on the

Pareto front, can be selected by a user decision.

5.2 Ford Taurus Crash Test

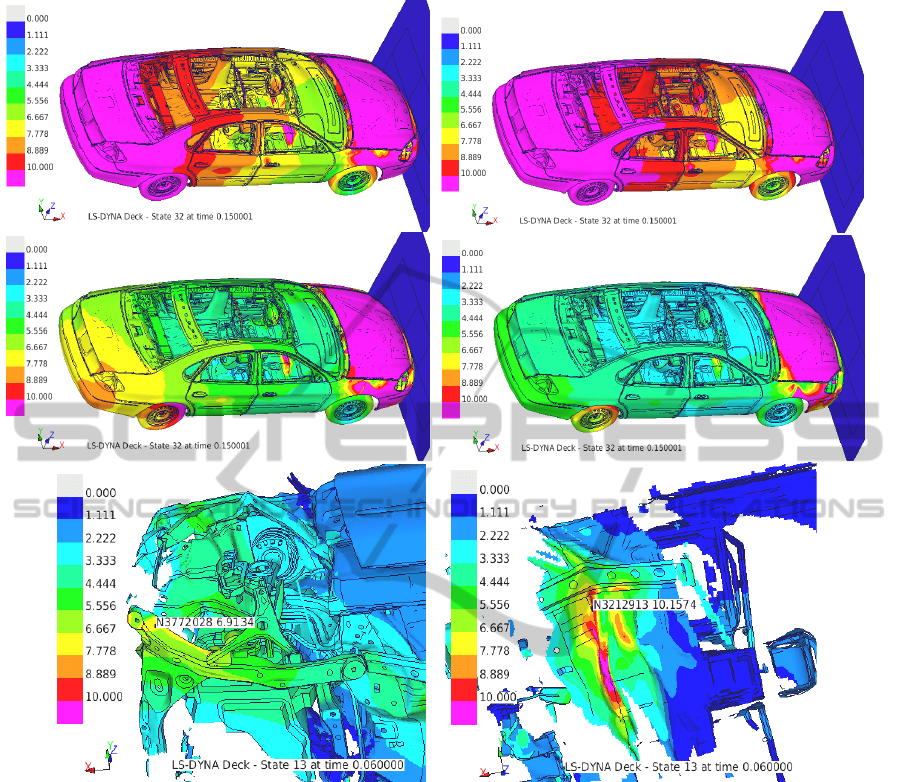

The crash model shown on Fig.2 contains 1 million

nodes, 32 timesteps, 25 simulations. Processing of

this model with the temporal clustering algorithm

described above has been performed on a 16-CPU

Intel-Xeon 2.9GHz workstation with 24GB main

memory. It required 3min per iteration and

converged in 4 iterations.

Crash intrusions in the foot room of the driver

and passenger are commonly considered as critical

safety characteristics of car design. These

characteristics possess numerical uncertainties, the

analysis of which falls in the subject of Sec.3-4. The

upper left part of Fig.2 shows the scatter measure

s(y), in mm, distributed on the model. The scatter in

the foot room is so large (>10mm) that direct

minimization of intrusion is impossible. Temporal

clustering allows to identify sources of this scatter

and subtract relevant contributions. Further images

show how the scatter decreases in these subtractions.

After the 4

th

iteration the scatter in the foot room

reaches a safe level (<3mm). Several bifurcation

points have been identified and subtracted per

iteration; in this way the performance of the

algorithm has been optimized. The two major

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

488

Figure 1: Audi B-Pillar crash test in DesParO Metamodel Explorer. Top: constraints on intrusion and mass are imposed.

Center: two optimal designs are found. Bottom: inspection of optimal design in DesParO Geometry Viewer.

NONLINEAR METAMODELING AND ROBUST OPTIMIZATION IN AUTOMOTIVE DESIGN

489

Figure 2: Temporal clustering of Ford Taurus crash test using DiffCrash. Upper left: original scatter in mm. Upper right –

center left – center right: consequent iterations of scatter subtraction. Bottom: two major bifurcations found.

bifurcations found are shown on the bottom part of

Fig.2. They represent buckling phenomena on the

left longitudinal rail and a fold on the floor of the

vehicle, which appear in earlier time steps. In total,

15 bifurcation points have been identified,

representing statistically independent sources of

scatter. The whole scatter in the model can be

decomposed over the corresponding basis functions

Ψ(y). In this way the dimensionality of the problem

is reduced to 15 variables (g-coefficients)

completely describing the stochastic behavior of the

model.

6 CONCLUSIONS

We have presented and discussed methods for

nonlinear metamodeling of a simulation database

featuring continuous exploration of simulation

results, tolerance prediction and rapid interpolation

of bulky FEM data. For the purpose of robust

optimization, the approach has been extended by the

methods of reliability and causal analysis. The

efficiency of the methods has been demonstrated for

several application cases from automotive industry.

Further plans include to use the results of causal

analysis as a basis for modifications of a simulation

model for improving its stability. We also plan to

consider non-linear relationships between stochastic

variables. Linear methods such as PCA and GS

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

490

.

determine only a linear span over principal

components, while some stochastic variables can

become non-linear functions of others. For

determination of such dependencies the methods of

curvilinear component analysis (CCA) can be

applied.

ACKNOWLEDGEMENTS

Many thanks to the team of Prof. Steve Kan at the

NCAC and the Ford company for providing the

publically available LS-DYNA models and to

Andreas Hoppe and Josef Reicheneder at AUDI for

providing PamCrash B-pillar model. The availability

of these models fosters method developments for

crash simulation. We are also grateful to Michael

Taeschner and Georg Dietrich Eichmueller (VW)

and to Thomas Frank and Wolfgang Fassnacht

(Daimler) for fruitful discussions.

REFERENCES

J. W. Tukey, Exploratory Data Analysis, Addison-Wesley,

London, 1997.

D. L. Donoho, High-Dimensional Data Analysis: The

Curses and Blessings of Dimensionality. Lecture on

August 8, 2000, to the American Mathematical Society

"Math Challenges of the 21st Century".

D. R. Jones, M. Schonlau, W.J. Welch, Efficient Global

Optimization of Expensive Black-Box Functions,

Journal of Global Optimization, vol.13, 1998, pp.455-

492.

A. J. Keane, S. J. Leary, A. Sobester, On the Design of

Optimization Strategies Based on Global Response

Surface Approximation Models, Journal of Global

Optimization, vol.33, 2005, pp. 31-59.

M. D. Buhmann, Radial Basis Functions: theory and

implementations, Cambridge University Press, 2003.

L. Cizelj, B.Mavko, H.Riesch-Oppermann, Application of

first and second order reliability methods in the safety

assessment of cracked steam generator tubing, Nuclear

Engineering and Design 147, 1994.

A. W. van der Vaart, Asymptotic statistics. Cambridge

University Press, 1998.

C.-A.Thole, L. Mei, Reason for scatter in simulation

results. In Proceedings of the 4th European LS-Dyna

User Conference. Dynamore, Germany, 2003.

C. A.Thole, Compression of ls-dyna simulation results. In

Proceedings of the 5th European LS-DYNA user

conference, Birmingham., 2005

C.-A.Thole, L. Mei, Data analysis for parallel car-crash

simulation results and model optimization. Simulation

modelling practice and theory, 16(3):329–337, 2008.

I.Nikitin, L.Nikitina, Y.Astakhov, C.-A.Thole, A.Stork,

S.Klimenko, Towards Interactive Simulation in

Automotive Design, Visual Computer 2008, V24

pp.947-953.

I. Nikitin, L. Nikitina, T. Clees, Stochastic analysis and

nonlinear metamodeling of crash test simulations and

their application in automotive design, to appear in:

Computational Engineering: Design, Development and

Applications, Ed.: F.Columbus, Pub.: Nova Science,

New York 2010.

I. Nikitin, L. Nikitina, T. Clees, C.-A.Thole, Advanced

mode analysis for crash simulation results. In:

DYNAmore Stuttgart: 9th LS-DYNA Forum 2010 :

12.-13. Oktober 2010 in Bamberg. Stuttgart, 2010,

S.I/1/11-I/1/20.

I. Nikitin, L. Nikitina, T. Clees, Nonlinear metamodeling,

multiobjective optimization and their application in

automotive design, in Proc. of the 16-th European

Conference on Mathematics for Industry, July 26-30,

2010 Wuppertal.

NONLINEAR METAMODELING AND ROBUST OPTIMIZATION IN AUTOMOTIVE DESIGN

491