INTEGRATED OPTIMIZATION OF PRODUCT DESIGN

CONCEPT AND PRODUCT LIFECYCLE SCENARIO

BASED ON GENETIC ALGORITHM

Masakazu Kobayashi and Masatake Higashi

Toyota Technological Institute, 2-12-1 Hisakata, Tempaku, Nagoya, Japan

Keywords: Design optimization, Conceptual design, Lifecycle design, Lifecycle assessment, Functional optimization,

Layout optimization, Hierarchical optimization, Genetic algorithm.

Abstract: Due to rise of environmental awareness in recent years, companies are required to assess and reduce

environmental burdens of their products. However, in practical product development, since not only

environmental burdens but also product characteristics such as performance and cost need to be

simultaneously considered for creating attractive products, designers are forced to take a great deal of time

and effort to balance them at a higher level at every stage of product development. In response to this, this

paper proposes an integrated method for optimizing product design concept and product lifecycle scenario

for supporting conceptual design phase. The proposed method combines integrated optimization of

functional / layout design which we developed in the previous researches and lifecycle assessment (LCA).

Using the proposed method, optimal functional structure, components / parts layout and lifecycle scenario

that balance product characteristics and environmental burdens at a higher level can be obtained.

1 INTRODUCTION

Due to rise of environmental awareness in recent

years, companies are required to assess and reduce

environmental burdens of their products such as

carbon emissions. However, in practical product

development, since not only environmental burdens

but also product characteristics such as performance,

cost and size need to be simultaneously considered

for creating an attractive product, designers are

forced to take a great deal of time and effort to

balance them at a higher level.

Based on the above background, this paper

proposes a new integrated optimization method for

creating a product concept and its lifecycle scenario

that balance various criteria including lifecycle ones

at a higher level. To allow for such optimal design,

the proposed method is based on our integrated

optimization method (Kobayashi et al., 2009). This

method is an integration of functional / layout

optimizations, which are based on genetic algorithm

(GA), for supporting a conceptual design phase.

During a conceptual design phase, since there are

various decision-makings, designers are asked to

make optimal decisions to create great product

concepts by considering various product

characteristics such as performance, cost and size.

However, since functional / layout designs, which

are main two tasks of a conceptual design phase, are

very different tasks, their design problems are highly

hierarchized and their solution spaces are vast, it is

extremely difficult for designers to build up great

concepts only with their own decision makings. To

overcome such difficulty, in our previous method,

functional / layout optimizations are combined and

executed cooperatively by exchanging information.

Using this method, both a functional structure and a

parts layout that balances various criteria at a higher

level can be obtained. To allow for simultaneous

consideration of various criteria including lifecycle

ones during a conceptual design phase as described

above, this paper makes an attempt to combine this

integrated optimization method and LCA. As for

design variables, in addition to functional structure

and parts / components layout, decision makings

throughout product lifecycle are considered. As for

criteria, in addition to product characteristics,

environmental burdens are considered. Using the

proposed method, optimal product concept (a

functional structure and a components / parts layout)

and its lifecycle scenario that balance various criteria

208

Kobayashi M. and Higashi M..

INTEGRATED OPTIMIZATION OF PRODUCT DESIGN CONCEPT AND PRODUCT LIFECYCLE SCENARIO BASED ON GENETIC ALGORITHM.

DOI: 10.5220/0003671702080213

In Proceedings of the International Conference on Evolutionary Computation Theory and Applications (ECTA-2011), pages 208-213

ISBN: 978-989-8425-83-6

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

including lifecycle ones at a higher level can be

obtained.

2 INTEGRATED OPTIMIZATION

METHOD

2.1 Overview

This paper proposes an integrated method for

optimizing a product design concept (a functional

structure and a components / parts layout) and its

lifecycle scenario by considering various criteria

including lifecycle ones, based on our previous

method. The improved point is (1) To integrate LCA

in order to evaluate environmental burdens as

additional criteria of the integrated optimization and

(2) To handle decision makings throughout product

lifecycle as additional design variables of the

integrated optimization.

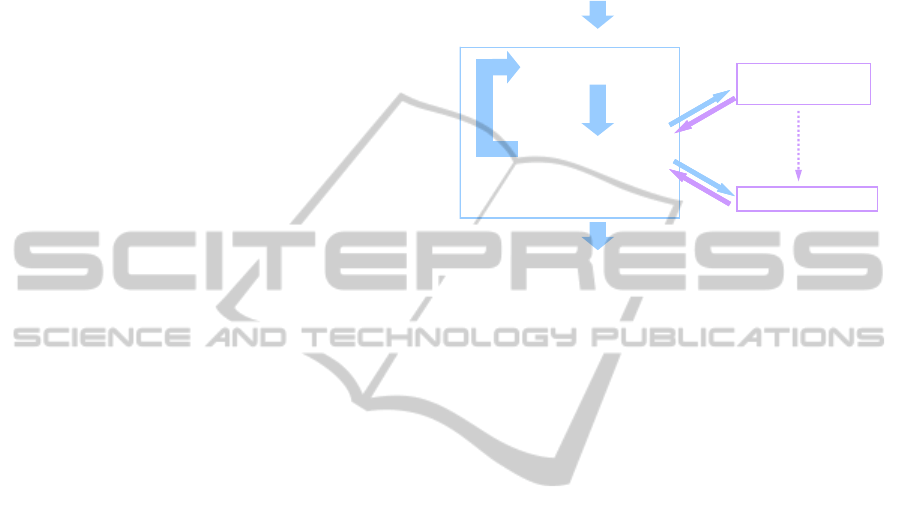

Figure 1 shows the overview of the proposed

integrated optimization method. This method

consists of functional / layout optimizations plus

LCA. Functional optimization is the main part of the

proposed method and executed just one time.

Functional optimization is based on the hierarchical

genetic algorithm (HGA) (Yoshimura and Izui,

2002) in order to consider hierarchical nature of a

functional structure. In the functional optimization,

selection of functions and parts (Parts correspond to

the functions at the bottom level of the functional

structure) from their alternatives and selection of

reuse / recycle / disposal scenario at the EOL stage

for each parts are considered as design variables. As

for criteria, performance, cost, total area and total

carbon emission are considered. Although only one

decision making throughout product lifecycle and

one index of environmental burden are considered in

this paper, the proposed method has a potential to

handle more design variables and criteria. Any of

them can be configured as an objective function and

the rest of them are configured as constraint

conditions. This paper assumes that performance and

cost can be calculated by simply summing up the

values associated with each part, whereas to

calculate total area and total carbon emission, layout

optimization and LCA need to be executed. So, they

are repeatedly invoked from the functional

optimization for evaluating generated design

proposals at its each iteration. In the layout

optimization, based on the information about size of

parts selected in the functional optimization, layout

with minimum area is calculated. Layout

optimization is based on the sequence-pair

representation and the traditional GA with the

special crossover operator (Murata et al., 1996);

(Nakaya et al., 2000). In lifecycle assessment, total

carbon emission is calculated from the selected parts

and lifecycle scenario.

Generation of solutions

Evaluation of solutions

Layout optimization

using GA

S

o

l

u

t

i

o

n

C

a

r

b

o

n

e

m

i

s

s

i

o

n

S

o

l

u

t

i

o

n

C

a

r

b

o

n

e

m

i

s

s

i

o

n

Iteration

•Performance

•Carbon emission

•Cost

•Area

(Selection, crossover, mutation)

Functional optimization using HGA

Optimal solution

Functional structure includin

g

alternatives

•Optimal functional structure

•Optimal layout

•Optimal lifecycle scenario

Lifecycle assessment

S

o

l

u

t

i

o

n

O

p

t

i

m

a

l

l

a

y

o

u

t

A

r

e

a

S

o

l

u

t

i

o

n

O

p

t

i

m

a

l

l

a

y

o

u

t

A

r

e

a

Area

Figure 1: Overview of the integrated optimization.

2.2 Preconditions of the Proposed

Method

Before explaining the details of the proposed method,

the following assumptions are made.

A components / parts layout is limited to two-

dimensional plane. Shape of components and parts is

limited to rectangle.

All components and parts can be placed freely

without any connection constraints.

Total area of the product equals to the area of

rectangle that envelopes all parts placed in a

configuration plane.

Each part has the values associated with

performance and cost. Their total values can be

calculated by simply summing up these values.

2.3 Functional Optimization using

Hierarchical Genetic Algorithm

In practical product designs, functional structure is

highly hierarchized and decision makings in the

upper level may affect lower functional structures

greatly. To optimize such hierarchical selection

problems, our method adopts HGA.

The most distinctive feature of HGA is

hierarchical genotype representations to exactly

describe hierarchical structures of mechanical

system designs and special operators of crossover

INTEGRATED OPTIMIZATION OF PRODUCT DESIGN CONCEPT AND PRODUCT LIFECYCLE SCENARIO

BASED ON GENETIC ALGORITHM

209

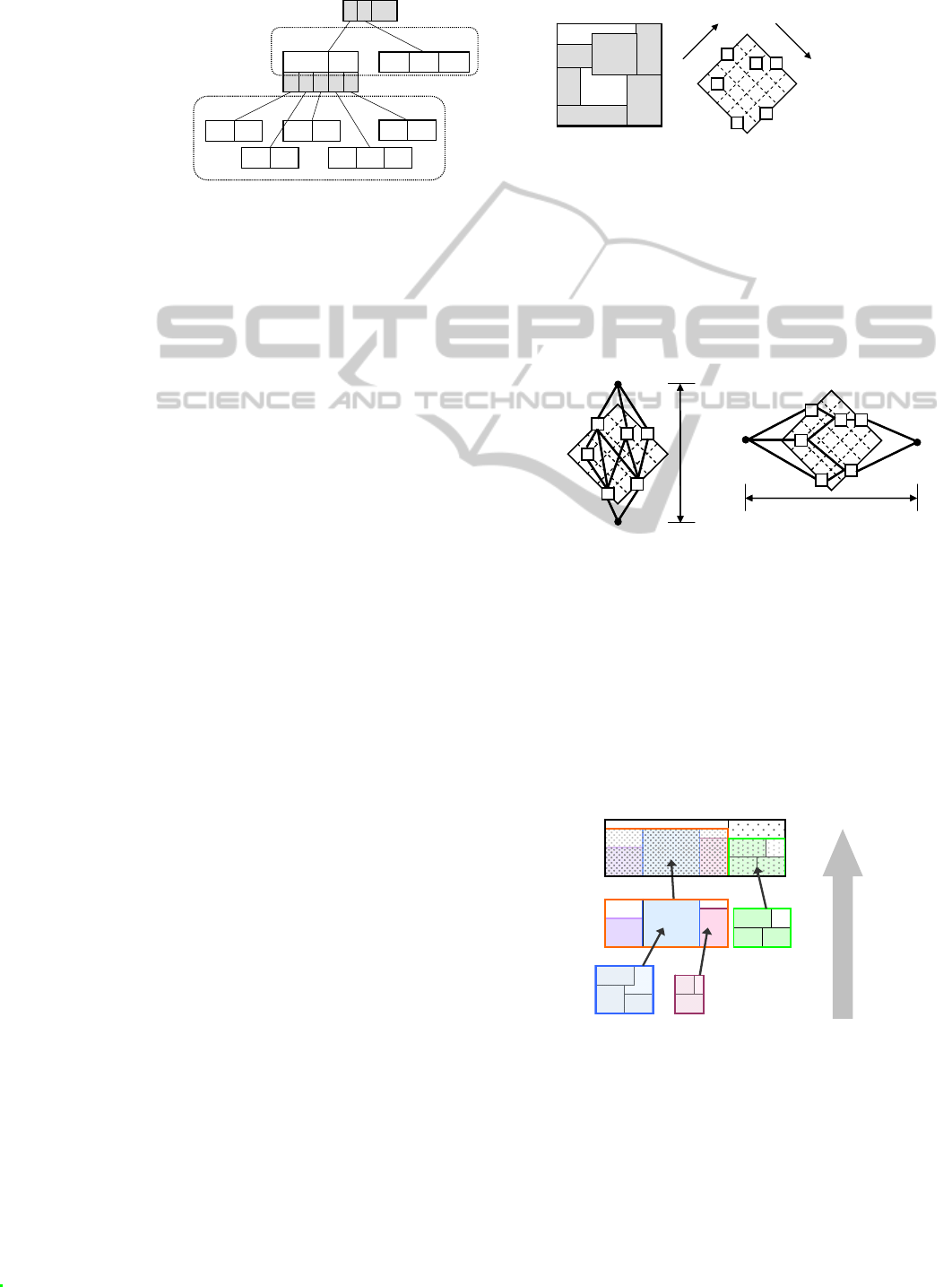

and mutation for manipulating them. Figure 2 shows

an example of a hierarchical design problem.

. . .BA . . .BA

cba ed

A-2A-1

cba ed

A-2A-1

a-2a-1 a-2a-1

b-2b-1 b-2b-1

e-2e-1 e-2e-1

B-3B-2B-1 B-3B-2B-1

Alternatives of A and B

Alternatives of a, b, c, d and e

Upper structure

Sub-structure of

A-1 and A-2

d-3d-2d-1 d-3d-2d-1

c-2c-1 c-2c-1

Figure 2: Hierarchical design problem.

In our method, HGA is adopted to optimize

product’s functional structure in the form of a

hierarchical tree structure. An individual of HGA

corresponds to one design proposal and its organism

strings show selections of functions / parts and

selection of reuse / recycle / disposal scenario at the

EOL stage in that design proposal. The lowest string

corresponds to the combinations of the part selection

and its lifecycle scenario selection. In other word,

the same parts with different lifecycle scenarios are

considered as different alternatives. For example,

part A with disposal scenario and part A with reuse

scenario are different alternatives. The other higher

strings correspond to selection of functions. Since

our method adopts single-objective HGA, any of

performance, cost, total area and total carbon

emission can be configured as an objective function

and the rest are configured as constraint conditions.

As described the previous section, performance and

cost can be calculated by simply summing up the

values associated with each part, whereas total area

and total carbon emissions can not be calculated by

simple summation. Therefore, layout optimization

and LCA, as described in the later sections, are

executed for evaluating each individual in each

generation.

2.4 Layout Optimization using GA and

Sequence-pair Representation

In our method, parts shape and a configuration space

are limited to rectangle and two dimensional, so

components / parts layout can be described by

sequence-pair representation and solved by GA.

Sequence-pair was originally developed for

VLSI layout design, which is the rectangle packing

problem. This method represents relative positions

of rectangles by using a pair of rectangle name

sequences, called

+

and

-

.

+

and

-

indicate the

rectangle sequences in diagonally right up and

diagonally right down respectively. Figure 3 shows a

layout example, its relative position and its sequence

pair.

b

d

a

e

c

f

a

b

d

f

c

e

0

1

2

3

4

5

0

1

2

3

4

5

(a) Layout (b) Relative position (c)

-

and

+

-

= [f, c, d, e, a, b]

+

= [e, c, a, b, f, d]

-

+

Figure 3: Example of layout and its sequence-pair.

When relative positions of rectangles are

described by

+

and

-

, the absolute positions of the

rectangles without overlap within minimum area can

be uniquely obtained by making horizontal and

vertical constraint graphs based on

+

and

-

and by

calculating longest paths in both graphs. Figure 4

shows their examples. See the reference (Murata et

al., 1996) for the details.

a

b

d

f

c

e

width

a

b

d

f

c

e

width

a

b

d

f

c

e

height

a

b

d

f

c

e

height

Figure 4: Horizontal / Vertical constraint graphs.

The original research (Murata et al., 1996) uses

simulated annealing for searching the optimal layout

with minimum area, whereas, our method uses GA

with the special crossover operator called PREX

(Placement-based Partially Exchanging Crossover)

(Nakaya et al., 2000).

Since components / parts layout of a practical

product is hierarchized, layout optimization is

repeatedly executed from a part level to a product

level to obtain hierarchical components / parts layout.

Figure 5 shows its concept.

A-1

b-2

b-1

a-1

a-2

a-3

A-2

A-3

B-1 B-2

B-3

Other

A

B

A-2

A-3

A B

Parts

Components

Product

Figure 5: Hierarchical layout optimization.

ECTA 2011 - International Conference on Evolutionary Computation Theory and Applications

210

2.5 Lifecycle Assessment

In the practical LCA, there are various indexes of

environmental burden such as emissions of CO

2

,

SO

x

and NO

x

throughout entire product lifecycle,

usage rate of renewable material and reuse / recycle

rate, which are determined by entire product

lifecycle scenario. However, because this research is

at an early stage, the proposed method handles only

selection of reuse / recycle / disposal scenario at the

EOL stage and carbon emission as a design variable

and an index of environmental burden respectively.

Total carbon emission of each design proposal is

calculated by the following concepts.

Carbon emission is evaluated for each part and

sum of them is defined as total carbon emissions

GHG

total

. GHG is an acronym for Green House Gas.

There are two types of parts. One has the fixed

value of carbon emission GHG

i

and the other has the

value of carbon emission per unit area uGHG

i

. Most

parts belong to the former type, whereas some parts

such as an electronic substrate belong to the latter

type. In the latter type, actual value of carbon

emission is calculated by multiplying uGHG

i

by the

area Area

i

calculated by layout optimization.

The value of carbon emission varies with the

selection of reuse / recycle / disposal scenario, so the

value for each scenario needs to be assessed by LCA.

The selection also affects performance and cost of

the part, so the relationship among scenario selection,

carbon emission, cost and performance needs to be

assessed. For example, use of recycled material

increases manufacturing cost in exchange for lower

carbon emission. Reuse of used parts considerably

reduces both carbon emission and cost but

performance of such parts can not be expected. In

particular, in the field where rate of technological

evolution is high, old parts become rapidly obsolete,

so reuse of such parts equals use of low performance

parts. Thus the proposed method is useful in

balancing product eco-friendliness and other criteria

at higher level.

Finally, total carbon emission GHG

total

is calculated

by the below equation.

n

j

jj

m

i

itotal

uGHGAreaGHGGHG

11

(1)

Where GHG

i

is the fixed value of carbon emissions

of part i, whereas, uGHG

j

is the value of carbon

emissions per unit area of part j. Area

j

is the value of

area of part j.

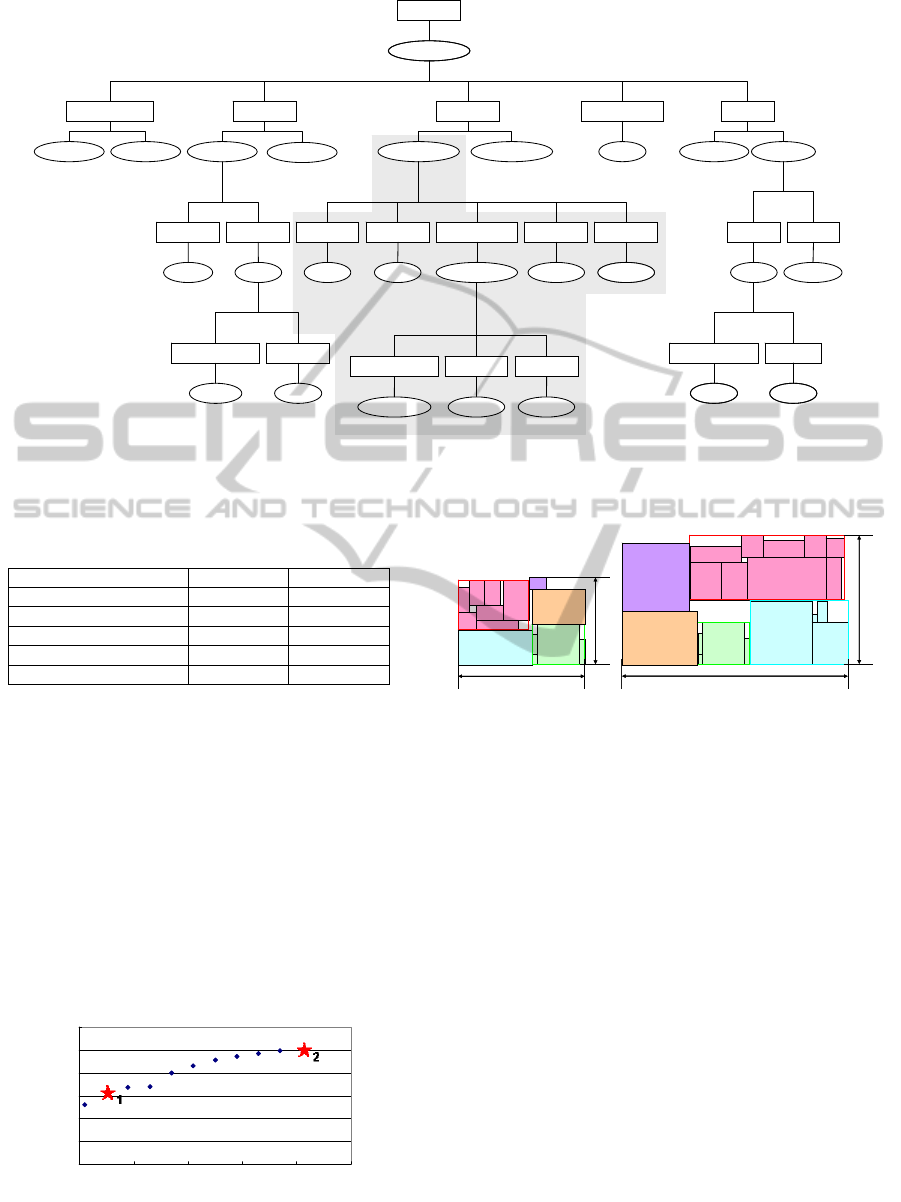

3 CASE STUDY

3.1 Problem Description

In the case study, internal devices of a personal

computer are designed using the proposed method .

“Internal devices” means that input devices, a

display and an enclosure are not included. To make

the case study simpler, only reuse and disposal are

considered as alternatives of the lifecycle scenario at

the EOL stage. Reuse scenario means reuse of the

part used in the previous generation whereas

disposal one means use of the new part.

A computer consists of the following 5

components: motherboard, HDD, cooling system,

power supply and auxiliary storage. Motherboard,

cooling system and power supply can be

decomposed into more than one part, whereas HDD

and auxiliary storage can not be decomposed any

more. Figure 6 shows its functional structure. Note

that, due to space limitation, the lower functional

structure of Motherboard B is not described in this

figure. Motherboard B is similar to Motherboard A,

but has powerful CPU, more Memory and discrete

graphic card. (R) writen after the part name means

that the part is reused one. Table 1 shows examples

of their alternatives and specifications. As for the

new parts, prices and sizes are based on their retail

price surveys and size measurments. Performances

are subjectively and intuitively configured. Carbon

emission is based on the reference (Japan Environm

ental Management Association For Industry, 2007).

As for the reused parts, their specifications are

estimated from ones of the similar or same new parts.

Table 1: Part example (HDD).

HDD

Cost

(USD)

Dimension

(cm)

Perfor

mance

CO

2

(kg)

MK8009GAH 75 5.5*8.0 2 1.31

MK1214GAH 150 5.5*8.0 3 1.31

MK4007GAL (R) 30 5.5*8.0 1 0.78

WD1600BEVT 42 7.0*10.0 4 2.72

WD3200BEVT 66 7.0*10.0 5 2.72

MK8025GAS (R) 21 7.0*10.0 2 1.63

WD5000AAKB 160 10.0*14.5 7 10.88

WD1002FBYS 220 10.0*14.5 10 10.88

6L320R0 (R) 80 10.0*14.5 4 6.53

As for criteria, performance is handled as an

objective function, whereas cost, total area and total

carbon emission are handled as constraint conditions.

Table 2 shows parameters of HGA and GA.

INTEGRATED OPTIMIZATION OF PRODUCT DESIGN CONCEPT AND PRODUCT LIFECYCLE SCENARIO

BASED ON GENETIC ALGORITHM

211

Supply

Power

Read/Write

Outer information

Process

Information

Storag e

Inter information

Battery

Optical drive

Memory card

reader

HDD

Process

Information

Personal ComputerPersonal Computer

DVD combo

DVD burner

BD burner

DVD combo

DVD burner

BD burner

SD memory reader

CF memory reader

SD memory reader

CF memory reader

Motherboard B

Power supply

Discard

Heat

Cooler

Control

Power

Controller

Convert Electric

power to Torque

Motor

Generate

Wind

Fan

80mm Fan

120mm Fan

Process

Information

Store Data

Transfer

Data

Other

functions

Chipset

Atom Z530

Atom Z520

Atom Z540

Atom Z530

Atom Z520

Atom Z540

DDR2-533 1G

DDR2-533 2G A

DDR2-533 2G B

DDR2-533 1G

DDR2-533 2G A

DDR2-533 2G B

Support

communication

Motherboard A

WLAN module A

WLAN module B

Support Wireless

communication

WLAN module

TV tuner A

TV tuner B

Receive TV

TV tuner

Other

functions

Other

devices

Other

devices

Other

devices

Sub-boardDIMMCPU

MK8009GAH

WD1600BEVT

WD5000AAKB

MK8009GAH

WD1600BEVT

WD5000AAKB

MK1214GAH

WD3200BEVT

WD1002FBYS

MK1214GAH

WD3200BEVT

WD1002FBYS

Lithium polymer A,B

Lithium ion A,B

Discard

Heat

Cooling system

Remove

Heat

Convey

Heat

Cooler

Heat pipe

Radiation sheet

Generate

Wind

Motor

Motor FanFan

40mm Fan

60mm Fan

80mm Fan

Convert Electric

power to Torque

Sheet A

Sheet B

SD memory reader (R)

CF memory reader (R)

SD memory reader (R)

CF memory reader (R)

DVD combo (R)

80mm Fan (R)

120mm Fan (R)

Pentium M (R)

DDR2-533 512M (R)

80mm Fan

(

R

)

60mm Fan (R)

40mm Fan (R)

6L320R0 (R)MK8025GAS (R)

WLAN module (R)

TV tuner (R)

DVD burner (R)

DDR2-533 1GB (R)

MK4007GAL (R)

Figure 6: Functional structure designed in the case study.

Table 2: Parameters of HGA and GA.

HGA GA

Population 100 60

Crossover rate 1 1

Mutation rate 0.05 0.01

Generation gap 0.9 0.5

Terminal generation 200 50

3.2 Results

For comparison, both our previous method that

considers neither lifecycle scenario nor carbon

emission and the proposed method are executed here.

Figure 7 shows the results using our previous

method. In this case, 12 optimizations ars executed

under 12 various cost constraints from 550 USD to

2550 USD and constant area constraint (Area < 1200

cm

2

). Note that reused parts are not available in this

case. The optimal layouts of the design solutions

denoted by two stars in Figure 7 are shown in Figure

8.

0

20

40

60

80

100

120

500 1000 1500 2000 2500 3000

Cost

Performance

Figure 7: Relationships between performance and cost of

the obtained solutions using our previous method.

Battery

Cooling

system

HDD

Card reader

Motherboard

240mm

174mm

Battery

Cooling

system

HDD

Card reader

Motherboard

240mm

174mm

435mm

240mm

Cooling

system

Motherboard

HDD

Optical

drive

Power supply

435mm

240mm

Cooling

system

Motherboard

HDD

Optical

drive

Power supply

Figure 8: Optimal layouts (Left: star 1, Right: star 2).

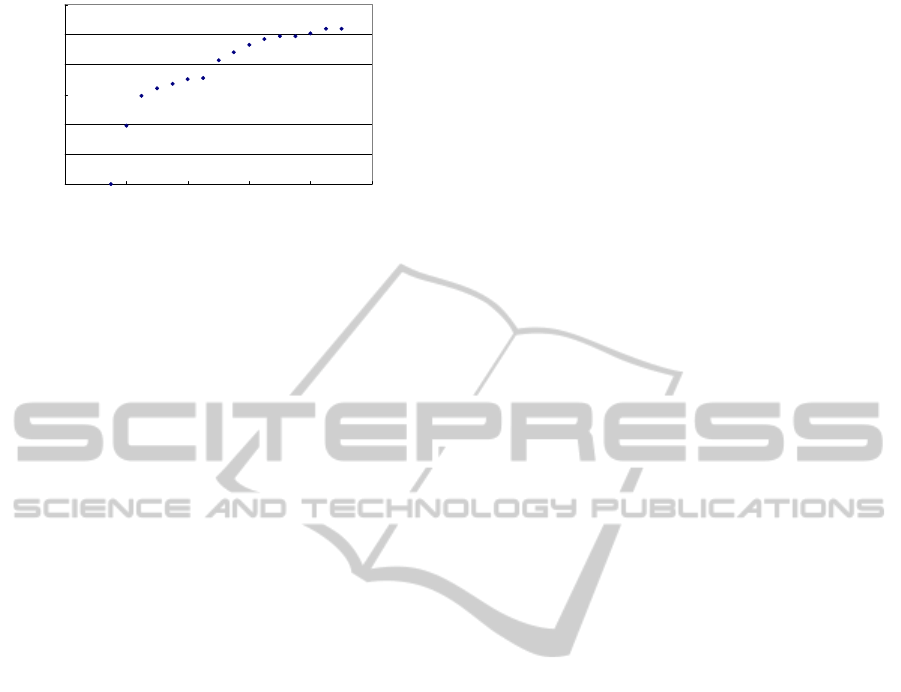

Figure 9 shows the result using the proposed

method. In this case, 16 optimizations are executed

under 16 various constraints of carbon emission

from 7.5 kg to 45 kg and constant const and area

constraints (Cost < 3000 USD and Area < 1500 cm

2

).

This results shows that the constraint of carbon

emission makes it difficult to design high

performance PCs even if the constraints of cost and

area are sufficiently relaxed. The design solusions

with higher performance tend to consist of only new

parts whereas the design solutions with lower

performance tend to consists of many reused parts.

From the other point of view, the parts that are

making rapid progress such as CPUs and HDD are

infrequently reused, whereas the parts that are not

making progress such as auxiliary storages and

cooling fans are frequently reused. Use of reused

parts can reduce carbon emission, but at the same

time makes it difficult to achieve high performance.

Thus the proposed method is useful in balancing

product eco-friendliness and other criteria at a higher

level.

ECTA 2011 - International Conference on Evolutionary Computation Theory and Applications

212

0

20

40

60

80

100

120

0 1020304050

Carbon emission

Performance

Figure 9: Relationships between performance and cost of

the obtained solutions using the proposed method.

4 CONCLUSIONS

Due to rise of environmental awareness in recent

years, companies are required to assess and reduce

environmental burdens of their products. In response

to this, this paper proposes a new integrated method

for simultaneously optimizing a product concept and

its lifecycle scenario by evaluating product

characteristics such as performance, cost and size

and environmental burdens such as carbon emission

as criteria. Using the proposed method, optimal

product concept and its lifecycle scenario that

balance product characteristics and environmental

burdens at a higher level can be obtained. In the case

study, the proposed method is applied to a design of

a personal computer and the results show the needs

of consideration of lifecycle scenario and

environmental burdens during conceptual design

phase.

As for future works, we are planning to consider

modularization of parts and components. In recent

products, components and parts are modularized due

to various reasons. Modularization also affects

lifecycle characteristics of the product. Therefore, to

allow optimal modular design for product lifecycle,

we are planning to expand our method proposed in

this paper.

ACKNOWLEDGEMENTS

This study was supported in part by a grant of

Strategic Research Foundation Grant-aided Project

for Private Universities from Ministry of Education,

Culture, Sport, Science, and Technology, Japan

(MEXT), 2008-2012 (S0801058).

REFERENCES

Kobayashi, M., Suzuki, Y. and Higashi, M. (2009).

Integrated Optimization for Supporting Functional and

Layout Designs during Conceptual Design Phase.

Proceedings from IDETC/CIE 2009: ASME 2009

International Design Engineering Technical

Conferences & Computers and Information in

Engineering Conference, San Diego, CA.

Yoshimura, M. and Izui, K. (2002). Smart Optimization of

Machine Systems Using Hierarchical Genotype

Representations. Transaction of ASME, Journal of

Mechanical Design, 124, 375-384.

Murata, H., Fujiyoshi, K., Nakatake, S. and Kajitani, Y.

(1996). VLSI Module Placement Based on Rectangle-

Packing by the Sequence-Pair. IEEE Transactions on

Computer-Aided Design of Integrated Circuits and

Systems, 15(12), 1518-1524.

Nakaya, S., Wakabayashi, S. and Koide, T. (2000). An

adaptive genetic algorithm for VLSI floorplanning

based on sequence-pair. Proceedings from

ISCAS2000: 2000 IEEE International Symposium on

Circuits and Systems, Geneva, SWITZERLAND.

Japan Environmental Management Association for

Industry (2007). Implementation manual of product

LCA.

INTEGRATED OPTIMIZATION OF PRODUCT DESIGN CONCEPT AND PRODUCT LIFECYCLE SCENARIO

BASED ON GENETIC ALGORITHM

213