ONTOLOGICAL FRAMEWORK FOR THE ENTERPRISE

FROM A PROCESS PERSPECTIVE

Operational, Tactical and Strategic Integration for Improved Decision-making

Edrisi Muñoz

1

, Elisabet Capón

1

, Jose M. Laínez

2

, Antonio Espuña

1

and Luis Puigjaner

1

1

Department of Chemical Engineering, Universitat Politècnica de Catalunya, Av. Diagonal, 647, E08028 Barcelona, Spain

2

School of Chemical Engineering, Purdue University, West Lafayette, IN, U.S.A.

Keywords:

Enterprise model, Supply chain, Decision support systems, Ontology framework, Knowledge management.

Abstract:

Enterprises are highly complex systems in which one or more organizations share a definite mission, goals and

objectives to offer a product or service. Thus, enterprises comprise several functions which interact with each

other, such as production, marketing, sales, human resources or logistics. As a result, decision-making in the

enterprise becomes a highly challenging task, and such decision process is usually separated in several levels.

Nevertheless, such levels are closely related, since they share data and information. Therefore, effective

integration among the different hierarchical levels, by means of tools improving information sharing and

communication, may play a crucial role for the enhanced enterprise operation, and consequently for fulfilling

the enterprise’s goals. In order to achieve integration among the different decision levels, it is necessary to

establish a common modeling framework. In this work, an ontological framework is built as the mechanism

for information and knowledge models sharing for multiple applications. The potential of the general semantic

framework developed (model maintenance, usability and re-usability) is demonstrated in the enterprise supply

chain network design-planning problem case study presented. Further work is underway to unveil the full

potential to implement a large-scale semantic web approach to support business processes decisions.

1 INTRODUCTION

The European chemical sector, despite having an in-

tern mature market, keeps a strong dynamism over the

global market and its trade flow in 2009 was positive

in about 30 billion euros (Council, 2010). However,

the current landscape of businesses is ruled by the

globalization of trade. Such a trend has opened new

markets, business opportunities and also the adoption

of worldwide information and communication tools

which brought forth a diverse number of available al-

ternatives for customers to fulfill their demands. As a

result, enterprises not only face a fiercer competition

for a contracted market due to the recent economic

recession which leads to dwindling margins, but also

deal with a higher degree of uncertainty associated

with external factors such as demand, product prices

or raw materials supply. In addition, companies must

comply with increasingly stricter constraints related

to safety and environmental regulations.

In such scenario, enterprises must strive to remain

competitive by improving their operations to deliver a

higher customer satisfaction while still generating di-

vidends to shareholders. In order to offer a better ser-

vice to customers, quick time-to-market and opera-

tional flexibility have become crucial business drivers

in many industries to respond rapidly to the contin-

uously changing market conditions. Certainly, this

pressure for higher flexibility has made enterprises

evolve to more complex systems. Nowadays, enter-

prises consist of multiple business and process units

with different scales working together; the organiza-

tion of the different scales and levels within such com-

plex systems is crucial to understand, analyze, syn-

chronize and improve their operations. We believe

that one important step to accomplish such tasks is

to represent the enterprise in an adequate ontological

model, which captures the features relevant for man-

agers to support decision making processes.

In order to deal with the problem complexity, it is

necessary to decouple the system across a hierarchy

of appropriately chosen levels without disregarding

the interrelationship that exists among them. For this

purpose, we consider as basis the supply chain (SC)

concept which can be defined as the group of inter-

linked resources and activities required to create and

538

Muñoz E., Capón E., Laínez J., Espuña A. and Puigjaner L..

ONTOLOGICAL FRAMEWORK FOR THE ENTERPRISE FROM A PROCESS PERSPECTIVE - Operational, Tactical and Strategic Integration for

Improved Decision-making.

DOI: 10.5220/0003720705380546

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development (SSEO-2011), pages 538-546

ISBN: 978-989-8425-80-5

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

S

c

h

e

d

u

l

i

n

g

P

r

o

c

e

s

s

c

o

n

t

r

o

l

a

n

d

m

o

n

i

t

o

r

i

n

g

S

t

r

a

t

e

g

i

c

T

a

c

t

i

c

a

l

O

p

e

r

a

t

i

o

n

a

l

Figure 1: Decision levels in enterprise structure.

deliver products and services to customers. Decisions

are taken at different stages within the supply chain

and at different levels in the management hierarchy.

These decision levels differ in business scope,

time horizon and resolution, data certainty and ac-

curacy, process detail and optimization mechanism

(Lasschuit and Thijssen, 2004). Traditionally, enter-

prise management has been divided in three decision

levels: strategic, tactical and operational (Figure 1).

Long-term strategic level defines the business scope

by determining the structure of the supply chain in a

time period of years. Medium-term tactical planning

is concerned with decisions such as the assignment

of production targets to facilities and the distribution

from facilities to markets. The operational level is re-

lated to short-term planning or scheduling which de-

termines on a daily or weekly basis the assignment of

tasks to units and the sequencing of tasks in each unit.

Precisely, a day-to-day question in process plants

consists of optimally fulfilling customer’s demands

by managing production orders and accommodating

them to the available resources. Control of produc-

tion processes is an additional function concerning

the operational level that involves the real time ma-

nipulation of production variables to deal with pro-

cess disturbances and maintain product qualities and

production rates near the target values. The aforemen-

tioned functional decision levels have different space

and time scales, but they are intimately related to each

other since the decisions made at one level directly af-

fect others. According to (Shobrys and White, 2002),

companies pursuing integration among the different

decision levels report substantial economic benefits.

Similarly, it is of utmost importance to coordi-

nate and integrate information and decisions among

the various functions that comprise the whole supply

chain. Recently, enterprise-wide optimization (EWO)

has emerged as a new area which aims at optimizing

the operations of supply, production and distribution

to reduce costs and inventories. Specifically, EWO

places emphasis on production facilities focusing on

their planning, scheduling and control taking into ac-

count the knowledge in the domain of chemical engi-

neering. In this area, only some modest attempts at

integrating a small subset of enterprise-wide decision

models exist, since the complex organizational struc-

tures underlying business processes challenge our un-

derstanding of cross-functional coordination and its

business impact (Varma et al., 2007). Models and

tools that allow a comprehensive application of the

EWO are a research field that has not been deeply

studied yet.

A general classification distinguishes between

qualitative and quantitative models. The former rep-

resent the physical and logic relationships among the

elements of the system to describe the reality (i.e.,

conceptual or semantic models); whereas the latter al-

low supporting decisions based on the system’s actual

data (i.e., mathematical or statistical models). It is

also relevant to mention that information systems can

be categorized into transactional or analytical ones.

Transactional systems are concerned with the acqui-

sition, processing and communication of data over the

enterprise (e.g., ERP systems); while, analytical sys-

tems introduce some reasoning to propose solutions

for business problems (e.g., simulation and optimiza-

tion).

Despite the great advances in centralized trans-

actional systems, the huge amount of data stored in

such systems is usually not utilized to feed analyti-

cal systems that can provide smarter solutions which

ultimately could represent a competitive advantage in

the current business environment. Therefore, effort

must be devoted (i) to develop improved models and

(ii) to the readily integration of information systems

so as to provide decision support tools within a coher-

ent framework which takes into account the available

information on actual plant operations and market

conditions. Holistic analytical systems which are in-

stanced automatically from transactional systems data

by means of an ontological framework are required to

open new ways of making satisfactory overall deci-

sions.

This paper proposes a semantic model approach,

namely a heavyweight ontology, for representing an

integrated enterprise environment. A case study is

presented to demonstrate how the ontology can be

used as the link between transactional and analytical

systems.

2 PREVIOUS WORKS

Several ontological approaches have been presented

in the literature regarding the enterprise domain as an

ONTOLOGICAL FRAMEWORK FOR THE ENTERPRISE FROM A PROCESS PERSPECTIVE - Operational, Tactical

and Strategic Integration for Improved Decision-making

539

important medium for attaining information systems

interoperability. (Grubic and Fan, 2010) present a

complete review of current state-of-the-art in this area

and identify the outstanding research gaps. Basically,

the existing ontologies only address the strategic level

granularity and disregard the tactical and operational

levels. In addition, the methodological approaches

adopted are too far from the vast theoretical base re-

lated to the supply chain management, and only a very

limited view on the scope of supply chain is tackled.

No formal account of information flow supported ac-

tivities such as replenishment, transport or reverse lo-

gistics is reported. This work aims at reducing some

of the aforementioned research gaps.

Moreover, an explicit account of material trace-

ability and service is missing, a static view on supply

chain ontology prevails, and all of the work related

to supply chain ontology is centered on the organiza-

tion and structure of human knowledge of that reality

rather than with the reality itself. For this reason, it is

necessary to develop more realistic and robust supply

chain systems.

On the one hand, based on a previous work

(Munoz et al., 2011) which uses a semantic model for

an effectiveproduction plant modeling of the schedul-

ing and control levels, an improved ontology is de-

veloped to include the enterprise strategic level. As

a result, the levels integration is achieved by means

of a common model for re-usability, usability and a

shared information structure based on the ANSI/ISA

standards and supply chain management. Thus, the

level of granularity of the model comprises the strate-

gic and operational levels.

On the other hand, the supply chain enterprise

modeling structure considers the whole supply chain

ranging from suppliers, producers, distributors and re-

tailers, and includes the transport tasks.

3 ONTOLOGY FRAMEWORK

The proposed ontology supports different activities

by streamlining information and data integration, by

means of an integrated model which captures the ac-

tivities developed along the different levels of the en-

terprise structure in an enough general manner. As

a result an integrated decision making framework is

provided. This section describes the domain, in this

case the enterprise, of the ontology developed. Thus

the methodology applied for its development is out-

lined. Finally, the work done for the use of this onto-

logical model as a connection between transactional

and analytical models is presented.

3.1 Domain Definition

The domain of the ontology comprises the enterprise

entity, as defined at the introduction section. The

enterprise activities related to the operational, tac-

tical and strategic functions have been semantically

modeled using robust process-operational and supply

chain principles.

This work describes and completes the model

related to the tactical and operational functions,

whose semantical model was already developed by

(Munoz2010). The strategic functions have been in-

troduced, adding to the aforementioned model, the

supply chain management functionality. This supply

chain management considers most of the functions

that are found through the whole enterprise structure.

Information from different hierarchical levels is

needed to improve overall process performance. This

requires important changes for integrating the deci-

sion making system. However, the desired change

cannot be made unless the information system is ro-

bust. In general, at the strategic level, the supply chain

design and planning are optimized with information

contained at the different hierarchical enterprise lev-

els. For this reason the use of an ontology, which pro-

vides the shared and common domain structures that

are required for the semantic integration of informa-

tion sources, may result in an competitive advantage.

Although it is still difficult to find consensus among

ontology developers and users, there is some agree-

ment about protocols, languages and frameworks. In-

deed, ontologies are hierarchical domain structures

that provide a domain theory, have a syntactically and

semantically rich language, and a shared and consen-

sual terminology (Klein et al., 2002).

Batch Process Ontology (BaPrOn) is a proce-

dural oriented ontology that supports the manage-

ment of operational concepts (physical models, pro-

cedures, functions and processes) in accordance with

ANSI/ISA-88 batch process standards, categorizing

them and examining the relationships between them.

BaPrOn was presented in a previous work (Munoz

et al., 2010). In BaPrOn a conceptualization through

the ANSI/ISA-88 representation provides the advan-

tage of establishing a more general conceptualization

in the batch process domain. Such generalization is

the result of years of joint work by recognized batch

manufacturing experts who met to define a percep-

tive view of batch plants organization and its corre-

sponding hierarchy of control functions. As a con-

sequence, following the ANSI/ISA-88, virtually all

activities concerning batch processes can be properly

represented from control to scheduling tasks, as re-

ported by (Munoz et al., 2011). In addition, this allo-

KEOD 2011 - International Conference on Knowledge Engineering and Ontology Development

540

ws the association among the elements mentioned be-

fore, and the further identification of any information

resource if it is required. As a result, representation

of a chemical flexible process has been developed and

distributed inside an ontology.

The ANSI/ISA-88 defines a physical model

(equipment) and a procedural model (tasks). Both the

procedural and physical model are related each other

by means of the recipes: a recipe consists of the set of

information that uniquely defines the production re-

quirementsfor a specific product. The standard differ-

entiates between four types of recipes: general, site,

master and control. At planning and control level, the

information arrives detailed disposed in master and

control recipes. However when the strategic level is

to be modeled, the general and site recipes gather the

information related to this decision level.

The general recipe is handled at the company level

as the building block for lower-level recipes. It con-

tains the information about the required raw materi-

als, their quantities and processing stages for making

the product. Such recipe is further specified for the

manufacturing sites by the site recipes, which con-

tain the conditions and constraints related to the pro-

duction site for determining its scheduling. Master

recipes are derived from site recipes and are targeted

at the process cell including the following information

categories: header, formula, equipment requirements

and procedure. Control recipes are batches that are

created from master recipes. Specifically, they con-

tain the product-specific process information that is

required to manufacture a particular batch of product.

Regarding the strategic level, the supply chain

management decisions are related to the facility lo-

cation, production capacity and resources allocation,

distribution flows and inventory policies. Therefore,

the flow of materials, information and economic re-

sources along the wide enterprise structure are mod-

eled, as well as the restrictions regarding mass bal-

ances, capacity and technological constraints, such

as product recipes, product sequencing, unstable and

perishable materials, economic limitations, suppliers’

capacity and market demand among others.

3.2 Methodology

Various methodologies exist to guide the theoreti-

cal approach to the design of ontologies, and numer-

ous building tools are available. However, there is a

lack of consensus on a uniform approach to design-

ing and maintaining these ontologies. The method-

ology adopted in this paper is based on two on-

tology development methodologies "Methontology"

(López et al., 1999) and "On-To-Knowledge" (Sure

and Studer, 2002). On the one hand, by the use of

"Methontology", a support for the entire life-cycle

of ontology development is provided. On the other

hand, the analysis of usage scenarios of the "On-to-

Knowledge" methodology, allows to present knowl-

edge efficiently and effectively.

The phases that involve the characteristics of the

aforementioned methodologies are grouped inside the

PDCA cycle (Figure 2). Using the PDCA (Plan,

Do(study), Check and Act) cycle allows to coordi-

nate the continuous improvement efforts of the two

methodologies. As a result of the cycle, a good plan-

ning and effective actions come out. Moreover, the

base of quality management creates an easy manner

for improving the developed methodology about on-

tologies.

Plan Phase. This stage tries to make an arrangement

by first capturing the requirements and specifi-

cations, and next adequately documenting them.

The description of general information (e.g., date,

creators, and versions) is detailed. Besides the on-

tology motivations, the uses and applicability and

potential users are also described. The possible

knowledge sources are defined as well. Owing to

its expressive, declarative, portable, domain inde-

pendent and semantically definition, the language

used in the ontological approach is OWL (ontol-

ogy web language). One of the main benefits of

OWL is the support for automated reasoning, and

to this effect, it has a formal semantics based on

Description Logics (DL). The decidability, which

refers to the existence of an effective method for

determining membership in a set of formulas (the-

orems), of the logic ensures that sound and com-

plete DL reasoners can be built to check the con-

sistency of an OWL ontology. Furthermore, rea-

soners can be used to derive inferences from the

asserted information, e.g., infer whether a partic-

ular concept in an ontology is a subconcept of an-

other.

Do Phase. In this stage the principal components

of the conceptualization model are established.

Glossary of terms, concepts and properties, hier-

archies, the taxonomy, class and instant attributes

among others are described. Then a formaliza-

tion of all the content should be made in order

to agree with the knowledge sources. An iden-

tification of other ontologies that probably could

be reused is performed in order to determine if

they could be added to the model. In this stage the

translation of the model to an ontology language

must be done. The OWL ontology editors used

for the development of this model were Protégé

(Horridge et al., 2007) as main editor and Swoop

ONTOLOGICAL FRAMEWORK FOR THE ENTERPRISE FROM A PROCESS PERSPECTIVE - Operational, Tactical

and Strategic Integration for Improved Decision-making

541

Figure 2: Ontology Methodology Cycle.

(Kalyanpur et al., 2006) as complementary editor,

being freeware and also robust softwares.

Check Phase. In this stage, some key activities are

accomplished. The language and the conceptual-

ity are checked in order to standardize them with

the support of expertise and experts. The reason-

ing of the ontological model is done, which is

one of the most important tasks. Then, a short

informatics application can be developed in or-

der to test the ontology in the main application

environment. The support for debugging defects

in OWL ontologies has been fairly weak. Com-

mon defects include inconsistent ontologies and

unsatisfiable concepts. An unsatisfiable concept

is one that cannot possibly have any instances or

it represents the empty set. However, these er-

rors can be detected automatically using a DL

reasoner, which simply reports the errors, with-

out explaining why the error occurs or how it can

be resolved correctly. In this work the RacerPro

reasoner from Protégé and Pallet reasoner from

Swoop were used as reasoners for testing the On-

tology. They detected some problems of incon-

sistence which were related to unsatisfiable class

description and individuals that were asserted to

belong to those classes of the model

Act Phase. Having found defects in the ontology,

their resolution can be non-trivial, requiring an

exploration of remedies with a cost/benefit anal-

ysis. In this case, one would like to generate re-

pair solutions that impact the ontology minimally.

Particular care and effort must be taken to ensure

that ontology repair is carried out efficiently. Fi-

nally, by a robust implementation in the field, all

the formalization of relevant changes and the ag-

gregation of arguments are done. The necessary

documentation of the implementation is fulfilled

for the maintenance ontology task.

The effectiveness of the PDCA cycle arises from

leadership efforts toward the simultaneous creation of

a cooperative and learning guideline to facilitate the

implementation of any process-management and the

continuous improvement of processes.

3.3 Models Usability

In order to exploit the full potential of the ontologi-

cal model, for connecting transactional and analytical

systems, java has been used as a high-level program-

ming language. Using the platform NetBeans IDE 7.0

all the code was built. Java presents a good versatil-

ity, efficiency and security. Java code can run on most

computers because of its interpreters and runtime en-

vironments, known as Java Virtual Machines (VMs),

exist for most operating systems.

The application of the ontological model takes

place inside the business layer. In this particular

work the business layer is integrated by the enterprise

strategics tasks which are represented along with the

tactical and operational levels. Once strategic deci-

sions are taken by the appropriate analytical system

the actual supply chain is also represented. In addition

at the operational level the master recipe keeps the

planning data (later translated as information). The

proposed ontology is intended to promote transver-

sal process-oriented management, to enable crossover

among the different functionality silos in which busi-

nesses have typically been structured. In order to ob-

tain (and manage) a comprehensive view of the over-

all enterprise. These structures can recognize the ex-

KEOD 2011 - International Conference on Knowledge Engineering and Ontology Development

542

isting trade-offs and impacts of the available alterna-

tives at the different information aggregation levels,

and discard non-significant effects, through retuning

the decision-making/optimization model according to

the current enterprise status.

The ontological model consists of 182 classes, 64

restrictions, and 152 object properties. These compo-

nents make the ontology reasoning and its use pos-

sible. The reasoning time for the consistency of the

model and classes is 1.141 and 0.235 sCPU respec-

tively, in an Intel-Core2 @ 2.83GHz, in a successful

compilation.

Considering knowledge diversity, the technical ef-

fort required to deal with the process system and its

representation along the knowledge found at differ-

ent decision levels ensured that all parts within the

ontology were easily accessible. This is a particular

and explicit way of representing the knowledge by the

content format and the content type attributes found in

the ontology structure classes. These improvements

were brought about by making this information vis-

ible and readily available to diverse entities (human

and computers) at different enterprise decision levels.

The analytical systems for taking decisions about

the strategic level are based on mathematical opti-

mization, specifically the centralized approach to sup-

ply chain design and planning presented by (Lainez

et al., 2009) is considered in this case. In addition,

transactional systems related to data management are

represented by databases (MySQL databases) linked

to the different parts of the ontological model. It re-

sults in an improved way to manage these databases

since they are better structured and they can be ade-

quately mined by the potential users.

4 CASE STUDY

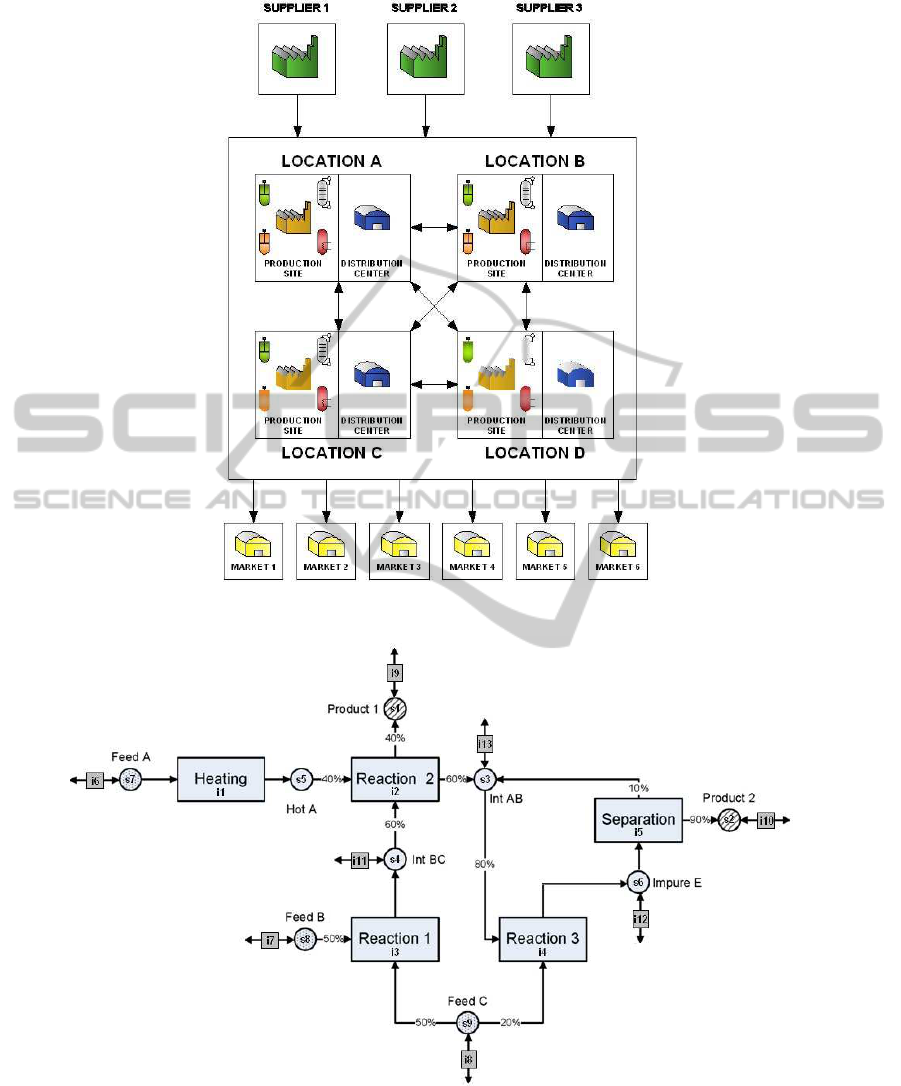

The case study is based on a supply chain network

design-planning problem presented by (Lainez et al.,

2009). It consists of three suppliers, four potential

locations for the processing sites and the distribution

centers in a planning horizon of five annual periods

(Figure 3). The production process fulfills the de-

mand of six markets that entails two final products

and one intermediate product.

The strategic analytical optimization model pre-

sented by (Lainez et al., 2009) entails decisions re-

lated to the facilities to be opened, the increase of ca-

pacity in each time period, the linkages among facili-

ties, the assignment of manufacturing and distribution

tasks to the networks nodes, and the amount of final

products to be sold, among others. Such approach can

be friendly captured by the ontological environment.

Qualitatively speaking, the problem representation in

the proposed ontological framework results in 573 in-

stances. The reasoning time for the problem instances

is 0.922 sCPU in a successful compilation.

It is important to mention that each possible site

is fully represented in the ontology. Each produc-

tion plant (site) may contain a set of four equipment

technologies as presented by (Kondili et al., 1993), a

benchmark problem for the scheduling of batch pro-

cess industries. The production process consist of five

production tasks and nine states, namely three raw

materials, two final products and four intermediates

(Figure 4). Specifically, each site is described by 111

instances, which may be adequately used to take op-

erational decisions.

The analytical optimization model must be pro-

vided with the necessary information, which is de-

rived from the ontological model and the related data

contained in the database. Additionally, the ontologi-

cal model optimizes the way in which the databases

are distributed along the enterprise structure. As a

result, databases are well located and their data are

easily available and can be transformed into valuable

information.

In order to generate the required inputs for the

optimization model which has been implemented in

GAMS, the Java application is used. Such code gen-

erates the .txt files which are called by the optimiza-

tion problem (Lainez et al., 2009). For this case study,

the specific information is presented in Table 1.

The "task" model element is part of the ontolog-

ical model as shown in Figure 5. It is necessary to

Table 1: Information provided by the ontology to the ana-

lytical model.

Model Elements

states final products

locations raw materials

facilities distribution tasks

markets production tasks

activities supplier sites

technologies production sites

equipment distribution centers

Model Parameters

capacity transports process inputs

cost raw material process outputs

facility investment cost SC demand

facility location relationship supplier capacity

market location relationship transport costs

market price transport resources

max capacity technology max facility capacity

min capacity technology min facility capacity

ONTOLOGICAL FRAMEWORK FOR THE ENTERPRISE FROM A PROCESS PERSPECTIVE - Operational, Tactical

and Strategic Integration for Improved Decision-making

543

Figure 3: Supply chain structure of the case study.

Figure 4: State task network representation of the production process considered in the case study.

export such instances to a format readable by the ana-

lytical system, namely a .txt file (Table 2). Therefore,

it is necessary to write the adequate Java code (Figure

6) in order to create the necessary input files.

The results of the optimization model are identical

to those reported in the original paper. Furthermore,

the previous results can be dated back to the ontolog-

ical model for further exploitation by the other de-

KEOD 2011 - International Conference on Knowledge Engineering and Ontology Development

544

Figure 5: Example of instances required for defining the model element "tasks".

Figure 6: Example of the Java code for giving the model element "tasks" to the analytical model.

cision levels, such as the operational system of each

site. This can be achieved by automatically updating

the databases with the resulting optimization data.

Table 2: Elements of the model element "tasks".

tasks.set

RecipeElementP11

RecipeElementP12

RecipeElementP13

RecipeElementP21

RecipeElementP22

5 CONCLUSIONS

This ontology enhances the way for achieving a suc-

cessful enterprise decision making supporting tool

which adapts and recognizes the different elements

found through the hierarchy models that are associ-

ated to the whole supply chain.

Moreover, a general semantic framework is pro-

posed, which is able to model any enterprise particu-

lar case, proving its re-usability. Furthermore, it has

been proved the ontology usability by its application

to an optimization framework. As a whole, the main

ONTOLOGICAL FRAMEWORK FOR THE ENTERPRISE FROM A PROCESS PERSPECTIVE - Operational, Tactical

and Strategic Integration for Improved Decision-making

545

contributions of this environment and the model be-

hind are re-usability, usability, higher efficiency in

communication and coordination procedures.

This work represents a step forward to support

the integration, not just communication, of different

software tools applicable to the management and ex-

ploitation of plant database information, resulting into

an enhancement of the entire process management

structure.

In addition, it has been proved the adequacy of an

ontology as a means for sharing information about a

general model for different problem representations.

As a result, it solves the problem of integration, stan-

dardization and compatibility of heterogeneous mod-

eling systems.

Further work is underway to unveil the full poten-

tial to implement a large-scale semantic web approach

to support business processes decisions.

ACKNOWLEDGEMENTS

Dirección General de Educación Superior Tecnológ-

ica (DGEST), Academy Excellence Program, ref-

erence 072007004 - E.A. from México and finan-

cial support received through the research Project

EHMAN (DPI2009-09386) funded by the Euro-

pean Union (European Regional Development Fund

ERDF) and the Spanish "Ministerio de Ciencia e In-

novación" is fully appreciated.

REFERENCES

Council, T. E. C. I. (2010). Cefic review 2009-2010. sus-

tainability and innovation driving chemistry solutions

for the future. Technical report, CEFIC.

Grubic, T. and Fan, I.-S. (2010). Supply chain ontology:

Review, analysis and synthesis. Computers in Indus-

try.

Horridge, M., Jupp, S., Moulton, G., Rector, A., Stevens,

R., and Wroe, C. (2007). A practical guide to build-

ing owl ontologies using protege 4 and co-ode tools.

Technical report, The University Of Manchester.

Kalyanpur, A., Parsia, B., Sirin, E., Grau, B. C., and

Hendler, J. (2006). Swoop: A web ontology edit-

ing browser. Web Semantics: Science, Services and

Agents on the World Wide Web, 4(2):144 – 153. Se-

mantic Grid –The Convergence of Technologies.

Klein, M., Fensel, D., Kiryakov, A., and Ognyanov, D.

(2002). Ontology versioning and change detection

on the web. In In 13th International Conference on

Knowledge Engineering and Knowledge Management

(EKAW02, pages 197–212.

Kondili, E., Pantelides, C., and Sargent, R. (1993). A

general algorithm for short-term scheduling of batch

operations–i. milp formulation. Computers & Chemi-

cal Engineering, 17(2):211 – 227.

Lainez, J. M., Kopanos, G., Espuna, A., and Puigjaner, L.

(2009). Flexible design-planning of supply chain net-

works. AICHE JOURNAL, 55(7):1736–1753.

Lasschuit, W. and Thijssen, N. (2004). Supporting supply

chain planning and scheduling decisions in the oil and

chemical industry. Computers & Chemical Engineer-

ing, 28:863–870.

López, M. F., Gómez-Pérez, A., Sierra, J. P., and Sierra,

A. P. (1999). Building a chemical ontology using

methontology and the ontology design environment.

IEEE Intelligent Systems, 14(1):37–46.

Munoz, E., Capon-Garcia, E., Moreno-Benito, M., Espuna,

A., and Puigjaner, L. (2011). Scheduling and con-

trol decision-making under an integrated information

environment. Computers and Chemical Engineering,

35:774 – 786.

Munoz, E., Espuna, A., and Puigjaner, L. (2010). Towards

an ontological infrastructure for chemical batch pro-

cess management. Computers & Chemical Engineer-

ing, 34(5):668–682.

Shobrys, D. E. and White, D. C. (2002). Planning,

scheduling and control systems: why cannot they

work together. Computers & Chemical Engineering,

26(2):149–160.

Sure, Y. and Studer, R. (2002). On-to-knowledge method-

ology. Technical report, University of Karlsruhe.

Varma, V. A., Reklaitis, G. V., Blau, G. E., and Pekny, J. F.

(2007). Enterprise-wide modeling & optimization - an

overview of emerging research challenges and oppor-

tunities. Computers & Chemical Engineering, 31(5-

6):692–711.

KEOD 2011 - International Conference on Knowledge Engineering and Ontology Development

546