DEVELOPMENT OF SEQUENTIAL ASSOCIATION RULES FOR

PREVENTING MINOR-STOPPAGES IN SEMI-CONDUCTOR

MANUFACTURING

Sumika Arima, Ushio Sumita and Jun Yoshii

Graduate School of Systems and Information Engineering, University of Tsukuba

Tennoudai 1-1-1, Tsukuba, Ibaraki 305-8573, Japan

Keywords:

Semi-conductor manufacturing, Minor-stoppages, Sequential association rules, Preventive maintenance

policies.

Abstract:

In semi-conductor manufacturing, the machine downtimes due to minor-stoppages often exceed 40% of the

working hours of a day, and would amount to the huge loss. However, effective methodological tools for

predicting and preventing the minor-stoppages are hard to come by. The purpose of this research is to fill this

gap by establishing effective preventive maintenance policies for controlling minor-stoppages. Our approach

is to develop association rules based on sequential data along the time axis so that the resulting rules could be

used for predicting occurrences of certain minor-stoppages. The proposed methodology is applied to a real

data set and yields two preventive maintenance policies in a concrete form, thereby demonstrating its power

and usefulness. While the paper focuses on the testing process, the methodology proposed in this paper is

valid for other production processes, provided that similar sequential data could be collected.

1 INTRODUCTION

Semi-conductor manufacturing is characterized by a

sequence of sophisticated manufacturing processes,

often exceeding several hundred production steps.

Such processes possess both aspects of continuous

and discrete operations. On one hand, many pro-

duction steps involve chemical diffusion for etch-

ing layers of circuits and such steps ought to be

controlled continuously. On the other hand, the

final products are semi-conductor chips which are

clearly discrete in nature. Combined with necessary

ultra-precision technologies, these factors make semi-

conductor manufacturing extremely difficult to con-

trol and force one to rely upon quite expensive auto-

mated production machines. Accordingly, the cost of

machine downtimes in semi-conductor manufacturing

is quite huge. When a major failure of a production

machine occurs, vender engineers have to be often

called in and the repair may sometimes take more than

a few days.

Apart from such major failures, in semi-conductor

manufacturing, the machine downtimes due to minor-

stoppages would also amount to the huge loss. A

minor-stoppage is defined to be a machine failure

which requires the direct involvement of an operator

for repair but the repair time is quite short once the

problem is addressed by the operator. Frequency of

minor-stoppages is typically quite high and it is not

rare to have multiple minor-stoppages occurring si-

multaneously. Since one operator deals with several

machines, a machine with a minor-stoppage may have

to wait until it is attended by the operator. Because

of such waiting times, the machine downtimes due

to minor-stoppages often exceed 40% of the working

hours of a day. Accordingly, it is extremely important

to develop effective ways for controlling such minor-

stoppages.

In the literature, the issue of enhancing the yield

and reducing the machine downtime in manufacturing

has been addressed largely from the point of view of

detecting root-causes of the product defects based on

some data mining techniques. (Gardner and Bieker,

2000), for example, employ a combination of self-

organizing map neural networks and rule induction

to identify the critical poor yield factors in the wafer

manufacturing process. In (Chen et al., 2005), cor-

relations between combinations of machines and the

defective products are first analyzed. The technique

of association rule mining is then used to establish the

root-cause machine identifier efficiently. (Chien et al.,

2007) focus on the wafer fabrication process and chal-

349

Arima S., Sumita U. and Yoshii J..

DEVELOPMENT OF SEQUENTIAL ASSOCIATION RULES FOR PREVENTING MINOR-STOPPAGES IN SEMI-CONDUCTOR MANUFACTURING.

DOI: 10.5220/0003713503490354

In Proceedings of the 1st International Conference on Operations Research and Enterprise Systems (ICORES-2012), pages 349-354

ISBN: 978-989-8425-97-3

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

lenge the problem of detecting root-causes based on a

Kruscal-Wallis test, K means clustering and the vari-

ance reduction approach.

While these contributions may enable one to iden-

tify the correlation structure between combinations of

machines and the defective products, and detect root-

causes of the defections, they do not provide preven-

tive maintenance policies automatically. In particular,

in semi-conductor manufacturing, effective method-

ological tools for preventing the minor-stoppages are

hard to come by. Part of the reason for this difficulty

may be found in that there are many differentpotential

sources of minor-stoppages. Certain minor-stoppages

may be attributed to factors related to products, in-

cluding shape, size, weight, pins, and the like. De-

terioration of machine conditions may cause minor-

stoppages. HR (Human Resource) related factors

such as work-shifts, skills of workers and training

programs would also affect minor-stoppages.

The purpose of this paper is to establish ef-

fective preventive maintenance policies for control-

ling minor-stoppages in semi-conductor manufac-

turing. Our approach is to first classify types of

minor-stoppages based on real data. These types

are categorized in such a way that, once a type

of a minor-stoppage is identified, the cause of the

minor-stoppage could be located with high proba-

bility. The next step is to analyze a sequence of

minor-stoppages by types where occurrences of cer-

tain minor-stoppages would be recognized to trigger

minor-stoppages of other type, thereby providing a

foundation for establishing preventive maintenance

policies. This kind of the association rule approach is

prevalent in marketing and is often employed for dis-

covering purchasing patterns to be expected with high

probability. The uniqueness of this paper is to de-

velop such association rules based on sequential data

along the time axis so that the resulting rules could

be used for predicting occurrences of certain minor-

stoppages.

The structure of this paper is as follows. The test-

ing process in SAW (Surface Acoustic Wave) man-

ufacturing is described in a succinct manner in Sec-

tion 2. Along with the testing process, 10 minor-

stoppages of principal interest are explained in detail.

Section 3 is devoted to establish the association rules

for predicting occurrences of such minor-stoppages.

Numerical results are provided in Section 4 based on

real data, demonstrating the practical usefulness of

the proposed approach. Some concluding remarks are

given in Section 5.

Throughout the paper, vectors are indicated by un-

derbars, e.g. a

T

= [a

1

,...,a

N

], etc.

Figure 1: Six major stages of SAW manufacturing pro-

cesses.

2 SAW MANUFACTURING

PROCESS

We consider the manufacturing process of SAW fil-

ters, which are used in mobile phones, optical routers

and the like for screening out electronic signals out-

side a pre-specified frequency range so that elec-

tronic noises can be eliminated in communication.

The manufacturing process consists of six production

stages as depicted in Figure 1.

The first stage is to cover the surface of each sil-

icon wafer with a thin film through chemical vapor

deposition, followed by photo-lithography to create

a circuit pattern within the silicon wafer. These two

stages are repeated so as to form a layer of circuit

patterns. Then individual silicon wafers are cut into

chips through dicing. In wire-bonding and packag-

ing, each chip is mounted onto a metallic lead-frame

and is covered by a cap. All of the finished products

then go through complete testing before shipment to

customers. In this paper, we focus on the testing stage

and establish preventive maintenancepolicies for con-

trolling minor-stoppages within the testing procedure.

The structure of a testing machine is depicted in

Figure 2 for facilitating the explanation of the de-

tailed operations involved in the testing procedure.

Here, sensors A through N are indicated by putting

each of them in a square. In line with the conven-

tion, throughout the paper, we call a finished product

“a work”. Several thousands of works constituting a

lot are first placed into the bowl-feeder, which rotates

counter clockwise so as to feed works into the linear-

feeder. Sensors A and B located near the entrance

to the linear-feeder examine whether or not the right

face of a work is placed up. If Sensor A detects a

work with face down, it turns on the system to flip the

work over by blowing air. If the work is still judged

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

350

Bowl-feeder

Linear-feeder

Pre-Alignment

Frequency

Testing

Ejection of

Defect Products

Retrieval of

Finished Products

C

D

E

F

G H

I

J

K

L

M

N

A

B

Insulation

Testing

Figure 2: Structure of a testing machine.

as its face down by Sensor B, it would be blown back

to the bowl-feeder by ejecting air.

At the entrance of the linear-feeder, Sensor C de-

termines whether or not a work is there. The first work

fed into the linear-feeder would turn on the vibra-

tion system which facilitates all the works within the

linear-feederto be movedforward toward the entrance

to the wheel mechanism. Since the wheel mechanism

rotates around 12 fixed stations located in equal angu-

lar positions with fixed time interval, we name the 12

stations Wi, i=1, 2, c , 12 in sequence counter clock-

wise. Upon reaching W1, a work is sucked into one

of the 12 heads of the wheel mechanism to be moved

counter clockwise to W2, W3, etc.

There are two types of minor-stoppages possible

in the feeding process. The first case is that the bowl-

feeder is stuck and the linear-feeder is starved. The

second case is due to completion of the entire lot of

works, which requires a new lot of works to be fed

into the bowl-feeder. The former is called “PF-Stuck

Al” where PF stands for Parts Feeder and Al means

Alarm, while the latter is named as “WC Al” with

WC describing Work Completion. In order to cope

with PF-Stuck Al and WC Al, Sensors D, E and F are

employed as shown in Figure 3. Sensor D is located at

the point of the ten work length from W1. Sensor E is

attached to the stage of W1, and Sensor F is installed

at the up position of a head of the wheel mechanism

above W1. PF-Stuck Al is detected if Sensor F signals

no work present 10 times in a row under the condi-

tion of either “Sensor D identifying the presence of a

work and Sensor E signaling non-existenceof a work”

or “Sensor E recognizing the presence of a work”.

WC Al is detected if either “Sensors E and F signal

non-existence of a work simultaneously 10 times in a

row” or “Sensor F signals non-existence of a work 15

times in a row”. Sensor F would also see if the work

is sucked in an appropriate position. If not, “WS-F

Al” is detected where WS-F stands for Work Supply-

Figure 3: Locations of sensors along the linear-feeder.

Failure. Upon detecting PF-Stuck Al, WC Al or WS-

F Al, the testing machine is automatically stopped and

the appropriate alarm is signaled. This alarming pro-

cess is similar for other minor-stoppages and will not

be mentioned hereafter.

Upon reaching W2, a work remains to be sucked

to the head and Sensor G of W2 checks if the work

is there and the bottom of the work shows the cor-

rect side. If the bottom side is correct, R-at-W2-Flag

is set to be 1 where R stands for Recognizable. In

this case, it is also checked to see if the horizontal

position of the work is appropriate, finding the cor-

rective rotational angle to be implemented at W3, if

necessary. If the bottom side is found to be wrong,

R-at-W2-Flag is set to be 0. At W3, as soon as a work

is placed back to the stage with the corrective rota-

tion if necessary, a vacuum sensor called Sensor H is

activated. If the work was not sucked appropriately

to the head previously and was not corrected at W3,

it would not cover Sensor H completely, resulting in

air leak. In this case, “PASM Al” is signaled, where

PASM means Pre-Alignment Sucking Miss. At W4,

Sensor I similar to Sensor G is switched on. If the two

sensors do not produce consistent judgment concern-

ing the presence of a work, PASM Al is also reported.

When the work is placed 180in a wrong direction, the

above air leak test may still be passed. If Sensor I de-

tects this case, R-at-W4-Flag is set to be 0. Otherwise,

it is set to be 1.

At W5, each work is tested to see if its frequency

falls into the pre-specified range. If the test is success-

ful, F-Flag is set to be 1 with F meaning Frequency.

Otherwise, it is set to be 0. Upon completion of the

test, Sensor J is turned on to make sure that the work

is moved to W6. If Sensor J detects the work left on

the stage of W5, “WL-at-W5 Al” is issued where WL-

at-W5 stands for Work Left at W5. W6 is to check if

the insulation functions properly. Upon completion of

the insulation test, I-Flag is set to be 1 if successful,

and 0 otherwise, where I stands for Insulation. As for

Sensor J at W5, Sensor K at W6 is then set on to see

whether or not the work is transferred to W7 appro-

priately. If not, “WL-at-W6 Al” is reported.

Sensor L is activated at W7 to see if there is a work

on the stage of W7. If it reports non-existence of a

work despite Sensor F reported otherwise, “SM Al” is

issued where SM stands for Sucking Miss. If any of

DEVELOPMENT OF SEQUENTIAL ASSOCIATION RULES FOR PREVENTING MINOR-STOPPAGES IN

SEMI-CONDUCTOR MANUFACTURING

351

R-at-W2-Flag, R-at-W4-Flag, F-Flag and I-Flag has

the value of 0, the work is detected as a defect at W7.

Such defects are sorted according to the values of the

flags and are dropped into appropriate cells. Sensor

M checks the presence of a work at W8. If it finds

a work, the values of R-at-W2-Flag, R-at-W4-Flag,

F-Flag and I-Flag for the work are examined. If any

of them is 0, it means that the work is failed to be

detected as a defect at W7 and “FDD Al” is issued

where FDD means Failure to Detect a Defect. After

W8, each work is passed over to W9 without doing

anything and reaches W10 where it is pushed out into

a tray as a finished product. Necessary statistics are

also collected at W10 to see if the cumulative yield

of finished products stays above a pre-specified level.

If this level is not met, “YF Al” is reported with YF

meaning Yield of Finished products.

The wheel mechanism continues to rotate over

W11 and Sensor N at W12 examines to make sure

that there is no work present at W12. If any, it im-

plies that a finished product was not taken out appro-

priately at W10 and “FRF Al” is issued where FRF

stands for Failure to Retrieve a Finished product. The

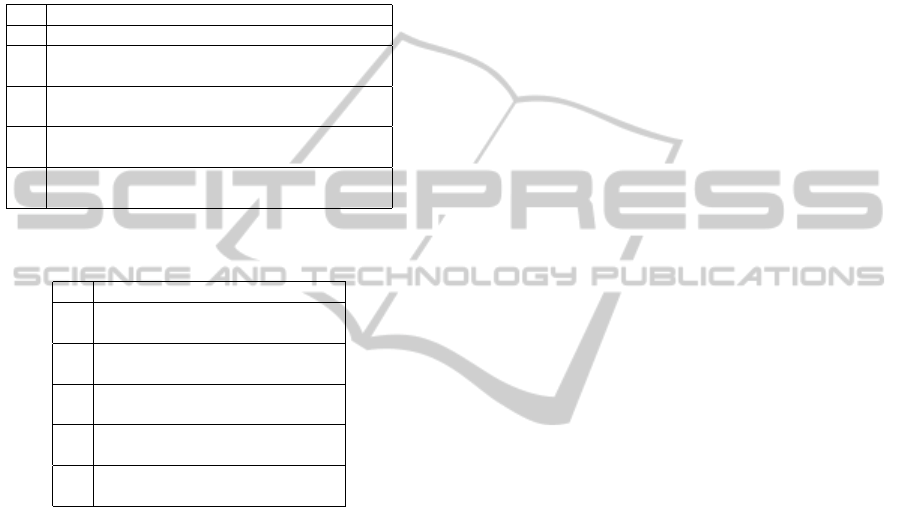

definitions of the flags are provided in Table 1. The

ten minor-stoppages of principal interest to this paper

discussed above are summarized in Table 2.

3 DEVELOPMENT OF

ASSOCIATION RULES FOR

PREVENTING

MINOR-STOPPAGES BASED

ON SEQUENTIAL DATA

For analytical purposes, we define a “window” as a

set of works constituting a production lot, typically

with its size in the range from 5000 to 60000 and its

average around 30000. All orders under considera-

tion are then expressed as a sequence of windows of

length K along the time axis for each testing machine.

The purpose of this section is to develop association

rules, each of which indicates that the occurrence of

a certain combination of minor-stoppages in a certain

pattern within 2 consecutive windows would be likely

to result in the occurrence of specific minor-stoppages

in the immediately following window.

The problem of how to mine association rules

from a large-scale data set has been addressed by

many researchers, represented by (Agrawal et al.,

1993) and (Agrawal and Srikant, 1994). Sub-

sequently, the association rule approach has been

applied to sequential data for prediction, see e.g.

(Agrawal and Srikant, 1995), (Lu et al., 1998), (Jiang

Table 1: The definitions of the flags.

Name Position Sensor

R-at-W2-Flag Recognizable at W2 W2 G

R-at-W4-Flag Recognizable at W4 W4 I

F-Flag Frequency W5 -

I-Flag Insulation W6 -

Table 2: The ten minor-stoppages.

Name Position Sensor

PF-Stuck Al Parts Feeder Stuck Linear-feeder D,E,F

WC Al Work Completion Linear-feeder E,F

WS-F Al Work Supply Failure W1 F

PASM Al Pre-Alignment W3,W4 G,H,I

Sucking Miss

WL-at-W5 Al Work Left at W5 W5 J

WL-at-W6 Al Work Left at W6 W6 K

SM Al Sucking Miss W7 F,L

FDD Al Failure to Detect a Defect W8 M

YF Al Yield of Finished product W10 -

FRF Al Failure to Retrieve W12 N

a Finished product

and Gruenwald, 2006) and (Qin and Shi, 2006) to

name a few. However, these papers are exclusively

dealing with marketing problems. To the best knowl-

edge of the authors, the sequential association rule ap-

proach has not been applied to production control.

Real data have been collected from a semi-

conductor factory producing SAW devices. The data

set consisting of K

L

windows would be used as the

learning data and a set of association rules would be

established tentatively by following the procedure de-

scribed in this section. The next K

T

windows would

be then used as the testing data, where a tentative as-

sociation rule is chosen to be a formal rule if the ac-

curacy of the association rule over the testing data ex-

ceeds a pre-specified level. For each of such formal

rules, an action plan is devised so as to reduce the

minor-stoppages.

In practice, the learning data may be collected for

3 months, while the testing data may consist of the

windows over the subsequent 2 months. The result-

ing selected association rules would be applied to real

data for 1 month following the testing period so as to

reduce minor-stoppages. This learning-testing proce-

dure would be repeated monthly on a rolling horizon

basis for updating the selected association rules.

Let N = {1,...,N} be the set of types of

minor-stoppages under consideration, and define

the minor-stoppage occurrence vector x

T

(k) =

[x(k,1),... ,x(k,i),... ,x(k, N)], where x(k,i) denotes

the number of minor-stoppages of type i occurred in

the k-th window. We intend to establish association

rules by observing the incremental changes

∆x

T

(k) = x

T

(k) − x

T

(k− 1), k = 2,...,K

L

, (1)

in relative to its mean and variance over the entire K

L

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

352

windows. More formally, let µ and σ

2

be defined by

µ = [µ

1

,...,µ

N

] ;

µ

i

=

1

K

L

− 1

K

L

∑

k=2

∆x

T

(k,i) , (2)

and

σ

2

= [σ

2

1

,...,σ

2

N

] ;

σ

2

i

=

1

K

L

− 2

K

L

∑

k=2

{∆x(k, i) − µ

i

}

2

. (3)

Then ∆x(k, i) can be standardized as

z(k) = [z(k, 1), . . . ,z(k,N)] ;

z(k,i) =

∆x(k,i) − µ

i

σ

i

. (4)

Based on the value of z(k,i), we introduce the in-

dicator function I(k,i) for describing whether the i-th

minor-stoppage in the k-th window is in tendency of

decreasing, being stable, or increasing. Namely, for a

given threshold value α > 0, we define

I(k,i) =

−1 if z(k,i) ≤ −α

0 if z(k, i) ∈ (−α,α) .

1 if z(k, i) ≥ α

(5)

If z(k, i) exceeds α, the i-th minor-stoppage is judged

to be in increase in the k-th window. If the value is

within ±α, it is considered to be in a stable state.

When the value falls below α, the i-th minor-stoppage

is defined to be in decrease.

Let M(k,i,y) be the number of occurrences of

y ∈ {−1,1} for the i-th minor-stoppage in the (k− 1)-

st and the k-th windows. If we define δ

{ST}

= 1 if

the statement ST is true and δ

{ST}

= 0 otherwise,

M(k, i, y) can be written from (5) as

M(k, i, y) = δ

{I(k−1,i)=y}

+ δ

{I(k,i)=y}

. (6)

A typical association rule R would consist of the con-

dition part expressed in terms of a set of M(k,i,y)’s

for i ∈ N and y ∈ {−1, 1}, and the conclusion part

written as I(k+ 1, r) = 1 for some r ∈ N .

In order to identify such association rules from the

learning data, the traditional measures of SUPPort,

CONFidence and LIFT are employed. For notational

convenience, a “unit” is defined as a set of three con-

secutive windows for which an association rule can be

tested. We note that, for the learning data consisting

of K

L

windows, there are K

L

− 3 units since ∆x

T

(k)

in (1) can be defined only for k ≥ 2 and the last two

windows would not have the third window for testing

the conclusion part of an association rule.

Given an association rule R , let VAL(R ) be the

set of units for which R is VALid. Similarly, we de-

fine COND(R ) and CONC(R ) to be the set of units

meeting the CONDition of R and that satisfying the

CONClusion of R respectively. It should be noted

that VAL(R ) = COND(R ) ∩CONC(R ). The three

measures SUPP, CONF and LIFT are then defined

as

SUPP(R ) =

|VAL(R )|

K

L

− 3

, (7)

CONF(R ) =

|VAL(R )|

|COND(R )|

(8)

and

LIFT(R ) =

|CONF(R )|

|CONC(R )|/(K

L

− 3)

, (9)

where |A| denotes the cardinality of a set A. One

observes that, SUPP(R ) is the portion of the units

satisfying R against the entire K

L

− 3 units, while

CONF(R ) is that against the set of the units satisfy-

ing the condition part of R . LIFT(R ) describes how

the probability of selecting a unit satisfying the con-

clusion part of R from the entire K

L

− 3 units can be

lifted by restricting the sample set to the units meeting

the condition part of R .

Given α > 0 in (5) along with β > 0 and γ > 0, we

define the followings.

a) An association rule R is said to be effective on

data D if SUPP(R ) ≥ β, CONF(R ) ≥ γ and

LIFT(R ) > 1.

b) An association rule R is said to be formal if it is

effective on both the learning data and the testing

data.

For each of the selected formal rules, an action plan

is devised so as to reduce the minor-stoppages by im-

plementing the action plan whenever the condition(s)

of the rule could be observed.

4 NUMERICAL RESULTS

In this section, we present numerical results based on

real data obtained from a semi-conductor manufac-

turing plant, where one testing machine was observed

for minor-stoppages continuously. The data collected

through the three month period January-March 2010

constitute the learning data with K

L

= 166, while the

following two month data in April and May would be

used for testing with K

T

= 84. The ten types of minor-

stoppages discussed in Section II are considered for

analysis, where

N = { PF-Stuck,WC,WS-F,PASM,WL-at-W5,

WL-at-W6,SM,FDD,YF,FRF} . (10)

DEVELOPMENT OF SEQUENTIAL ASSOCIATION RULES FOR PREVENTING MINOR-STOPPAGES IN

SEMI-CONDUCTOR MANUFACTURING

353

With α = 0.5, β = 0.02 and γ = 0.30, forty-four

rules are found to be effective based on the learning

data. By examining these rules against the test data,

five rules are selected to be formal, as shown in Ta-

ble 3. For each of the five rules, Table 4 exhibits the

three indices SUPP, CONF and LIFT based on the

learning data as well as the test data.

Table 3: Effective association rules.

No LHS RHS

1 M(k, WC,1) = 1 ⇒ I(k + 1,WS-F) = 1

2 M(k, FRF,1) = 1 ⇒ I(k+ 1,WS-F) = 1

M(k,FRF,−1) = 1

3 M(k, FRF,1) = 1 ⇒ I(k+ 1,PF-Stuck) = 1

M(k,FRF,−1) = 1

4 M(k, WC,−1) = 1 ⇒ I(k+ 1,WS-F) = 1

M(k,WS-F,−1) = 1

5 M(k, WL-at-W6,1) = 1 ⇒ I(k+ 1,PF-Stuck) = 1

M(k,PF-Stuck,−1) = 1

Table 4: SUPP, CONF and LIFT for rules 1 through 5.

No Data SUPP CONF LIFT

1 Learning 0.066 0.306 1.691

Test 0.060 0.313 1.382

2 Learning 0.030 0.385 2.128

Test 0.048 0.364 1.608

3 Learning 0.024 0.308 1.502

Test 0.048 0.364 2.036

4 Learning 0.030 0.333 1.844

Test 0.036 0.333 1.474

5 Learning 0.030 0.500 2.441

Test 0.024 0.667 3.733

The conclusion parts of the five rules consist of

the increase of WS-F or PF-Stuck. In order to prevent

WS-F, it would be effective to clean the head parts

of the wheel mechanism, while cleaning the linear-

feeder would decrease the likelihood of occurring PF-

Stuck. Hence, the preventive maintenance policies

derived from the five rules would be :

1) if the condition part of Rule 1, Rule 2 or Rule 4

is realized, then clean the head parts of the wheel

mechanism; and

2) if the condition part of Rule 3 or Rule 5 is realized,

then clean the linear-feeder.

5 CONCLUSIONS

In this paper, a novel approach is proposed for es-

tablishing preventive maintenance policies so as to

control the minor-stoppages in the testing process of

semi-conductor manufacturing. Based on the real

data collected from an actual factory, sequential asso-

ciation rules are established, where the occurrence of

a certain combination of minor-stoppages within two

consecutive windows would indicate the likelihood

of occurrence of a certain minor-stoppage to become

higher in the next window. Five association rules are

found to be effective, yielding two preventive main-

tenance policies in a concrete form. While the paper

focuses on the testing process, the methodology pro-

posed in this paper is valid for other production pro-

cesses, provided that similar sequential data could be

collected.

REFERENCES

Agrawal, R., Imielinski, T., and Swami, A. (1993). Min-

ing association rules between sets of items in large

databases. Proceedings of the 1993 ACM SIGMOD

International Conference on Management of Data,

pages 207–216.

Agrawal, R. and Srikant, R. (1994). Fast algoritms for min-

ing association rules. Proceedings of the 20th Confer-

ence on Very Large Data Bases, pages 478–499.

Agrawal, R. and Srikant, R. (1995). Mining sequential pat-

terns. Proceedings of the International Conference on

Data Engineering.

Chen, W., Tseng, S., and Wang, C. (2005). A novel man-

ufacturing defect detection method using association

rule mining techniques. Expert Systems with Applica-

tions, 29:807–815.

Chien, C., Wang, W., and Cheng, J. (2007). Data mining

for yield enhancement in semiconductor manufactur-

ing and an empirical study. Expert Systems with Ap-

plications, 33:192–198.

Gardner, M. and Bieker, J. (2000). Data mining solves

tough semiconductor manufacturing problems. Pro-

ceedings of the sixth ACM SIGKDD International

Conference on Knowledge Discovery and Data Min-

ing.

Jiang, N. and Gruenwald, L. (2006). Research issues in

data stream association rule mining. ACM SIGMOD

Record, 35(1):14–19.

Lu, H., Han, J., and Feng, L. (1998). Stock movement

prediction and n-dimensional inter-transaction associ-

ation rules. Proceedings of the 1998 ACM SIGMOD

Workshop on Research Issues on Data Mining and

Knowledge Discovery, pages 12:1–12:7.

Qin, L. and Shi, Z. (2006). Efficiently mining association

rules from time series. International Journal of Infor-

mation Technology, 12(4):30–38.

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

354