DYNAMIC RESPONSE ANALYSIS OF MULTIBODY SYSTEM

IN DISCRETE EVENT SIMULATION

Namkug Ku

1

, Sol Ha

1

, Myung-Il Roh

2

and Kyu-Yeul Lee

1

1

Seoul National University, Shinlim-Dong Kwanak-Gu, Seoul, Korea

2

University of Ulsan, Daehak-ro, Nam-gu, Ulsan, Korea

Keywords: Dynamic response analysis, Multibody system, Discrete event simulation.

Abstract: There are several kinds of mechanical systems that are under event-triggered conditions. For the dynamic

analysis of such mechanical systems, a simulation program that can generate equations of motion for

mutibody systems in the discrete-event simulation framework was developed. For complex multibody

systems, a dynamics kernel was developed to generate the equations of motion for multibody systems based

on multibody dynamics. To generate the equations of motion, the recursive formulation method was used.

Using the developed dynamics kernel, the dynamic responses of multibody systems can be carried out under

continuous conditions. The general multibody dynamics kernel, however, cannot deal with discontinuous-

state variables and event-triggered conditions. The multibody dynamics kernel, therefore, was integrated

into the discrete-event simulation program to deal with multibody systems in discontinuous environments.

The discrete-event simulation program was developed based on the discrete-event system specification

(DEVS) formalism, which is a modular and hierarchical formalism for analyzing systems under event-

triggered conditions.

1 INTRODUCTION

In many engineering fields, the need for accurate

dynamic-response analysis using a simulation tool is

increasing. Especially in the shipbuilding industry,

there are various types of mechanical systems that

have to be analysed. Fig. 1 shows three examples of

such mechanical systems. Fig. 1(a) shows a goliath

crane, which is used to lift and transport heavy loads

and important facilities in shipyards. Fig. 1(b) shows

a floating crane, whose capacity is usually greater

than that of the goliath crane. As shown in the figure,

unlike the goliath crane, the floating crane is

operated on the sea. Fig. 1(c) shows floating

offshore wind turbines. All of these facilities are

mechanical systems that have to be analysed in their

dynamic aspects for accurate design.

The mechanical systems shown in Fig. 1 can be

considered as multibody systems, which are

collections of interconnected rigid bodies, consistent

with various types of joints that limit the relative

motion of pairs of bodies. Planners of shipbuilding

process, therefore, use commercial programs when

they receive requests for dynamic-response analysis.

These methods, however, have some limitations. As

the commercial programs for dynamic analysis are

Figure 1: Various types of mechanical systems in the shipbuilding industry: (a) goliath crane; (b) floating crane; and (c)

floating offshore wind turbines.

(b)

(a)

Load

Goliath Crane

Wire rope

Floating Crane

Load

(c)

Floating Offshore

Wind Turbines

447

Ku N., Ha S., Roh M. and Lee K..

DYNAMIC RESPONSE ANALYSIS OF MULTIBODY SYSTEM IN DISCRETE EVENT SIMULATION.

DOI: 10.5220/0003760804470453

In Proceedings of the 1st International Conference on Operations Research and Enterprise Systems (ICORES-2012), pages 447-453

ISBN: 978-989-8425-97-3

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

usually developed for general purposes, they may

not be suitable for the various requirements of

process planning in shipbuilding.

For instance, the block-lifting and transport

process, which is carried out by a goliath or floating

crane, consists of several discontinuous stages, such

as hoisting-up, transport, and hoisting-down.

Meanwhile, most of the commercial programs for

multibody dynamic analysis cannot deal with

discontinuous-state variables as well as event- and

state-triggered conditions.

Therefore, the dynamics kernel was developed,

which can generate the equations of motion of

multibody systems for the accurate analysis of

dynamic systems. To deal with a multibody system

in a discontinuous environment, the multibody

dynamics kernel was integrated into the discrete-

event simulation program, which was developed

based on the discrete-event system specification

(DEVS) formalism. DEVS formalism is a modular

and hierarchical formalism for modelling and

analyzing systems under event-triggered conditions,

which are described by discontinuous-state variables.

2 RELATED WORKS

ADAMS (Automatic Dynamic Analysis of

Mechanical Systems) is a software system consisting

of a number of integrated programs that help an

engineer in performing three-dimensional kinematic

and dynamic analyses of mechanical systems

(Orlandea et al., 1977, Schiehlen, 1990). ADAMS

generates equations of motion for multibody systems

using augmented formulation. The user can define

any multibody system composed of several bodies

that are interconnected by joints. ADAMS supplies

various types of joints, such as fixed, revolute, and

spherical joints. Various external forces can also be

applied to multibody systems, but ADAMS cannot

handle discontinuous-state variables as well as

event- and state-triggered conditions.

ODE (Open Dynamics Engine) is an open-

source library for simulating multibody dynamics

(Smith, 2006). Similar to ADAMS, ODE derives

equations of motion for multibody systems using

augmented formulation. ODE cannot handle

discontinuous-state variables as well as event- and

state-triggered conditions.

RecurDyn is a three-dimensional simulation

software that combines dynamic-response and finite-

element analysis tools for multibody systems. It is

two to 20 times faster than other dynamic solutions

because of its advanced, fully recursive formulation.

Various joints and external forces can also be

applied to multibody systems, but RecurDyn cannot

handle discontinuous-state variables as well as

event- and state-triggered conditions.

On the other hand, Praehofer, Zeigler, et al.

(1990, 2000) proposed a modelling and simulation

method that can handle simulation models of

discrete events and times. They also developed a

simulation framework based on the proposed

method. In the case of discrete-event simulation, the

operation of a simulation system is represented as a

chronological sequence of events. Process or

material flow simulation systems and the like are

included in the category of discrete-event simulation.

On the other hand, in the case of discrete-time

simulation, the operation of a simulation system is

represented as the progress of time. State changes

occur only at discrete-time instants. Dynamic

simulation systems and the like are included in the

category of discrete-time simulation, but the

developed simulation framework focuses only on the

material flow simulation system of a workshop.

Thus, it was difficult for it to be applied to a large

factory such as a shipyard, and it was hard to use the

existing design and production information for the

simulation.

Many researches related to mutibody dynamic

analysis and discrete-event simulation have been

conducted, but they had some limitations in their

application to process planning in shipyards, as

mentioned earlier. To overcome these limitations, a

dynamics kernel that can automatically generate the

equations of motion of multibody systems was

developed and was integrated into the discrete-event

simulation program.

3 DEVELOPMENT

OF A MULTIBODY DYNAMICS

KERNEL FOR DYNAMIC

ANALYSIS

The facilities in shipyards, as shown in Fig. 1, are

multibody systems. For the modelling and dynamic

analysis of these multibody systems, a dynamics

kernel was developed. In this section, the coordinate

system and the properties of the rigid body will be

explained. The three formulations (augmented,

embedding, and recursive formulations) for the

derivation of equations of motion will be presented.

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

448

3.1 Construction of the Kinematics

of a Multibody System

3.1.1 Reference Frames and Properties

of the Rigid Bodies

To model the multibody system, the position and

orientation of the rigid bodies must be defined with

respect to the inertial reference frame. Because the

body fixed frames represent the position and

orientation of each rigid body, such frames should

be defined for every rigid body.

For each rigid body, moreover, it is necessary to

define the mass, mass moment of inertia about three

axes of the body fixed frame, and position of the

center of mass with respect to the body fixed frame.

3.1.2 Derivation of Equations of Motion

by using Recursive Formulation

The process of the derivation of equations of motion

for multibody systems with a large number of bodies

is difficult because many vectors and matrix

manipulations are involved. For this reason, various

formulations for the derivation of equations of

motion have been developed. In this study, recursive

formulation was used to derive equations of motion

because its computational efficiency is better than

that of the other formulations, such as the augmented

and embedding formulations.

1) Augmented formulation

One of the formulations for the derivation of

equations of motion is augmented formulation,

which is represented by the following equation:

Figure 2: Augmented formulation for the derivation of

equations of motion.

2) Embedding formulation

Another formulation for the derivation of

equations of motion is embedding formulation,

which is represented by the following equation. As

the dependent coordinates are eliminates in the

equations of motion, the constraint equations are not

explicitly shown.

Figure 3: Embedding formulation for the derivation of

equations of motion.

where is the mass and the mass moment of inertia

matrix and is the Coriolis and centrifugal matrix.

3) Recursive formulation

Figure 4: Recursive formulation for the derivation of

equations of motion.

A recently developed recursive algorithm for

formulating and solving equations of motion is

presented in this section. The equations of motion

used in recursive formulation are shown in Fig. 4

(Haug, 1992, Featherstone, 2008). Once the

velocities and accelerations of the generalized

coordinates are determined, the velocities and

acceleration of each body can be computed. Further,

recursive formulation can be utilized to find the

forces and moments acting on each link in a

recursive fashion, starting from the force and

moment applied to the rigid body, which is

connected to the end of the multibody system

(Sciavicco et al., 2000).

Although the equations are derived, the

operations required for implementation are

substantially difficult. Compared to the two other

formulations, however, augmented formulation is

easier in terms of operations because it uses absolute

coordinates.

d

−F

0

Te

d

⎡⎤⎡⎤

⎡⎤

=

⎢⎥⎢⎥

⎢⎥

⎢⎥⎢⎥

⎣⎦

⎣⎦⎣⎦

r

r

r

M

C

λ

CF

F

&&

(,) 0t =Cr

Constraint:

λ

: Lagrange Multiplier

()

0+=

rr

r

Cr Cr r

&& & &

Differentiation twice

r

C

r

:

Differentiation

C

with respect to

r

: Absolute Coordinates

M

: Mass and mass moment of inertia

e

F

: External force

(,) (,,)

e

+=Mq k q q F q q q

%% %

&& & & &&

,,,

TTeTe

where == =MMkMJJ JJ JqF F

%% %

&

&

J

: Velocity transformation matrix,

=rqJ

&&

q

: Generalized coordinate

M

: Mass and mass moment of inertia

e

F

: External force

1ii ii

q

−

=+vv S

&

*B

iiiiii

=+×fIavIv

T

iii

=τ Sf

1i i ii ii

qq

−

=+ +aa S S

&

&& &

1

Be

iiii

−

=−+ffff

i

v

: Velocity vector of body i (6 components)

i

a

: Acceleration vector of body i (6 components)

i

q

: Generalized coordinate (joint values)

i

S

: Velocity transformation matrix

i

I

: Mass and mass moment of inertia of body i

B

i

f

: Resultant force exerted on body i

e

i

f

: External force exerted on body i

i

f

: Force exerted on the joint i which is on body i

i

τ

: Force generated by joint i

(1)

(2)

(3)

(4)

(5)

DYNAMIC RESPONSE ANALYSIS OF MULTIBODY SYSTEM IN DISCRETE EVENT SIMULATION

449

As the embedding and recursive formulations

use relative coordinates, however, these

formulations need additional computation to

calculate the constraint force. Unlike augmented

formulation, moreover, the values that are associated

with relative motion between the bodies are

explicitly calculated using the embedding and

recursive formulations.

In the case of augmented formulation, the

number of equations of motion is 6n+p, which is

proportional to the number of bodies. As the

computational time for the calculation of the inverse

matrix is proportional to (6n+p)

3

, the complexity of

computation is O(n

3

) for solving the equations of

motion.

The number of equations of motion derived

using embedding formulation is 6n-p. As the

computation time for the calculation of the inverse

matrix is proportional to (6n-p)

3

, the complexity of

computation is O(n

3

) for solving the equations of

motion for the multibody system. As the matrix of

embedding formulation is smaller than that of

augmented formulation, the computational

efficiency of embedding formulation is better than

that of augmented formulation.

Unlike the two other formulations, recursive

formulation does not need to assemble a system of

equations of motion for each body as it is a recursive

method. Therefore, although the number of matrices

increases in proportion to the number of bodies n,

the size of the matrix of the equations of motion is

always 6×6. Consequently, the complexity of

computation is O(n) for solving the equations of

motion (Stejskal et al., 1996). In this study, due to

the computational efficiency, recursive formulation

was used to derive the equations of motion.

3.2 External Forces for the Dynamic

Response Analysis

Eq. 1 shows the external forces considered for the

dynamic response analysis. The external forces

consist of the hydrostatic forces with nonlinear

effects considering wave elevation, the linearized

hydrodynamic force, the mooring force, the

aerodynamic force, and the gravitational force, as

follows:

() () () ()

,,, , ,,

()

e

Hydrostatic Hydrodynamic Mooring

Aerodynamic Gravity

tt t=+ +

++

f

qqq

f

q

f

qq

f

q

fqf

&&& &&&

(1)

The module for calculating the external forces is

developed, and it is used for the dynamics kernel

(Ku et al., 2011).

4 MULTIBODY DYNAMICS

KERNEL IN DISCRETE EVENT

SIMULATION

In the previous section, the development of the

dynamics kernel was presented. However, it is hard

to deal with the discontinuous state variables, event

triggered conditions, and state triggered conditions

using the dynamics kernel. To overcome this

limitation, this study adopts the DEVS (Discrete

Event System Specification) formalism to develop

the simulation program.

4.1 DEVS (Discrete Event System

Specification) Formalism

The DEVS formalism, a set-theoretic formalism,

specifies ‘discrete event systems’ in a hierarchical

and modular form. The DEVS formalism consists of

two kinds of models: an atomic model and a coupled

model. The atomic model is the basic model and has

specifications for the dynamics of the model.

Formally, 7 components, which are state variables,

input events, output events, external transition

function, internal transition function, output function,

and time advance function, specify the atomic model.

The coupled model provides the method of assembly

of several atomic and/or coupled models to build

complex systems hierarchy. Each DEVS model,

either atomic or coupled, has correspondence to an

object in the real-world system to be modeled

(Zeigler, 1990, Zeigler et al., 2000).

However, the simulation progresses by changing

the state variables for not only every event but also

every unit time. Thus, the DTSS (Discrete Time

System Specification) model is combined with

DEVS model. The atomic model of DTSS is

composed of 7 components, which are state

variables, input events, output events, external

transition function, output function, integral function,

and state event function. The simulation model is

called ‘combined DEVS and DTSS simulation

model’. In this paper, for simplicity, the simulation

model will be called ‘DEVS simulation model’.

In this study, each facility shown in Fig. 1 is

modeled as an atomic model based on DEVS

formalism, and the coupled models are defined by

assembly of the several atomic models. In the next

sub-section, it will be explained how to define the

atomic model and the coupled model for the

simulation of the process planning in shipbuilding.

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

450

4.2 Modelling for the Simulation

of the Process Planning

in Shipbuilding

A ship is a huge structure made up of a large number

of hull structural parts called block. For example, A

deadweight 300,000 ton VLCC (Very Large Crude

oil Carrier, hereafter simply referred to as the ‘300K

VLCC’), which has a length, breadth, and depth of

about 320 m, 60 m, and 30 m, respectively, is

divided into a number of building blocks (e.g. about

200 building blocks in the case of the 300K VLCC)

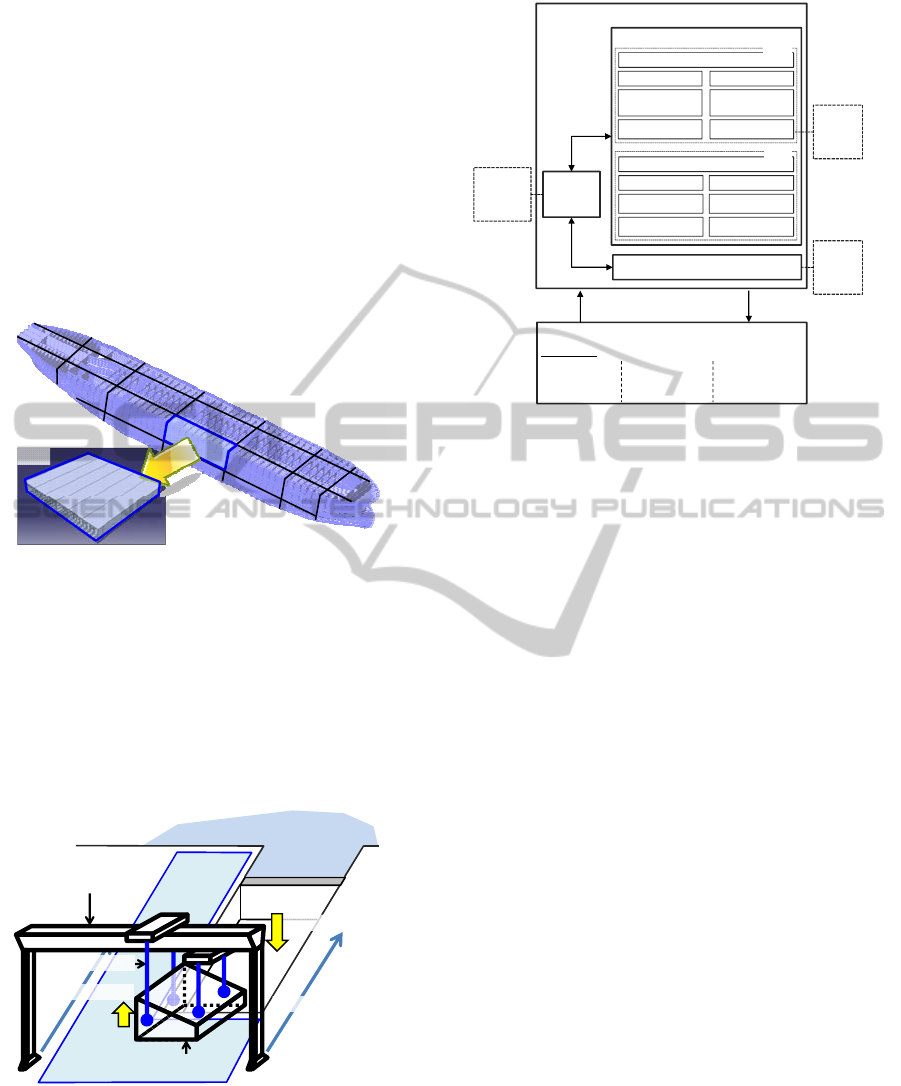

as shown in Fig. 5.

Figure 5: Very large crude oil carrier and its block.

Each block is assembled in an assembly shop

near the dock, and the blocks are waiting on the PE

(Pre-Erection) area. Then, the blocks are moved into

the dock by using a goliath crane and welded

together according to a suitable sequence, called the

block erection, as shown in Fig. 6. Basically, the

construction process of a ship is similar to that of a

large product by use of Lego blocks.

Figure 6: Block-lifting and transport process.

Figure 7: DEVS simulation model for the block-lifting and

transport simulation.

Fig. 7 shows how to define the atomic model and

the coupled model for the simulation of the block-

lifting and transport process. The goliath crane, the

wire rope, and the block are defined as atomic

models. The each atomic model is connected with

the object function. Each object function has the

mathematical model of the atomic model. For

instance, the object functions of the goliath crane

and the block have their equations of motion, and

the object function of the wire rope has the equation

to calculate the tension considering its physical

properties, such as wire length and elongation. The

dynamics kernel is used as the object function for the

dynamic analysis. The atomic models of the

facilities exchange the external forces each other.

Beside these three models, also the scenario

manager, which manages discontinuous events, is

defined as an atomic model. We can see the event

list, composed of hoisting-up, transport, and

hoisting-down are defined for the block-lifting and

transport simulation. Every event contains the name

of the atomic model and the behavior. For example,

event #1 means that the atomic model ‘wire rope’

will carry out the event ‘hoisting-up’.

Fig. 8 shows that how the events are dealt by

sending messages between the atomic models. To

trigger event #1, the scenario manager sends the

massage ‘hoisting-up’ to the model ‘wire rope’ and

waits until the event is done by the model ‘wire rope’

(Fig. 8-a). After receiving the massage ‘done’ from

the model ‘wire rope’, event #2 will be triggered

with same sequence with event #1 (Fig. 8-b).

300,000 ton VLCC(Very Large Crude oil Carrier)

L=320m, B= 60m, D= 30m, T=20m

Block

Sea

Dock

PE area

Goliath Crane

Block

1) Hoisting-Up

2) Transport

3) Hoisting-Down

Wire rope

Goliath Crane

(Atomic Model)

Block

(Atomic Model)

‘Object

Function’

Equations

of

Motion

Wire

rope

(Atomic Model)

external force

external force

‘Object

Function’

Equations

to calculate

the tension

Simulation (Coupled Model)

Scenario Manager (Atomic Model)

Command Done

State Variable

Input Output

External Transition

Function

Output

Function

Time Advance

Function

Internal Transition

Function

DEVS

State Variable

Input Output

External Transition

Function

Integral

Function

State Event

Function

Output

Function

DTSS

‘Object

Function’

Equations

of

Motion

Event List

Event #1:

‘Wire rope’,

Hoisting-Up

Event #2:

‘Goliath Crane’,

Transport

Event #3:

‘Wire rope’,

Hoisting-Down

DYNAMIC RESPONSE ANALYSIS OF MULTIBODY SYSTEM IN DISCRETE EVENT SIMULATION

451

Figure 8: Sequence of sending messages between the

atomic models.

After modelling the goliath crane, wire rope, and

block using DEVS simulation model, shipbuilding

process, which is composed of several discontinuous

stages, can be easily simulated by defining the event

list.

5 APPLICATION TO

SIMULATION OF

BLOCK- LIFTING AND

TRANSPORT

This section presents an example of block-lifting and

transport and the result of the simulation.

Figure 9: The goliath cranes and block model in the

simulation of the block-lifting and transport.

The block-lifting and transport is carried out

using two goliath cranes, six block loaders, and one

block models. The goliath crane is composed of a

main body, upper trolley, and lower trolley. The

upper trolley and lower trolley are interconnected by

sliding joints with main body. The block loader

consists of two bodies, interconnected by revolute

joints with each other. As explained in sub-section

3.1.2, the equations of motion, i.e. the dynamics

model, are generated by using recursive formulation.

Fig. 9 shows the goliath cranes and block model in

the simulation of the block-lifting and transport.

Discrete events of the simulation are as

following;

a. Hoisting-up the block

b. Transportation of the block by moving the

goliath crane to the dock

c. Block turn-over: the process of turning the

block upside down.

d. Hoisting-down the block

Fig. 10 shows the simulation results. The graph

shows that tension of the wire rope, which is marked

with red.

Figure 10: Tension of the wire rope, which is marked with

red, calculated by using developed program.

The weight of the block is about 830ton.

Therefore, around 140ton is reasonable amount of

the tension, because there are total six wire ropes.

We can also see that dynamic responses are different

according to the events such as hoisting-up,

transportation, turn-over, and hoisting-down, which

means that the developed program can deal with the

discrete events.

6 CONCLUSIONS AND FUTURE

WORKS

A simulation framework was proposed and

implemented in this study. The dynamics kernel is

integrated into the discrete event simulation program

for the process planning in shipbuilding. To evaluate

the efficiency of the implemented simulation

program, it is applied to the simulation of the block-

Goliath Crane

(Atomic Model)

Block

(Atomic Model)

Wire

rope

(Atomic Model)

External

force

Simulation

(Coupled Model)

Scenario Manager

(Atomic Model)

Event List

Event #1:

‘Wire rope’,

Hoisting-Up

Event #2:

‘Goliath Crane’,

Transport

Event #3:

‘Wire rope’,

Hoisting-Down

Hoisting-Up

Done

External

force

Goliath Crane

(Atomic Model)

Block

(Atomic Model)

Wire

rope

(Atomic Model)

External

force

Simulation

(Coupled Model)

Scenario Manager

(Atomic Model)

Event List

Event #1:

‘Wire rope’,

Hoisting-Up

Event #2:

‘Goliath Crane’,

Transport

Event #3:

‘Wire rope’,

Hoisting-Down

Transport

Done

External

force

(a)

(b)

Upper Trolley

Goliath Crane 1

Block

Goliath Crane 2

Lower Trolley

Block Loader

- Main dimension of the goliath crane

Length: 177m, Height: 103.6m, Breadth: 51.434m

- Max Lifting Capacity of the goliath crane: 600 tons

- Weight of Block: 828.5ton

0

20

40

60

80

100

120

140

160

180

0 200 400 600 800 1000 1200 1400 1600

Time

(ton)

Transportation of

the block ends

Block

Turn-over

starts

Block

Turn-over

ends

Hoisting

-Up

starts

Hoisting

-Up

ends

Transportation of

the block starts

Hoisting

-Down

starts

Hoisting

-Down

ends

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

452

lifting and transport.

As future works, we will apply the developed

program to various simulation systems for process

planning in shipbuilding such as the simulation of

dynamic analysis of offshore structures and block

assembly processes in order to improve the

efficiency and applicability of the proposed

simulation program.

ACKNOWLEDGEMENTS

This work was supported by:

a) Industrial Strategic Technology Development

Program (10035331, Simulation-based

Manufacturing Technology for Ships and Offshore

Plants) funded by the Ministry of Knowledge

Economy (MKE, Republic of Korea);

b) Research Institute of Marine System Engineering

at Seoul National University;

c) Marine Technology Education and Research

Center, through the Brain Korea 21 project of Seoul

National University; and

d) SM-11: “A Study on the network-based

architecture of virtual system for the simulation of

underwater vehicles” of the Underwater Vehicle

Research Center.

REFERENCES

Orlandea, N., Chace, M. A., and Calahan, D. A., 1977, A

Sparsity-Oriented Approach to the Dynamic Analysis

and Design of Mechanical Systems-Part1&2, Journal

of Engineering for Industry, Transactions of the

ASME, Vol. 99, No. 3, pp 773-779.

Schiehlen, W., 1990, Multibody Systems Handbook,

Springer, pp 361-402.

Smith, R., 2006, Open Dynamics Engine v0.5 User Guide,

pp 15-20.

Zeigler B P, 1990, Object oriented simulation with

modular, hierarchical models: intelligent agents and

endomorphic systems, Boston: Academic Press.

Zeigler B P, Praehofer H, Kim T G, 2000, Theory of

modelling and simulation, 2nd ed., Boston: Academic

Press.

Featherstone, R. (2008), Rigid Body Dynamics, Springer,

pp 92-100.

Haug, E. J. (1992), Intermediate Dynamics, Prentice-hall,

pp 345-346.

Stejskal, V., Valasek, M. (1996), Kinematics and

Dynamics of Machinery, Marcel Dekker, Inc. pp 289.

Ku, N. K., Jo, A. R., Ha, S., Friebe, M., Cha, J. H., Park,

K. P., Lee, K. Y. (2010), Development of a Multibody

Dynamics Kernel for Motion Analysis of a Floating

Wind Turbine, The International Society of Offshore

and Polar Engineers 2011, Hawaii.

DYNAMIC RESPONSE ANALYSIS OF MULTIBODY SYSTEM IN DISCRETE EVENT SIMULATION

453