THIN FLEXIBLE POLYMER-BASED ENERGY SYSTEMS

FOR LOW-POWER WIRELESS MONITORING DEVICES

Clint Landrock

1,2

, Bozena Kaminska

1,2

, Yindar Chuo

1

, Badr Omrane

1

and Jeydmer Aristizabal

1

1

Department of Engineering Science, Simon Fraser University, 8888 University Dr., Burnaby, Canada

2

IDME Technologies Corp, Vancouver, Canada

Keywords: Energy harvesting, Integration, Micro-sensors, Polymer electronics, Solar cells, Photovoltaic, Super-

capacitor.

Abstract: In this work we present the novel design for a polymer based energy harvesting and storage system for thin

flexible wearable biomedical devices. The energy system employs novel long lasting polymer solar cells

and polymer hybrid sodium-ion super capacitors capable of both immediately storing harvested photo

energy and slowly discharging power for micro to milli-watt devices. The polymer nature of this platform

system makes its suitable for roll-to-roll print manufacturing, supporting applications requiring high volume

and low cost. We present performance results for the two energy system components along with results for

an integrated single cell energy system.

1 INTRODUCTION

One the most important challenges in sensors and

systems deployed in wireless, portable or wearable

applications will be in selecting the energy source.

For most electronics, the energy required to power

its microprocessor is negligible, however, its’ sensor

and actuator elements may consume significant

amounts of power. In medical applications as in

remote hospitals or home-monitoring, ultra-

lightweight systems with small footprints operating

autonomously are required. Often the primary

energy source for such applications is a battery,

which must be substantially larger than the system it

powers in order to meet the requirements for

wireless use. In wearable systems the battery

footprint becomes a very important issue.

Recent efforts to reduce this battery footprint

along with increasing device lifetimes and reliability

have included supplementary power sources using

solar or mechanical energy harvesting. Integrated

solar cells on outdoors wireless sensor nodes, and

vibration energy harvesters used on automotive

sensor units are some commonly found examples.

Assisted powering of autonomous electronic devices

with energy harvesting is a non-trivial challenge that

requires the matching of function and environment,

and hence, there is no universal solution (e.g.,

photovoltaic energy harvesting is not suitable with a

subcutaneous implantable bio-sensor).

Solar energy is attractive as it is arguably the

most accessible energy source found on Earth.

Silicon-based solar cells can achieve 20% in power

conversion efficiency (PCE), but their high material

and manufacturing costs along with rigid and fragile

structures discourage greater use. Unlike silicon-

based solar cells, polymer solar cells (PSC) cost

much less to manufacture due to roll-to-roll

processing and the extremely low quantities of

active material required. The polymer inks used for

the active layers can be printed onto thin, flexible

substrates using a variety of print-based

manufacturing such as roll-to-roll, or ink-jet

printing. Recent advances in polymer solar cell

technology have increased its PCE to higher than

8% (Green et al, 2011) and efficiencies could reach

as high as 17% in the near future (Park et al, 2009).

PSCs have comparable PCEs to silicon-alternatives

such as Cadmium-Telluride (CdTe) and Copper-

Indium-Gallium-Selenide (CIGS) solar cells without

the toxicity concerns. Combined with a low cost of

manufacturing, PSCs can offer a very attractive sub-

dollar-per-watt figure, and are anticipated to greatly

surpass silicon-based solar cells in both use and

application range.

Despite their exciting outlook, a few challenges

hinder the widespread use of flexible PSCs. First,

239

Landrock C., Kaminska B., Chuo Y., Omrane B. and Aristizabal J..

THIN FLEXIBLE POLYMER-BASED ENERGY SYSTEMS FOR LOW-POWER WIRELESS MONITORING DEVICES.

DOI: 10.5220/0003793802390244

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 239-244

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

their lifetime is limited when they are fabricated in

air. A controlled fabrication chamber is needed to

completely eliminate oxygen and moisture in order

to produce long-lasting PSCs; however, such

specialized equipment greatly increases the

fabrication costs. Second, to provide a complete

energy solution, the PSCs must be integrated with an

efficient energy storage reservoir. This reservoir

system should exhibit both high power and energy

densities, and must be similarly thin, flexible, and

lightweight to take advantage of all the PSC

characteristics.

Recent studies have shown that ionic polymer

metal composites (IPMC) as energy storage films

exhibit supercapacitor and rechargeable battery like

characteristics (Landrock and Kaminska, 2011).

Polymer ion-exchange membranes based on

perfluorosulfonic acid (PSFA) based films such as

Nafion™ (DuPont) and Aquivion™ (Solvay

Solexis) are low cost and widely available. Without

hydration these ion exchange membranes can be

used in the construction of polymer energy storage

(PES) devices, which can be conveniently shaped

and scaled into nearly any dimension or geometry,

and operated at high-temperature conditions

(Landrock and Kaminska, 2010). Furthermore, the

ions can be tailored within the polymers for specific

applications. Here we present on a sodium-ion

(Na+) hybrid super-capacitor. Sodium-ions have the

distinction of being very stable, low in toxicity and

high in energy density, making them an ideal choice

for use in biomedical devices.

Many recently developed biomedical devices

consume power measured in the mW and even nW

range. Marzencki et al (2010), have presented a

wearable wireless sensor system requiring 2.1V

operating voltage with 1.86mW to 16.6mW power

used in conjunction with a mobile phone for data

collection; while Xiaodan et al (2009) have reported

on a 1V sensor interface chip requiring a mere

450nW of power. However in order to take

advantage of these devices small footprint and

flexible nature a powering system that is comparably

small and flexible.

This paper presents a fully flexible polymer-

based powering system with a footprint of 1cm

2

and

less than 50um thick, capable of supplying an

operating voltage of 2.7V and 100uA continuously

during day light hours.

2 DEVICE COMPONENT

ARCHITECTURE

Several methods in improving the lifetime of

polymer/organic solar cells have been reported in the

recent past. Inverted solar cell structures were

demonstrated to have better stability in air by

(Krebs, 2008), while allowing for better roll-to-roll

processing. The stability of the enhanced, inverted

PSCs is up to a few weeks, however, with a low

power-conversion efficiency (PCE) of ~0.08%

(Manceau, 2010). A new interfacial layer containing

chromium-oxide was inserted between the cathode

and active polymer to improve performance and

stability of polymer solar cells (Wang, 2010). The

improved interfacial layer provided stability up to

one week holding a PCE of 3.5% in an inert

environment, but decreased by half within 12 days

(Wang, 2010).

Thin, flexible, disposable batteries have been

demonstrated and are available (in limited

quantities) off-the-shelf from niche companies that

provide “soft” batteries such as Enfucell,

PowerPaper and BlueSpark. The batteries are

primarily based on zinc/manganese-dioxide

technology. Typically a zinc anode and manganese

dioxide cathode surround a polymer electrolyte.

Most devices range from 0.3mm to 1mm thick, and

provide energy capacities between 2 to 5mAh/cm

2

.

The nominal cell voltage is configured to 1.5V, a

requirement for aqueous electrolytes as water

electrolyzes above 2V. The internal resistances of

the devices are typically high, around 300Ω. The

energy sources also only provide low nominal

continuous current (0.03mA to 1.5mA). It is

common for the devices to have a limited operating

temperature range between -20°C to 60°C. These

devices are not applicable tor solar energy

harvesting applications, where cells can easily be

heated under the sun to temperatures above 70°C.

Here we present the latest performance results of

novel PSC and PES devices as well as a combined

system for energy harvesting and storage in

operation.

2.1 Stable Polymer Solar Cells

It is well known that polymer solar cells are subject

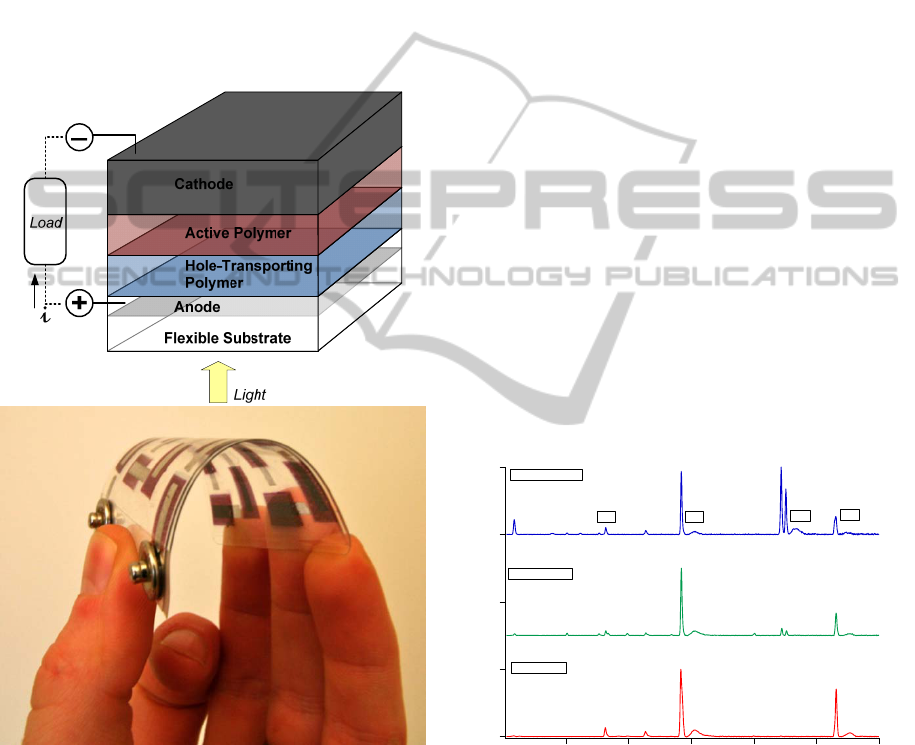

to oxygen and moisture degradation. Figure 1

illustrates the typical structure of a solar cell

comprised of a bulk heterojunction (active layer)

such as poly(3-hexlthiophene) and [6,6]-phenyl C61

butyruc-acud-nethyk-ester (P3HT:PCBM blend).

The active layer degrades due to oxidation of sulfur

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

240

atoms in the P3HT thiophene ring (Krebs, 2008).

Oxygen and moisture in the active layer are

generated by two known mechanisms. The first is

due to oxidation of the cathode (typically

Aluminum) that allows for Oxygen diffusion

directly into the active layer. The second is oxygen

diffusion into the active layer from the transparent

anode, typically Indium-Tin-Oxide (ITO) via the

hole-transporting layer, poly(3,4-

ethylenedioxythiophene):poly(styrene-sulfonate)

commonly known as PEDOT:PSS. This degradation

leads rapidly to dramatic drops in PCE and failure of

the device.

Figure 1: Structure of a generic polymer solar cell and

photograph of a working polymer solar panel. The panel

consists of 12 cells connected in series and can generate

5Vin outside light.

Photooxidation due to exposure to UV rays acts as a

catalyst in the degradation process. PSC device life

times typically run from several hours to several

days (Manceau, 2010; Wang, 2010). The high-

quality polymer solar cells that are achieved

typically are done so in controlled fabrication

chambers filled with inert gas (e.g. nitrogen) or

under high vacuum. The additional costs associated

with the use of specialized air-controlled and high

vacuum chambers conflicts with the cost

effectiveness of roll-to-roll (R2R) or print-types of

manufacturing.

Our group has recently shown a polymer solar

cell with a PCE around 2% that has lasted for over

one year and shows little evidence of degradation

using a novel cathode (Hohertz et al. 2011). The

novel cathode design allows diffusion of Indium

ions into the active layer, which attract oxygen

atoms creating a non-reactive Indium-oxide

compound (In2O3) before degradation can occur.

Evidence of this diffusion has recently been shown

using X-ray photoelectric spectroscopy (XPS), a

sensitive technique that probes the chemical

composition within a sample (Hohertz et al., 2011).

Figure 2 shows XPS results (Kratos Axis Ultra DLD

XPS) of active layers from newly prepared and six

month old novel PSCs in comparison to a standard

PSC fabricated with an Al cathode. It can be clearly

seen from the energy peaks that In, InO-, and In

2

O

3

are present in the novel PSC sample after 6months,

and appears to be just forming in the newly

fabricated samples. The Al-cathode device however

does not show this behavior. This result strongly

suggests that Indium diffuses into the active layer

and forms a strong oxide bond, preventing the

oxygen atoms from destroying the Sulfur bonds.

Figure 2: Broad-spectrum scans of Aluminium Cathode

vs. Indium Cathode based PSCs.

2.2 Hybrid Polymer Energy Storage

We have recently demonstrated a novel hybrid

energy storage film, which exhibits high temperature

resistance, good chemical resistance, and good

durability, an ion-transport/electrolyte medium

(Landrock and Kaminska, 2011; Landrock, 2010).

4

3

2

1

0

Intensity (A.U.)

600500400300200100

Binding Energy (eV)

Indium 6 Month Old

Indium 1 Day Old

Al 6 Month Old

S 2p

C 1s

O 1s

In 3d

THIN FLEXIBLE POLYMER-BASED ENERGY SYSTEMS FOR LOW-POWER WIRELESS MONITORING

DEVICES

241

The traditional fabrication processes for PFSA-based

ionic polymer metal composites involve tedious

electrode compositing steps to ensure good electrode

implantation; however, we have shown that

simplified fabrication techniques can results in

devices (Figure 3) with reasonable power and energy

storage capacity (Landrock, 2010) ranging from

40F/g to 332F/g and 31mAh/cm

2

respectively with a

working voltage of 2.7V for a single sodium-ion

cell.

Figure 3: Schematic of a IPMC-based Na-ion hybrid

energy storage film and photograph of a basic device.

2.3 Architecture of Energy System

For an energy-harvesting device to be useful a

storage reservoir is necessary for that energy unless

it can be consumed immediately through a matching

load. Energy harvesting devices are usually

independent from the energy storage reservoir,

which is inefficient, inconvenient, and as an

incomplete system is a major deterrent when

considering energy harvesting solutions. Here we

show an integrated powering system that combines

PSCs along with PES in a thin, compact

configuration. Figure 4 illustrates the flexible energy

stack, as a printed film roll, composed of an PSC

functional layer and a PES layer disposed on the two

opposing surfaces of a flexible carrier substrate. The

carrier substrate acts as the structural backbone of

the flexible energy stack, and can range from 10 to

several 100s of microns thick, largely depending on

the carrier substrate requirements. The electrical

connections and circuit routing between the PSC,

PES, and other application specific system

components are also made within the carrier

substrate layer. This is similar in construction to

flexible circuit board functions. The stack is further

protected on both sides by UV-shielding plastic

films that transmit only the visible light within the

primary, non-damaging, absorbing wavelengths of

the PSC. The percentage of the light intensity

transmitted through the protective film is dependent

on the thickness and composition of the polymer

where 70-90% transmission of the incident light can

be expected when the film is in the range of 100µm

to 200µm thick.

Figure 4: Architecture of integrated energy

harvesting/storage system along with the system blocks

for the integration configured to power a device.

3 EXPERIMENTAL RESULTS

& SYSTEM PERFORMANCE

The operational performance of the PSCs was

studied under ambient conditions using a calibrated

solar simulator (AM1.5G 100mW/cm2, Newport

Solar Simulator) as well as in direct sunlight

outdoors (latitude 52°25'N, Vancouver CANADA).

Results for a single cell are summarized in Table 1

in comparison to short-lifetime conventional Al-

cathode based PSCs. The stability of the device was

evaluated based on the percentage drop in

performance over time. The conventional Al-based

PSC showed a decrease in all categories of

performance by more than 50% within 24 hours, and

fully fails within 2 days; whereas the novel-cathode

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

242

PSC show less than 5% decrease in open-circuit

voltage (VOC), short-circuit current (JSC), Fill

Factor (F.F), and PCE even after one year. I-V

characteristics are shown in Figure 5. It can be

expected that with improvement in active polymer

blend formulation, substitution with higher

efficiency photoactive polymers, more conductive

anode materials, more efficient electrical

interconnects, even higher PCE values can be

achieved.

Table 1: Polymer Solar Cell Performance.

Measurement PSC Novel

Cathode

Conventional PSC

with Al Cathode

V

OC

(V) 0.55 / 0.52 0.6 / 0

J

SC

(mA/cm2) 8.5 / 6.2 8.5 / 0

F.F. (%) 65 / 60 70 / 0

PCE (%) 3.03 / 2.05 3.6 / 0

Stability (days) >365 1

Figure 5: I-V curve for a single PSC after 1 year of

operation.

The energy storage films have a nominal

capacitance of approximately 3mF/cm

2

, or 300F/g.

The methods of measurement and characterization

are reported in further detail under another article

(Aristizabal, 2011). The PES films also show very

stable energy storage attributes in the range of 20°C

to 100°C, with less than 10% drop in capacitance at

110°C compared to room temperature. The

breakdown voltage of a 1cm

2

device is

approximately 10V. The PES film is also fast

charging, and is suitably charged with input sources

anywhere from 0.5mA up to 1000mA. Figure 6

shows the typical discharge curve of a 1cm

2

PES

cell. It is charged for 2min at constant voltage of 4V,

10mA current limited (e.g. equivalent of what a

small array PSCs connected in series can provide).

The PES cell is discharged through a constant

100uA load until the voltage falls below 50% of its

initial value. The plot shows the full 2.7V potential

from the sodium-ions.

Figure 6: Discharge profile for a single PES cell with a

constant current load of 100uA charged with 5V.

Figure 7: Energy system test results: top photograph

shows the actual energy system with PSC panel and PES

cell that is just viewable behind the solar cells (gold

coloured cell); the bottom plot shows charge/discharge

curve of a PSC-PES system in operation.

Testing of the integrated three-dimensional (3D)

system was initiated by connecting a PES to a PCS

as seen in Figure 7, and ambient indoor low-light

conditions of 0.2 W/m

2

were used to radiate the

PSC. Measurement of the charge and discharge of

the PES was done by connecting a digital acquisition

PSC active

area

PES

Cell

Current Densit

y

(

mA/cm

2

)

THIN FLEXIBLE POLYMER-BASED ENERGY SYSTEMS FOR LOW-POWER WIRELESS MONITORING

DEVICES

243

(DAQ) module to the setup, which allows real-time

monitoring. The 3D test layout configuration is

however ideal for device performance. In two-

dimensional configurations long interconnects

between the organic devices and the capacitors result

in excessive energy lost reducing the effectiveness

of PCSs. This low-light demonstration shows the

versatility of the 3D energy harvesting system

configuration. With more techniques (such as vias

and monolithic fabrication) even more energy

efficient 3D configurations can be envisioned and

have been previously reported by our group

(Landrock et al., 2011), however they are not always

convenient for testing purposes.

4 CONCLUSIONS

This work describes an energy harvesting system

comprised of polymer solar cells and a hybrid

polymer energy storage film. We have shown that

this system may be used to generate and store useful

amounts of electrical power, up to several milli-

watts per cm

2

, making it useful for a number of

wireless biomedical sensors applications.

ACKNOWLEDGEMENTS

This research is supported in part by the Natural

Sciences and Engineering Research Council of

Canada (NSERC) and MITACs.

REFERENCES

M. Green et al., “Solar Cell Efficiency Tables (Version

37),” Prog. Photovolt: Res. Appl., vol. 19, 2011,pp.

84-92.

S. H. Park, A. Roy, S. Beaupre, S. Cho, N. Coates, J. S.

Moon, D. Moses, M. Leclerc, K. Lee, A. J. Heeger,

“Bulk Heterojunction Solar Cells with Internal

Quantum Efficiency Approaching 100%”, Nature

Photonics, vol.3, May 2009, pp.297-303.

C. Landrock and B. Kaminska “Ionomer composite thin

film capacitors,” in IEEE Transaction on

Components, Packaging and Manufacturing

Technology, 2nd ed. vol. pp, issue 99, 2011, pp. 1-1.

C. Landrock and B. Kaminska “High temperature polymer

capacitors for aerospace applications,” in Proc.

Design, Autom. Test in Europe (DATE’10), 2010, pp.

1349–1352.

C. Landrock, B. Omrane, Y. Chuo, B. Kaminska, and J.

Aristizabal, “2D and 3D Integration with Organic and

Silicon Electronics,” in Proc. Design, Autom. Test in

Europe (DATE’11), 2011, pp. 1–6

M. Marzencki, K. Toavakolian, Y. Chuo, B. Hung, P. Lin,

B. Kaminska, “Miniature wearable wireless real-time

health and activity monitoring system with optimized

power consumption”, Journal of Medical and

Biological Engineering, 30(4), pp. 227-235.

Z. Xiaodan, X. Xiaoyuan, Y. Libin, L. Yong, “A 1-V 450-

nW fully integrated programmable biomedical sensor

interface chip”, IEEE Journal of Solid-State Circuits,

vol 44, issue 4, pp.1067-1077.

F. C. Krebs, “Air Stable Polymer Photovoltaics Based on a

Process Free From Vacuum Steps and Fullerenes,”

Sol. Energy Mater. Sol. Cells, vol. 92, 2008, pp. 715-

726.

M. Manceau et al., “Further Insights into the

Photodegradation of Poly(3-hexylthiophene) by

Means of X-ray Photoelectron Spectroscopy,” Thin

Solid Films, vol. 518, 2010, pp. 7113-7118.

M. Wang et al., “Performance and Stability Improvement

of P3HT:PCBM-Based Solar Cells by Thermally

Evaporated Chromium Oxide (CrOx) Interfacial

Layer,” ACS Appl. Mater. Interfaces, vol. 2, 2010, pp.

2699-2702.

D. Hohertz, B. Omrane, C. Landrock, Y. Chuo, K.

Kavanagh, B. Kaminska, “Long life indium based

organic photovoltaics,” Procs of SPIE Photonics

North 2011, 4 pages, May 2011.

C. Landrock, “High Temperature Capable Ionic Polymer-

Metal Composite Capacitors and Power Storage

Systems”, Procs. Of SAE Power Systems Congf. Nov.

2010, pp1-17.

J. Aristizabal, B. Omrane, C. Landrock, S. V. Grayli, Y.

Chuo, J. N., Patel, B. Kaminska, C. Menon, “Tungsten

Lamps as an Affordable Light source for Testing of

Photovoltaic Cells”, Journal of Electronic Testing,

vol. 27, no. 3, 2011, pp.403-410.

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

244