IN-SITU SPECTROSCOPIC INVESTIGATION OF UNFOLDING

AND AGGREGATION OF INSULIN UNDER ULTRASONIC

EXCITATION

An Ultrasonic Actuator for FTIR-spectrometry on Biomatter

Helge Pfeiffer

1

, Nikos Chatziathanasiou

1

, Filip Meersman

3

, Christ Glorieux

2

,

Karel Heremans

3

and Martine Wevers

1

Katholieke Universiteit Leuven

1

Department of Metallurgy and Materials Engineering, Group Material Performance and Non-destructive Testing,

Kasteelpark Arenberg 44, B-3001 Leuven, Belgium

2

Department of Physics, Acoustic and Thermal Physics Section, Celestijnenlaan 200D, B-3001 Leuven, Belgium

3

Department of Chemistry, Unit of Molecular and Nanomaterials, Celestijnenlaan 200F, B-3001 Leuven, Belgium

Keywords: Ultrasonic actuator, Fourier Transform Infrared Spectroscopy, Insulin, Fibrillogenesis, Protein Aggregation.

Abstract: It is well-known that fibrillogenesis of proteins can be influenced by diverse external parameters, such as

temperature, pressure, agitation or chemical agents. This paper presents a newly developed ultrasonic

actuator cell and a corresponding first feasibility study shows that also ultrasonic excitation at moderate

intensities has a clear influence on the unfolding and aggregation behaviour of insulin. Irradiation with an

average sound intensity of about 180 mW/cm

2

leads to a decrease of the unfolding and aggregation

temperature up to 7 K.

1 INTRODUCTION

The main topic of this paper is the spectroscopic

detection and interpretation of the in-situ molecular

response of biomolecules on ultrasonic excitation.

The novelty of this approach is the monitoring of

empirical and molecular parameters during the

application of ultrasound rather than after treatment,

as in many other studies. To the best of our

knowledge, there is almost no literature on in situ or

even on time resolved methods, and this is due to a

number of inherent difficulties to combine ultrasonic

excitation and spectroscopic detection. As a relevant

example for a biological process to study,

fibrillogenesis was selected. The aggregation of

globular proteins, sometimes leading to amyloid

fibrils, is of great importance for biology, medicine

and also industrial processes. In the medical field,

there is a strong link between fibrillogenesis, and a

number of neurodegenerative diseases, such as the

Alzheimer disease (Dobson, 2003). Preliminary

investigations in the framework of this research

project showed that even very small sound velocity

intensities (range of μW/cm

2

) have a stimulating

influence on the aggregation behaviour of synthetic

polymers (publication under preparation). In the

work presented here, the impact of ultrasonic

excitation on insulin fibrillogenesis was monitored

by infrared spectroscopy (Bouchard, Zurdo et al.,

2000). This approach enables the quantitative

determination of the varying population of

secondary structures that are characteristic for the

unfolding and aggregation process, i.e. the

transformation of a dominant α-helix population into

the β-sheet conformation (β-strands) as well as the

appearance of side bands that indicate aggregation.

2 MATERIALS AND METHODS

2.1 Ultrasonic Excitation System

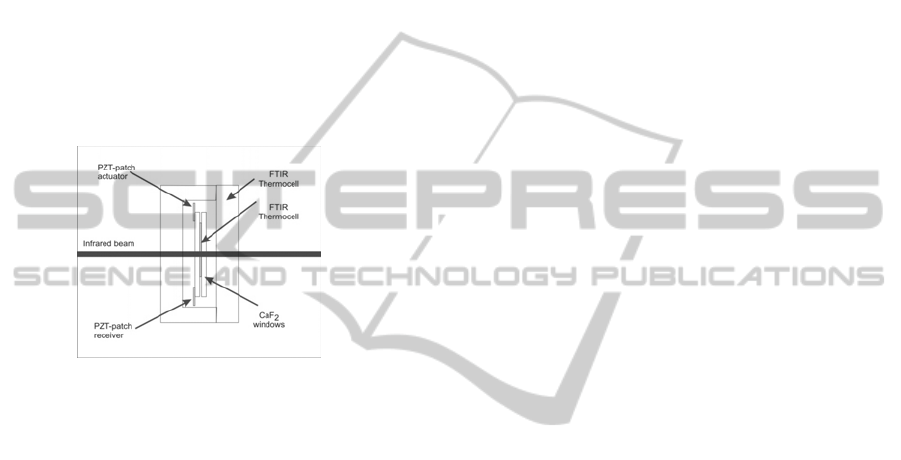

The infrared sample holder was equipped with a

home-made ultrasonic actuator (Figure 1). It consists

of two CaF

2

plates (10x20mm) that are separated by

a polytetrafluorethen spacer (50 μm thickness) with

a centred square opening of 5 x 5 mm. At one plate,

two identical piezoceramic lead zirconate titanate

372

Pfeiffer H., Chatziathanasiou N., Meersman F., Glorieux C., Heremans K. and Wevers M..

IN-SITU SPECTROSCOPIC INVESTIGATION OF UNFOLDING AND AGGREGATION OF INSULIN UNDER ULTRASONIC EXCITATION - An

Ultrasonic Actuator for FTIR-spectrometry on Biomatter.

DOI: 10.5220/0003797003720375

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 372-375

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

(PZT) transducers (with wrapped-around electrode,

provided by Meggit/InSensor®, Denmark) were

attached by epoxy resin adhesive, and the nickel

electrodes were wired to shielded contacts. The

liquid sample was loaded into the 5 x 5 mm opening

of the polytetrafluorethen spacer. The thickness of

the liquid layer was thus determined by the thickness

of the polytetrafluorethen gasket, d, which was in

the range of 50 micrometer. The CaF

2

plates were

closed and sealed by parafilm and vacuum grease to

prevent leakage of water. Since water loss,

especially induced by the heating of the sample,

would cause problems, in addition to these

measures, the stability of water concentration was

ensured by observing the intensity of the infrared

water peak.

Figure 1: Ultrasonic cell for in-situ spectroscopic

investigation of ultrasonic actuation. Scheme of operation

mode, vibrations in the CaF

2

sample assembly in the

transmission cell are generated by a PZT actuator and the

response is monitored by the PZT receiver.

The CaF

2

plate assembly was mounted in a

commercial SPECAC® temperature cell. In order to

avoid the transfer of essential amounts of ultrasonic

energy into the temperature cell, the ultrasonically

active plates were firmly embedded within heat-

resistant foam that isolated the plates due to the big

mismatch of acoustic impedances. Placing the foam

also reduced the thermal contact between the cell

and the probed region in the sample, resulting in an

offset between the registered temperature and the

actual sample temperature.

For the ultrasonic excitation, the following

approach was followed: a sinusoidal electrical signal

consisting of a continuous wave (cw) with a

frequency of about 50 kHz and an amplitude of 200

mV

pp

was generated by an Iwatsu SG-4511

pulse/function generator. The exact resonance

frequency was fine-tuned using the output signal

monitored at the oscilloscope. The electrical signal

from the generator was connected to the input of a

broadband amplifier (AR Worldwide 75A250). The

PZT transducer finally transformed the amplified

voltage signal into a mechanical oscillation that

released plate waves into the CaF

2

plates. Due to the

continuous operation mode, standing wave patterns

were generated by multiple reflections that depend

on the material, the frequency and the geometrical

boundary conditions of the sample holder. The

receiving PZT transducer was connected to a

LeCroy 9310 AM oscilloscope in order to monitor

the amplitude of the standing ultrasonic wave. For

connecting the electronic devices, shielded standard

BNC cables with an impedance of 50 Ohm were

used.

For driving the PZT transducer, a resonance

frequency was used that was fine-tuned by the

output signal. Whereas the main resonance

(thickness resonance) was in the range of 4 MHz, a

resonance around 50 kHz was selected.

According to a number of simplifications, the

sound intensity in the insulin solution can be

estimated. The final intensity estimated is in the

range of I = 180 mW/cm

2

given an average

displacement of ξ = 110 nm. Note that the threshold

of sound intensity in diagnostic medical applications

is also in the range of I = 100 mW/cm

2

, such as

mentioned above. On the other hand, the intensities

are too low to enable the forming of acoustic

cavitations. The present set-up thus meets the targets

of the intended study.

2.2 FTIR Spectroscopy

The unfolding and aggregation of insulin was

followed by FTIR-spectroscopy using a Bruker IFS-

66 spectrometer equipped with a liquid nitrogen-

cooled mercury cadmium telluride detector. 64

spectra with a resolution of 2 cm

-1

were co-added in

order to achieve a good signal to noise ratio. The

spectra were processed using the OPUS software of

the spectrometer, and the positions of the peaks were

determined using the peak seeking function of the

software. The temperature was controlled by both a

heating and cooling element, and it is measured by a

thermocouple that was attached at the thermocell.

The temperature was rising with a rate of

α

= 0.25

K/min. In this way, one obtains one spectrum for

every Kelvin that represents an average of the

spectroscopic signals in that temperature interval.

2.3 Preparation of Samples

Insulin from bovine pancreas [11070-73-8] was

obtained from Sigma Aldrich and was dissolved in

D

2

O [7789-20-0] obtained from Cambridge Isotope

Laboratories, Inc. (99.9%). The solvent D

2

O was

selected because the bending vibration of H

2

O

IN-SITU SPECTROSCOPIC INVESTIGATION OF UNFOLDING AND AGGREGATION OF INSULIN UNDER

ULTRASONIC EXCITATION - An Ultrasonic Actuator for FTIR-spectrometry on Biomatter

373

interferes with Amide I band of proteins. The final

concentration was 50 mg/mL. The pD of 1.2 was

adjusted by adding DCl (20wt% in D

2

O

99+atom%D, [7698-05-7], Janssen Chimica).

Between preparation and measurements, there was

sufficient time for enabling deuterium water

exchange (minimum one hour).

3 RESULTS AND DISCUSSION

3.1 Results on FTIR Study of

Ultrasonic-assisted Fibrillogenesis

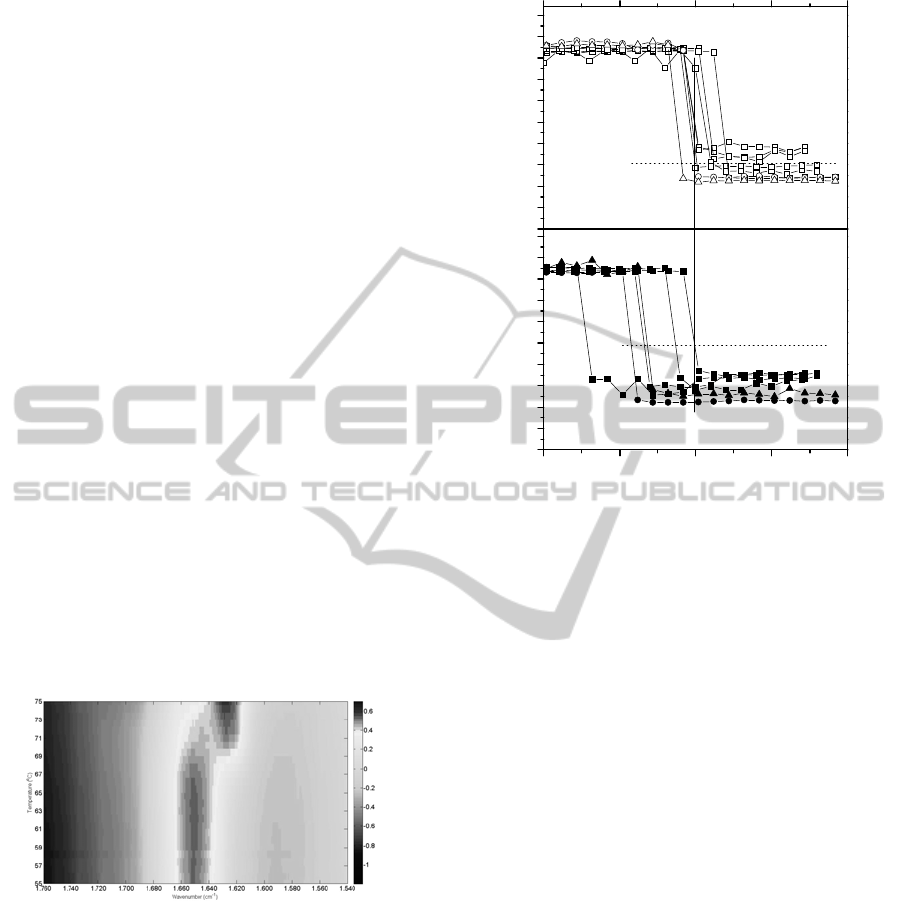

The unfolding and aggregation of insulin can be

monitored by FTIR spectroscopy. This is possible

using the amide I band that is sensitive to the

transformation from the α helical into the β sheet

structure. In Figure 2, the transition from the α-helix

conformation which is located at around 1650 cm

-1

to the β-sheet conformation which is located at

around 1628 cm

-1

is shown. The wavenumbers as

well as the temperature agrees with literature values

(Bouchard, Zurdo et al., 2000). At starting transition,

a small shoulder at the lower wave number appears,

which indicates the presence of β-sheet structure and

as the temperature rises it slowly becomes a separate

band. One should keep in mind that there are always

remaining α−helical structures even after the

complete formation of fibrils.

Figure 2: Contour plot of the infrared spectra. The

amplitudes are represented by the grey-scale. The amide I

band in the middle shows the unfolding at 71 °C.

The peak position of the amide I band as a

function of temperature is shown in Figure 3. The

temperature axis is shifted so that the average

unfolding and aggregation temperatures of the

respective sample series are set to zero. The

spreading of the transition temperature does thus

represent the variation around the average values. In

the respective samples that were subjected to

ultrasound, the temperature axis was also shifted by

the corresponding unfolding and aggregation for the

-10 -5 0 5 10

1610

1615

1620

1625

1630

1635

1640

1645

1650

1655

1660

1610

1615

1620

1625

1630

1635

1640

1645

1650

1655

1660

-10 -5 0 5 10

b)

k (cm

-1

)

ΔT (°C)

a)

k (cm

-1

)

Figure 3: Thermotropic shift of the amide I band of insulin

without ultrasound a) and under ultrasonic ultrasonic

excitation b). The temperature axis is normalised

according to the average transition temperature in the

sample series without ultrasound.

non-ultrasonic case. According to Figure 3, b), the

transition temperatures are always lower if

ultrasound was applied. The variation of the

ultrasound assisted shift (between 1 and 7 K) is

essentially not due statistics but due to the spatial

variation of the ultrasonic effects at the sample that

arises from the standing wave pattern. The variations

of transition temperatures should thus be attributed

to the position of the infrared beam in different

sound nodes and antinodes.

3.2 Discussion

There are different possibilities to explain the shift

of the unfolding and aggregation temperature by

ultrasonic excitation. A first and manifest reason is

the heating due to ultrasound and the heat

dissipation due to the operation of the ultrasonic

transducer itself (transducer self-heating, (Wu and

Nyborg, 2006)) that account for a difference of

approximately 1 K according to thermography tests

performed. But the highest difference in unfolding

temperature observed is more than 7 K. Therefore it

can be expected that other reasons must be taken

into account. Electromagnetic effects can be

excluded for this case, because the shift of

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

374

temperature would be much more constant due to

the constant output control of the ultrasonic device,

moreover that effect was checked to be negligible.

Another possibility would be a local change of the

conditions of the electrolytic buffer solution. It is

known that ultrasonics is able to change the pH, a

phenomenon that is called ultrasonic vibrational

potential – for the case that the pH was lowered by

ultrasonics a temperature decrease would be

explainable. However, this effect was checked to be

negligible.

The most probable explanation is the

acceleration of the unfolding and aggregation

process by ultrasonic induced acoustic micro-

streaming (Wu and Nyborg, 2006). One

distinguishes between two types of micro-streaming;

the simplest type is acoustic streaming in a liquid

bulk phase that is sometimes called “quartz wind”.

The other type is related to interactions where

several kinds of boundaries, surfaces or

inhomogeneities are involved. Due to the small

liquid layer thickness with respect to the

wavelength, one should expect that the second type

of acoustic micro-streaming applies to our

experiment described above. Acoustic-micro-

streaming leads finally to additional mobility inside

the liquid that promotes mixing processes.

It is known, that unfolding and aggregation

leading to fibrillogenesis is a kinetic process.

Aggregation itself is determined by the frequency of

mutual contacts between hydrophobic groups, and

mixing of the solution would definitely enhance the

probability of these contacts. Nonlinear ultrasonic

effects will cause micro-streaming in liquids

(Suslick, 1988), and they will have an effect similar

to the direct mixing of components. In this way, a

reduction of the transition temperature should

anyway be expected. An interesting reference in this

context are studies on the kinetics of protein

aggregation on agitation (stirring). Stirring was

clearly leading to an increase of the kinetics of

insulin fibrillogenesis with respect to an unstirred

reference sample (Grudzielanek, Smirnovas et al.,

2006). This was accordingly explained by

eliminating the diffusion control causing aggregation

nuclei immediately start growing. Similar

observations are reported for whey protein fibril

formation (Bolder, Sagis et al., 2007), here, also the

breaking up of immature fibrils is discussed,

suggesting a similar behaviour for the shorter fibrils

observed in the AFM images of our samples (not

shown).

REFERENCES

Bolder, S. G., L. M. C. Sagis, et al. 2007. "Effect of

stirring and seeding on whey protein fibril formation."

Journal of Agricultural and Food Chemistry 55(14):

5661-5669.

Bouchard, M., J. Zurdo, et al. 2000. "Formation of insulin

amyloid fibrils followed by FTIR simultaneously with

CD and electron microscopy." Protein Science 9(10):

1960-1967.

Dobson, C. M. 2003. "Protein folding and misfolding."

Nature 426(6968): 884-890.

Grudzielanek, S., V. Smirnovas, et al. 2006. "Solvation-

assisted pressure tuning of insulin fibrillation: From

novel aggregation pathways to biotechnological

applications." Journal of Molecular Biology 356(2):

497-509.

Suslick, K. S. (1988). Ultrasound: its chemical, physical,

and biological effects. New York, N.Y., VCH

Publishers.

Tata, D. B. and F. Dunn. 1992. "Thermodynamic method

of b/a analysis of liposome suspensions - prediction

via single relaxation theory." Journal of Ultrasound in

Medicine 11(8): 441-447.

Wu, J. and W. L. M. Nyborg (2006). Emerging therapeutic

ultrasound. Hackensack, N.J., World Scientific.

IN-SITU SPECTROSCOPIC INVESTIGATION OF UNFOLDING AND AGGREGATION OF INSULIN UNDER

ULTRASONIC EXCITATION - An Ultrasonic Actuator for FTIR-spectrometry on Biomatter

375