A KNAPSACK PROBLEM APPROACH FOR OPTIMAL

ALLOCATION OF MAINTENANCE RESOURCES ON ELECTRIC

POWER DISTRIBUTION NETWORKS

Eduardo Tadeu Bacalhau, F´abio Luiz Usberti, Christiano Lyra Filho and Celso Cavellucci

University of Campinas, School of Electrical and Computer Engineering,

Av. Albert Einstein 400, 13083-852, Campinas, S˜ao Paulo, Brazil

Keywords:

Reliability, Maintenance, Knapsack problem, Dynamic programming.

Abstract:

The definitions of optimal preventive and corrective maintenance of electric power distribution networks can

be seen as a special case of a knapsack problem. This paper proposes a dynamic programming approach to

deal with this problem. The approach is developed for one or more years of planning horizon. Case studies

compare the optimal dynamic programming approach with an heuristic method.

1 INTRODUCTION

The optimal allocation of maintenance resources on

power distribution network must define the best com-

promise between investment and system reliability.

Previous approaches relies on heuristic method to ad-

dress this non-linear multicriteria optimisation prob-

lem.

The problem can be viewed as a special case

of multidimensional knapsack problem (Martello and

Toth, 1990). This paper relies on this interpretation

in order to develop an exact optimisation procedure

based on dynamic programming (DP).

Case studies compare the proposed approach with

a previous heuristic algorithm developed to deal with

the problem. Discussion of the case studies gives

some insights into future developments of these ideas.

2 MAINTENANCE ON ELECTRIC

POWER DISTRIBUTION

NETWORKS

Electric power distribution networks are composed

by electric circuits that transport electric energy from

substations to the customers. The system reliability

is measured by indices such as System Average In-

terruption Frequency Index (SAIFI) and System Av-

erage Interruption Duration Index (SAIDI) (Brown,

2002) which determine the network quality. After oc-

currence of a failure of one equipment, maintenance

actions are employed in order to repair or replace this

equipment. Since failures deteriorates the reliability

indices, actions must be applied (Endrenyi and An-

ders, 2006; Bertling et al., 2007).

All preventive or corrective actions have a cost,

therefore the objective of the optimisation problem is

to minimize the cost of maintenance regarding safety

values for the system reliability.

This work considers a radial network proposed by

(Sittithumwat et al., 2004). This network is divided

in sections defined by protection equipments such as

break-fuses, switch-fuses and reclosers which seek to

avoid the failure throughout the system distribution

network. Besides, all equipments which compose the

system are described into the optimisation model pro-

posed.

2.1 Optimisation Model

The optimisation model proposed (Reis, 2007)

presents an objective function to minimize the cost

of preventive and corrective maintenance action with

a reliability constraints (SAIFI). The SAIFI is calcu-

lated by following equation:

SAIFI

t

=

∑

s∈S

λ

t

s

N

s

NT

, (1)

where S is the set of all sections, λ

t

s

is the failure rate

of section s in the period t, N

s

is the number of cus-

tomers in section s and NT is the total number of cus-

tomers in the network.

462

Tadeu Bacalhau E., Luiz Usberti F., Lyra Filho C. and Cavellucci C..

A KNAPSACK PROBLEM APPROACH FOR OPTIMAL ALLOCATION OF MAINTENANCE RESOURCES ON ELECTRIC POWER DISTRIBUTION

NETWORKS.

DOI: 10.5220/0003865504620466

In Proceedings of the 1st International Conference on Operations Research and Enterprise Systems (ICORES-2012), pages 462-466

ISBN: 978-989-8425-97-3

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

The failure rate of section s in period t, λ

t

s

, can be

calculated by equations:

∑

n∈N

k

e

x

t

en

= 1 , (2)

λ

t

e

= λ

(t−1)

e

∑

n∈N

k

e

δ

k

e

n

x

t

en

(3)

and

λ

t

s

= λ

s

+

∑

e∈E

s

λ

t

e

, (4)

where λ

t

e

is the failure rate for equipment e in the

period t, N

k

e

is the set of all preventive maintenance

actions, δ

k

e

n

is the failure rate multiplier for equip-

ment k

e

for action level n and x

t

en

is a boolean de-

cision variable denoting whether the equipment e re-

ceived (x

t

en

= 1) or not (x

t

en

= 0) maintenance level n

in period t.

Finally, the optimisation model is described as:

min

x

t

en

HP

∑

t=1

(

∑

e∈E

"

∑

n∈N

k

e

(p

k

e

n

x

t

en

) + λ

t

e

c

k

e

#

× α

t

)

s.t. SAIFI

t

≤ SAIFI

perm

∀t = 1, ..., HP,

where E is a set that contains all the equipment which

can receive preventive maintenance, SAIFI

perm

is the

maximum permitted value for SAIFI, p

k

e

n

is the cost

for action preventive level n for equipment k

e

, c

k

e

is

the cost for action corrective level for equipment k

e

and α

t

is a parameter which is related to each period.

3 KNAPSACK PROBLEM

Since the problems were developed for more than

one year of planning horizon we are going to con-

sider the multidimensional knapsack problem (MKP)

(Martello and Toth, 1990). The MKP could be defined

as a set N = {1, ..., n} of items that should be packed

in a set M = {1, ..., m} of knapsacks with given capa-

cities, b

0,i

i ∈ M. Associated with every item j ∈ N

there is a value c

j

and a weight a

ij

, which is the

amount of resource used by the item j in the ith knap-

sack. The goal is to find a subset of the items that

yield the maximum value subject to the capacity con-

straints of the knapsacks. Therefore, a formulation for

MKP can be defined as:

F

n

(b) = max

n

∑

j=1

c

j

x

j

,

s. to :

n

∑

j=1

a

ij

x

j

≤ b

0,i

i ∈ M (5)

x

j

∈ {0, 1}, j ∈ N,

where a

ij

, c

j

, b

0,i

≥ 0 for i = 1, ..., m and j = 1, ..., n.

3.1 Knapsack Problem on Dynamic

Programming

A MKP can be solved via dynamic programming,

that chooses items with highest costs c

j

and with

volumes v

j

that do not exceed the knapsack capacity

V (Puchinger et al., 2010). The following equation

shows the dynamic programing for the binary knap-

sack problem:

Get F

n

(V

0

)

Where F

k

(V) = max{F

k−1

(V), F

k−1

(V − v

k

) + c

k

}

With F

0

(V) = 0 ∀v

(6)

To determine the optimal solution we should cre-

ate an indicator I

k

that is equal 0 if F

k

(V) = F

k−1

(V)

and 1 otherwise. After that we analyze all indicators

from I

n

up to I

1

. If the indicator I

k

= 0 then x

∗

k

= 0,

else x

∗

k

= 1.

4 ADAPTED KNAPSACK

PROBLEM

As from the optimisation model and the presen-

ted knapsack problem we can formulate an adapted

model for the maintenance problem. First, we are go-

ing to present the knapsack problem on dynamic pro-

gramming for one year of planning horizon. In this

model we should define the parameter SAIFI

perm

as

the knapsack capacity V and define δ

sm

k

e

and δ

cm

k

e

as

the failure rate multipliers for equipment k

e

in the ab-

sence and occurrence of preventive maintenance re-

spectively.

Get F

n

(V

0

)

Where F

k

e

(V) = min

n

F

k

e

−1

(V − v

cm

k

e

) + p

k

e

+

(λ

k

e

−1

δ

cm

k

e

)c

k

e

,

F

k

e

−1

(V − v

sm

k

e

) +

(λ

k

e

−1

δ

sm

k

e

)c

k

e

o

With F

0

(V) = 0 ∀ V,

(7)

where p

k

e

is the maintenance preventive cost for

equipment k

e

, c

k

e

is the maintenance corrective cost

for equipment k

e

, v

cm

k

e

is the reliability volume cal-

culated for equipment k

e

which received preventive

A KNAPSACK PROBLEM APPROACH FOR OPTIMAL ALLOCATION OF MAINTENANCE RESOURCES ON

ELECTRIC POWER DISTRIBUTION NETWORKS

463

maintenance and v

sm

k

e

is the reliability volume for

equipment k

e

which not received preventive mainten-

ance.

The reliability volumes can be defined as the fol-

lowing equations:

v

cm

k

e

=

(λ

k

e

−1

δ

cm

k

e

)N

s

NT

,

if maintenance is performed, and

v

sm

k

e

=

(λ

k

e

−1

δ

sm

k

e

)N

s

NT

,

if maintenance is not performed,

(8)

where N

s

is the number of customers in section s.

The problem was divided in two subproblems de-

scribing the possible choices of maintenance action.

It means that we can write the number of subproblem

such as 2

HP

where HP is the number of years of plan-

ning horizon. Besides, the number of knapsacks is

going to be exactly the number of years of this plan-

ning. Since that the failure rates are dependent year to

year, we must have a different knapsack for each year.

Therefore, to develop a adapted model for more than

one year we must apply the multidimensional knap-

sack problem to the problem. Likewise, we can de-

note this idea for two years of planning horizon.

Get F

n

(V

1

0

, V

2

0

)

Where F

k

e

(V

1

, V

2

) =

min

n

F

k

e

−1

(V

1

− v

cm

1,k

e

, V

2

− v

cm

2,k

e

)

+(2p

k

e

) +

((λ

k

e

−1

δ

cm

k

e

) + (λ

k

e

−1

δ

cm

k

e

)

2

)c

k

e

,

F

k

e

−1

(V

1

− v

cm

1,k

e

, V

2

− v

sm

2,k

e

)

+(p

k

e

) +

((λ

k

e

−1

δ

cm

k

e

) + (λ

k

e

−1

δ

cm

k

e

δ

sm

k

e

))c

k

e

,

F

k

e

−1

(V

1

− v

sm

1,k

e

, V

2

− v

cm

2,k

e

)

+(p

k

e

) +

((λ

k

e

−1

δ

sm

k

e

) + (λ

k

e

−1

δ

sm

k

e

δ

cm

k

e

))c

k

e

,

F

k

e

−1

(V

1

− v

sm

1,k

e

, V

2

− v

sm

2,k

e

)

+

((λ

k

e

−1

δ

sm

k

e

) + (λ

k

e

−1

δ

sm

k

e

)

2

)c

k

e

,

With F

0

(V

1

, V

2

) = 0 ∀ V

1

, V

2

,

(9)

where v

cm

1,k

e

is the volume of reliability for equipment

k

e

which received preventivemaintenance at year one,

v

cm

2,k

e

is the volume of reliability for equipment k

e

which received preventive maintenance at year two,

v

sm

1,k

e

is the volume of reliability for equipment k

e

which not received preventive maintenance at year

one, v

sm

2,k

e

is the volume of reliability for equipment

k

e

which not received preventive maintenance at year

two, V

1

is knapsack for first year and V

2

is knapsack

for second year.

However, is important to note that the volume of

reliability calculated to the second year depends on

the choice taken on previous year and the knapsack of

the second year should tolerate both volume of reli-

ability calculated for each year. Thus, the volume of

reliability in this case must be calculated as follows:

v

cm

2,k

e

= v

sm

1,k

e

δ

cm

k

e

=

(λ

k

e

−1

(δ

sm

k

e

δ

cm

k

e

)) N

s

NT

,

if not realized maintenance at year one or

v

cm

2,k

e

= v

cm

1,k

e

δ

cm

k

e

=

(λ

k

e

−1

(δ

cm

k

e

))

2

N

s

NT

,

if realized maintenance at year one and

v

sm

2,k

e

= v

sm

1,k

e

δ

sm

k

e

=

(λ

k

e

−1

(δ

sm

k

e

))

2

N

s

NT

,

if not realized maintenance at year one or

v

sm

2,k

e

= v

cm

1,k

e

δ

sm

k

e

=

(λ

k

e

−1

(δ

cm

k

e

δ

sm

k

e

)) N

s

NT

,

if realized maintenance at year one.

(10)

Finally, to more years of planning horizon we pro-

ceed in the same way. We increase a knapsack for

each year added and the volume of equipments con-

tinues being calculated depending of choices taken in

previous years.

5 CASE STUDIES

These case studies rely on a comparison between the

dynamic programming approach (DPA) and a heur-

istic method previously developed. This heuristic

method is a state space search which consist in com-

bine the depth search with simulated annealing (DSA)

(Bacalhau, 2009).

We have created three instances for these case

studies. All instances were executed for one year of

planning horizon and for each instance five values of

reliability constraints were chosen through the follow-

ing equation:

SAIFI

β

= SAIFI

min

+ (SAIFI

max

− SAIFI

min

) × β (11)

where SAIFI

min

is minimum value that can be cal-

culated for reliability indices, SAIFI

max

is maximum

value that can be calculated for reliability indices and

β is 0.2, 0.4, 0.6, 0.8 and 1.0.

An instance with 30 equipments was tested, in the

attempt to show the efficiency of the DPA method

with a limited number of options of optimisation.

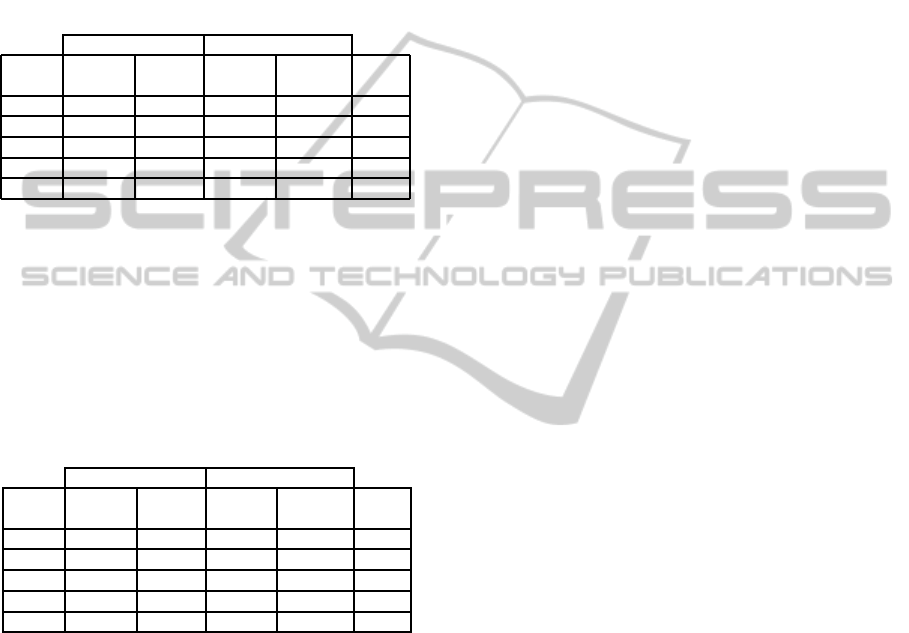

Table 1 illustrates the optimal results obtained for this

instance:

Table 1: Results - Instance with 30 equipments.

DPA DSA

Cost Time Cost Time Profit

SAIFI (x 1000) (s) (x 1000) (s) (%)

0.3476 10.076 0.156 11.345 1.201 11.14

0.3819 6.821 0.702 7.114 0.296 4.11

0.4163 4.785 1.622 4.815 0.218 0.61

0.4506 3.369 2.854 3.369 0.140 0

0.4849 2.414 4.633 2.414 0.171 0

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

464

The best results are described by numbers in bold.

The DPA method performed better when the reliabil-

ity constraints were tighter.

After that, we haveincreased the number of equip-

ments, trying to show the robustness of the DPA

method for cases where the optimisation procedure

is more complex. We have created an instance with

300 equipments. The Table 2 illustrates the optimal

results obtained for this instance:

Table 2: Results - Instance with 300 equipments.

DPA DSA

Cost Time Cost Time Profit

SAIFI (x 1000) (s) (x 1000) (s) (%)

2.9757 80.498 11.528 107.627 290.825 25.20

3.2543 53.466 52.244 54.908 250.846 2.61

3.5330 33.562 124.738 35.879 1295.747 6.45

3.8117 24.962 242.035 26.664 1681.954 6.38

4.4068 19.169 398.083 22.214 231.554 13.70

The DPA method performed better in all cases and

the computational time is better in all except one case.

These results show the efficiency of the approach in

cases with a larger number of equipments.

Following this idea, we have created an instance

with 400 equipments. The idea was to show the

growth of computational time. In the Table 3 we can

see the results for this instance.

Table 3: Results - Instance with 400 equipments.

DPA DSA

Cost Time Cost Time Profit

SAIFI (x 1000) (s) (x 1000) (s) (%)

3.9625 106.270 25.755 142.048 7258.345 25.18

4.3336 70.830 111.821 72.987 705.412 2.95

4.7046 44.351 255.748 47.611 2240.451 6.84

5.0757 33.111 446.880 38.455 1290.745 13.89

5.4468 24.437 712.909 28.601 5070.507 14.55

The performance obtained in this case is similar

with the previous results, but the computational time

obtained by DPA method is much lower.

6 DISCUSSION

We have done case studies in order to make a compar-

ison between dynamic programming approach and a

heuristic method.

Three examples of networks were executed using

the radial network mentioned. One of them was cre-

ated with a reduced number of equipments and two of

them with a large number of equipments.

The DPA method got a cost profit in all instance

where the reliability constraints were tighter, taking

up to 25% profit in large instances cases.

In instances with a small number of equipments,

the heuristic method got the best results for compu-

tational time and obtained the same results when the

reliability constraints were looser. However, when the

number of equipments increased the computational

time of the heuristic method was much greater than

the DPA method.

For two-years of planning horizon the results were

promising as well, however the algorithm has in-

creased its computational resources since the bell-

man’s principle leads to a combinatorial explosion of

the problem (Bellman, 2003). For this reason, we

have done some approximations of parameters into

the procedure. In some cases, these approximations

lead the algorithm to produce a non-optimal solution.

However, some alternatives could be studied to

apply this approach, trying to reduce the complexity

and the computational time for this problem. With

these approximations, the dynamic programming still

provide good quality solutions, although it may lose

the optimality guarantee.

7 CONCLUSIONS

We have developed a knapsack problem approach us-

ing dynamic programming for the problem of pre-

ventive maintenance on power distribution networks.

The approach was studied for one and two years of

planning horizon and its optimisation model for knap-

sack problem adapted was presented.

Cases studies were conducted followed by a dis-

cussion about the results obtained for three examples

of radial networks developed.

The results obtainedby dynamic programmingap-

proach were promising in relation to a presented heur-

istic method. In all cases the approach had a better

performance, but the best results of cost and compu-

tational time were obtained when the reliability con-

straints were tighter and the number of equipments

larger.

A discussion was produced from the case stud-

ies. The results were analysed proving the robustness

of the approach. Besides, results for more than one

year of planning horizon were discussed, highlighting

some alternatives for the problem complexity.

ACKNOWLEDGEMENTS

This work has been supporting by CNPq and CAPES.

A KNAPSACK PROBLEM APPROACH FOR OPTIMAL ALLOCATION OF MAINTENANCE RESOURCES ON

ELECTRIC POWER DISTRIBUTION NETWORKS

465

REFERENCES

Bacalhau, E. T. (2009). Heuristic methods for optimal alloc-

ation of maintenance resources on electric power dis-

tribution networks. Master’s thesis, Campinas State

University. In Portuguese.

Bellman, R. E. (2003). Dynamic Programming. Dover Pub-

lications, Incorporated.

Bertling, L., Miranda, V., Matos, M. A., and Hilber, P.

(2007). Multiobjective optimization applied to main-

tenance policy for electrical networks. IEEE Transac-

tions on Power Systems, 22(4):1675 – 1682.

Brown, R. E. (2002). Electric Power Distribution Reliabil-

ity. CRC Press, New York.

Endrenyi, J. and Anders, G. (2006). Aging, maintenance

and reliability. IEEE power & energy magazine, pages

59–67.

Martello, S. and Toth, P. (1990). Knapsack Problems: Al-

gorithms and Computer Implementations. Wiley, New

York.

Puchinger, J., Raidl, G. R., and Pferschy, U. (2010). The

multidimensional knapsack problem: Structure and

algorithms. INFORMS J. on Computing, 22:250–265.

Reis, P. A. (2007). Reliability based optimization of main-

tenance plans for power distribution systems. Master’s

thesis, Campinas State University. In Portuguese.

Sittithumwat, A., Soudi, F., and Tomsovic, K. (2004). Op-

timal allocation of distribution maintenance resources

with limited information. Electric Power Systems Re-

search, 68:208 – 220.

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

466