LOW-COST ENZYME-BASED BIOSENSOR FOR LACTIC

ACID AMPEROMETRIC DETECTION

Electrical Modeling and Validation for Clinical and Food Processing Applications

M. Scaramuzza

1

, A. Ferrario

1

, E. Pasqualotto

1

, G. Rosati

1

, A. De Toni

1

, M. Quarta

2

,

A. Paccagnella

1

and C. Reggiani

2

1

Department of Information Engineering, University of Padova, via Gradenigo 6/B, Padova, Italy

2

Department of Human Anatomy and Physiology, University of Padova, via Marzolo 3, Padova, Italy

Keywords: Lactate oxidase, Amperometric detection, Low-cost, Clinical applications, Food processing applications.

Abstract: In this work we present the preliminary resulting measurements of an enzyme-based biosensor for the

amperometric detection of lactic acid (LA). The sensor is based on low-cost gold electrodes on polymeric

substrate. The redox catalytic enzyme used for analyte amperometric detection is lactate oxidase (LOx)

from Pediococcus sp. This enzyme has been immobilized over electrodes surfaces by direct adsorption

methodologies. Analysis of the enzyme-modified electrodes have been carried out by means of

Electrochemical Impedance Spectroscopy (EIS) and with the development of an equivalent electrical model,

in order to improve the adsorption process. Biosensors performance have been evaluated with Cyclic

Voltammetry (CVM) measurements in different lactic acid solutions with concentrations from 1 μM up to

300 mM. The lactate sensitivity of this disposable biosensor results in about 6.24 µA mM

-1

cm

-2

.

1 INTRODUCTION

Lactic acid detection with low-cost devices

represents a growing need both in medical and food

processing applications, where large-scale

screenings are required (Castillo and Gáspár, 2004).

In food processing applications, LA

measurements are an easy and effective way to

determine food quality because lactate is correlated

with degradation processes in milk products

(Palmisano, Quinto et al., 2001). Lactic acid is

noticeable in biotechnology, health care, and sports

medicine applications because its levels are tightly

correlated with mortality of patients in shock status

or during hypoxia. Normal physiological blood

lactate concentrations are below 2 mM, and lactate

levels exceeding 7–8 mM are usually associated

with multiple organ failure (Sung, Bae et al., 2006).

The most widely used technique for LA

detection is a colorimetric and chromatographic

analysis, which are expensive and time-consuming

due to sample pre-treatment. Conversely, both

amperometric (Boujtita and Chapleau, 1996) and

potentiometric (Lee, Wu et al., 2008)

electrochemical analysis allow high sensitivity and

fast response. Two principal electrochemical

enzyme-modified sensors refer to L-lactate oxidase

(LOx) and L-lactate dehydrogenase. This work

investigate LOx-modified gold electrodes for LA

detection. The related catalytic reaction pathway is

(Gamero and Pariente, 2010):

L-lactate + (LOx)

OX

→ pyruvate + (LOx)

RED

(LOx)

RED

+ (Med)

OX

→ (LOx)

OX

+ (Med)

RED

(Med)

RED

→ (Med)

OX

+ e

−

where ferricianyde/ferrocianyde has been used as

redox mediator (Med). EIS measurements and an

equivalent electrical model have been used to

analyze enzyme adsorption on gold surfaces and its

role on sensor efficiency.

2 DEVICE AND

MEASUREMENTS SET-UP

EIS measurements have been performed with a

Solartron SI1260 impedance analyzer in a frequency

range between 1 Hz and 1 MHz. An Ag/AgCl in

KCl 1 M (CHI111, CH Instruments Inc., US) has

380

Scaramuzza M., Ferrario A., Pasqualotto E., Rosati G., De Toni A., Quarta M., Paccagnella A. and Reggiani C..

LOW-COST ENZYME-BASED BIOSENSOR FOR LACTIC ACID AMPEROMETRIC DETECTION - Electrical Modeling and Validation for Clinical and

Food Processing Applications.

DOI: 10.5220/0003867603800383

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 380-383

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

been used as reference electrode. A custom-built

Labview program has been developed to drive the

instrumentation and acquire measurements data.

CVM measurements have been performed with a

CHI 440A potentiostat (CH Instruments Inc., US)

with the electrochemical cell composed by the

previous Ag/AgCl electrode and a platinum counter

electrode (CHI129, CH Instruments Inc., US). The

potential range investigate was -0.20 V to +0.70 V

for Fe(CN)

6

4-/3-

with a scan rate of 50 mV/s. All data

have been analyzed with MATLAB 7.9, while fitting

results have been obtained with ZVIEW

2.80

(complex fitting, data-modulus weighting) software.

LOx, PBS (Phosphate Buffer Saline), redox

mediators and other chemicals have all been

provided by Sigma Aldrich. LOx (50 units/mg) has

been obtained as lyophilized powder. All solution

has been prepared with Millipore water.

The biosensor consists of circular 50 nm thick

gold electrodes with 1 mm diameter and of a gold

contact pad both on polymeric substrate. Electrodes

have been contacted through micro-positioned

probes (Wentworth Laboratories).

Figure 1: CVM measurements on 1 mm diameter

electrodes for different redox mediator concentrations with

scan rate of 50 mV/s.

3 REDOX MEDIATOR

CONCENTRATION

During gold electrodes surfaces preliminary

electrical characterization, EIS and CVM

measurements have been performed in “fresh”

condition, i.e. gold electrodes without any biological

coverage. The aim of these measurements was to

determine the best trade-off between SNR (Signal-

to-Noise Ratio) of interfacial charge transfer and

redox mediator concentration (see Figure 1). From

these tests the measurement solution has been

chosen as ferri/ferrocyanide 1 mM in PBS 100 mM.

4 COVERAGE STUDY AND

FITTING TECHNIQUE

An equivalent electrical model has been developed

to assess electrodes enzymatic coverage (see Figure

2). The main feature of this model is the a-weighted

contribution of two different electrical impedances

(Huang, Nguyen et al., 2004).

Figure 2: Equivalent electrical model for electrode

coverage studies. Parameter a is the numerical impedance

multiplier. Free electrode interface equivalent element

CPE

fresh

is multiplied for (1-a), while full enzyme-covered

electrode impedance for a.

Enzyme-free electrodes have been measured

with EIS in PBS and results have been fitted with an

equivalent electrical model composed of a series

between a Constant Phase Element CPE (Onaral,

Sun et al., 1984), CPE

fresh

, and a parallel between

R

Au

and C

Au

: the former is related to electrochemical

interfacial processes between electrodes and

electrolyte, while the other takes into account the

electrodes material. Impedance frequency

dependence is modeled with CPE

fresh

=

1/C

fresh

(j2πf)

nfresh

, where f is the frequency and n

fresh

is

a number between 0 and 1. Values for R

Au

and C

Au

(see Table I) have been obtained using COMSOL

Multiphysics 3.4 (AC/DC In-plane electric currents

module) to simulate the sensor electrical impedance

(2 cm length, 50 nm thick) with 1 mm diameter

active circular area and 100 μm probe contact area.

Gold electrical parameters have been set to

conductivity σ = 4.5

10

7

S/m and relative dielectric

permittivity ε

r

= 6.9. Electrolyte spreading resistance

R

e

value has been obtained by fitting EIS

measurements of PBS. To obtain second branch

model parameters values, electrodes surfaces have

been full covered with 25 mg/mL LOx in PBS 100

mM solution. The immobilization protocol consisted

in the deposition of 1 μL of enzyme solution directly

onto the electrodes for 1 hour and then rinsed with

0 0.1 0.2 0.3 0.4

-1

-0.5

0

0.5

1

x 10

-5

Voltage [V]

Current [A]

0.5 mM

1 mM

2 mM

5 mM

LOW-COST ENZYME-BASED BIOSENSOR FOR LACTIC ACID AMPEROMETRIC DETECTION - Electrical

Modeling and Validation for Clinical and Food Processing Applications

381

de-ionized water (Parra and Casero, 2006).

Functionalization data have been fitted with similar

equivalent circuit with CPE

LOx

. In the complete

electrical model the weighting parameter a is the

only fitting variable. The behavior of a as a function

of immobilized LOx concentration C

LOx

has been

obtained from EIS measurements: each curve

depicted in Figure 3 has been fitted using the

coverage model, obtaining a values described in

Figure 4.

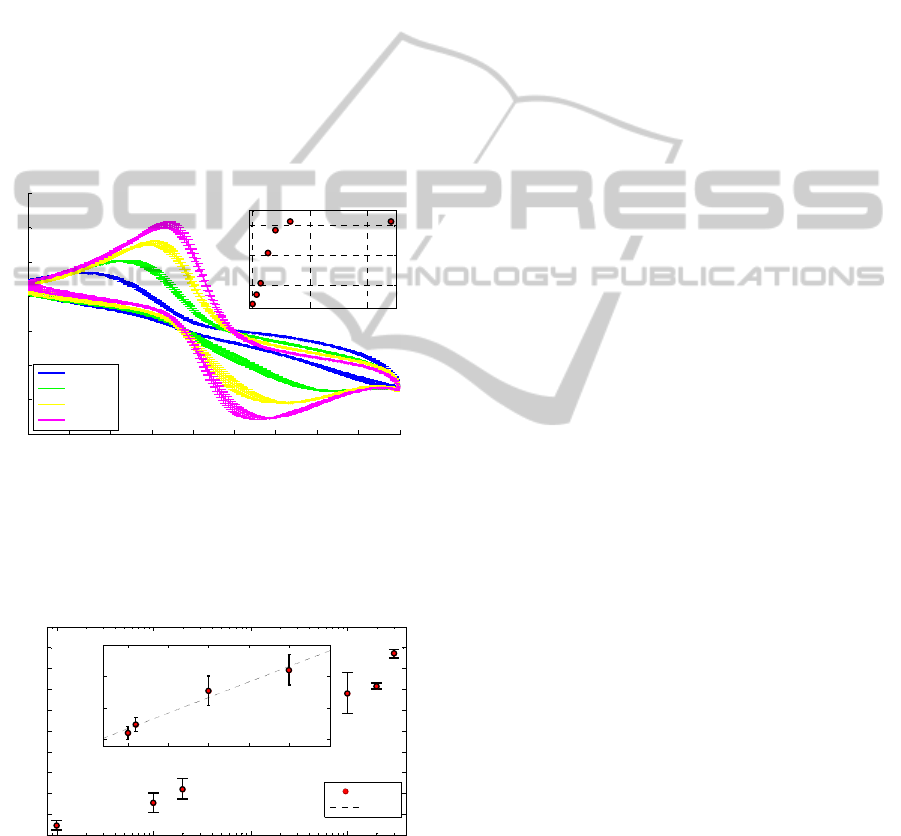

Figure 3: EIS measurements on round gold electrodes (1

mm diameter) with different concentrations of

immobilized LOx. Box: EIS response |Z| at 1 kHz.

Figure 4: Variation of coverage parameter a as a function

of enzyme concentration C

LOx

. Fitted parameters are: m =

1.086, n = -0.7414, p = -0.8473. With the described power

function the goodness of fit is R

2

= 0.9979.

As can be seen from Figure 5, parameter a trend

reaches a saturation level for LOx concentrations

above about 10 mg/mL, which corresponds to a =

0.94, therefore in these conditions an adequate

electrode coverage degree is obtained. Moreover,

sensors electrical response as a function of C

LOx

has

been evaluated with CVM measurements in order to

assess the electric transduction efficiency. Figure 5

shows CVM reduction currents peaks with 1 mM

and 100 mM LA in measurement solution: the trade-

off between SNR and electrodes coverage can be

obtained for C

LOx

= 10 mg/mL.

Figure 5: CVM peak currents with different concentrations

of immobilized LOx and 1 mM (blue) and 100 mM (red)

LA. For C

LOx

below 10 mg/mL the solutions cannot be

properly detected.

Table 1: Electrical parameters for Figure 2 model.

Parameter Value Error [%]

R

Au

0.6078 Ω -

C

Au

2.62 10

-18

F -

CPE

fresh

C

fresh

4.4 10

-7

F 1.82

n

fresh

0.89784 0.35

R

e

821 Ω 0.94

CPE

LOx

C

LOx

2.3 10

-7

F 1.71

n

LOx

0.88817 0.31

5 LACTIC ACID DETECTION

The enzymatic biosensor has been tested with LA

racemic mixture at different concentrations. First 2

mm diameter gold electrodes have been used to

detect LA concentration range between 70 μM up to

1.2 M in order to verify transduction saturation

levels. Results of CVM measurements are depicted

in Figure 6. In order to study sensor lower detection

limits and sensitivity, CVM measurements have

been carried out in a lower LA concentration range,

i.e. down to 1 μM, with 1 mm diameter electrodes.

Figure 7 depicts reduction peaks currents as a

function of LA concentration and sensor linear

response range comparable with other works in

literature (Gamero and Pariente, 2010). The

corresponding LA sensitivity is about 6.24 µA mM

-1

cm

-2

(Jena and Raj, 2006).

6 CONCLUSIONS

Low-cost gold electrodes-based sensors have been

functionalized with immobilized lactate oxidase

enzymes using direct adsorption protocols.

Electrodes surface coverage has been investigated

10

2

10

3

10

4

10

5

10

6

10

3

10

4

Frequency [Hz]

|Z| [

Ω

]

PBS

1 mg/mL

2 mg/mL

5 mg/mL

7 mg/mL

10 mg/mL

25 mg/mL

0 5 10 15 20 25

1500

2000

2500

C

LOx

[mg/mL]

|Z| [

Ω

]

1 2 5 10 25

0

0.5

1

1.5

x 10

-6

C

LOx

[mg/mL]

i

p,red

[A]

LA 1 mM

LA 100 mM

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

382

with EIS measurements in concentration range

between 1 mg/mL up to 25 mg/mL. An equivalent

electrical model based on a weighted contribution

approach has been developed in order to obtain a

numeric parameter that is related to the electrode

coverage. Both this methodology and CVM

measurements have identified in 10 mg/mL the

enzyme concentration that leads to adequate

electrodes coverage. The sensors lactic acid

detection performance have been evaluated using

CVM measurements: the upper saturation levels is

reached at about 300 mM, and the sensitivity is

about 6.24 µA mM

-1

cm

-2

.

This work is part of a University of Padova

research project for the development of an

innovative cell-based Lab-On-Chip for clinical and

food-processing massive screening applications.

Figure 6: CVM response of 2 mm diameter gold sensors

with different LA concentration in measurement solution.

Box: CVM reduction peaks currents as a function of LA

concentrations. The response saturates for LA

concentrations above 300 mM.

Figure 7: CVM reduction peaks currents as a function of

LA concentrations for round gold electrodes (1 mm

diameter). The tested LA concentrations vary from 1 μm

up to 300 mM. Box: magnification in milli-molar range.

Regression line: i

p,red

= 4.9 10

-2

C

LA

+ 1.1 10

-6

.

ACKNOWLEDGEMENTS

This project is partially supported by the University

of Padova project “Design and validation of a

biosensor to monitor myogenic cell growth in vitro”

(Department of Human Anatomy and Physiology,

Department of Information Engineering). This

project is partially supported by University of

Padova project MISCHA (Microfluidic laboratory

for Scientific and teCHnological Applications).

REFERENCES

Boujtita, M.; Chapleau, M. and Mum, N. E. (1996)

Enzymatic Electrode for the Determination of L-

Lactate, Electroanalysis, 8 (5), 485-488.

Castillo, J. and Gáspár, S. (2004). Biosensors for life

quality: Design, development and applications.

Sensors and Actuators B, 102, 179-194.

Gamero, M. and Pariente, F. (2010). Nanostructured rough

gold electrodes for the development of lactate oxidase

– based biosensor. Biosensors and Bioelectronics, 25,

2038-2044.

Huang, X.; Nguyen D.; Greve, D. W. and Domach M. M.

(2004). Simulation of Microelectrode Impedance

changes Due to Cell Growth, IEEE Sensors Journal, 5

(4), 576-583.

Jena, B. K. and Raj, C. R. (2006) Electrochemical

Biosensor Based on Integrated Assembly of

Dehydrogenase Enzymes and Gold Nanoparticles,

Anal. Chem., 78, 6332-6339.

Lee, H. C.; Wu, W. Y.; Lin, J. L.; Chin, Y. L.; Lee, K. Y.

and Sun, T. P. (2008) Evolution of the TiO2

membrane on ITO PET substrate applied to a lactate

biosensor using a potentiometric differential readout,

circuit Sensors, 2008 IEEE, 898-901.

Onaral, B.; Sun H. H. and Schwan, H. P. (1984). Electrical

Properties of Bioelectrodes, IEEE Transactions on

Biomedical Engineering, 12 (BME-31), 827-832.

Palmisano, F.; Quinto M; Rizzi R. and Zambonin (2001)

Flow injection analysis of L-lactate in milk and

yoghurt by on-line microdialysis and amperometric

detection at a disposable biosensor, Analyst, 126, 866-

870.

Parra, A. and Casero, E. (2006). Design and characteri-

zation of a lactate biosensor based on immobilized

lactate oxidase onto gold surfaces. Analytica Chimica

Acta, 555, 308-315.

Sung, W. J. and Bae, Y. H. (2006) Glucose oxidase,

lactate oxidase, and galactose oxidase enzyme

electrode based on polypyrrole with polyanion/PEG/

enzyme conjugate dopant, Sensors and Actuators B,

114, 164-169.

-0.2 -0.1 0 0.1 0.2 0.3 0.4 0.5 0.6 0.

7

-6

-4

-2

0

2

4

6

8

x 10

-6

Voltage [V]

Current [A]

w/o LA

0.07 mM

0.13 mM

1.2 mM

0 0.5 1

4

5

6

x 10

-6

C

LA

[M]

i

p,red

[A]

0 0.5 1 1.5 2 2.5

-2

0

2

x 10

-7

residuals

10

-4

10

-3

10

-2

10

-1

1.15

1.2

1.25

1.3

1.35

1.4

1.45

1.5

1.55

x 10

-6

C

LA

[M]

i

p,red

[A]

0 0.5 1 1.5 2 2.5

1.1

1.15

1.2

1.25

x 10

-6

C

LA

[mM]

i

p,red

[A]

data

linear

LOW-COST ENZYME-BASED BIOSENSOR FOR LACTIC ACID AMPEROMETRIC DETECTION - Electrical

Modeling and Validation for Clinical and Food Processing Applications

383